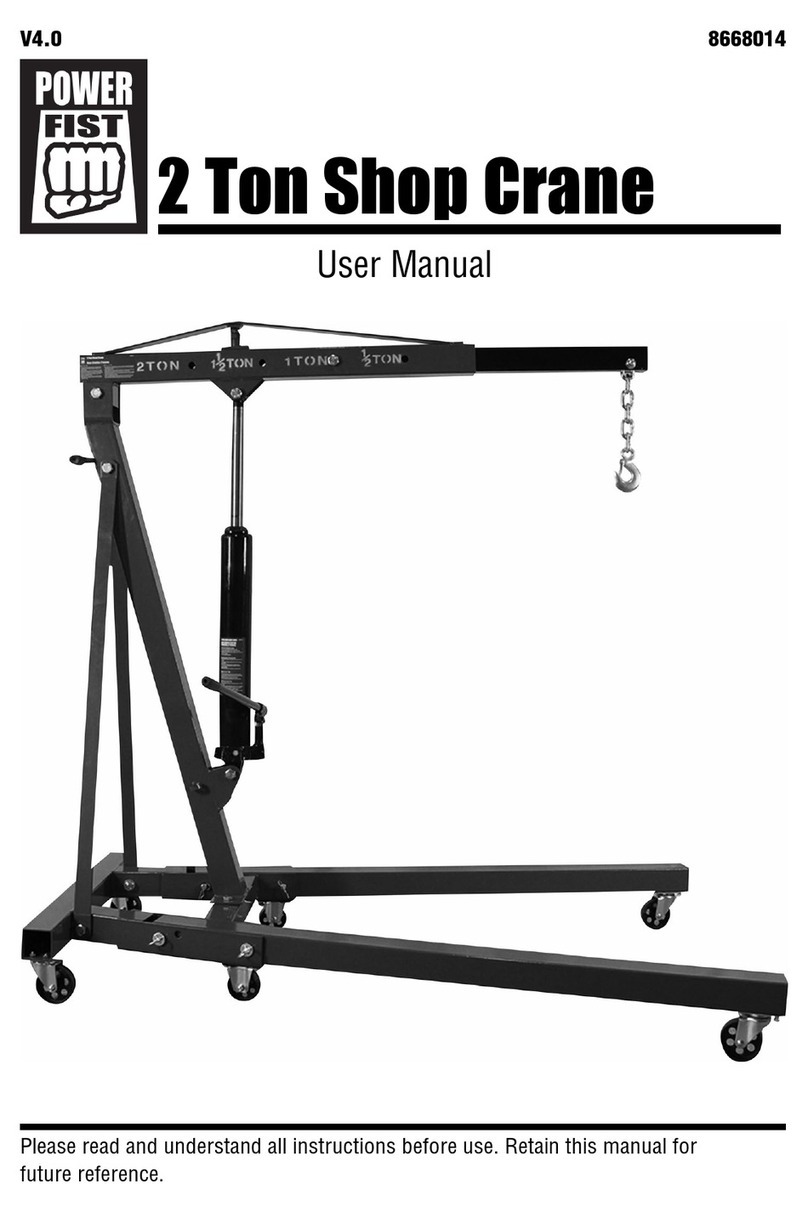

Power Fist 8732315 User manual

V1.0 8732315

Please read and understand all instructions before use. Retain this manual for

future reference.

This page is intentionally left blank.

SPECIFICATIONS

Capacity 2,000 lb

Maximum Length 51 in.

Maximum Height 80 in.

Lift Range 5 to 80 in.

Reach 51 in.

Operation Mode Manual

Swivel Angle 360º

Material Steel

Colour/Finish Powder Coat, Black

Mounting Size 10 x 10 in.

Winch Capacity 2,000 lb

Winch Cable 30 ft

INTRODUCTION

This easy-to-use crane is perfect for lifting and loading generators, pressure

washers, drum barrels and other heavy cargo onto trucks and trailers. It

features a 360° pivoting base.

SAFETY

WARNING! Read and understand all instructions before using this tool.

The operator must follow basic precautions to reduce the risk of

personal injury and/or damage to the equipment.

HAZARD DEFINITIONS

Please familiarize yourself with the hazard notices found in this manual. A

notice is an alert that there is a possibility of property damage, injury or death

if certain instructions are not followed.

DANGER! This notice indicates an immediate and specic hazard that will result in

severe personal injury or death if the proper precautions are not taken.

WARNING! This notice indicates a specic hazard or unsafe practice that could result in

a serious injury if the proper precautions are not taken.

CAUTION! This notice indicates a potentially hazardous situation that may result in

minor or moderate injury if proper practices are not taken.

