8

7. Bale stacker start-up

Use the start button to start and pause the loading

program. Press this button to start automatic

loading. The external button ( 1 ) has the same

function.

Use the Menu to choose between the two loading

programs. Choose the loading program where the

bale clamp starts in the inner position or the other

program where the bale clamp starts in the outer

position. By pressing the start button when the bale

clamp is in the inner position, the bale clamp comes

out. You use this for turning the bale. When

pressing the start button a second time, the

loading program will start.

By pressing Menu, you can switch the program so

the bale clamp starts in the outer position. Press the

start button to start the loading program.

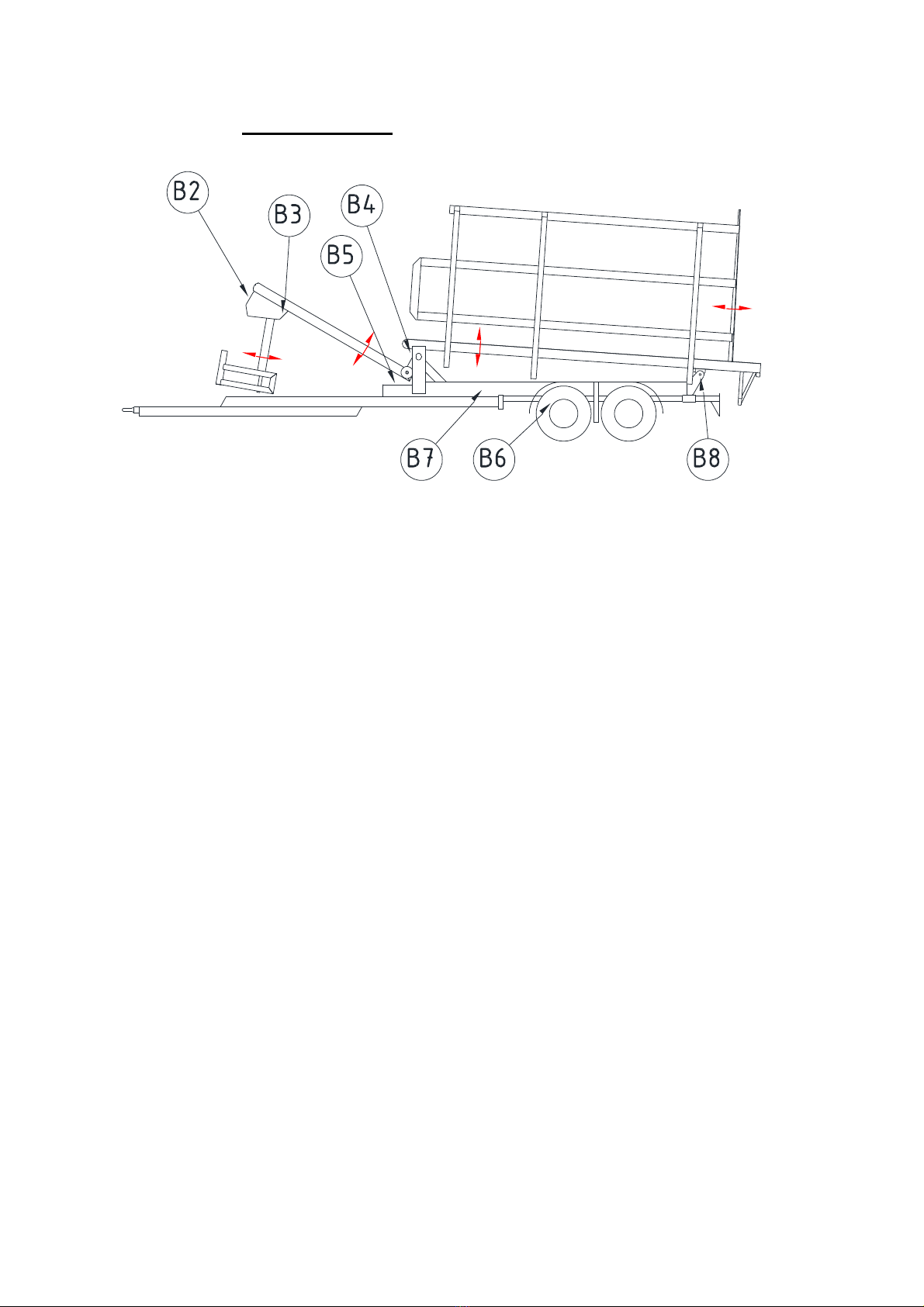

When the loading program starts, the bale clamp

compresses the bale until reaching the compression

pressure set in the PLC. The bale is then lifted

upwards until sensor B2 is activated.

In this position the bale clamp releases the bale

when the set pressure is reached. The fork yoke then

moves downwards until sensor B3 is activated, and

the trailer is ready to receive the next bale.