8

ADJUSTMENT MODES

There are the following methods for entering each mode.

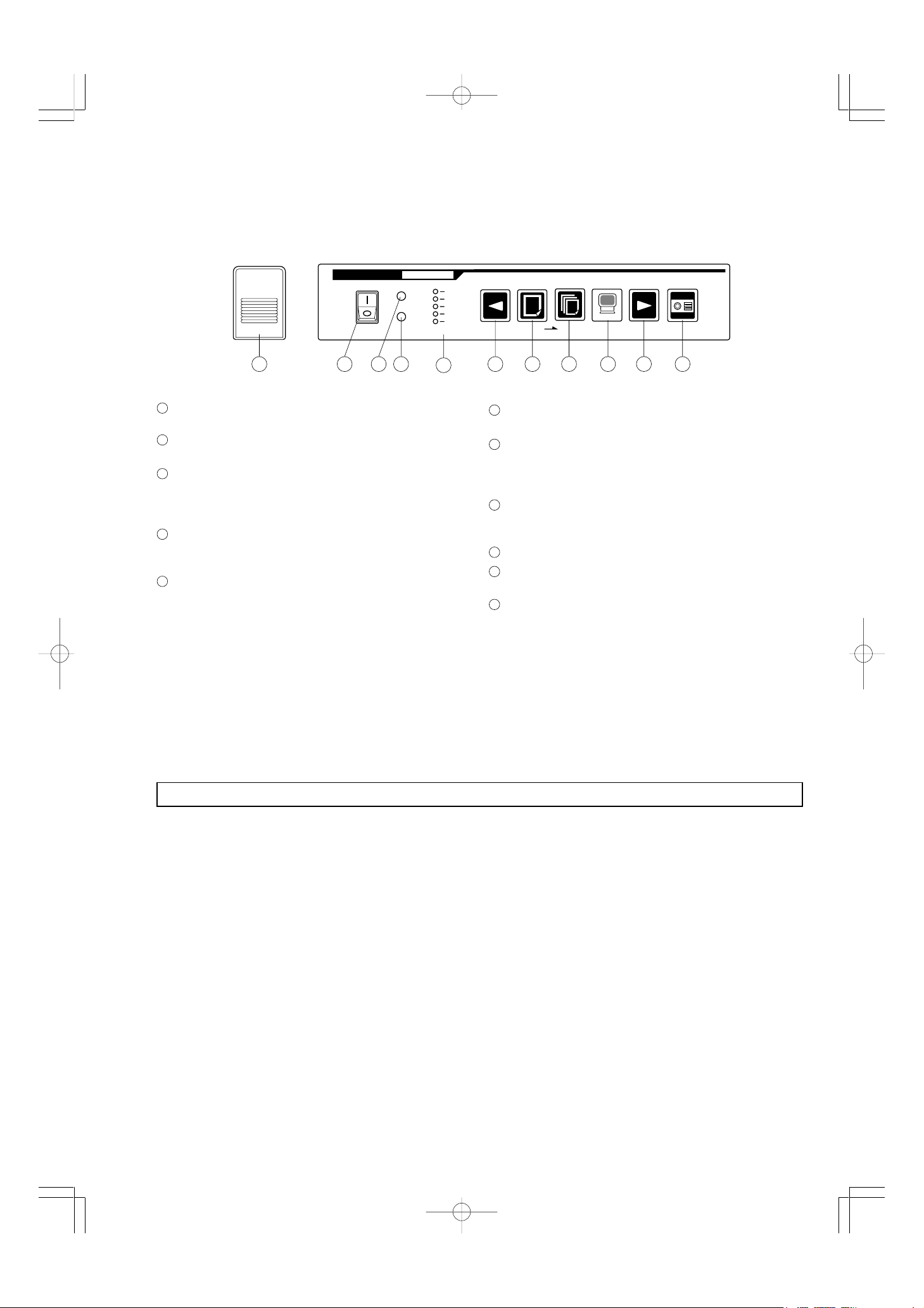

(1) Adjustment 1: Switch on the power while holding down SW5.

(2) Adjustment 2: Switch on the power while holding down SW1 and SW4.

To end an adjustment mode, switch off the power and switch it back on without holding down any of the keys. (Test

mode continues until the power is switched off.)

