Power Test SuperFlow AutoDyn AD-30 User manual

SUPERFLOW AUTODYN AD-30

AWD CHASSIS DYNAMOMETER

PIT INSTALLATION

PI0030CS02

REV: 3.30.2020

AutoDyn AD-30 AWD Chassis Dynamometer

Safety Warnings ..........................................................................................................2

Dangers Due to Non-observance of Safety Instructions ...............................................................2

Document Conventions .....................................................................................................................2

Test Cell Room Requirements ...................................................................................3

Hazards of Dynamometer Testing ...................................................................................................3

Test Cell Design ..................................................................................................................................4

Pit Design .............................................................................................................................................6

Pit Drainage .........................................................................................................................................7

Ventilation ...........................................................................................................................................7

Combustion Air .............................................................................................................................................8

Heat Extraction ..............................................................................................................................................9

Vehicle Cooling............................................................................................................................................10

Exhaust Extraction.......................................................................................................................................11

Absorber Cooling and Pit Ventilation ......................................................................................................12

Vehicle Restraint Requirements .....................................................................................................13

Electrical Requirements ...................................................................................................................14

Dynamometer Chassis ................................................................................................................................15

Data Acquisition System ............................................................................................................................15

Miscellaneous...............................................................................................................................................15

Air Requirements .............................................................................................................................15

Static Electricity ................................................................................................................................16

Convenience Issues ..........................................................................................................................16

Equipment Recommendations .......................................................................................................17

Ventilation Fans ...........................................................................................................................................17

Air Handling ................................................................................................................................................19

Water Pumps and Accessories...................................................................................................................20

Vehicle Tie-down Accessories ...................................................................................................................20

Installation Instructions

Required Tools ..........................................................................................................22

Pit Preparation ...........................................................................................................22

Rollset Preparation ...................................................................................................23

Placing the AutoDyn in the Pit .................................................................................26

Eddy Current Absorber Module and Driveshaft .....................................................31

Plumbing and Wiring ................................................................................................33

Rollset Covers ...........................................................................................................36

Contents

Drawings and Schematics

AD-30 AWD Dimensions 41

AD30 AWD Pit Location 42

AD-30 AWD Pit Layout (page 1 of 4) 43

AD-30 AWD Pit Layout (page 2 of 4) 44

AD-30 AWD Pit Layout (page 3 of 4) 45

AD-30 AWD Pit Layout (page 4 of 4) 46

Vehicle Tie-down Points 47

AWD Cover Plate Locations 48

AWD Electrical Drawing 49

AWD AD-30 Junction Box Assembly 50

Eddy Current Assembly Drawing 51

Energy Balance (Metric Units) 52

AutoDyn Room and Pit Airflow (U.S. Units) 53

Drawings

Page 1 3.30.2020

Product

Information

AD-30 AWD Pit Installation

AutoDyn AD-30 AWD Chassis Dynamometer

SuperFlow AutoDyn dynamometers can be installed in a pit so vehicles can drive on and off the

rolls for testing. Pit installations have certain advantages over above-ground dynamometers—

particularly that it is safer and easier to position the test vehicles on the rolls.

All Wheel Drive (AWD) dynamometer are designed to be installed in a pit because of the required

additional supports for the covers in front of and between the dynamometer rolls.

• The pit is normally constructed of poured concrete with provisions for drainage and

ventilation. Access for control cables and electrical wiring is also required through conduits

or trenches.

• Vehicle tie-downs should be embedded in the concrete around the pit so the vehicle can be

secured on the rolls. A minimum of three tie-downs is required at each end of the vehicle.

Ideally, tie-down anchors should be spaced around the dynamometer to provide for most

any situation. More information on this is provided later in this document.

• Air flow must be provided in both the test room and the dynamometer pit. This is necessary

for vehicle cooling, room ventilation, exhaust extraction, and eddy current absorber cooling.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 2

Safety Warnings

To ensure safe operation, this equipment must only be operated according to the

instructions in the SuperFlow Operator Manual. It is also essential that this equipment

is installed, maintained, and operated according to local safety requirements.

Any person instructed to carry out installation, maintenance or repair of the equipment must read

and understand the SuperFlow Operator Manual and in particular the technical safety instructions.

Any users of this equipment must operate only the controls of the equipment. Only qualified

personnel should remove exterior panels and service equipment.

