MAINTENANCE

During maintenance and cleaning always remove

the mains plug from the socket. Never use li uids

when cleaning electrical parts of the saw bench.

The Powercraft machines have been designed to

operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation

depends upon proper machine care and regular cleaning.

leaning

Keep the ventilation slots of the machine clean to

prevent overheating of the engine.

Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt.

If the dirt does not come off use a soft cloth moistened

with soapy water. Never use solvents such as petrol,

alcohol, ammonia water, etc. These solvents may

damage the plastic parts.

Lubrication

The machine requires no additional lubrication.

Faults

Should a fault occur, e.g. after wear of a part, please

contact your local Powercraft dealer.

In the back of this manual you find an exploded view

showing the parts that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during

transport, it is delivered in a sturdy packaging. Most of

the packaging materials can be recycled. Take these

materials to the appropriate recycling locations.

Take your unwanted machines to your local Powercraft-

dealer. Here they will be disposed of in an

environmentally safe way.

OLD ELECTRICAL TOOLS AND THE

ENVIRONMENT

If your electrical tools have been used so intensively that

they need to be replaced or if you no longer use them,

please consider the environment when you dispose of

them. Electrical equipment should not be discarded with

household waste, but should be recycled. For more

information, please contact your local service centre.

GUARANTEE

The guarantee terms can be found on the enclosed

guarantee card.

e declare under our sole responsibility that this

product is in conformity with the following standards or

standardized documents

EN55014-1, EN55014-2

EN61000-3-2, EN61000-3-3

EN61029-1, EN61029-2-7

in accordance with the regulations.

98/373/EE

73/23/EE

89/336/EE

from 01-09-2004

ZWOLLE NL

. Kamphof

Quality department

CE

ı

DECLARATION OF CONFORMITY (UK)