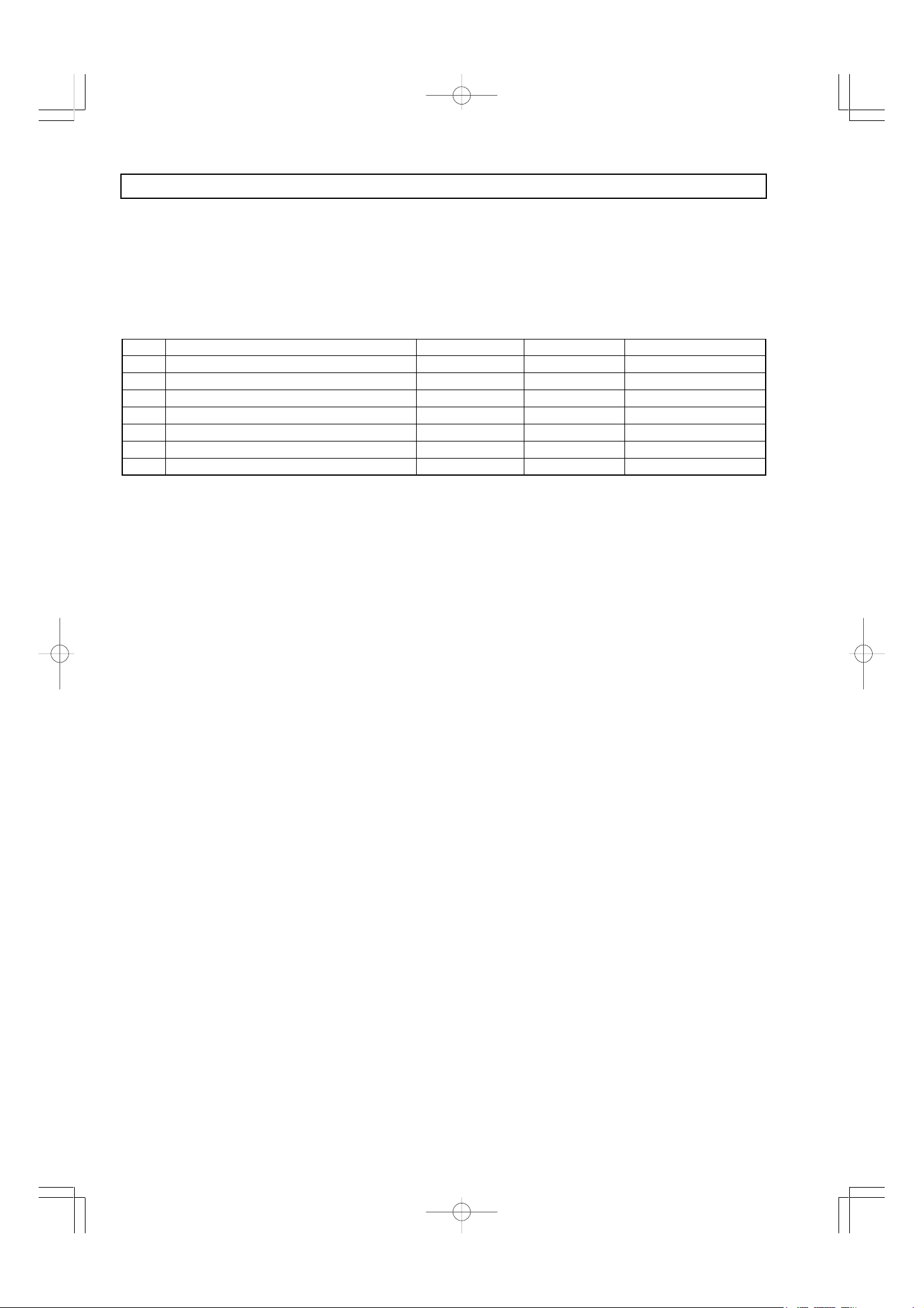

Adjustment mode specifications

No. Function summary Operation method Adjustment 1/2/3 Remarks

1 Test pattern printing Press SW3. 1 Both 2-surface/5-surface

2 Arbitrary sheet feed Press SW1/SWS5. 1 5-surface only

3 Continuous sheet feed (1 surface ↔5 surface) Press SW1. 2 Both 2-surface/5-surface

4 12.5% continuous printing Press SW2. 2 Both 2-surface/5-surface

5 20% continuous printing Press SW3. 2 Both 2-surface/5-surface

6 Test pattern printing Press SW4. 2 Both 2-surface/5-surface

7 Continuous copying Press SW5. 2 Both 2-surface/5-surface

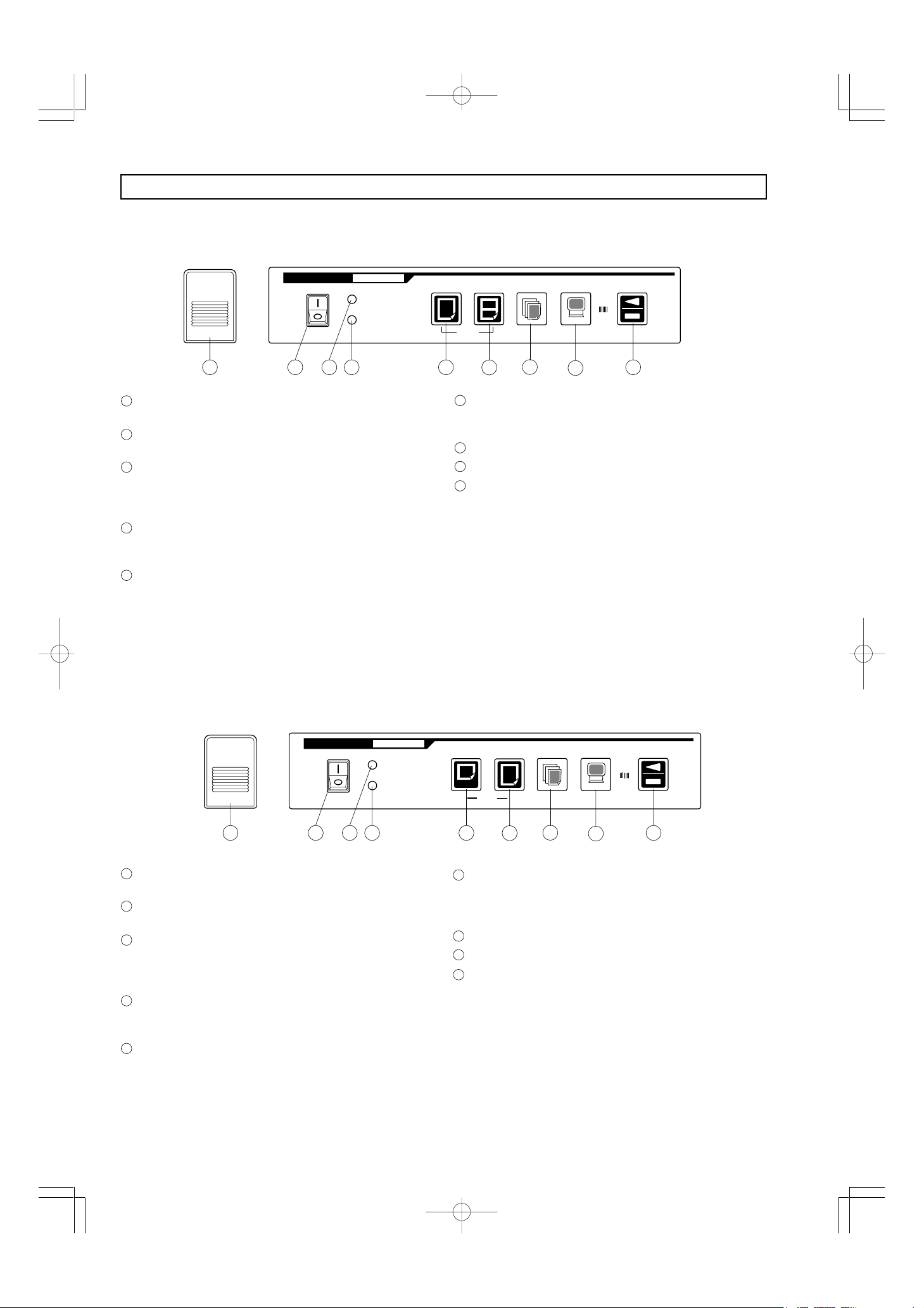

✽From the left side of the operation panel, the switches are SW1 - SW6.

✽For the 5-surface model, in Adjustment 1 mode, the COPY/STOP key is for normal copy/copy stop processing, but

sheet stretching/rewinding is not carried out.

1. Test pattern printing

Pressing SW3 prints the test pattern shown in the print

sample (same as for BF-030).

Each time SW3 is pressed, the printing is repeated.

The STOP key is enabled.

2. Arbitrary sheet feed (5-surface only)

(1)Pressing the L-FEED/R-FEED key alone feeds the

sheet about 1 cm left/right (with the motor driven at

low speed).

If you hold the key down for longer than 0.5 second,

the sheet is fed continuously left/right until you release

the key.

(2)If you press the R-FEED key while holding down the

STOP key the sheet latch is released/set. When the

sheet latch is set, all the LEDs except the paper end

LED lights up (to show that the paper tube can be turned

manually).

<Notes>

. These modes do not manage the pages with the CPU,

so be careful when working near the edge of the sheet.

