TABLE OF CONTENTS

ABOUT THIS MANUAL ...............................................................................................................................2

ACRONYMS.................................................................................................................................................6

SAFETY SYMBOLS.....................................................................................................................................8

SAFETY INSTRUCTIONS............................................................................................................................9

TORQUE AND SCREW SIZING.................................................................................................................15

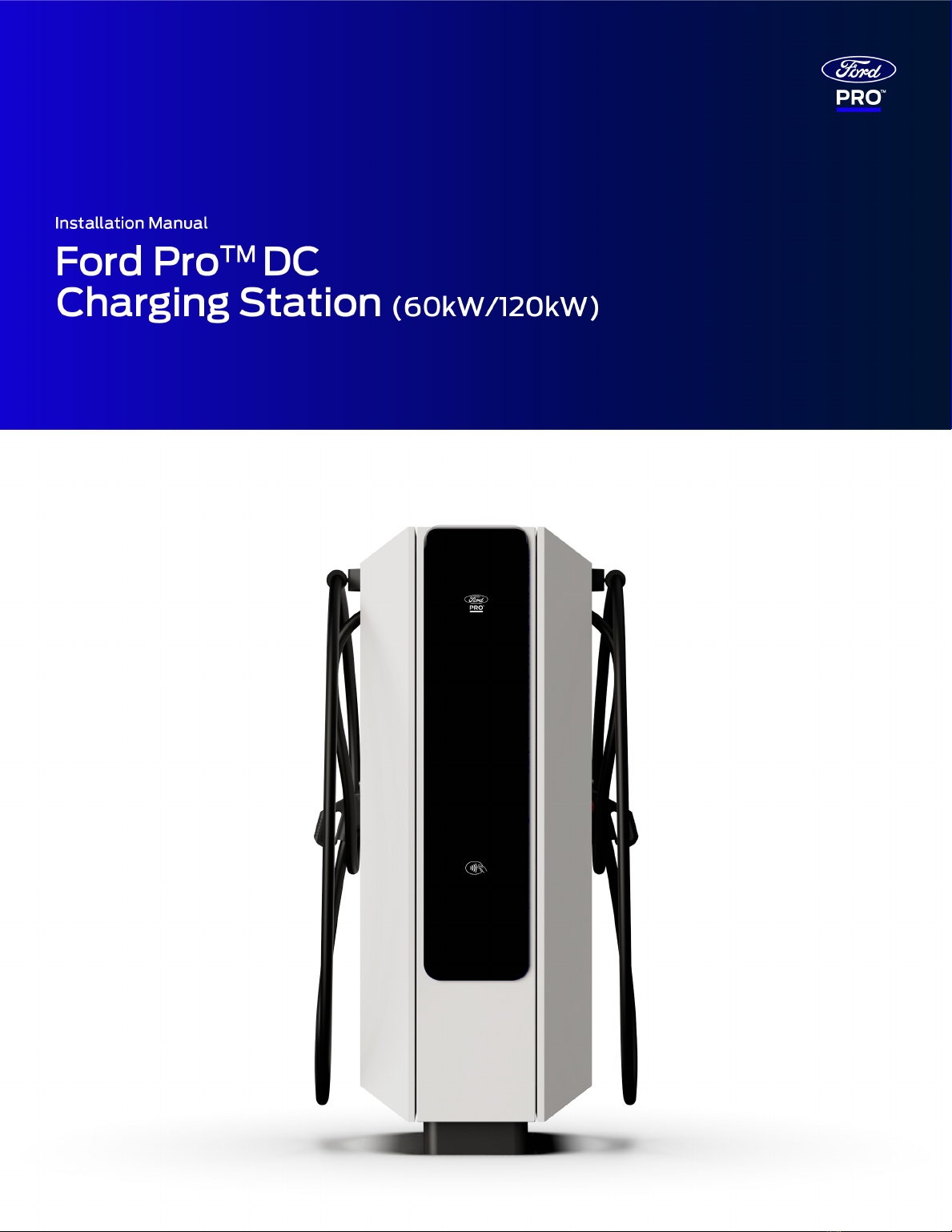

INTRODUCTION...................................................................................................................................16

Equipment overview...........................................................................................................................17

Charging process ...............................................................................................................................19

Advanced charge functionality............................................................................................................20

Open door detection...........................................................................................................................20

Power retrofit (optional)......................................................................................................................21

Regulatory framework ........................................................................................................................21

TECHNICAL CHARACTERISTICS ......................................................................................................22

Standalone NB 120 –IEC ..................................................................................................................22

Standalone NB 120 –US ...................................................................................................................23

DIMENSIONS AND WEIGHT................................................................................................................24

HANDLING AND TRANSPORTATION ................................................................................................26

Reception...........................................................................................................................................26

Storage...............................................................................................................................................26

Extended Storage...............................................................................................................................27

Unpackaging ......................................................................................................................................27

Handling and transportation ...............................................................................................................27

PREPARATION FOR INSTALLING THE EQUIPMENT.......................................................................30

Site recommendations........................................................................................................................30

Minimum working distances ...............................................................................................................32

Anchoring of the equipment................................................................................................................33

Ventilation system ..............................................................................................................................34

CABLE ACCESS AND CONNECTIONS..............................................................................................35

Access................................................................................................................................................36

Connections .......................................................................................................................................38

PROTECTIONS ....................................................................................................................................44

Insulation monitoring ..........................................................................................................................44

Overcurrent and short circuit protection..............................................................................................44

Overvoltage protection (optional)........................................................................................................44

Residual current protections (RCD) (optional)....................................................................................44