1. Follow all local building and fire codes.

2. Do not locate water pumps or exhaust fan motors in close proximity where fuel is present.

3. Install a carbon monoxide (CO) detector in the test cell and the console area.

4. Provide fire extinguishers rated for gasoline and oils.

5. Provide adequate lighting in the test cell and at the computer console.

6. Provide a switch outside the test cell to turn off the ventilation fans and water pumps.

7. Always use hearing and eye protection when necessary.

8. Regularly inspect the cell for fuel, oil, or liquid spills because flammable vapors can ignite.

9. Keep all personnel, flammable items, and sensitive objects away from any rotating object that

can throw debris radially outward.

Dangers Due to Non-observance of Safety Instructions

• Hearing damage due to high noise level

• Electrical shock

• Exposure to rotating parts

Document Conventions

The following conventions indicate items of interest or concern:

WARNING: Failure to take or avoid a specific action could result in physical harm to the

user or the hardware.

CAUTION: Failure to take or avoid a specified action could result in loss of data or equipment.

IMPORTANT: Essential operating information.

NOTE: Helpful information that may provide insight to the user/operator.

TIP: Additional information that may provide convenient workaround or solution.

Cross-references refer the reader to additional information in the chapter, manual, or other

sources (including Web sites).

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 3

Test Cell Room Requirements

Notice

It is imperative that you understand dynamometer testing can be hazardous. A properly

designed and built test cell is a prerequisite to providing a safe environment for testing

vehicles.

While SuperFlow provides specific test equipment designed to test your vehicles, we have

no control over how you build your test cell. These room recommendations are general and

may not specifically be suitable for your particular location or application.

A locally certified engineer or contractor must approve your designs and certify that they

conform to local building codes. Your local governing body regulations and insurance

company policies will rule over any questions or uncertainties.

SuperFlow, its employees, or agents do not assume any responsibility or liability for

suggestions, applications, or mechanical failure outside of the normal warranty or for

issues where negligence, ignorance, or mis-applied technologies are present. Ultimately,

you are responsible for ensuring your test cell is safe and conforms to all local codes and

regulations.

Read this document in its entirety before beginning construction. Contact SuperFlow Sales or

Customer Service if you have any questions or need assistance.

Hazards of Dynamometer Testing

Dynamometer testing involves running internal combustion engines. Doing so exposes the

operator to rotating parts, fluids under pressure, explosive fuels, high voltages, noise, heat, and

exhaust gases. Chassis dynamometer testing has additional risks associated with rotating

transmission parts, wheels, and chassis rolls.

These risks are generally associated with the vehicle under test rather than the dynamometer. It is

not possible for SuperFlow to protect the operator against all hazards by the design of the

dynamometer. Therefore, the dynamometer must be installed in an environment which is

specifically designed for this type of testing and provides maximum protection for the operator.

IMPORTANT: Safety equipment required to provide maximum protection for the operator must be

readily available for dynamometer testing.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 4

