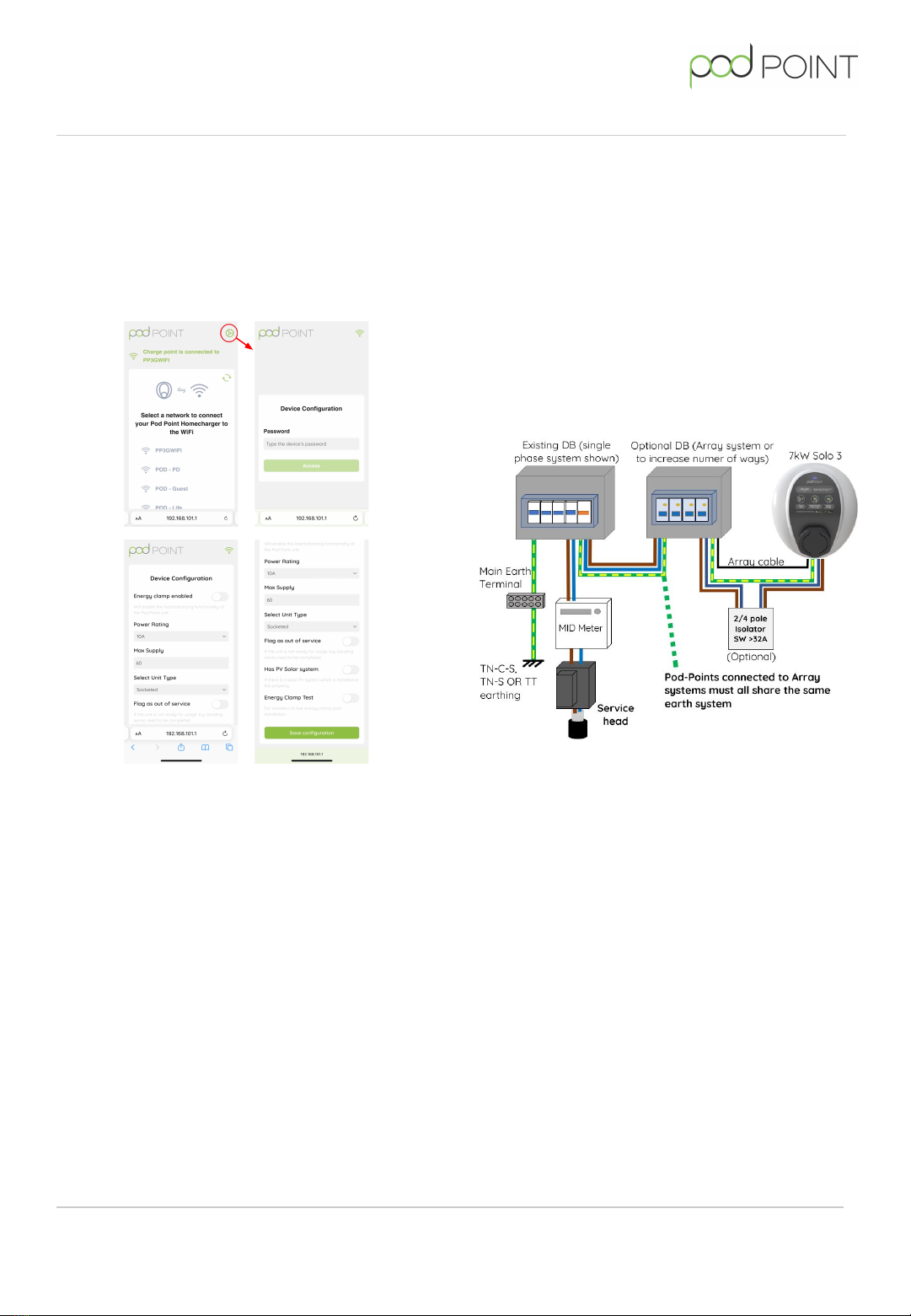

Pairing the Solo 3 to a Wi-Fi network

Detailed Solo 3 connection guide can be found

pod-point.com/technical/installation

On power up of the Solo 3 the front LED should

illuminate white. To connect the Solo 3 to a Wi-Fi

network do the following:

●Search for “podpoint” Wi-Fi network on your

mobile device and connect to it.

●On the device’s web browsers address bar

type: 192.168.101.1 then “Enter” or “OK”.

●A page displaying available networks will

show. Select the desired network and enter

the network password. Press “Connect” at the

bottom of the page.

Note:

The page will remain displayed but inactive after

“Connect” has been pressed.

●Wait for 1 minute. The LED should change to

blue with a short pink flash when it has

connected.

●If the status LED remains white, you may need

to restart the charger again and verify the

settings (see notes at end of this guide).

