6

Cylinder (Tank) Operation / Maintenance

Cylinder Pressure Readings: Oxygen is a true

compressed gas, while in the cylinder, thus the

cylinder pressure gauge can be used to determine

the amount of gas remaining in the cylinder. For

example, 2000 psi indicates full, 1000 psi indicates

half full, etc. Nitrous Oxide is a liquefied compressed

gas that vaporizes in the cylinder, thus the cylinder

pressure gauge cannot be used to determine the

amount of gas remaining in the cylinder until all liquid

in the cylinder vaporizes. While liquid remains in the

cylinder, the cylinder pressure gauge indicates the

vapor pressure which depends on and varies with the

temperature of the liquid. For example, at 68ºF, the

vapor pressure is about 750 psi; at 20ºF, it drops to

about 400 psi; while at 90ºF, it increases to about

1000 psi. After all the liquid vaporizes, the pressure

will decrease normally as the gas is withdrawn, and

the cylinder pressure gauge can then be used to

determine the amount of gas remaining in the

cylinder.

Cautions

Always turn on CYLINDER VALVES slowly

and fully.

NEVER ATTEMPT TO LOOSEN cylinder valve

packing nut. If valve stem is tight, return

cylinder to supplier.

Warning: Do not remove or alter gas

indexing pins

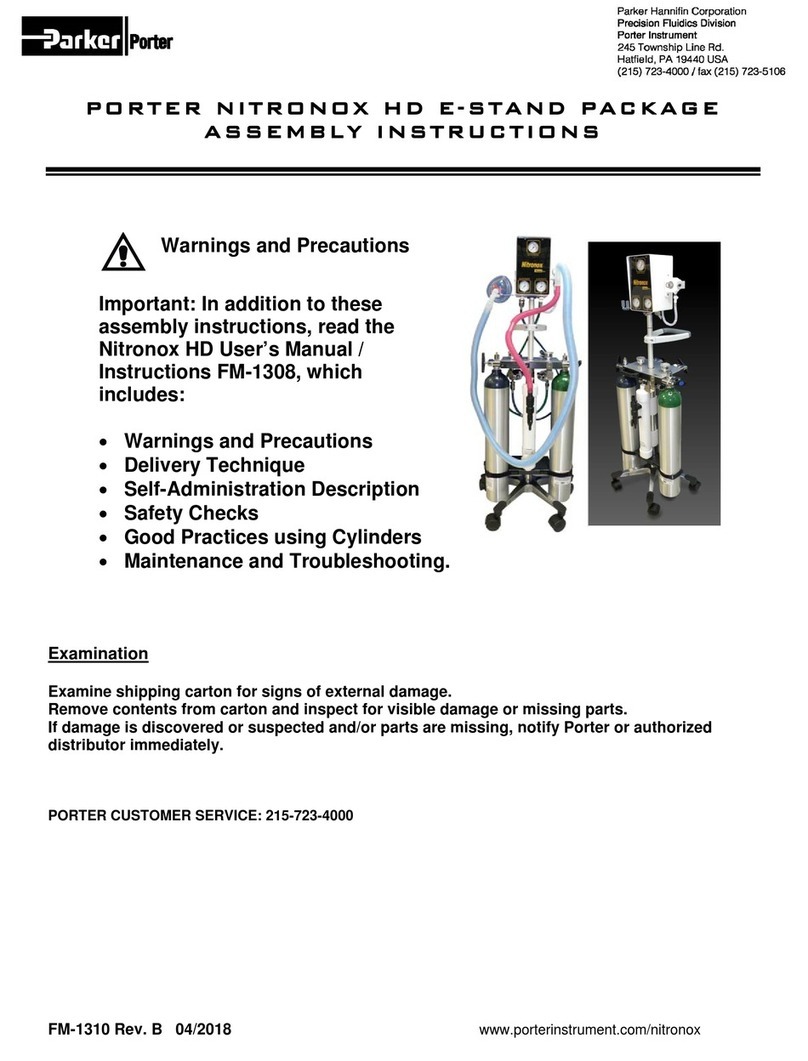

Good Practices: Cylinders with E-Stand

1. Two cylinders of O2and two cylinders of N2O are

typically connected at all times.

