2

Contents

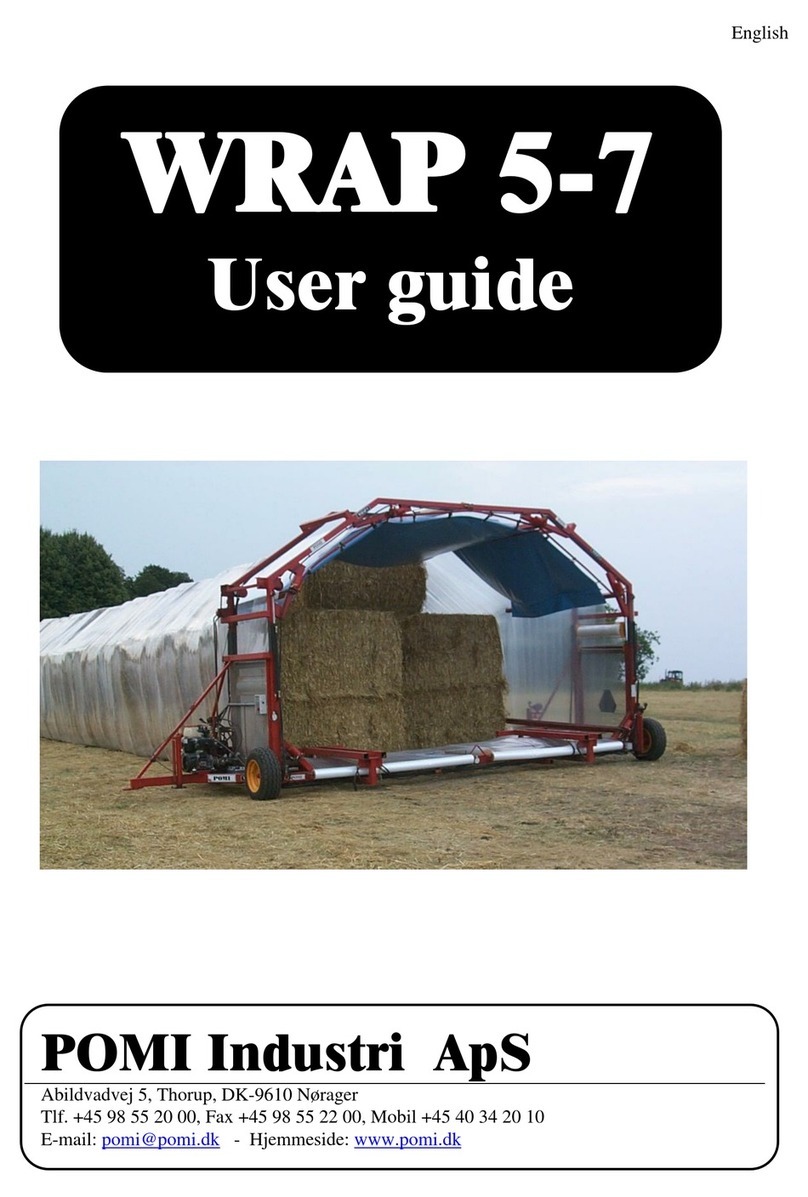

1. WRAP 5 WRAPPER................................................................................................................................. 3

2. SAFETY INSTRUCTIONS....................................................................................................................... 3

3. EU DECLARATION OF ACCORDANCE............................................................................................. 4

4. MACHINE IDENTIFICATION............................................................................................................... 5

5. BEFORE START....................................................................................................................................... 5

6. CHANGE FROM TRANSPORT TO WRAPPING................................................................................ 6

7. WRAPPING............................................................................................................................................... 7

7.1. POSITIONING OF BALES BEFORE WRAPPING............................................................................................ 8

7.1.1. Square bales....................................................................................................................................... 8