NOTICE! This notice indicates that a specic hazard or unsafe practice will result in

equipment or property damage, but not personal injury.

V1.0 TRUCK MOUNT CRANE 8732315

Page 3 www.princessauto.com / 1-800-665-8685

WORK AREA

1. Operate in a safe work environment. Keep your work area clean, well-lit

and free of distractions. Place lights so you are not working in a shadow.

2. Keep anyone not wearing the appropriate safety equipment away from

the work area.

3. Store unused tools properly in a dry, safe and secure location to prevent

rust, damage or misuse.

PERSONAL SAFETY

WARNING! Wear personal protective equipment approved by the

Canadian Standards Association (CSA) or American National Standards

Institute (ANSI).

PERSONAL PROTECTIVE EQUIPMENT

1. Always wear impact safety goggles that provide front and side protection

for the eyes. Eye protection equipment should comply with CSA Z94.3-07

or ANSI Z87.1 standards based on the type of work performed.

2. Wear steel toe footwear or steel toe caps to prevent a foot injury from

falling objects.

PERSONAL PRECAUTIONS

Control the tool, personal movement and the work environment to avoid

personal injury or damage to tool.

1. Do not operate any tool when tired or under the inuence of drugs,

alcohol or medications.

2. Avoid wearing clothes or jewelry that can become entangled with the

moving parts of a tool. Keep long hair covered or bound.

SPECIFIC SAFETY

WARNING! DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to the tool safety rules. If you use

this tool unsafely or incorrectly, you can suer serious personal injury.

1. Use the correct tool for the job. This tool was designed for a specic

function. Do not modify or alter this tool or use it for an unintended

purpose.

2. Failure to follow these instructions may result in loss of load, damage

to the crane, and/or crane failure resulting in personal injury or property

damage.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 4

3. Do not allow untrained persons to operate the crane.

4. Use the crane for lifting only. Do not work under a load that is supported

only by the crane.

5. Stabilize the load. Ensure that the load remains stable at all times. Lift

deadweight only.

6. Know the weight of the load being lifted. DO NOT overload the crane

beyond the rated capacity of each specied boom position. Overloading

can cause damage or failure of the crane.

7. The vehicle with the crane should be on a level surface capable of

sustaining the weight of the vehicle and load. Use of the crane on other

than level surfaces can result in crane instability and possible loss of load

or tipping of the vehicle.

8. Make sure there is enough clearance around the crane and the load for

movement.

9. Never attempt to use the crane unless it is properly lled with hydraulic

uid. Do not use brake uid or any other improper uid and avoid mixing

dierent types of oil when adding hydraulic oil.

10. Inspect the tool before each use. DO NOT use if bent, broken, cracked,

leaking, otherwise damaged, if any suspect parts are noticed or it has

been subjected to a shock load.

11. Check to ensure that all applicable bolts and nuts are rmly tightened.

12. Store the crane with the boom fully lowered, winch cable retracted,

hydraulic ram valve closed and position the boom over the vehicle's wheel

well when storing or driving.

JACK PRECAUTIONS

1. Do not use a handle extension for the jack handle.

2. Make sure the load is stable, so it does not shift when lifting or lowering.

3. Ensure that there are no obstructions under the load and that the area is

clear before lowering the device.

4. Lower the load in a slow and controlled manner to prevent shock loading.

Shock loading may cause to fail and lead to property damage and/or

severe personal injuries.

LIFTING PRECAUTIONS

1. Do not exceed the maximum capacity to prevent equipment failure or

damage.

V1.0 TRUCK MOUNT CRANE 8732315

Page 5 www.princessauto.com / 1-800-665-8685

2. Inspect the device before each use. Do not use if it is bent, cracked,

damaged or has been subjected to a sudden or unexpected (shock) load.

3. Ensure that all applicable pins, bolts and nuts are rmly tightened before

using.

4. Use only with accessories rated to handle the forces exerted by the device

during operation. Other accessories may break and forcefully launch

pieces.

5. Do not place your hands between moving components.

WINCH SAFETY

1. All users must understand the operation of all controls and learn how to

stop the winch quickly in case of emergency.

2. Keep hands clear of the winch and wire rope when spooling the line in or

out. Hold the wire rope by the strap. Fingers caught in the hook may be

pulled into the mechanism and crushed or pinched.

3. Never fully extend the wire rope while under load. Keep four complete

turns of the wire rope around the winch drum.

4. Do not exceed the winch load capacity.

5. Do not use the winch if damaged or it was subjected to a dynamic

shock load. Have the winch inspected and repaired by a qualied service

technician.