2. Minimize leak risks: Confirm Yoke Washers are

in place before replacing/mounting cylinders. Use

Porter #A-3399-000 replacement washers

(once/yr.). Have spare washers.

3. Minimize leak risks: With cylinder in position,

rotate swivel arm and move into secure locked

position when Tee Handle is tightened. To

prevent movement and potential damage to yoke

pins, always fasten the Hook & Loop strap

restraints around cylinders.

4. Assure E-Stand is populated with at least one full

cylinder of O2and N2O before starting any

procedure.

5. Label each cylinder with a tag or sticker

indicating “In-Use” and “Full” (“Full” is reserve).

6. Use Cylinder Valve Wrench to open the “In-Use”

cylinders of O2and N2O. Verify wrench is

attached to E-Block.

7. Cylinder pressure gages on E-Block provide a

visual indication of cylinder status (see details on

Cylinder Pressure Readings)

8. Caution: If all four cylinders (or both cylinders of

one gas) are open, the two cylinders of O2and

N2O will deplete in tandem. The “Full” cylinder

will empty with the “In-Use” cylinder and will not

be available as a future spare.

9. When “In-Use” cylinder is depleted, open the

spare “Full” cylinder (Close valve on empty

cylinder).

10. When “In-Use” O2cylinder is depleted, the

Oxygen Fail Safe will stop N2O flow through

flowmeter automatically.

11. When “In-Use” N2O cylinder is depleted, the

flowmeter will deliver 100% O2.

After use, turn off cylinder valves.

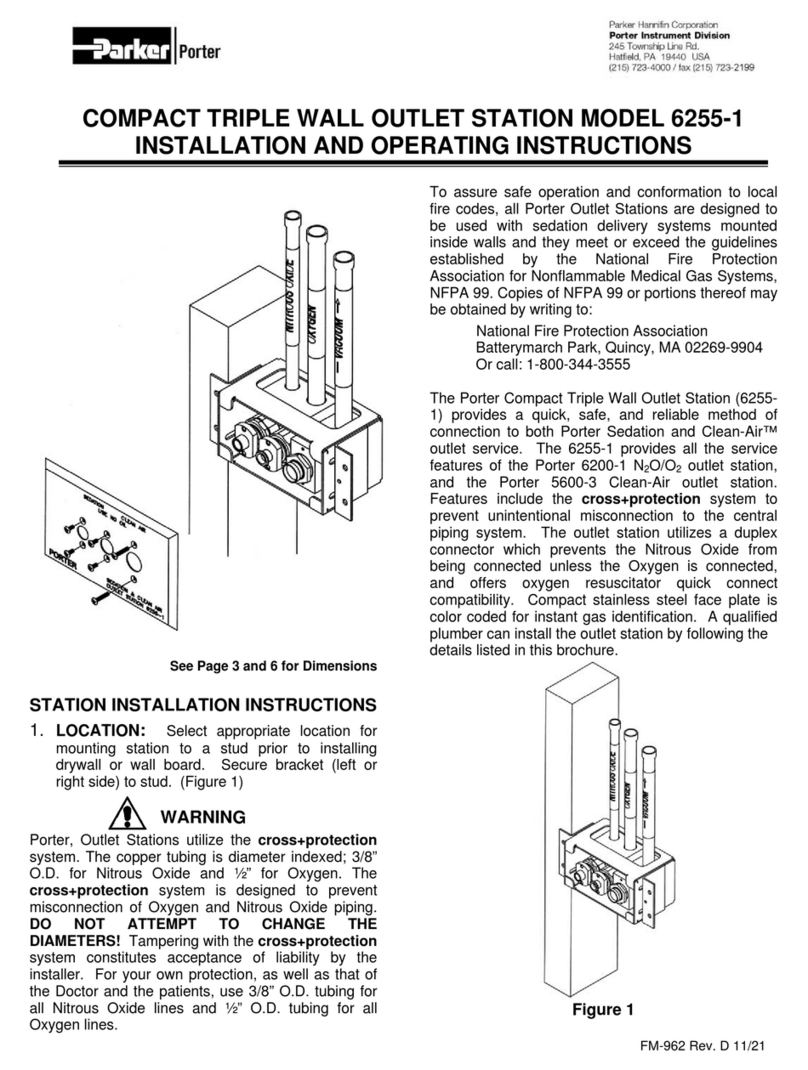

Connect to Gas Supply

1. Connect O2hose to flowmeter.

2. Connect N2O hose to flowmeter.

3. Connect hoses to O2/ N2O outlet fittings on

regulators. (Figure 1)

