Copyright Planika Sp. z o.o. www.planikafires.com IG0265#02 2 .06.2020 2

IT IS OBLIGATOR TO READ AND KEEP THIS INSTRUCTION MANUAL.

TABLE OF CONTENTS

1. INTRODUCTION ......................................................................................................................................................... 3

2. SAFETY INSTRUCTION ............................................................................................................................................... 3

2.1 Safety instruction regarding the use of the gas cylinder .................................................................................. 4

3. INSTALLATION ........................................................................................................................................................... 4

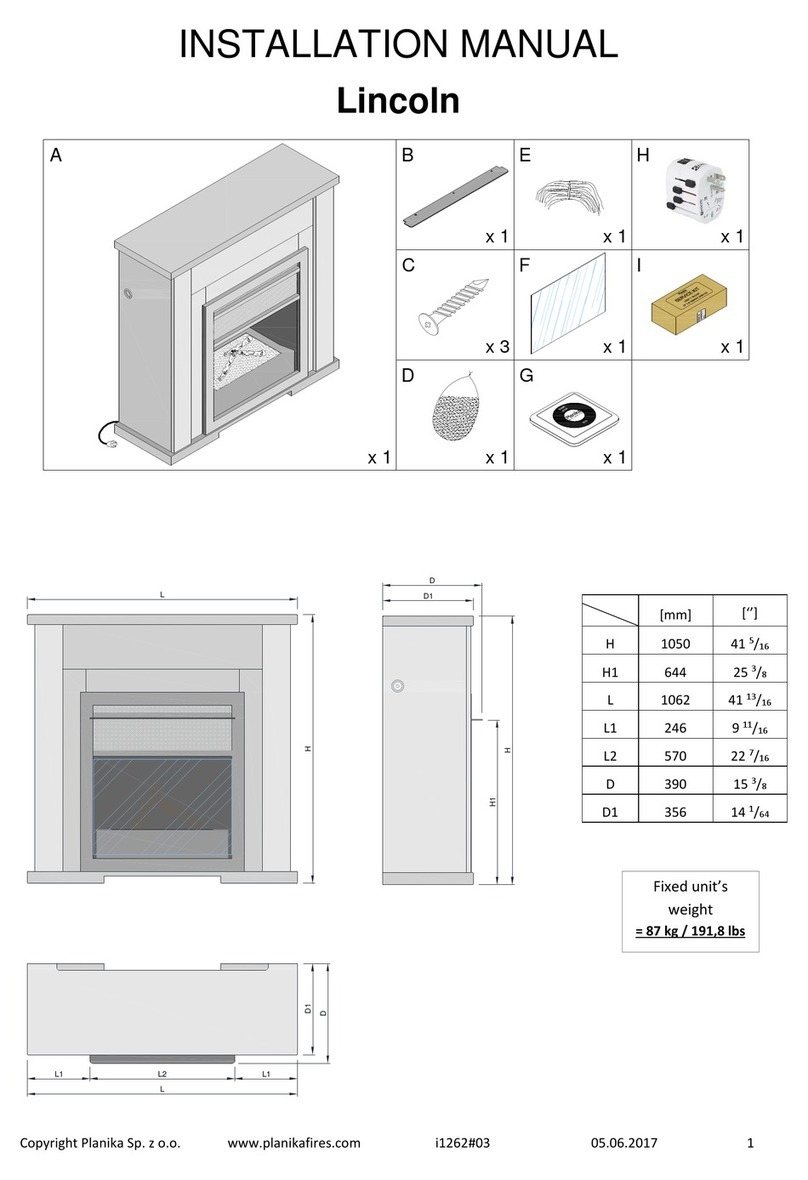

3.1. Box contents ..................................................................................................................................................... 4

3.2. Unboxing and installation ................................................................................................................................. 5

4. MONTAGE ................................................................................................................................................................. 6

4.1 Directions of how to design a housing for the fireplace ................................................................................... 7

4.2 Possible housing variants ................................................................................................................................. 8

4.2.1 Situations in which montage of glass screen protection is mandatory ........................................................ 8

4.2.2. Situations in which the glass screen montage is forbidden. ......................................................................... 8

4.3 Gas cylinder montage ....................................................................................................................................... 8

5. INSTALLATION OF THE GAS LINKAGE ...................................................................................................................... 10

5.1 Natural gas connection ................................................................................................................................... 10

5.2 Connection and replacement of the gas cylinder (LPG version) ..................................................................... 10

5.3 Pressure regulator replacement (LPG version) ............................................................................................... 13

6. OPERATING INSTRUCTIONS .................................................................................................................................... 14

6.1. Start-up of the device ..................................................................................................................................... 14

6.2. Regulation of the flame size ............................................................................................................................ 15

6.3. Device shutdown ............................................................................................................................................. 16

7. TESTING ................................................................................................................................................................... 17

7.1. Checking for gas leaks. .................................................................................................................................... 17

7.2. Checking the flame appearance...................................................................................................................... 17

8. MAINTENANCE AND UPKEEP .................................................................................................................................. 18

8.1. Testing and cleaning ....................................................................................................................................... 18

8.2. Glass cleaning .................................................................................................................................................. 18

. TROUBLESHOOTING ................................................................................................................................................ 18

10. TECHNICAL SPECIFICATION ................................................................................................................................. 1

11. MANUFACTURER’S CONTACT DETAILS ............................................................................................................... 1