6. Always use proper couplings when connecting the winch cable hook,

sling, eyebolt or other accessory to the load. Never connect the hook back

to the wire rope. This causes wire rope damage. Always use a sling or

chain of suitable strength.

7. Do not use inappropriate attachments to extend the length of the winch

wire rope.

8. After moving an item with the winch, secure the item. Do not rely on the

winch to hold it for an extended period.

9. Make sure the rope spools onto the drum in touching wraps. A rope that

cannot move without impediment can create a dangerous situation that

can injury you or a bystander or damage the load and/or the winch.

10. Never lift people or hoist loads over people.

11. Never come in-between the winch and the load when operating

12. Never operate the winch if the wire rope shows any signs of weakening, is

knotted or kinked.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 6

HYDRAULIC PRECAUTIONS

DANGER! Seek immediate medical attention if hydraulic uid under

pressure penetrates your skin. See Injection Injury precautions for

instructions before using a pressurized hydraulic system.

1. Do not touch or handle components while under pressure. Hydraulic uid

escaping under pressure has sucient force to penetrate your clothing

and skin. A pinpoint hole may inject hydraulic uid into your body. Seek

immediate medical attention if this occurs (see Injection Injury).

2. Never exceed the hydraulic system’s load capacity (see Specications).

3. Do not adjust the hydraulic system’s relief setting. The settings are preset

by the factory.

4. Hydraulic oil under pressure is hot and can cause a burn injury if touched,

sprayed or spilled. Allow the hydraulic system to cool before conducting

maintenance.

5. Hydraulic components require regular inspection. Release all pressure

from the system before you inspect it. Replace damaged hydraulic parts

with identical manufacturer's components.

6. Do not attempt makeshift repairs to a hydraulic system. Such repairs can

fail suddenly and create a hazardous condition.

7. Hydraulic uid has a combustible ash point of 200°F (93°F). Do not

expose the uid to an ignition source.

8. Change your clothing immediately if sprayed with hydraulic uid. Store

clothing or rags contaminated with hydraulic uid in an approved metal

safety can with a spring-closing lid and venting designed to contain a re.

9. Only use hydraulic uid in the pump. Do not substitute or mix brake uid,

or any other uid, with the hydraulic uid. This can result in a pump

failure and injure the user or bystander. It may also damage the pump.

INJECTION INJURY

DANGER! Seek immediate, professional medical treatment if uid

penetrates your skin. It may feel like a pricking or sting. Do not wait

for the appearance of symptoms. A toxic reaction can occur from the

exposure. Delay in treatment can lead to amputation or death.

Inform the medical sta that you have a uid penetration injury as soon as you

arrive at the medical facility. The severity of the symptoms will depend on the

type of uid injected. Bring the Safety Data Sheet for the uid with you to the

medical facility if possible.

V1.0 TRUCK MOUNT CRANE 8732315

Page 7 www.princessauto.com / 1-800-665-8685

INJECTION PRECAUTIONS

Fluid can penetrate the skin at 100 PSI pressure. Fluid escaping under pressure

from the tool has sucient force to penetrate your clothing and skin. Follow

the precautions below to avoid an injection injury.

1. Always check for leaks wearing a face shield, safety goggles, rubberized

gloves and protective clothes.

2. Release all pressure from the system before you inspect it.

3. Do not use your hands to detect a leak. Use a large piece of wood,

cardboard or paper and watch for discolouration.

4. Replace damaged parts with identical manufacturer's components to

ensure it is rated to handle the pressure.

UNPACKING

WARNING! Do not operate the tool if any part is missing. Replace

the missing part before operating. Failure to do so could result in a

malfunction and personal injury.

Remove the parts and accessories from the packaging and inspect for damage.

CONTENTS

Make sure that all items in the contents are included.

• Base

• Post

• Boom

• Boom Extension

• Long Ram Hydraulic Jack

• Jack Handle

• Chain and Hook

• Winch and Cable with Hook

• Winch Handle

• Pulley

• Assorted Hardware (Bolts, Washers,

Lock Washers and Nuts)