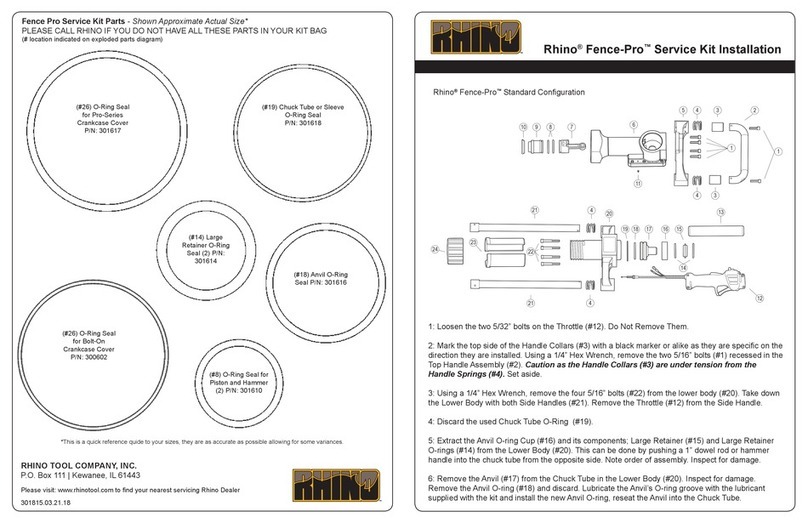

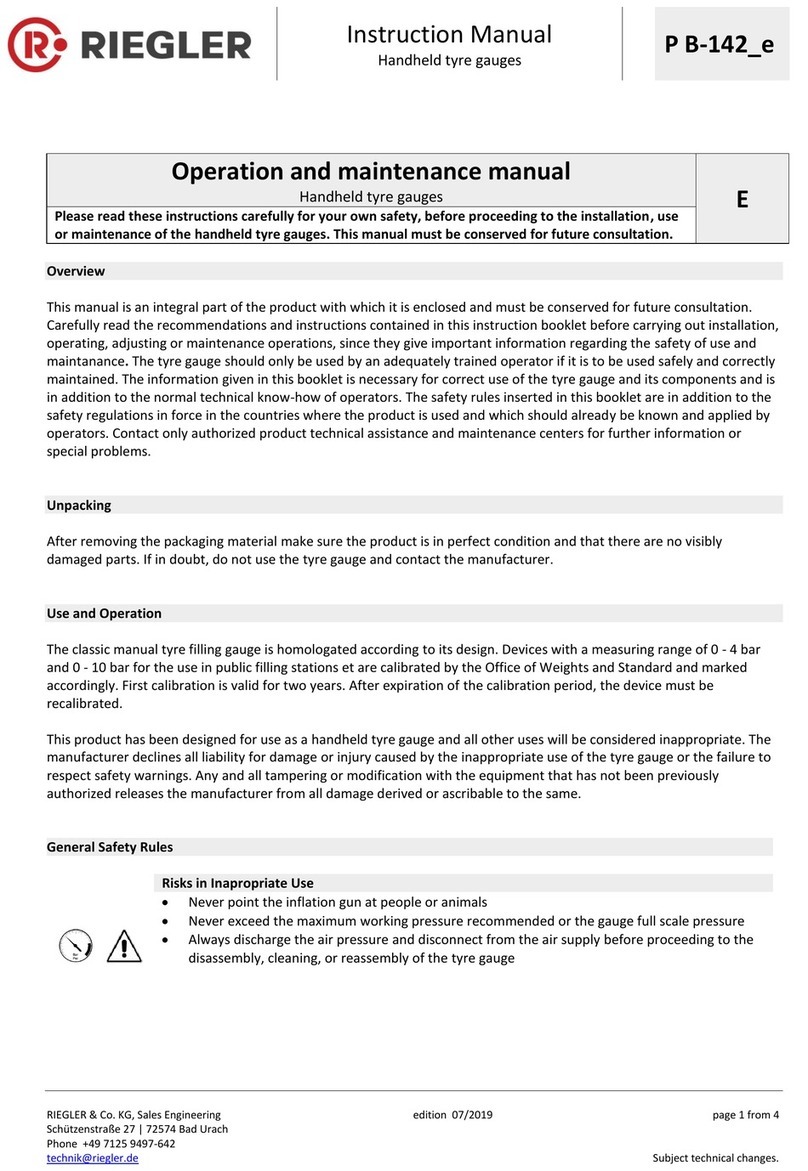

Test Cell Design

Figure 1. AutoDyn Test Cell

A dynamometer should be installed in a facility with proper lighting, electric power, compressed

air, good ventilation, exhaust extraction, and a fire detection system. There must be enough room

to easily install and remove the test vehicle. It should allow enough space to work on the vehicle

while it is in place on the dynamometer, yet small enough to take up minimal space in your

building.

A dedicated, separate room is not actually required for operation of the AutoDyn. However, a

properly built test cell provides protection, noise control, exhaust isolation, and directed cooling

of the test vehicle.

Figure 1 shows a setup where the vehicle is driven forward onto the dyno. The direction of travel

for the vehicle on the dynamometer is purely at the discretion of the system owner or test cell

designer. SuperFlow makes no distinction as to which is better—driving forward or driving

backward onto the dynamometer.

• Driving forward with the rear of the vehicle toward the access door makes it easier to

position the vehicle on the rollset. However, this means the ventilation fans are at the front

of the vehicle and will blow air through the room. This generally requires higher-capacity

fans to maintain proper ventilation and keep the room clear of dangerous exhaust gases.

• Backing onto a rollset and getting the vehicle straight can be difficult until the operator

gains experience. But having the ventilation fans sucking air at the back of the vehicle is

more efficient for moving air through all areas of the room and extracting errant exhaust

fumes, especially if you can produce a slight negative pressure in the room. This design

usually requires additional spot fans in front of the vehicle for cooling.

• A drive-through test cell is an ideal setup if the ventilation system can be designed around

having access doors at both ends of the room. These test cells generally operate with the rear

door closed and ventilation fans pulling air out of the room either through a ceiling vent or

through ducts on both sides of the rear door. This concept can also work for a drive-forward

design.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 5

Proper airflow through the test cell is critical for engine cooling and room ventilation. Having a

larger test cell than necessary makes it difficult to control airflow through the cell and increases

the cost because of the need for larger air-handling equipment. A large room also increases

heating and cooling costs.

TIP: Prefabricated rooms are available as an option to building a room.