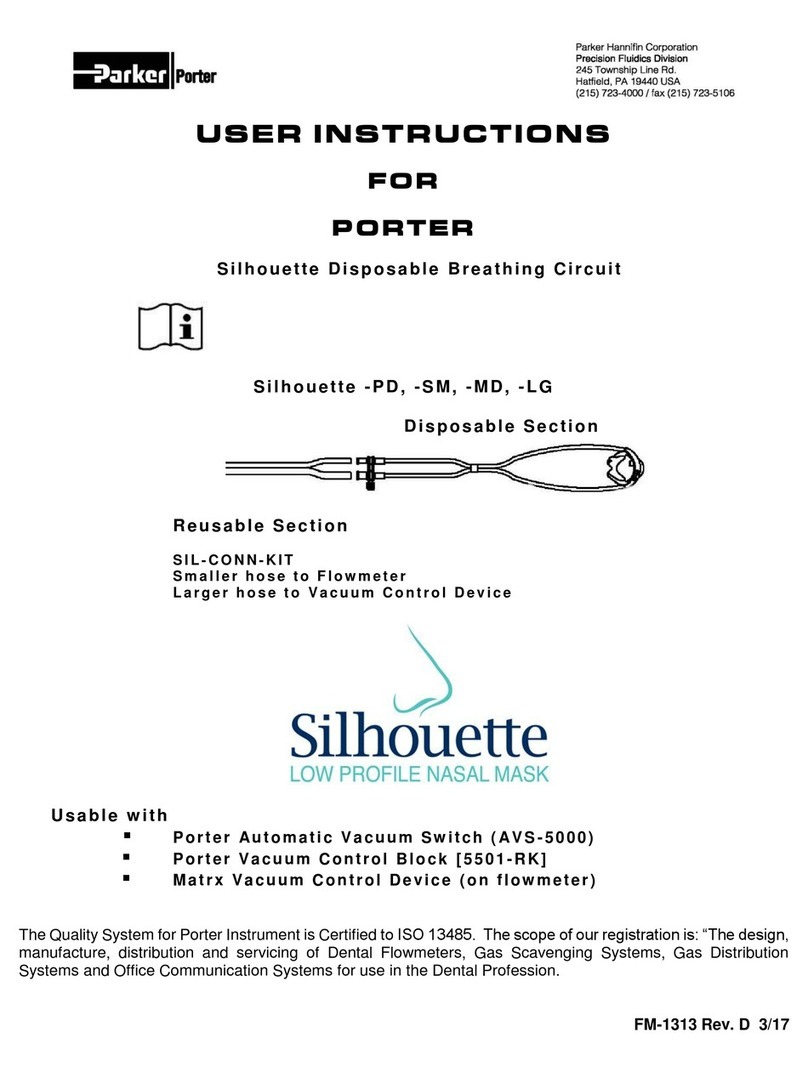

Connecting Breathing Circuits

Refer to FM-809 for User Instructions for Assembly

Installation and Cleaning of Porter Scavenger Rubber

Goods System. Also for attachment of AVS

(Automatic Vacuum Switch) and Bag Tee (with Quick

Disconnect).

Refer to FM-1330 for Assembly and Installation of

Medical Breathing Circuit Scavenger System for

medical applications.