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 8

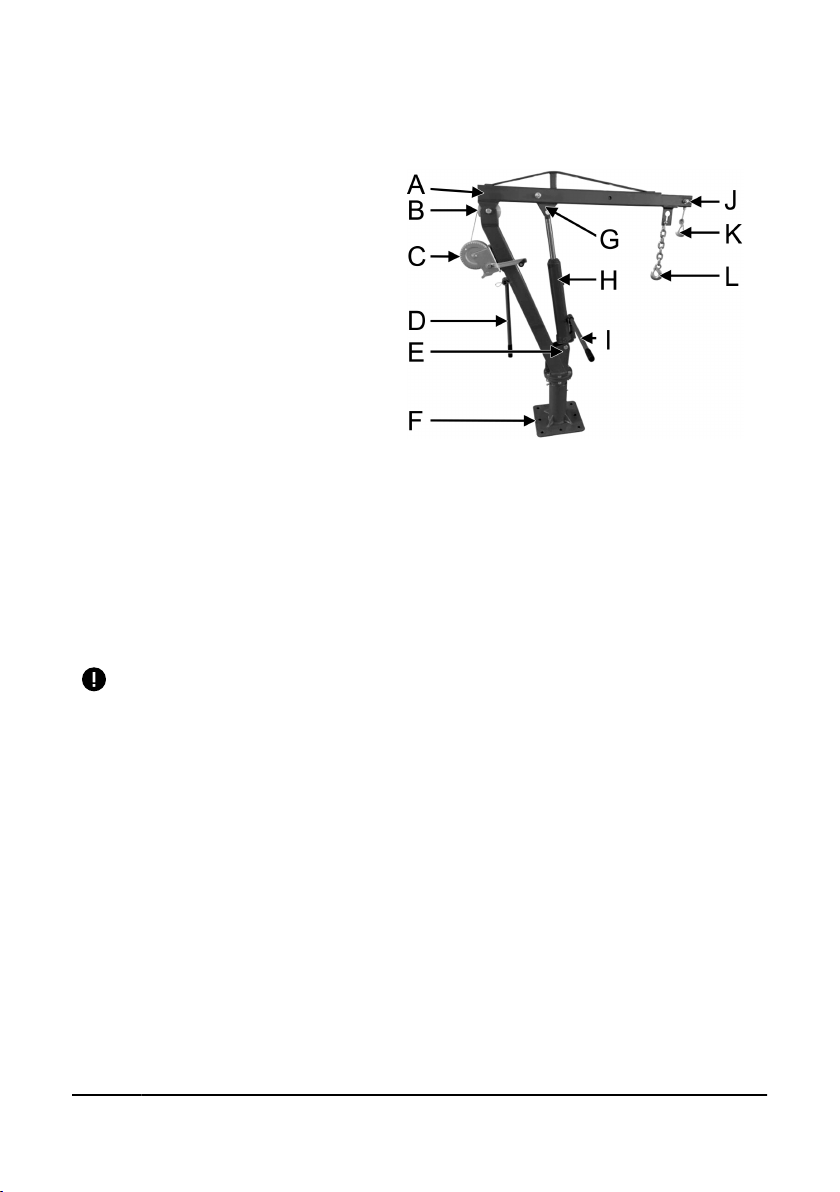

IDENTIFICATION KEY

A. Boom

B. Pulley

C. Winch

D. Crane Handle

E. Jack Attachment Point

F. Base

G. Jack Attachment Point

H. Long Ram Hydraulic Jack

I. Jack Handle

J. Boom Extension

K. Wire Rope and Hook

L. Chain and Hook

ASSEMBLY & INSTALLATION

ASSEMBLING THE CRANE

Some components are heavy and dicult to maneuver while installing.

Have another person available to help you during installation.

1. Place the base in the truck bed and check for proper clearance when the

crane is in use and when stored. A right rear corner mount is typical.

a. A wood truck oor will require the installation of a 3/8 in. thick steel

plate approximately six to eight inches larger than the base plate on

top of the wooden deck. If the oor is heavy metal and ribbed, no

metal plate is required under the crane base plate, but lling in the

ribbed oor to level it may be required. The base may now be placed

in position and used to locate the mounting holes through the truck

bed and back plate.

b. Dierent truck models may require additional bracing as the load

will be directed over the largest area possible. If additional bracing

is desired, install a brace which crosses both sides of the truck and

may be used with an outrigger, stabilizer or jack leg holder to keep

the truck stable during lifting operations.

FIGURE 1.

V1.0 TRUCK MOUNT CRANE 8732315

Page 9 www.princessauto.com / 1-800-665-8685

2. Check the mounting location below the truck bed

to avoid wiring, gas tanks, muers, etc. Adjust the

base position if needed to avoid puncturing the

understructure when drilling.

3. Use the base as a template and mark the holes that

you will use to mount the base to the truck bed.

Move the base aside.

4. Drill holes into the truck bed. Make sure the drill and

drill bit are suitable for drilling through the metal.

Use cutting oil if necessary.

5. Reposition the base over the holes. Secure in place

with bolts, washers and nuts (sold separately). Only

use hardware that exceeds the weight capacity of

the crane.