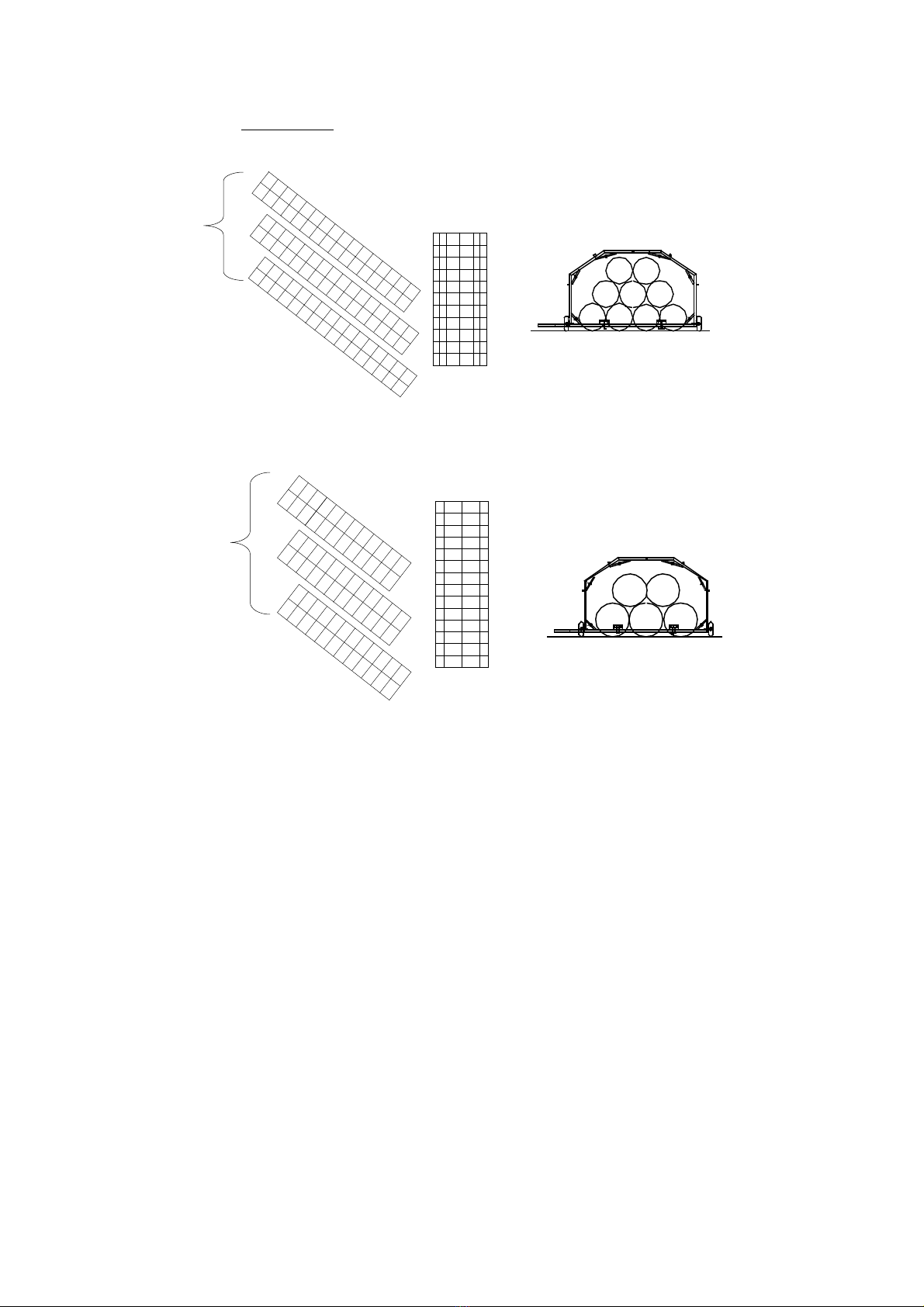

7.1.2. Round bales ....................................................................................................................................... 9

8. FINISHING.............................................................................................................................................. 10

9. CHANGE OF FOIL ROLLER............................................................................................................... 10

10. MACHINE OPERATIONS:................................................................................................................... 11

10.1. ELECTRICAL BOX................................................................................................................................. 11

10.2. REMOTE CONTROL .............................................................................................................................. 11

10.3. HYDRAULIC SYSTEM ........................................................................................................................... 12

10.4. FOIL GUARD ........................................................................................................................................ 13

11. BOTTOM FOIL....................................................................................................................................... 13

12. MAINTENANCE..................................................................................................................................... 14

12.1. CHECK BEFORE SEASON ...................................................................................................................... 14

13. GOOD ADVICE ...................................................................................................................................... 15

14. EXTRA EQUIPMENT............................................................................................................................ 16

14.1. HYDRAULIC LIFT OF TOWER ................................................................................................................ 16

14.2. FOIL ROLLER BASKET .......................................................................................................................... 17

15. PROBLEMS............................................................................................................................................. 18

Updated on 17.07.2001