Page 1 KIS100 Power Gate Operator

Introduction

The KIS100 gate operator is a proven product that provides a user friendly, dependable and

cost effective means of automating accordion gates used in residential and LULA elevators.

It has passed an accelerated life test of 25 years of normal residential use (100,000 cycles).

This product conforms to UL508A, ASME A17.1A, ASME A17.5, CSA-B44-94, and CSA-

C22.22, No. 14-M91.

Features & Benefits

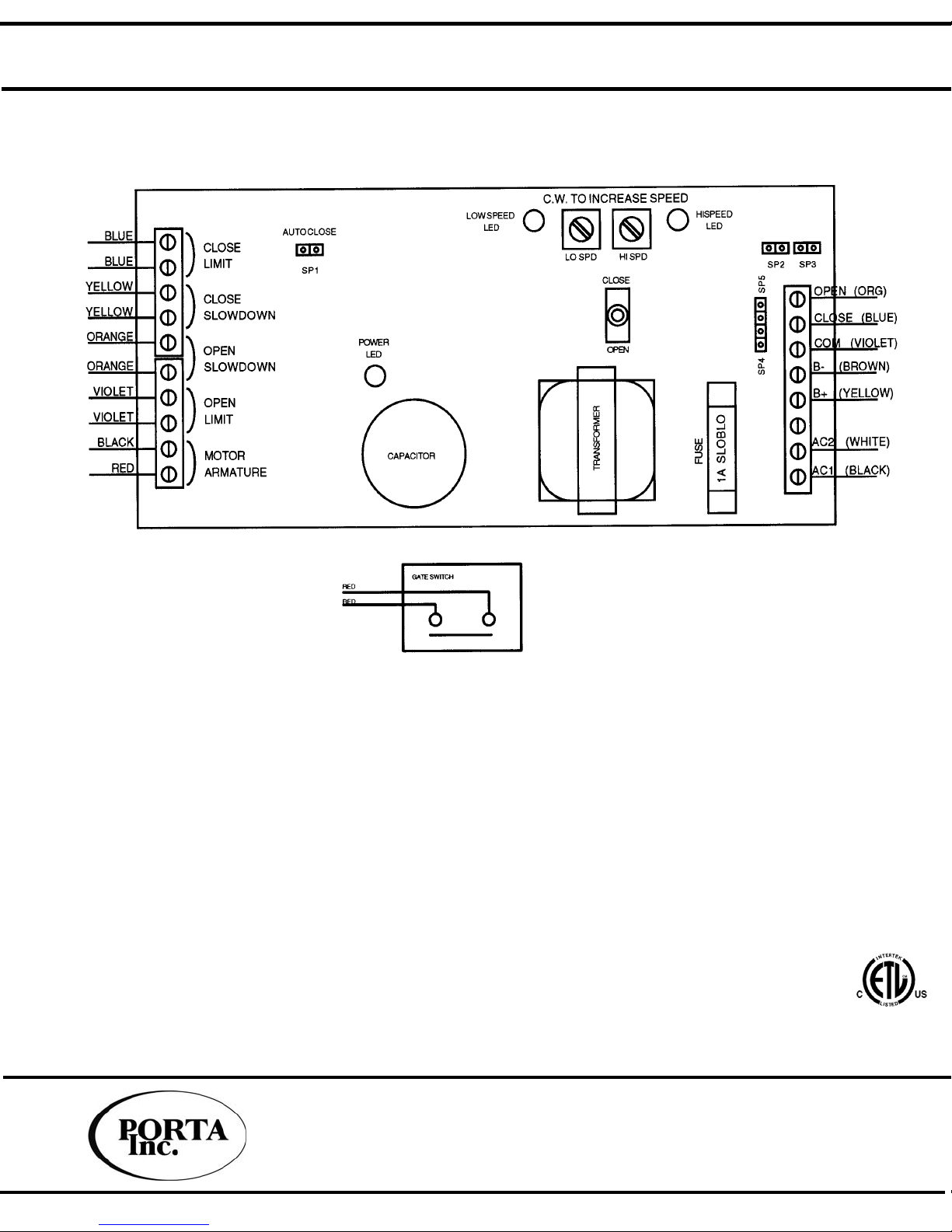

• Two Speed bi-directional gate operation

• Selectable Auto-Close feature

Will automatically close the gate when the open signal is removed

• Variety of Control Signalization

The KIS100 can accommodate a variety of control voltages or dry contact signals.

