7

1.3.3 LaserSafety

The FTIR3 instrument complies with the following laser safety regulations:

• British Standard BS EN 60825 (1992) – “Radiation safety of laser products, equipment classication,

requirements and user’s guide”. BS EN 60825 implements CENELEC European Normalization document EN

60825 (CENELEC is the European Committee for Electrotechnical Standardization).

•IEC Publication 825 (1984) – “Radiation safety of laser products, equipment classication, requirements

and user’s guide” and “amendment 1 to Publication 825 (1990).

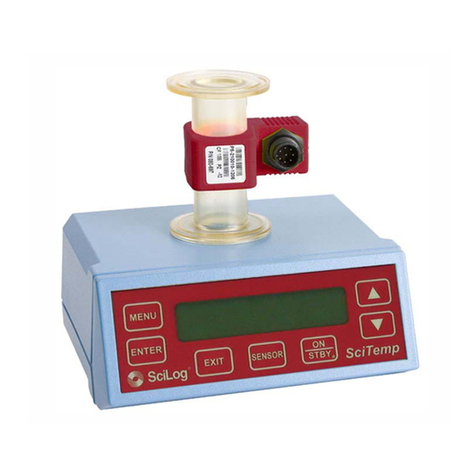

The FTIR3 Oil Analyzer instrument contains a CDRH Class I (BS EN 60825 and IEC 825 Class 1) VCSEL or

diode laser module, which emits red visible, continuous wave radiation and has a maximum output power of

less than 1 mW.

1.4 MaintenanceandServicing

1.4.1 Maintenance

Regular cleaning of the Sampling Cell is recommended using the Cleaning Fluid & Syringe kit ACCK05003. Do

not attempt to dismantle the Sampling Cell or any other part of the FTIR3 Oil Analyzer. The warranty will be void

if the cell or instrument show signs of tampering. For calibration, maintenance and repair needs, contact Parker

Kittiwake.

For continued best performance, Parker Kittiwake recommends that the FTIR3 Oil Analyzer is maintained in a

clean condition. In particular, the following points should be noted:

1. Care should be taken to avoid spills in the sample compartment – if this should occur, quickly mop up the spill

with absorbent cloth or similar. Avoid the use of harsh cleaning chemicals, a mild detergent and a damp cloth

should be sucient to remove any nal oil residues.

2. To prevent leakage from the sample cell, the integrity of the tube ttings should be checked before rst use

outside of the sample compartment and periodically as a further precaution.

3. Do not touch or otherwise contaminate the two IR windows located on the internal sidewalls of the sample

compartment. If these become dirty, the signal level will degrade causing a reduction in the quality of the spectra

recorded by the spectrometer. If gross contamination is suspected, contact Parker Kittiwake for advice.

4. Care should be taken to prevent contamination of the external faces of the sample cell windows. If this does

occur, it may be possible to clean the windows by rinsing with a suitable solvent. This procedure should only be

undertaken by a competent person, contact Parker Kittiwake for advice if unsure of how to proceed.

5. Similarly, and as noted above, the sample cell should be kept free of internal contamination by regularly ushing

with the cleaning uid between, and following, measurements on dirty oils.

6. A nal ush through of the sample cell with air, using the largest syringe supplied, is also recommended to

remove the bulk of the cleaning uid at the end of any measurement series and particularly before storing the

cell for an extended downtime period.

7. The spectrometer exterior should be cleaned with mild detergent and a damp cloth only.

1.4.2 ReturnsandPackaging

Return instrument to Parker Kittiwake for all servicing and repair. Please retain all original instrument packaging for

return shipping. All uids must be removed from the equipment and the FTIR3 Oil Analyzer cleaned appropriately

before return. Parker Kittiwake will not be liable for damage to returned goods resulting from inadequate packaging.

1.4.3 Recalibration

The FTIR3 Oil Analyzer does not require periodic recalibration. The spectrometer performs a series of

self-tests

on start-up and at predened intervals – warnings will be given should any of these tests fail. Consult

Parker Kittiwake if this should occur.

MA-K31014-KW FTIR Issue 1.indd 7 14/03/2017 20:16