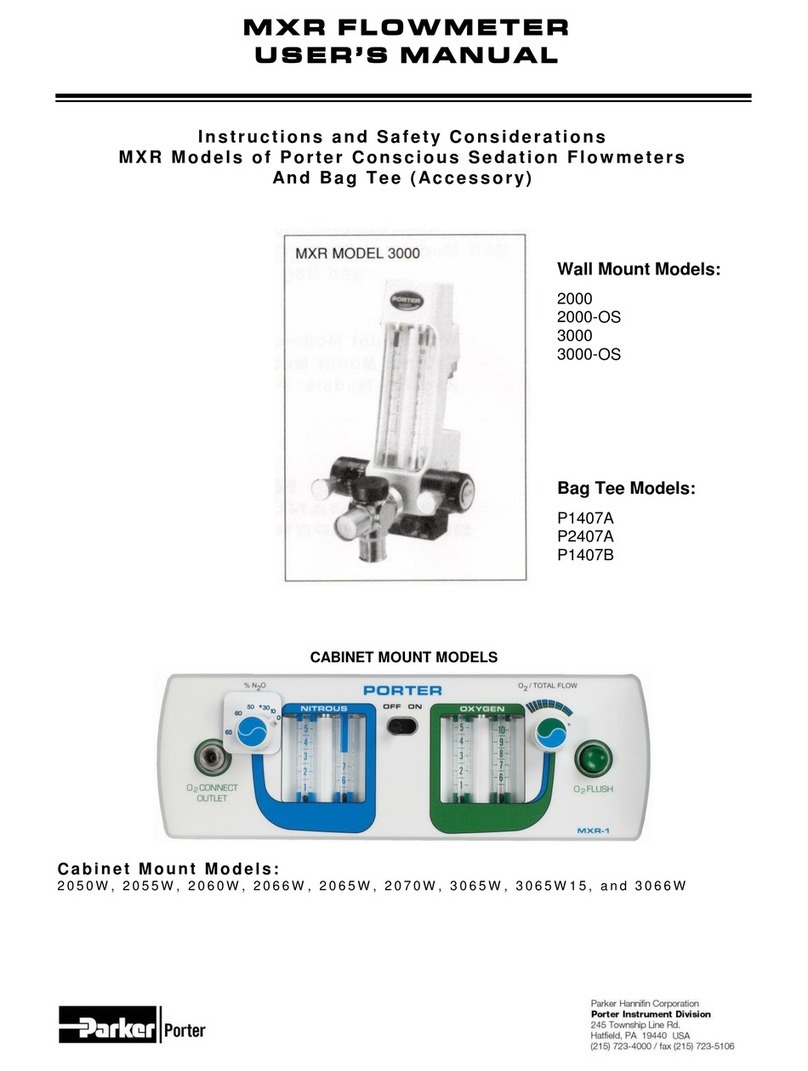

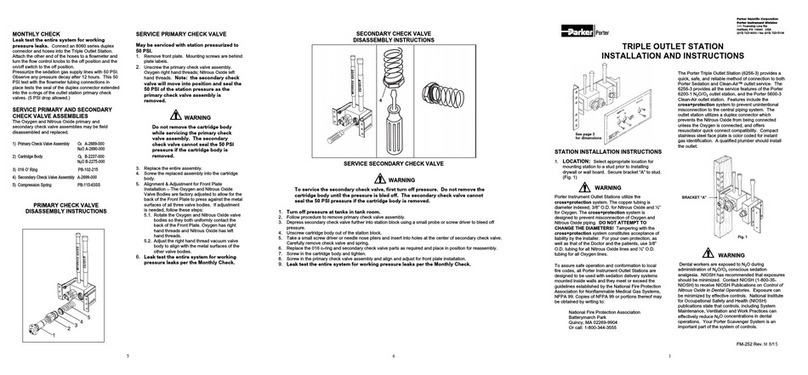

Monthly Check

Leak test the entire system for working pressure

leaks. Attach the hoses to a flowmeter and turn the

flow control knobs to the OFF position and the ON /

OFF switch to the OFF position.

Turn tanks ON. Pressurize the sedation gas supply

lines and “E” block with tank pressure. Turn tanks

OFF. Apply masking tape to both gage faces. Tap

lightly on gages and mark gage needle positions on

the masking tape. There should be little or no

movement of the gage needles after 15 minutes.

This test with the flowmeter tubing connections in

place tests the seal of the hose connectors, the “E”

Block and the flowmeter’s on / off switch.