The room should be no larger than necessary to ensure high air velocity around the vehicle during

tests. The room should be long enough to accommodate a vehicle on the dynamometer and still be

able to close the main access door. This helps minimize building heating or cooling loss while not

actually testing the vehicle. Typically, the room should be 30 ft. [9 m] long, 15 ft. [4.5 m] wide with

a 10-ft. [3.0-m] ceiling.

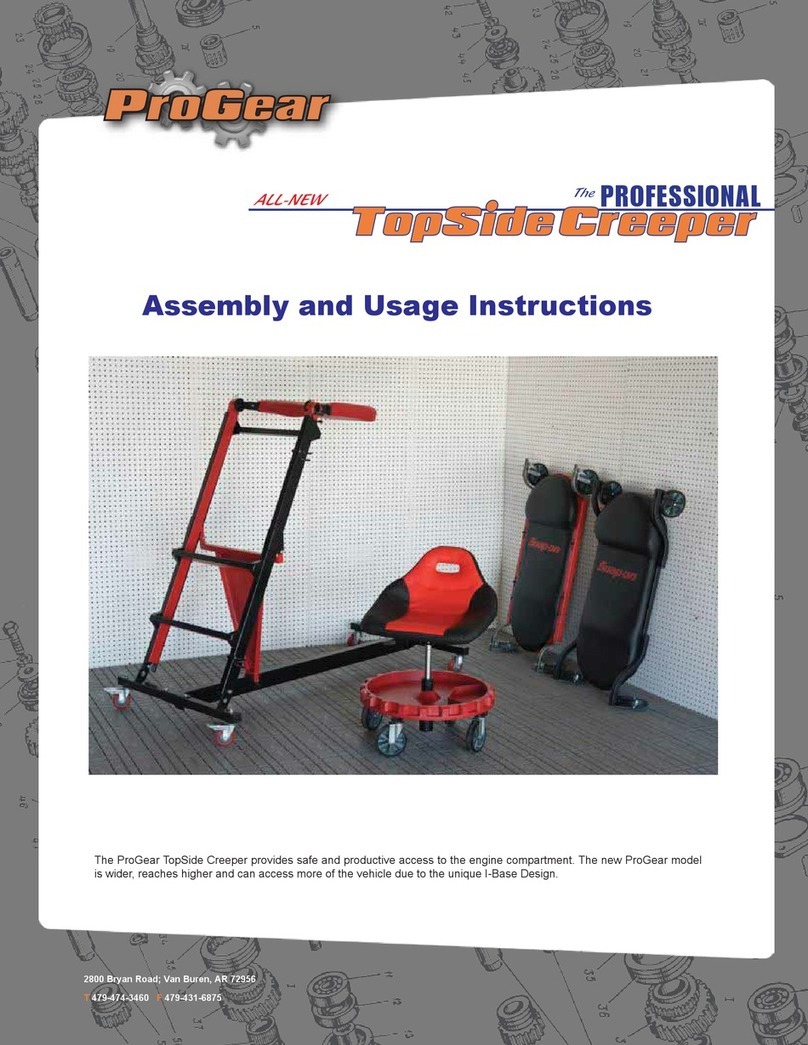

Figure 2. AD-30 AWD Test Room Dimensions

A separate control room or dedicated viewing area overlooking the dynamometer can be part of

the test cell design. This room may be used to house the computer and printer, thus providing a

convenient and safe viewing area during testing. Avoid positioning the control room where an

object thrown from the vehicle may create a hazard.

When building a dynamometer test cell, consider the following:

• Provide viewing windows so observers can watch a test in progress from a safe vantage point.

Position the window so it does not align with possible objects thrown by the vehicles. The viewing

window can be part of the control room and is more effective if it is located on the driver side of

the vehicle.

•The rotating tires may throw rocks or debris, so do not locate any storage or equipment in line

with the direction of the tire rotation.

• All test room doors should open outward from the room, and all doors should be fitted with

appropriate door latches.