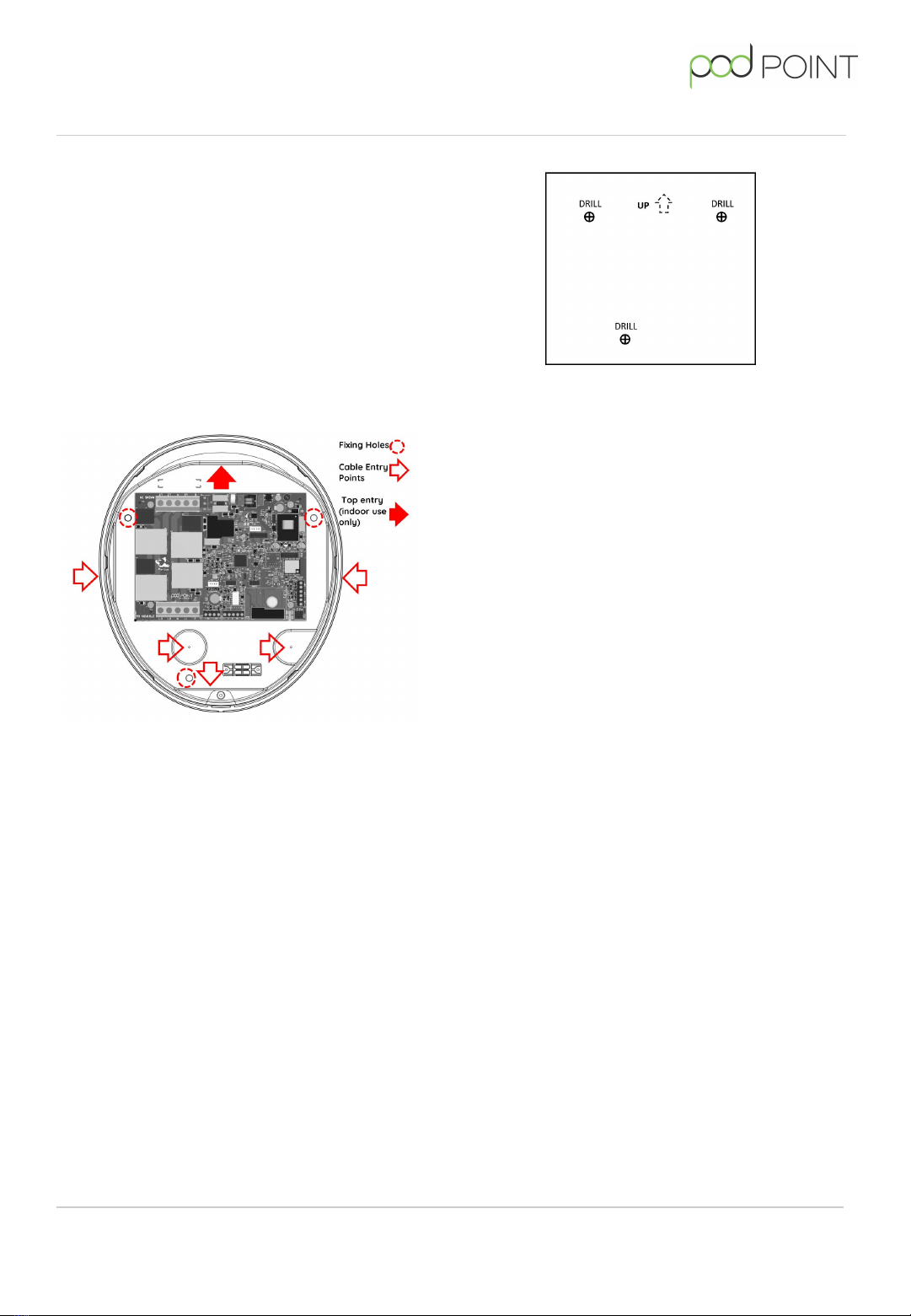

Fitting the front of the charger

Once the wiring, testing and setup of the Solo 3 is

completed, the front cover can be fitted in place.

Prior to fitting the front cover, visually check the

internal wiring will not interfere with assembly.

Dress if needed and remove any debris that may

have entered during installation.

Check that the front cover mating seal is in place

before fitting the cover to the housing. The front

cover can then be secured in place using the 6

screws.

Remote diagnostics

When connected to the internet via Wi-Fi the

charger will provide information on supply

voltage(s), status of the incoming earth,

charging current, temperature, rating of

connected cable, etc. This data is primarily used

for internal diagnostic purposes but is also used

for energy usage displayed in the Pod Point App.

In exceptional circumstances Pod Point may

contact the site/charger owner if an abnormality

is detected.