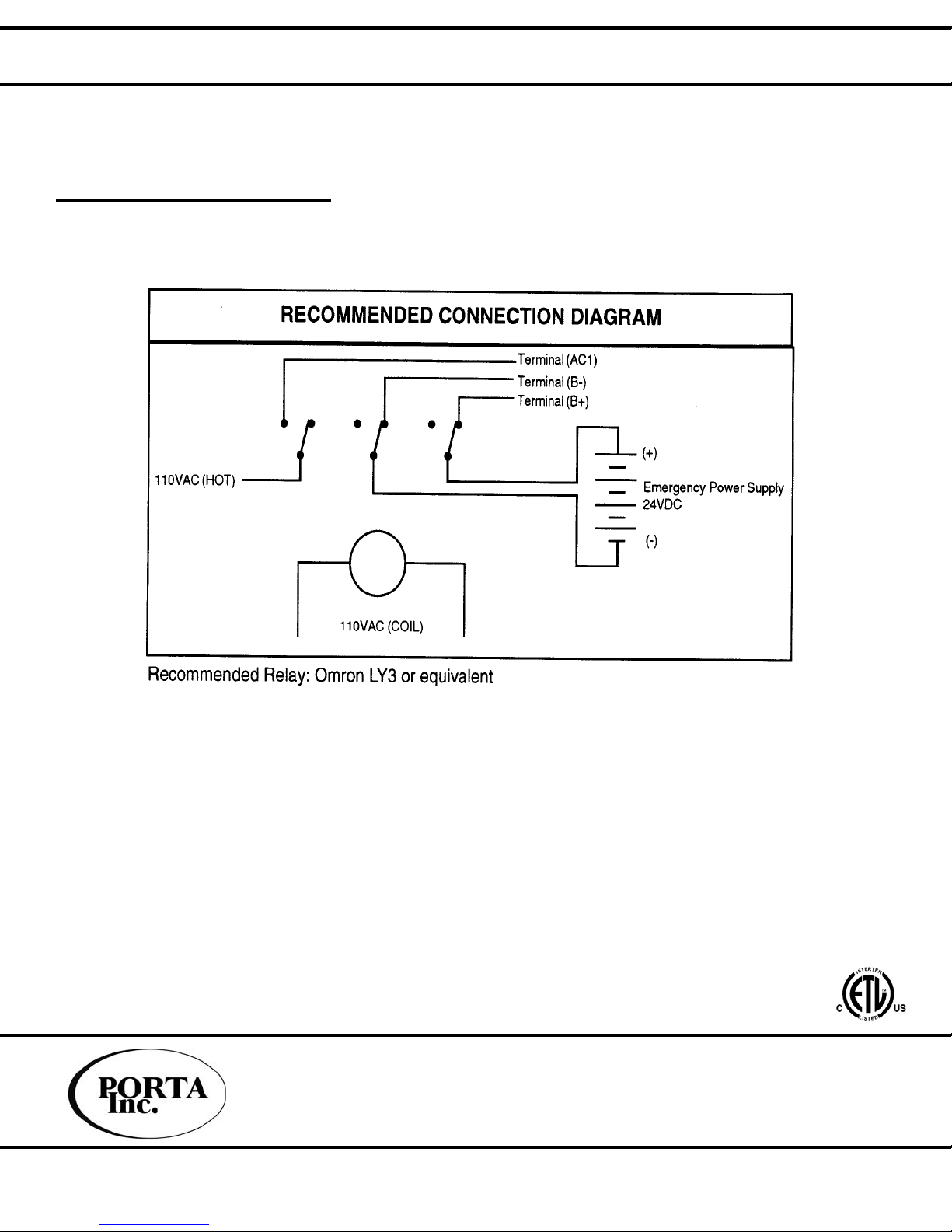

• Emergency Power Input

In the event that the 110VAC power is interrupted, 24VDC may then be applied to operate the unit.

