1.1 Organizzazione delle note di sicurezza ................................................................................................36

1.2 Note di sicurezza.........................................................................................................................................36

1.3 Precauzioni per l’uso sicuro ..................................................................................................................... 37

1.4 Tutela ambientale e smaltimento dei rifiuti / Direttiva WEEE ......................................................... 37

2 Identificazione di modello .......................................................................................................................................38

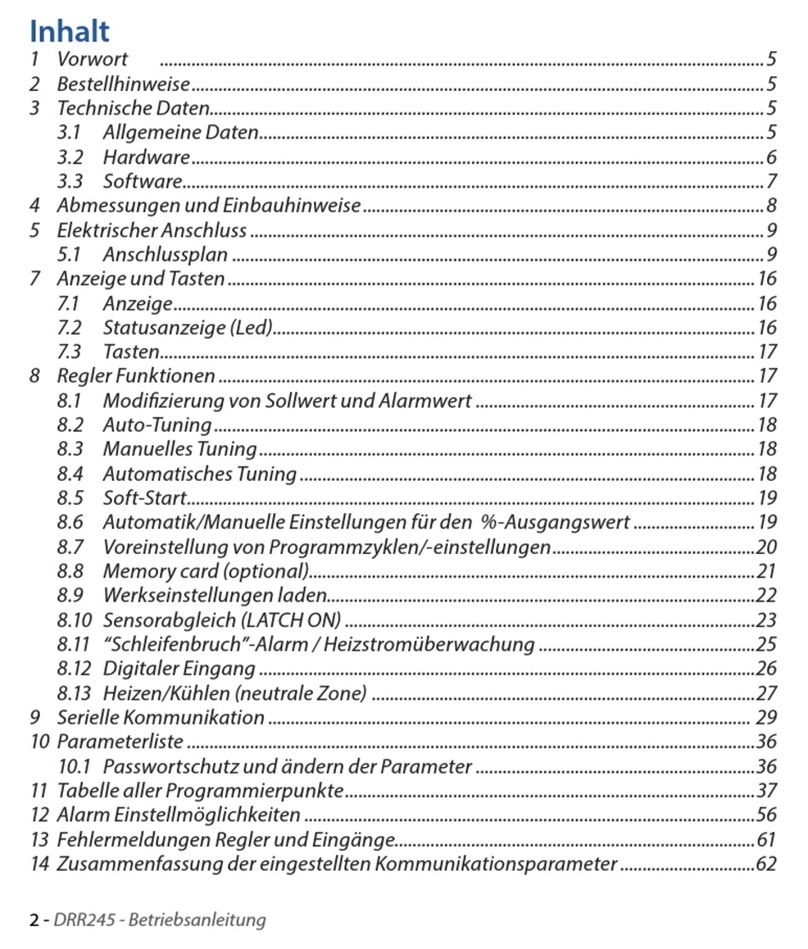

3 Dati tecnici...................................................................................................................................................................38

3.1 Caratteristiche generali ............................................................................................................................38

3.2 Caratteristiche Hardware.........................................................................................................................38

3.3 Caratteristiche software ...........................................................................................................................38

3.4 Modalità di programmazione ................................................................................................................39

4 Dimensioni e installazione ......................................................................................................................................39

5 Collegamenti elettrici................................................................................................................................................40

5.1 Schema di collegamento..........................................................................................................................40

5.1.a Alimentazione..................................................................................................................................40

5.1.b Ingresso analogico AI1................................................................................................................... 41

5.1.c Ingressi digitali................................................................................................................................. 42

5.1.d Uscita digitale ..................................................................................................................................42

5.1.e Uscita relè Q1 - Q2 (per ATR224-12ABC).....................................................................................42

5.1.f Uscita relè Q1 - Q2 (per DRR224-12ABC).................................................................................... 42

6 Funzione dei visualizzatori e tasti.......................................................................................................................... 43

6.1 Significato delle spie di stato (Led)......................................................................................................... 43

6.2 Tasti................................................................................................................................................................43

7 Funzioni del regolatore.............................................................................................................................................43

7.1 Modifica valore setpoint principale e di allarme................................................................................ 43

7.2 Tuning automatico ....................................................................................................................................44

7.3 Tuning manuale .........................................................................................................................................44

7.4 Tuning once .................................................................................................................................................44

7.5 Funzioni da Ingresso digitale ..................................................................................................................44

7.6 Regolazione automatico / manuale del controllo % uscita ............................................................45

7.7 Funzione LATCH ON...................................................................................................................................45

7.8 Funzione Soft-Start....................................................................................................................................46

8 Lettura e configurazione via NFC...........................................................................................................................46

8.1 Configurazione tramite memory card .................................................................................................. 47

8.2 Creazione / aggiornamento della memory card................................................................................ 47

8.3 Caricamento configurazione da memory card .................................................................................. 47

9 Caricamento valori di default................................................................................................................................. 47

10 Accesso alla configurazione....................................................................................................................................48

10.1 Funzionamento della lista parametri....................................................................................................48

11 Tabella parametri di configurazione.....................................................................................................................49

12 Modi d’intervento allarme.......................................................................................................................................60

12.a Allarme assoluto o allarme di soglia attivo sopra (par. 123

A L .1 . F .

=

A b . u P. A .

)..........................................60

12.b Allarme assoluto o allarme di soglia attivo sotto (par. 123

A L .1 . F .

=

A b . u P. A .

)...........................................60

12.c Allarme assoluto o allarme di soglia riferito al setpoint di comando attivo sopra (par. 123

A L .1 . F .

=

Ab . c. u.A.

)..................................................................................................................................................................60

12.d Allarme assoluto o allarme di soglia riferito al setpoint di comando attivo sotto (par. 123

A L .1 . F .

=

Ab . c.L.A.

)....................................................................................................................................................................60

12.e Allarme di Banda (par. 123

A L .1 . F .

=

band

)........................................................................................................ 61

12.f Allarme di banda asimmetrica (par. 123

A L .1 . F .

=

A.band

)............................................................................ 61

12.g Allarme di deviazione superiore (par. 123

A L .1 . F .

=

up.dev.

)......................................................................... 61

12.h Allarme di deviazione inferiore (par. 123

A L .1 . F .

=

Lo.dev.

)...........................................................................62

12.1 Label allarmi................................................................................................................................................62

13 Tabella segnalazioni anomalie..............................................................................................................................62

Index des sujets

1 Consignes de sécurité................................................................................................................................................66

1.1 Organisation des avis de sécurité...........................................................................................................66