&&

3LW$LU([LW'XFW

6HH(QHUJ\%DODQFH:RUNVKHHW

IRUVL]LQJLQIRUPDWLRQ

3LW$LU QOHW'XFW

6HH(QHUJ\%DODQFH:RUNVKHHW

IRUVL]LQJLQIRUPDWLRQ

9HKLFOH'LUHFWLRQ

7HVW&HOO$FFHVV'RRU

)URQW&RYHUV6HFXUHGWR3LW(GJH

0RYDEOH6SRW&RROLQJ)DQWR6XSSOHPHQW

9HKLFOH&RROLQJDV1HFHVVDU\

0 1 0805(&200(1'('5220/(1*7+

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 6

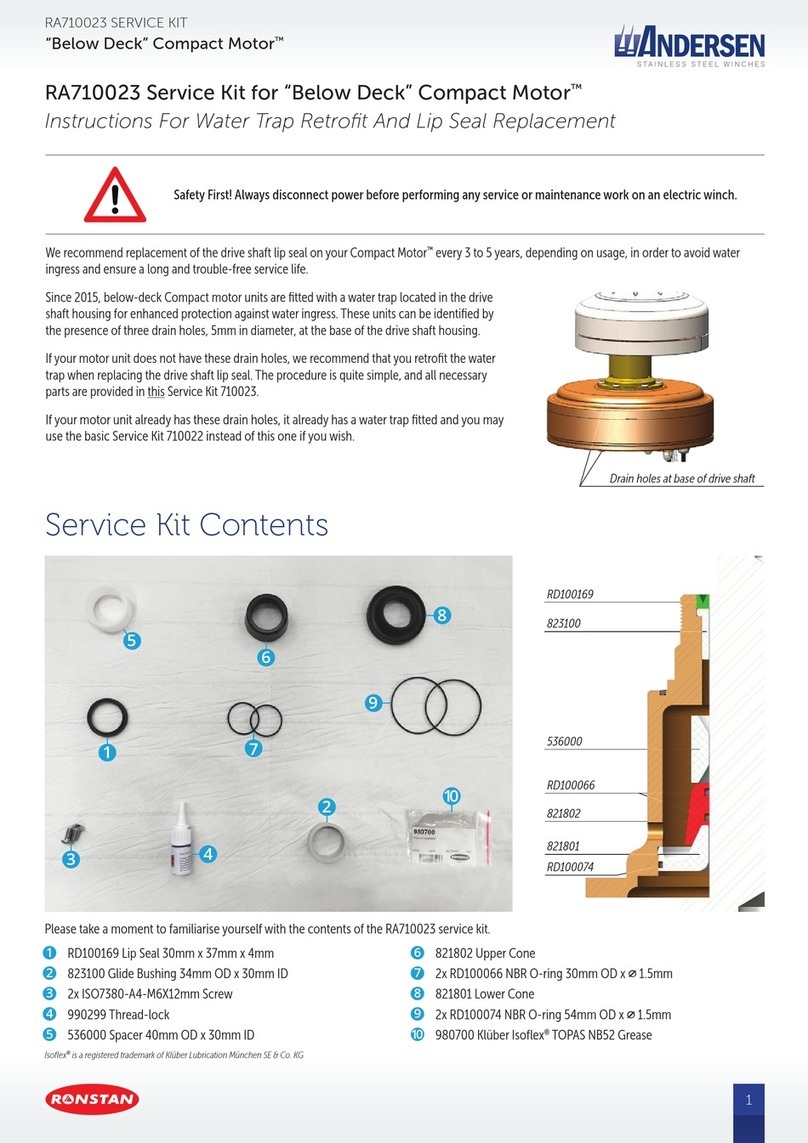

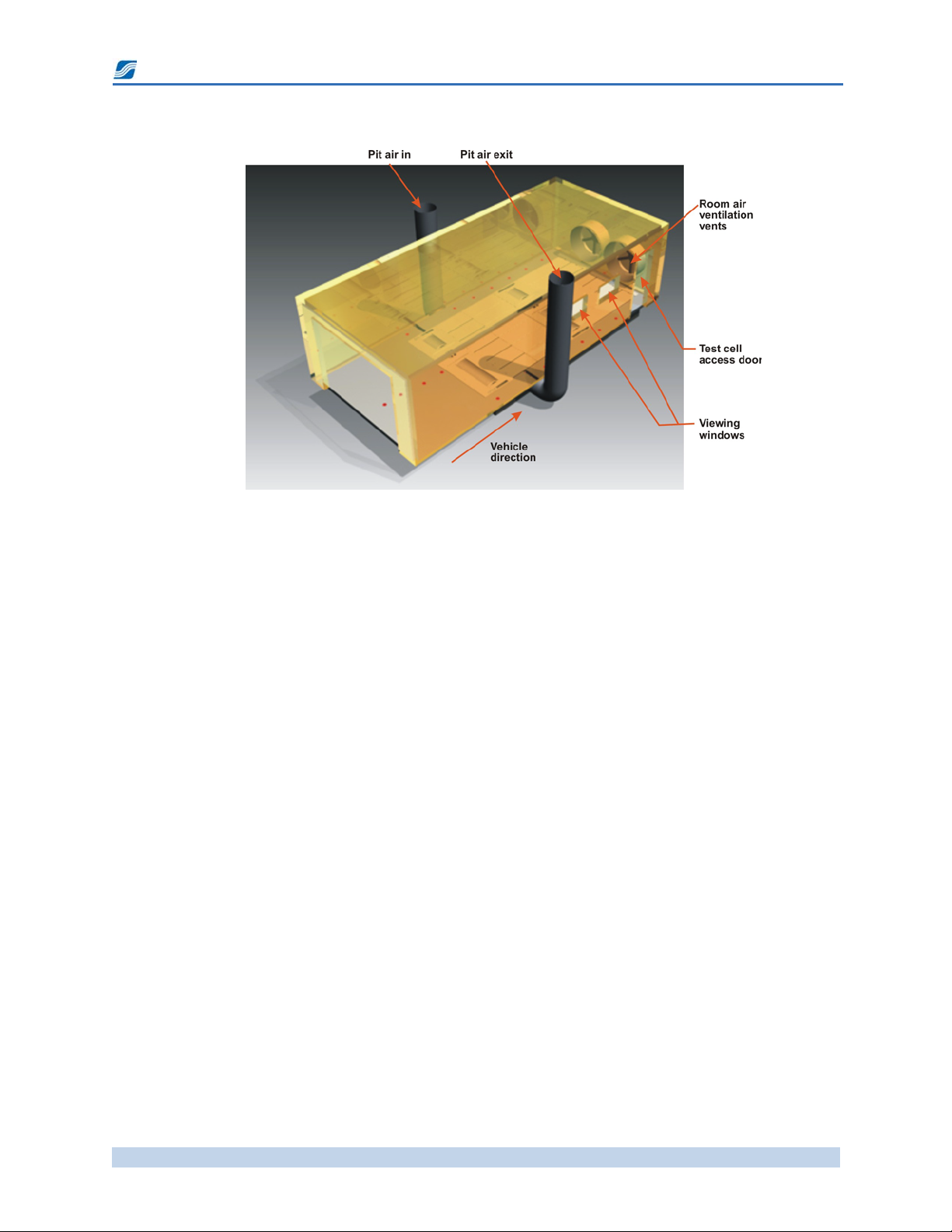

Pit Design

See Figures 3 through 6, “AD-30 AWD Pit Layout” on pages 43 through 46.

The pit for a SuperFlow AD30-AWD chassis dynamometer is constructed on site of poured

concrete with 6” minimum (20 cm) thick walls and steel rebar reenforcement. The concrete should

have a minimum strength of 4000 psi [280 kg/cm2].

Figure 3. Pit Design – Open View

The 24” (60 cm) diameter holes on each side of the pit are for a ventilation system that removes the

heat generated by the air-cooled eddy current power absorbers and any dangerous gases that may

collect in the pit. The ducting for the pit ventilation should extend to the side walls of the test cell

or at least far enough to clear a vehicle mounted on the dynamometer (see “Absorber Cooling and

Pit Ventilation” on page 12).

Embedded in the pit floor are eight weld plates to carry the main weight of the rear rollset.

Additional weld plates are embedded in the pit floor for the front rollset track rail. An angle-iron

weldment is cast in the pit top edges to strengthen the pit edges and support the AutoDyn top

