2

Summary

1 Introduction...........................................................................................4

2 Model identification...............................................................................4

3 Technical data......................................................................................4

3.1

General features......................................................................................... 4

3.2

Hardware features...................................................................................... 5

3.3

Software features ....................................................................................... 5

4 Dimensions and installation..................................................................6

5 Electrical wirings...................................................................................7

5.1

Wiring diagram ........................................................................................... 7

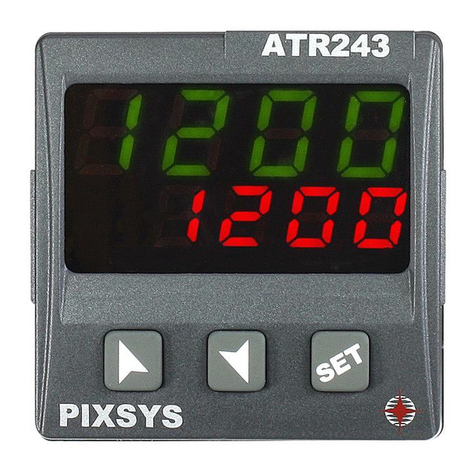

6 Displays and keys functions ...............................................................11

6.1

Numeric Indicators (Displays) .................................................................. 11

6.2

Meaning of Status Lights (Led) ................................................................12

6.3

Keys.......................................................................................................... 12

7 Controller Functions ...........................................................................13

7.1

Modifying Main Setpoint and Alarm Setpoint Values ............................... 13

7.2

Auto-tune.................................................................................................. 13

7.3

Manual Tuning.......................................................................................... 13

7.4

Automatic Tuning...................................................................................... 14

7.5

Soft Start................................................................................................... 14

7.6

Automatic/Manual Regulation for % Output Control ................................ 15

7.7

Pre-programmed cycle............................................................................. 16

7.8

Memory Card............................................................................................ 17

7.9

Loading default values.............................................................................. 18

8 LATCH ON Function...........................................................................18

8.1

Loop Break Alarm on Amperometric Transformer TA.............................. 20

8.2

Digital input Functions.............................................................................. 21

8.3

Dual Action Heating-Cooling .................................................................... 22

9 Serial Communication ........................................................................24

10 Configuration......................................................................................29

10.1

Modify Configuration Parameter............................................................... 29

11 Table of Configuration Parameters.....................................................30

12 Alarm Intervention Modes...................................................................41

13 Table of Anomaly Signals...................................................................45

14 Summary of Configuration parameters...............................................46