Powercraft 5

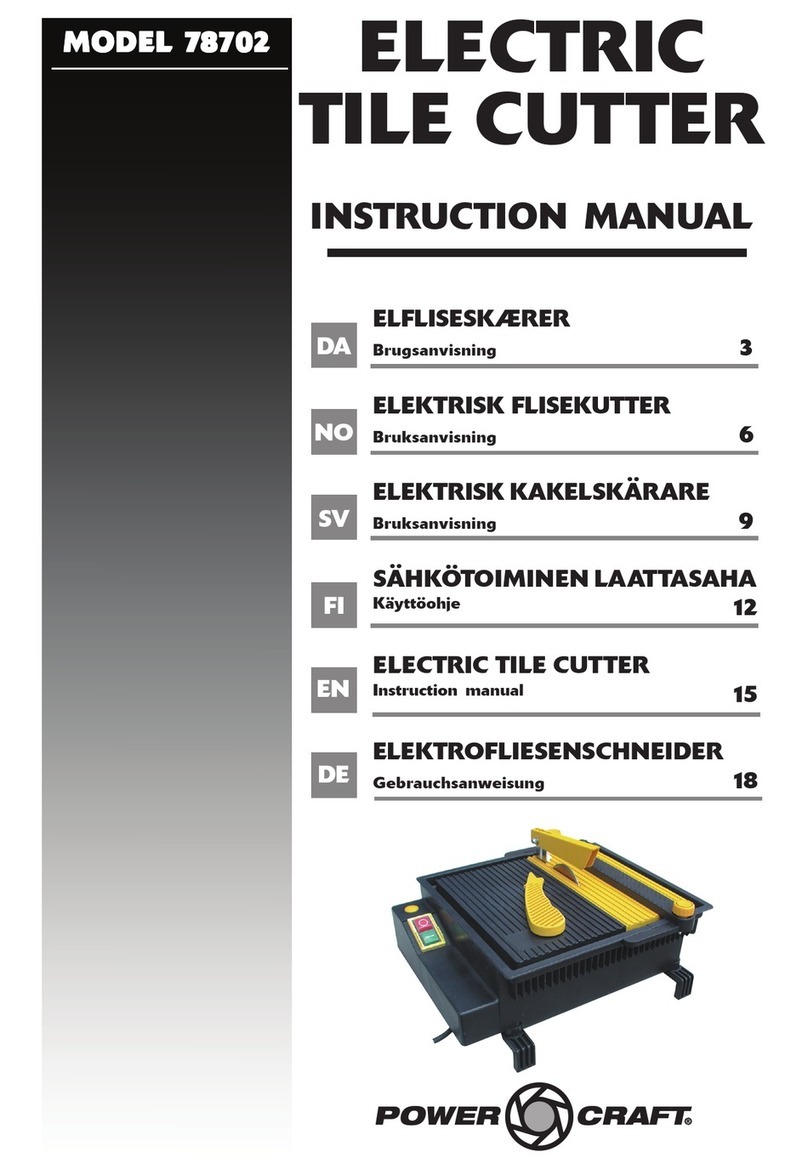

4. Mounting the adjusta le fence

• Connect the knob (7) with the fence (3) by using the

plate (1 hole with thread); do not tighten the knob

yet

• Slide the complete fence with (loosen) knobs onto

the table; the plates on the inner side of the table

• Set the required distance

• Tighten the knobs by rotating them (clockwise)

5. Place the water tank (4) under the ta le

INSTALLING THE TILE CUTTER

• The tile cutter may only be used as a fixed tool and

should be screwed down to a level and horizontal

surface. Please use the screw holes in the base of the

machine.

• The electrical supply must be connected to a 230 V

earthed wall socket. The mains voltage must comply

with the information on the type plate, and must be

protected by a circuit breaker.

• Do not use the power cable to pull the plug from the

socket. Protect the cable against heat, oil and sharp

objects.

Only use accessories and auxiliary e uipment

mentioned in the instructions for use or

recommended or mentioned by the manufacturer. Using

other accessories or auxiliary e uipment may carry a risk of

injury for you and others.

OPERATION

Fig.1

• Before starting the job, please ensure there is

sufficient water in the water tray (4) i.e. the diamond

blade runs through the water. During the job, the

water tray must be topped up.

• Do not start working before the maximum speed has

been reached.

• The diamond blade must NEVER be exposed to

sideways pressure; they can break and the flying

pieces become projectiles!

• Do not attempt to cut extremely small pieces from

the tiles. Always make sure that the full surface of the

tile is on the work table. The supplied mitre guide can

be used to push the tiles through the cutter. In the

early stages of cutting in particular, the tile must

remain absolutely level to avoid the tile moving up.

• Do not overload your tool. It is better and safer to

work within the indicated power range. Do not cut

materials other than tiles.

• Maintain your tools carefully. Keep the tools sharp

and clean in order to work properly and safely.

Follow the maintenance instructions and the

instructions for replacing the diamond blade.

• Stand safely and maintain your balance. Avoid any

unnatural body angles. Remain alert and pay

attention to your work. Use common sense. Do not

use the machine when you cannot concentrate or

when you are tired.

FULL-LENGTH ADJUSTABLE FENCE

Fig.1

The fence (3) enables you to cut parallel to the cutting

blade. Set up: Loosen the knobs (7) and set the required

distance. Tighten the knobs on both sides of the work

table. The markers determine the measurements (8).

MITRE GUIDE

Fig.1

The mitre guide has a variable setting between 0° and

45°. Loosen the knobs (5), set the mitre by tilting the

table (1) up until you have reached the required tilt.

Tighten the knobs (5) again on both sides of the work

table.

CLEANING, MAINTENANCE AND

REPAIR

• Please clean the tool immediately after use:

a. Disconnect the plug from the socket.

b. Remove the water tray from the machine and

drain the dirty water.

c. Unscrew the splash guard and clean it.

d. Loosen the star-shaped knob, fold up the table,

and polish the entire machine.

• The machine complies with all current safety

regulations. Repairs may only be carried out by an

approved company, because repair attempts by

unqualified people may cause injuries to the user and

bystanders. Regularly check the plug and the cable

and if they are damaged they should be replaced by an

approved company. Also check any extension cables.

Damaged safety guards and switches must be

replaced before the machine is used again.

CHECKING AND REPLACING THE

DIAMOND BLADE

Fig.2

• Cracked or distorted diamond blades must be

replaced.

• Type of disc: a diamond blade with a diameter of

180mm.

• Do not use diamond blades that do not meet the

specifications in these instructions.

• Ensure that the diamond blade is secured properly

and rotates in the correct direction.

• To replace a worn disc, please take the following

steps:

a. Disconnect the plug from the socket.

b. Remove the water tray from the machine.

c. Loosen the splash guard’s fixing bolts and remove

the splash guard.

d. Loosen the blade fixing nut (4).

e. Remove the counter flange (3) and blade (2) and

push the new blade on the flange (1). Consider

the rotation direction indicated on the blade.

Attach the counter flange (3).

f. Tighten the fixing nut (4) and the splash guard.

g. Ensure you do not leave any tools lying on the

splash guard.

4Powercraft