covers.

Weld plate locations are shown on Figure 6, “AD-30 AWD Pit Layout (page 4 of 4),” on page 46.

Install a 5/8” x 8 ft. copper rod through the pit floor into the soil below. The rod is used to ground

the AutoDyn chassis.

Access into the pit for the electrical wiring, compressed air, and sump pump drain is required.

Conduits or a covered trench may be used for the electrical wiring. Typically two electrical cables

will extend into the pit: one for the dynamometer control and the other for the dynamometer

power (see “Electrical Requirements” on page 14).

Floor anchors are required for securing the vehicle on the dynamometer with tie-down straps or

chains (see “Vehicle Restraint Requirements” on page 13). Anchors should be positioned around

the pit to provide multiple tie-points for a wide variety of vehicles.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 7

Suggested placement of floor anchors are shown in Figure 5, “AD-30 AWD Pit Layout (page 3 of

4),” on page 45 and Figure 7, “Vehicle Tie-down Points,” on page 47.

Pit Drainage

Water and other fluids can get into the pit from local ground water conditions or spillage from

other sources. If the water level gets too high it can cause damage to the AutoDyn. A sump pump

or floor drain must be provided in the pit floor to automatically remove any accumulated water.

Suggested pumps are shown in “Equipment Recommendations” on page 17.

