2

Contents

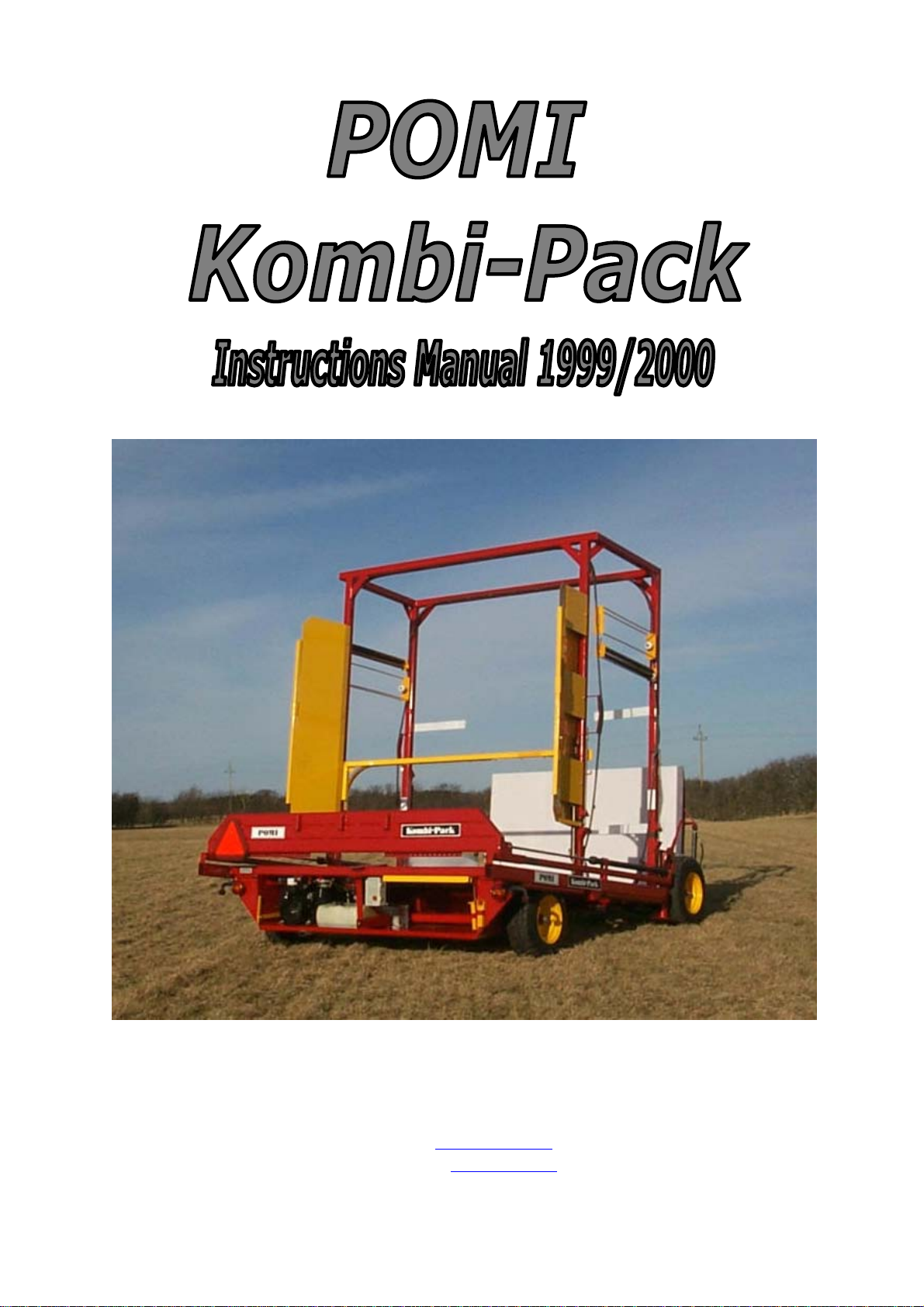

1. POMI KOMBI-PACK WRAPPER........................................................................................................... 3

2. PRECAUTION ............................................................................................................................................ 3

3. EU DECLARATION OF ACCORDANCE............................................................................................... 4

4. IDENTIFICATION OF THE MACHINE................................................................................................. 5

5. SOME ADVISE BEFORE STARTING WRAPPING SILAGE.............................................................. 5

6. BEFORE START ........................................................................................................................................ 5

7. REARRANGEMENT FROM TRANSPORT TO WRAPPING............................................................. 6

8. WRAPPING................................................................................................................................................. 6

WRAPPING OF SILAGE.................................................................................................................................... 6

WRAPPING OF STRAW,BIG-BALES WITH AMMONIAC ................................................................................. 6

WRAPPING OF MINI-BIG-BALES WITH AMMONIAC ...................................................................................... 6

WRAPPING OF STRAW FOR STORAGE ........................................................................................................... 6

9. CLOSING..................................................................................................................................................... 7

10. CHANGE FROM SILAGE OVER TO STRAW WRAPPING.......................................................... 7

11. ADJUSTING OF THE SENSORS ........................................................................................................ 8

12. ADJUSTMENT OF THE SUPPORT UNDER THE BALES............................................................. 8

13. CHANGE OF FOIL ROLLER.............................................................................................................. 8

14. FUNCTION OF THE MACHINE......................................................................................................... 9

14.1. ELECTRICAL BOX................................................................................................................................... 9

14.1.1. EL-DIAGRAM –BOX.......................................................................................................................... 10

14.1.2. ELECTRIC DIAGRAM –JUNCTION BOX............................................................................................... 11

14.2. REMOTE CONTROL.............................................................................................................................. 12

14.3. HYDRAULIC SYSTEM .......................................................................................................................... 12

14.4. FILM GUARD........................................................................................................................................ 12

15. MAINTENANCE.................................................................................................................................. 13

16. EQUIPMENT IN OPTION.................................................................................................................. 14

16.1. ROUND BALES EQUIPMENT.................................................................................................................. 14

16.2. HYDRAULIC RAISING OF THE FRAME.................................................................................................... 15

16.3. SILAGE BOX......................................................................................................................................... 16

16.4. EQUIPMENT FOR SILAGE...................................................................................................................... 16

16.5. RACK FOR BOTTOM FOIL...................................................................................................................... 17

16.6. BASKET FOR ROLLS OF FILM ................................................................................................................ 17

17. PROBLEMS.......................................................................................................................................... 18

Updated 13.06.2000