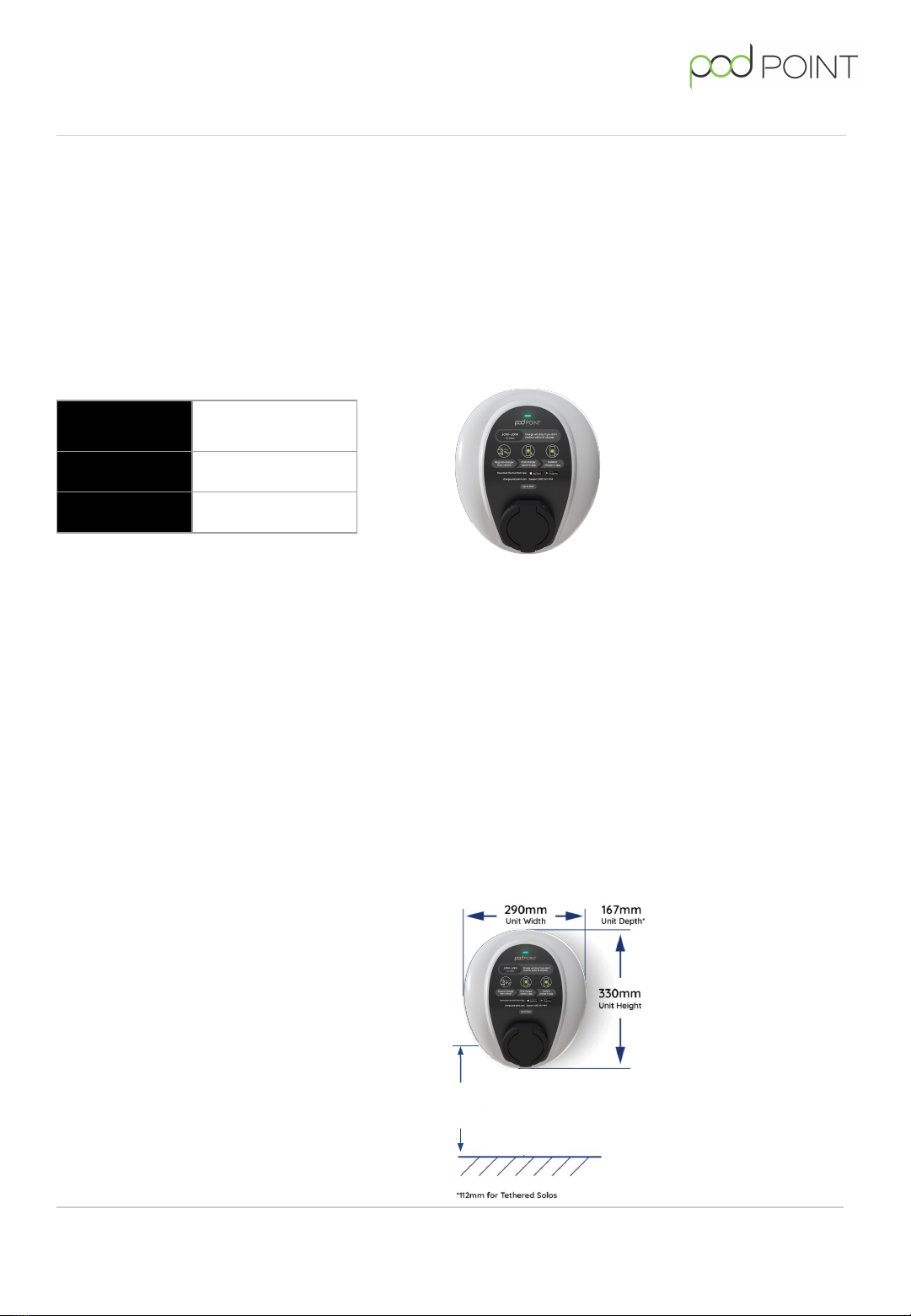

Solo 3 - Commercial

Solo 3 - Commercial PP-D-210451-3

Install Guide (No Dip Switches)

Theft of the Pod Point Solo 3

All Solo 3 EVSE includes a unique MAC address

to identify itself which is programmed into the

silicon and cannot be changed. If a Solo 3 is

reported as stolen and connection to the Pod

Point Network is attempted, it can be placed

permanently out of service.

Array configured Pod Point chargers do not

work as standalone units.

Additional product documents

We host our technical documentation across

two pages via pod-point.com

Technical documents

Installation documents

Or scan the QR code

here to get to our installer

documents page

Wi-Fi security

If a “guest” network can be setup on the router

(some ISP provided routers do not have this

feature), limiting connection to one device with

access limited only to the internet gives security

conscious users some peace of mind.

Setting up an allowlist on a router adds an

additional layer of security from attackers. This

requires some level of IT knowledge to add the

various MAC addresses. It also makes the

connection of any future devices more dicult.

Using the Wi-Fi router's SSID and password will

not automatically allow connection.

Viewing a router’s list of connected devices

should reveal the Solo 3 as “podpoint” followed

by a number (MAC address). This MAC address

may be used for the setting up of an allowlist.

WPS and PIN number access are regarded as

insecure and should be disabled in the router

settings if not used.