6. Insert the bearing (#43) into the base. Screw the base

handle (#34) into the base until the bearing is held in

place (Fig. 2).

7. Slide the post over the base and align the holes in

each (Fig. 3). Insert a bolt (#27) through each hole.

Slide a washer (#8) and lock washer (#7) over the

bolts and secure with a nut (#6).

8. Insert the boom into the post’s top bracket (Fig. 4).

Position the large pulley inside the boom so the

bushings align with the bolt holes. Insert a bolt (#42)

through the bolt holes. Secure with a washer (#24),

lock washer (#23) and nut (#22).

• Ensure the connection point for the hydraulic

jack is on the bottom and near the post when

connecting the boom.

9. Follow the instructions for

Installing The Jack

in the next section.

10. Slide the boom extension into the

boom. Until the hole in the boom

aligns with the hole at the 2,000 lb

mark.Insert a bolt (#21) through the

bolt holes. Secure with a washer (#24),

lock washer (#23) and nut (#22).

FIGURE 2.

FIGURE 3.

FIGURE 4.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 10

FIGURE 5.

11. Follow the instructions for

Installing

The Chain And Hook.

INSTALLING THE JACK

WARNING! The hardware (bolts, pin, washers, lock washers and

nuts) used to attach the jack to the equipment must be capable

of withstanding the load without deforming or breaking to prevent

equipment failure and/or personal injuries.

The hardware is included.

1. Align the ram’s bolt hole with the bolt

hole on the equipment's attachment

point. The attachment point location will

vary depending on the equipment and

application.

2. Insert a bolt (#21) through the mounting

points and the ram's bolt hole.

• Secure the bolt with a washer (#24),

lock washer (#23) and nut (#22).

3. Place the the clevis mount over the clevis

attachment point on the equipment and

align the bolt holes.

4. Insert a bolt (#27) through the clevis mount and attachment point. Secure

with a washer (#24), lock washer (#23) and nut (#22).

INSTALLING THE WINCH

Remove the wire rope from the winch before installation.

1. Prepare the hardware by sliding a lock washer (#39), then a washer (#38)

over the each bolt (#37). Set aside within easy reach.

2. Position the winch's base on the post. The winch's handle will be on the

right-hand side. Align the base's bolt holes with the post's screw holes.

Hold the winch in place.

3. Insert one of the prepared bolts through the base's bolt holes and screw

the bolt into post. Repeat with the other three prepared bolts. Tighten

each bolt until the lock washer begins to compress.

BEFORE FIRST USE

The steel rope must be broken-in before using to lift a heavy load. The break-in

process will stretch the cable, ensure the individual wires are seated and the

FIGURE 6.

V1.0 TRUCK MOUNT CRANE 8732315

Page 11 www.princessauto.com / 1-800-665-8685

wire compacted. Run the winch with a light load several times, before normal

use.

Also use a weight when spooling the wire rope onto the winch. This will

provide the correct tension when spooling.

INSTALLING A WIRE ROPE

1. Remove the bolt that connects the boom and boom

extension and set aside.

2. Push the boom extension into the boom.

3. Lift the boom so it is at a slight upward angle. The

angle will hold the boom extension in place.

4. Insert the end of the wire rope through the hole in the

bottom of the boom extension. Pull several feet of wire

rope through the hole.

5. Feed the wire rope down the boom extension and

boom until it comes out the other end.

6. Place the wire rope onto the pulley in the boom and

boom extension.

7. Continue pulling wire rope out of the boom until you

are sure it won't be pulled back by its own weight.

8. Mount and wrap the wire rope onto the winch.

MOUNTING A NEW WIRE ROPE

1. Pull the end of the wire rope over the top of

the drum.

2. Insert the wire rope end through a side hole

in the drum from the inside. Pull about one to

two feet of wire rope out.

3. Guide the wire rope into the next hole and pull

the excess through. Leave enough line to form

a large loop.

4. Guide the wire rope through the next hole from the inside and pull the

excess through.

5. Insert the end of the wire ripe under the large loop. The end must extend

past the loop, but stay within the edge of the drum to avoid impeding

rotation.

FIGURE 7.

FIGURE 8.

FIGURE 9.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 12

6. Hold the end of the wire rope in place. With your other hand, remove the

wire rope's slack by pulling it back through the holes, until the loop traps

the rope end.

7. Reel the new wire rope onto the drum by turning the handle, being careful

not to allow kinking.

8. Test the winch for proper operation.

MOUNTING A NEW WIRE ROPE

1. Route the end of the new wire rope under the bushing and through the

hole to the outside of the drum.