• A sump pump should be recessed in the pit floor and have a float-actuated switch to

automatically keep the pit empty of any water or other fluids.

• Make sure the electrical wiring conforms to local code requirements for installing an electric

motor in a below-floor-level enclosed area.

IMPORTANT: Many sump pumps come with a standard three-prong plug, so the easy solution is

to put an electrical outlet in the pit; however, because the outlet is in an enclosed pit, this may not

conform to local building codes. Consult a certified electrician to determine the proper installation

of a sump pump in this situation.

• Install check valves or a back flow preventer so water will not drain back into the pit.

• Be sure the pump wiring and plumbing do not interfere with the movement of the front

rollset.

NOTE: Local codes may require water pumped or drained from a dynamometer pit to be routed

through an oil separator or cleaner.

You may also wish to install a drain in the test room floor to help wash down the test cell area.

This drain may also have to be routed through an oil separator.

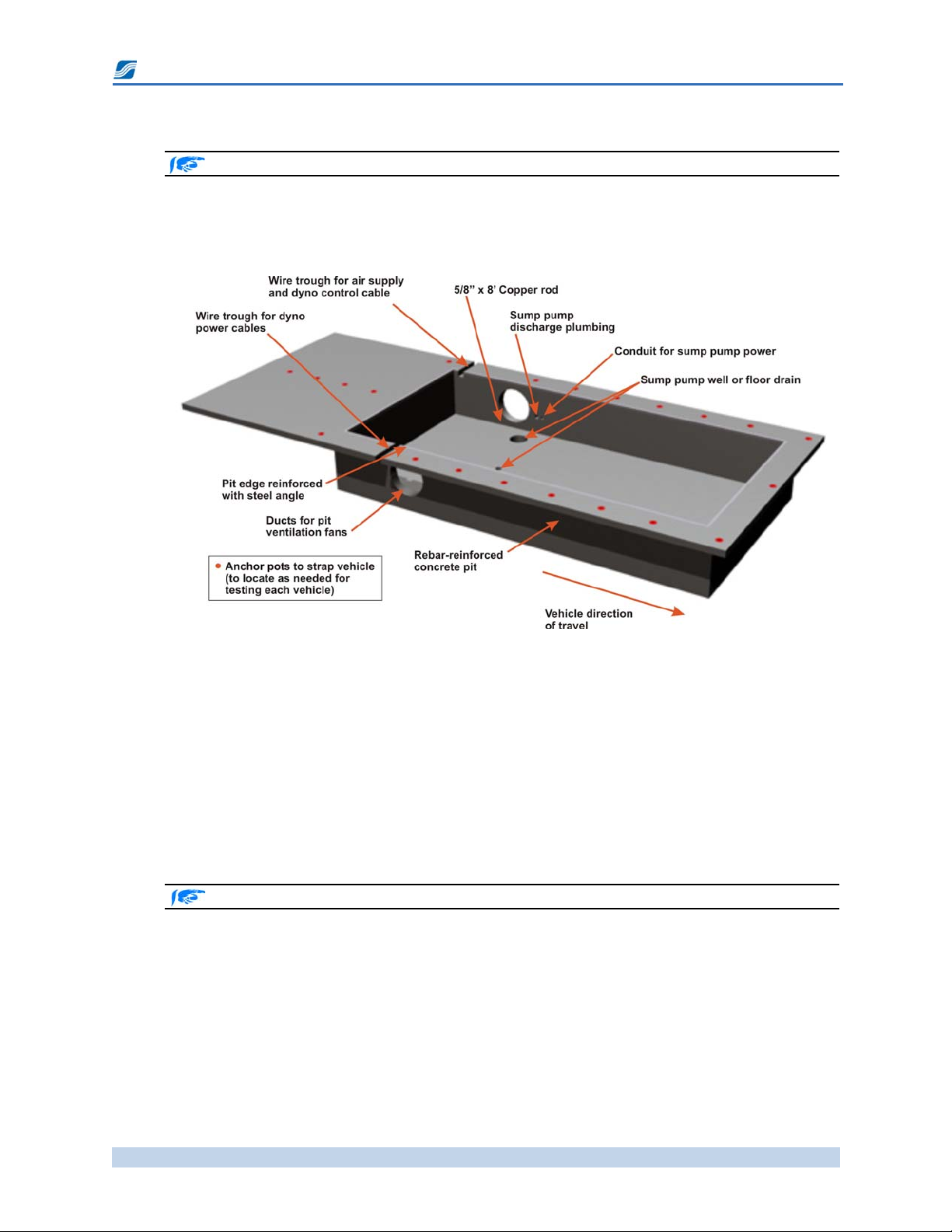

Ventilation

IMPORTANT: Electric fans, ventilation ducts, and the location of fans in the ducts must conform to

local codes and regulations. Always consult with local authorities when installing a ventilation

system.