. The sheet is not stretched after the sheet feed

operations.

. When the sheet latch is set, the sheet is not fed other

than for 1-cm feeds (Item 1).

. When the sheet is fed at positions where the paper

tube is thick, the movement distance decreases due

to insufficient torque.

. The fluorescent lamp is always lit. (It is not

extinguished even if the gain check result is NG.)

3. Continuous sheet feed

After a power-on reset, pressing SW1 feeds the sheet

continuously.

The interval between surfaces is about 2 seconds. For

the 5-surface model, the sheet is stretched each time

a surface is fed.

Continuous feed is an unending loop that continues

until the power is switched off. (The STOP key is

disabled.)

4. 12.5% continuous printing

Pressing SW2 continuously prints a black belt (about

10 mm) diagonal line at intervals about 12.5% of the

paper width.

The interval for each sheet is about 2 seconds.

5. Pressing SW2 continuously prints the same

as for Item 4, but with intervals of 20%.

6. Test pattern printing

Pressing SW4 prints the test pattern. The STOP key

is disabled.

7. Continuous copying

Switching on the power in Adjustment Mode 2 and

pressing SW5 automatically starts continuous copying

operations.

The interval between surfaces is 3 seconds.

For a 5-surface model, from Surface 1 to Surface 4 is

copied and after these four surfaces have been copied,

the sheet is returned non-stop to Surface 1 and

consecutive copying resumes.

Continuous feed is an unending loop that continues

until the power is switched off. (The STOP key is

disabled.)

Hidden mode

For a 5-surface model, if the power is switched on with

SW5 and SW6 held down, the sheet latch is released.