• GAL type G gate switch (optional)

Mounts within the KIS100 chassis

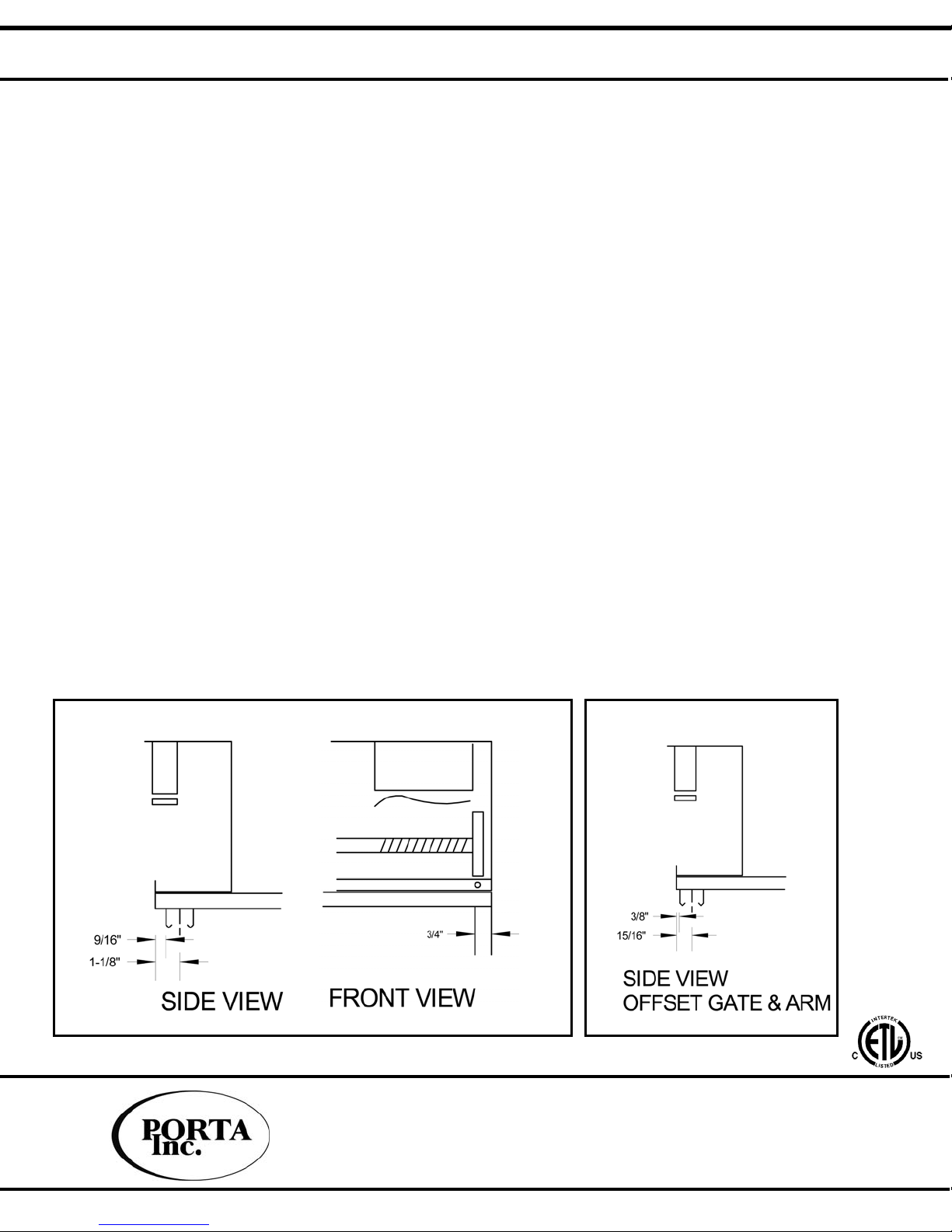

• Micro-switch slow downs and limits

Provide a simple and accurate means of decelerating and stopping the gate

• Magnetic coupling of gate to operator

Provides a simple and positive means of preventing damage or injury in the case of an

obstruction. If the resistance to gate closure exceeds the magnetic coupler, the gate dis-engages

and becomes a manual gate. There is nothing to get out of adjustment or reset. This coupling

system also allows for moderate mis-alignment of operator and gate.

•14" gate arm

Reduces bottom hinge lag

• Quiet Operation

A precision ground lead screw drive system provides virtually silent operation.