2. Insert the wire rope under the cable clamp.

3. Tighten the cable nut securely.

4. Reel the new wire rope onto the drum by turning the handle, being careful

not to allow kinking.

5. Test the winch for proper operation.

INSTALLING THE CHAIN AND HOOK

Make sure the chain, hook and hardware are rated to exceed the crane's weight

capacity.

1. Choose a short length of chain to avoid problems with clearing obstacles

when raising the load.

2. Attach a suitable shackle to the top chain link.

3. Align the shackle openings with the connection point on the boom

extension. Insert a bolt through the shackle and the connection point.

Secure the bolt with a nut or tighten if the shackle is threaded.

4. Attach another shackle and a hook to the bottom chain link, if the chain

does not have one already.

OPERATIONS

WARNING! No one other than the people involved in moving the load

should be in or on the vehicle. Anyone near the vehicle may be seriously

injured or killed if the load falls or the vehicle tips over under a heavy

load. Ensure each person has an unobstructed escape route away from

the work area.

V1.0 TRUCK MOUNT CRANE 8732315

Page 13 www.princessauto.com / 1-800-665-8685

WARNING! Dynamic shock loads are created by quick opening and

closing of the release valve when lowering the load. The resulting

overload may cause the hydraulic system to failure, which could result

in severe personal injury and/or property damage.

Inspect the crane at the beginning of the day before lifting. Any defects or

problems should be corrected before use.

The crane has two options for lifting and moving cargo: by hydraulic jack or by

manual winch. You can use them together or separately to lift a load.

1. Determine the load’s weight.

2. Adjust the boom extension position to 1,000 lb or 2,000 lb, based on the

load’s weight. Reinsert the bolt and secure with the washers and nut used

during assembly. The weight capacity of the boom arm is written next to

each bolt hole on the boom.

3. Position the vehicle so the crane can reach the load. Do this after

adjusting the boom extension arm in the previous step.

4. Keep the vehicle as level as possible during operation and always lift the

load straight up.

5. Loosen the base handle and rotate the crane until it is over the load.

6. To prevent the boom from swinging freely, always tighten the base handle

before lifting a load, after the load is positioned or when storing the crane

after use.

7. Always use outriggers (jack legs) from the truck to the ground. Be sure

these are rm and adequately positioned.

RAISING A LOAD

1. Close the release valve. Insert the slotted end of the handle over the valve

and twist to the right.

2. Insert the handle (#16) into the bottle jack's receiver.

3. Pump the handle until the load reaches the desired height.

LOWERING A LOAD

WARNING! Dynamic shock loads are created by quick opening and

closing of the release valve when lowering the load. The resulting

overload may cause the hydraulic system to failure, which could result

in severe personal injury and/or property damage.

WARNING! Before lowering the load, ensure that there are no

obstructions underneath and that all people are standing clear.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 14

1. Insert the slotted handle end over the release valve.

2. Open the release valve by slowly rotating the handle counterclockwise.

The load will descend as pressure is released from the jack’s system.

Control the speed by rotating the handle.

a. Rotate the handle counterclockwise to increase the speed.

b. Rotate the handle clockwise to decrease the speed.

3. Open the release valve fully once the ram has fully retracted.

4. Position supports, like jack stands, if the load will remain above ground

for an extended period. Consult the support device's manual for proper

placement.

5. Once the supports are carrying the load, open the valve to allow the ram

to retract fully.

6. When the work is done, raise the load enough with the jack to carefully

remove the supports.

HAND WINCH OPERATION

WARNING! Do not release the handle when the ratchet mechanism is

disengaged and there is a load on the line. The load will drop and can

cause a serious impact injury. The crank handle will also spin and can

cause a minor impact injury. Maintain a rm grip while unwinding until

the load is settled and there is slack in the wire rope.

The ratchet lever has 2 positions. The upper position is for winding the wire

rope onto the drum with the ratchet in gear. The lower position disengages the

ratchet pawl allowing the drum to freewheel in either direction.

WINDING/UNWINDING (NO LOAD)

1. Rotate the handle slightly to release pressure on the pawl.

2. Push the ratchet lever down until it clicks to disengage the ratchet

mechanism.

3. The drum can move freely in both directions.

4. Grasp the hook and pull the wire rope until the hook can be attached to

the load.

• Be careful as the crank handle will rotate freely and can cause an

impact injury if it strikes you.

5. Rewind any excessive wire rope by turning the crank handle. Make sure

the rope winds evenly onto the drum.