• Retrofit existing installations

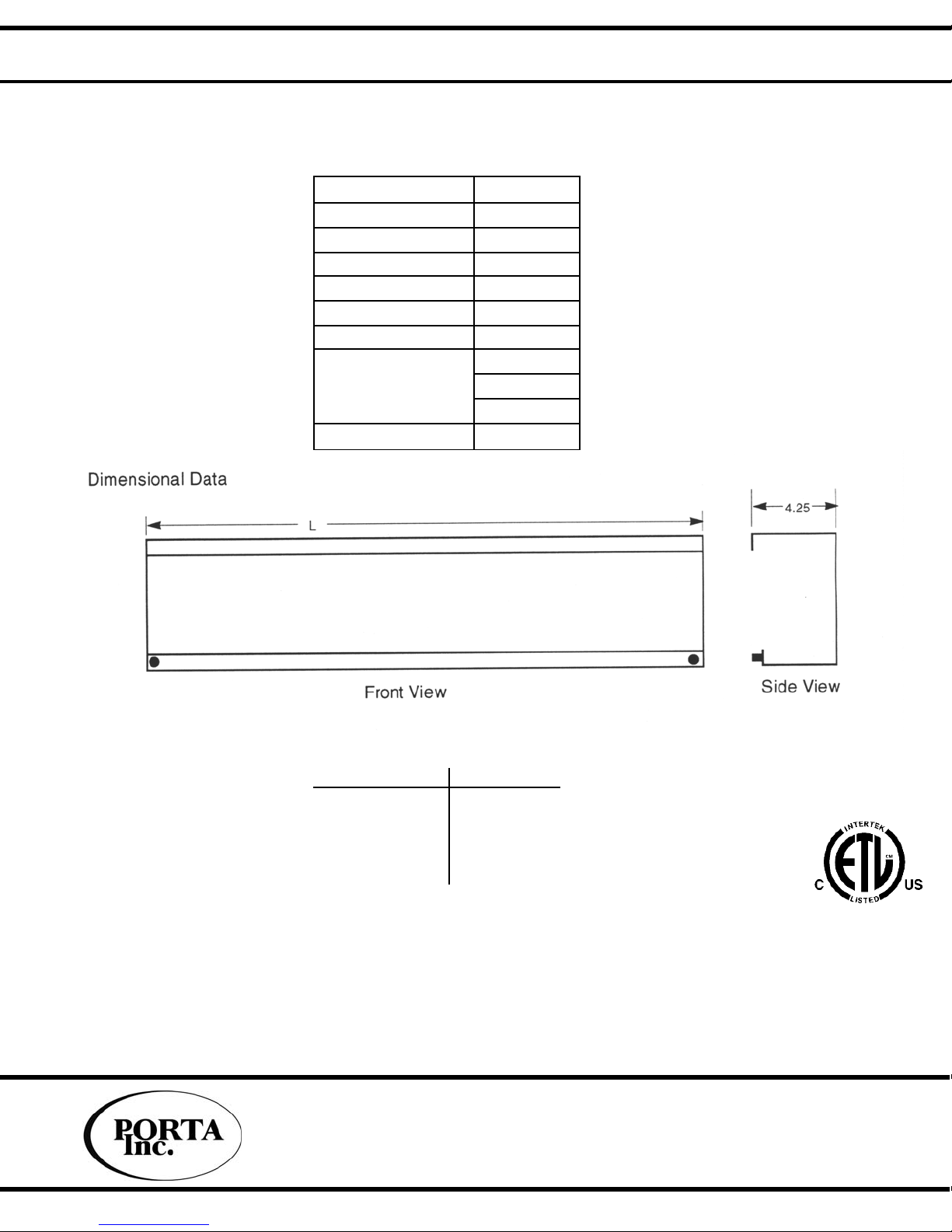

The footprint of the KIS100 is the same as the standard Accordion gate

• PWM motor drive

Provides quiet operation, longer motor life and reduced power consumption.

ATTENTION!

WARNING: The installation of this device should only be performed by a professional elevator

technician that has a full understanding of this device’s operation and function.

Note: If there is any doubt regarding the installation procedures, please call the factory for

assistance. We are available M-F 8:00 am to 5:00 pm Central Time.

WARNING: Failure to comply with all instructions and “WARNING”(s) can result in

a safety system compromise. This, in turn, can result in serious injury or death.

Porta Inc. Phone: (847) 593-4900

2420 Hamilton Rd. Fax: (847) 593-1394

Arlington Heights, IL 60005 website:emiporta.com

PATENT PENDING