V1.0 TRUCK MOUNT CRANE 8732315

Page 15 www.princessauto.com / 1-800-665-8685

WINDING UNDER LOAD

1. Move the ratchet lever into the upper position to engage the pawl.

2. Turn the crank handle to wind the wire rope evenly onto the drum. The

pawl will click as it catches the drum's cog.

3. Continue turning the handle until the load is high enough to clear any

obstacles.

UNWINDING UNDER LOAD (LOWERING, UNLOADING)

1. Hold the crank rmly, then push gently to relieve tension on the ratchet

lever.

2. Push the ratchet lever down until it clicks to disengage the ratchet

mechanism.

3. Turn the crank handle to unwind the wire rope until the load has settled

and there is slack in the line.

4. You may need to stop the unloading task at some point. Hold the load in

place and re-engage the ratchet system. Then turn the crank handle to

raise the load until you hear the pawl click. Gradually ease pressure on the

handle until you are sure the pawl is locked in place.

5. The wire rope should be fully retracted again after use.

OPERATING THE CRANE

1. Before lifting, set the boom to the lowest practical position that will allow

your load to safely clear any objects in the swing path.

2. Attach a hook to the lift point on the load.

3. Follow the instructions for

Raising A Load

with the winch and jack.

4. Begin pumping the handle to raise the boom with the jack. Stop when

hook is in position, but not bearing the load's weight.

5. Check that the hook is in the best position to raise the load without it

shifting.

6. Ensure all bystanders are out of the way in case the load slips or shifts.

7. Once the load is near the boom, attach the other hook for additional

safety.

8. Continue raising the boom until the load is high enough to clear any

obstacles. Remove the jack handle and set aside.

9. Loosen the base handle and move the load slowly to the desired spot with

the crane handle.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 16

10. Tighten the base handle once the load is in position for lowering.

11. Depending on the location, you may choose to lower the load by either

lowering the boom or reversing the winch.

12. Insert the jack handle end over the relief valve.

13. Open the release valve by slowly rotating the handle counterclockwise.

This will open the pressure valve and the boom arm will lower. Never

open or close the valve abruptly, as it may damage the jack and endanger

personnel in the work area. Control the speed by rotating the handle.

14. Lower the load the rest of the way with the winch, if needed.

15. Once the load is safely in the vehicle or on the ground, release enough

pressure to remove the hook.

16. Store the crane once all lifting operations are complete. No part of the

crane should stick out of the vehicle and the boom should be fully

lowered.

a. Slide the boom extension fully into the boom and secure with the

bolt.

b. Swing the crane into position for travel.

c. Tighten the base handle to secure the crane in place.

d. Lower the boom fully.

e. Return the jack handle to the storage bracket on the main post

f. Wind the slack wire rope onto the winch drum and engage the

ratchet lever.

CARE & MAINTENANCE

1. Maintain the tool with care. A tool in good condition is ecient, easier to

control and will have fewer problems.

2. Inspect the tool components periodically. Repair or replace damaged or

worn components. Only use identical replacement parts when servicing.

3. Keep the tool handles or gripping surfaces clean and dry.

4. Maintain the tool’s labels and name plates. These carry important

information. If unreadable or missing, contact Princess Auto Ltd. for

replacements.

5. Have a qualied technician inspect the jack:

V1.0 TRUCK MOUNT CRANE 8732315

Page 17 www.princessauto.com / 1-800-665-8685

a. Once a year.

b. After receiving a shock load. Take the jack out of service until the

technician certies that it is safe to use.

WARNING! Only qualied service personnel should repair the tool. An

improperly repaired tool may present a hazard to the user and/or others.

HYDRAULIC RAM MAINTENANCE

Monthly maintenance is recommended for the hydraulic ram. Any restrictions

due to dirt, rust, etc. can cause the either slow movement or extremely rapid

jerks, damaging the internal components. The following steps are designed to

keep the pump maintained and operational.

1. Lubricate the cylinder and the pumping mechanism with light oil.

2. Visually inspect for cracked welds, bent, loose, missing parts or hydraulic

oil leaks.

3. Inspect the hydraulic ram immediately if it was subjected to an abnormal

load or shock load.

4. Remove any hydraulic jack from service that is damaged, worn down or

operates abnormally, until repaired by an authorized service technician.

5. Check and maintain the ram oil level.

6. Always store the hydraulic ram in the fully retracted position. This will

help protect critical areas from corrosion.

7. Do not use brake or transmission uids or regular motor oil as they can

damage the seals. Always purchase and use products labeled Hydraulic

Oil.

REFILL THE HYDRAULIC JACK

The pump may become less ecient when the hydraulic oil level is too low or

contaminated by metal particulate through normal wear-and-tear.

1. Retract the ram and remove the oil ller plug.

2. Check and maintain the ram oil level.

• Check the oil level with the oil dip stick. Use a long plastic cable tie

as a substitute if the unit does not have a dipstick.

3. Fill the cylinder with a high quality hydraulic jack oil, up to the oil plug

opening.

a. Place a funnel into the oil ll neck. The funnel opening should be

wide enough to prevent the oil from collecting in the funnel’s cone.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 18

b. Pour oil into the funnel. Allow the oil to settle for one minute and

recheck the level. Repeat until the desired level is reached.

4. Follow the steps in Bleeding the Hydraulic System.

5. Insert the oil ller plug and hand tighten.

6. Wipe up any spilled oil. Dispose of oil soaked rags in a proper hazardous

waste container.

REPLACE THE HYDRAULIC OIL

Replace the hydraulic oil annually.

The oil can be removed by using a uid extractor tool.

FLUID EXTRACTOR TOOL

1. Retract the ram and remove the oil ller plug.

2. Follow the instructions for your uid extractor tool to remove the old

hydraulic oil.

3. Follow the instructions for Rell the Hydraulic Jack.

MANUAL OIL REPLACEMENT

1. Relieve pressure from the system by opening the release valve, then

loosening the oil ller plug.

2. Remove the jack from the crane.

3. Remove the oil ll plug.

4. Lay the jack on its side and drain the oil into a suitable container. Dispose

of used hydraulic oil in accordance with local by-laws.

5. Stand the jack on its base and wipe o any excess oil.

6. Reinstall the hydraulic jack onto the crane.

7. Follow the instructions for Rell the Hydraulic Jack.

BLEEDING THE HYDRAULIC SYSTEM

Bleed excess air from the hydraulic system as follows:

1. Open the release valve by turning it counterclockwise.

2. Remove the oil ller screw and ll the hydraulic jack with hydraulic uid.

3. Wait 5 minutes for trapped air to rise to the surface.

4. Pump the handle for several strokes to eliminate any air in the system.

5. Check the oil ller hole and if necessary, top o with more hydraulic oil.

V1.0 TRUCK MOUNT CRANE 8732315

Page 19 www.princessauto.com / 1-800-665-8685

6. Restore the oil ller screw. Close the release valve by turning clockwise.

7. Test the ram several times for proper operation before putting it into use.

Do not use the ram if it still does not appear to be working properly. Have

a qualied service technician service or repair the hydraulic system.

FLUSHING THE VALVE

Contaminants may block the release valve, causing issues when attempting to

lower a load. Clear the valve with the following steps.

1. Lower the ram and securely close the release valve.

2. Manually lift the ram several inches.

3. Open the release valve and force the ram down as quickly as possible.

LUBRICATION

Clean and lubricate all moving parts.

Lubricate the grease tting with a grease gun once a month or when the boom

becomes dicult to swivel on the post.

HYDRAULIC FLUID DISPOSAL

Do not drain hydraulic oil into the sewer system or dispose in an uncontrolled

location. Hydraulic uid may take more than a year to breakdown in the

environment and the ingredients may still be toxic. Contact your local

municipality for proper disposal instructions or locations.

DISPOSAL

Recycle a tool damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws for

electronic devices, batteries, oil or other toxic liquids.

DO NOT pollute the environment by allowing uncontrolled discharge of

waste oil.

TROUBLESHOOTING

Visit a Princess Auto Ltd. location for a solution if the tool does not function

properly or parts are missing. If unable to do so, have a qualied technician

service the tool.

8732315 TRUCK MOUNT CRANE V1.0

www.princessauto.com / 1-800-665-8685 Page 20

Table of contents

Languages:

Other Power Fist Construction Equipment manuals

Power Fist

Power Fist 8901092 User manual

Power Fist

Power Fist 660 lb User manual

Power Fist

Power Fist 8622946 User manual

Power Fist

Power Fist 8536708 User manual

Power Fist

Power Fist 8712937 User manual

Power Fist

Power Fist 8668014 User manual

Power Fist

Power Fist 8625949 User manual

Power Fist

Power Fist 8536625 User manual

Power Fist

Power Fist 8924094 User manual

Popular Construction Equipment manuals by other brands

allen

allen AT-16 Operations & parts manual

Atlas Copco

Atlas Copco CA300 instruction manual

HYVA

HYVA HC801 WARNING, OPERATING AND MAINTENANCE MANUAL

allen

allen WB1224 Assembly & parts manual

Parkside

Parkside PFMR 1400 A1 Original operating instructions

Hog Technologies

Hog Technologies HT1000SR Operation manual