Chassis dyno test cells require extensive ventilation systems to address five requirements for safe

and repeatable dyno testing:

• Provide air to the vehicle for combustion

• Remove heat from the test cell

• Cool the vehicle

• Extract exhaust gas and combustion by-products

• Provide pit ventilation and cool the dynamometer eddy current absorber

Although it is best to address these tasks individually, it is possible to combine some systems to

meet two or more of these requirements.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 8

Place the master control for the ventilation fans inside the room within easy access for the

dynamometer operator and an emergency cutoff switch outside the room.

See Figure 13, “AutoDyn Room and Pit Airflow (U.S. Units),” on page 53 or Figure 12, “Energy

Balance (Metric Units),” on page 52 for typical AutoDyn airflow requirements.

Suggested fans and other ventilation supplies are shown in “Equipment Recommendations” on

page 17.

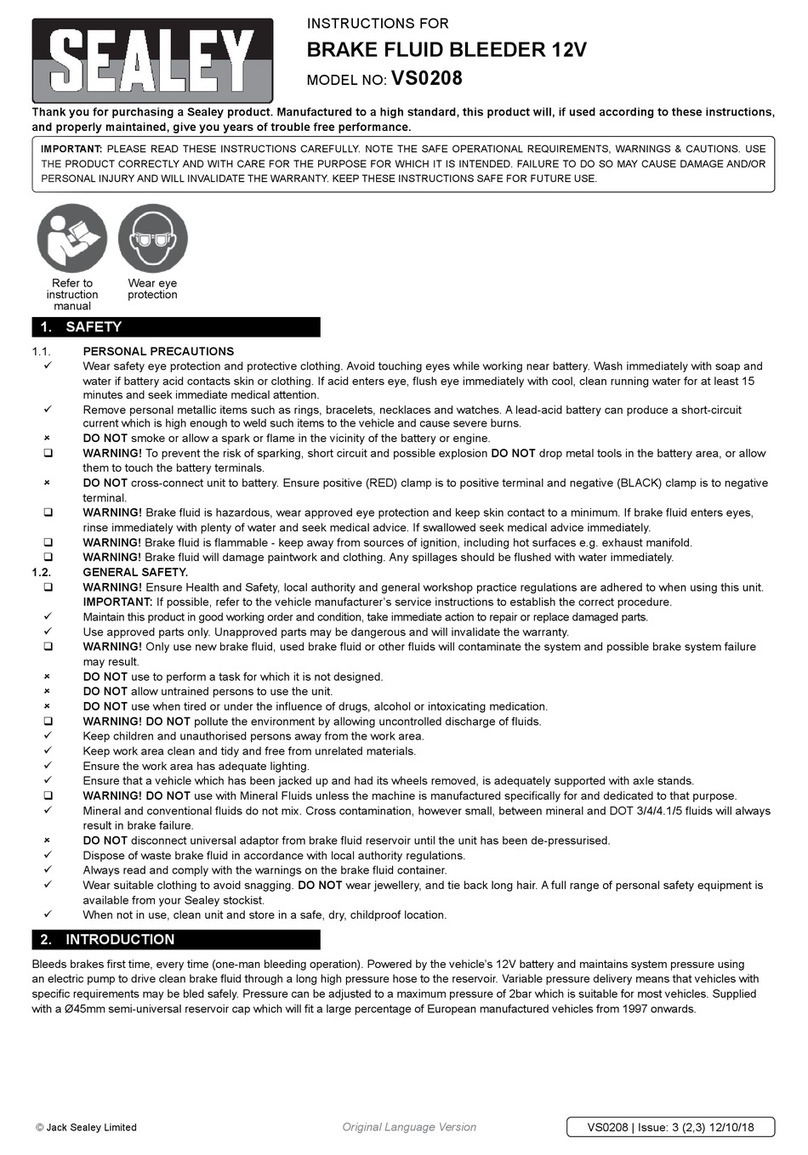

Figure 4. Ventilation Ducts

Combustion Air

Internal combustion engines need clean, cool air to function properly and produce the best

performance. Normally, the engine uses the same air for combustion the air in the dynamometer

test cell, so the airflow in the room must provide combustion air in addition to extracting any toxic

gases and keep the room cool.

If testing the vehicles without filters on the engine, you may be required to filter the air flowing

into the room. If required, filters can be installed on the inlet ducts. SuperFlow recommends 92%

efficient filters and also recommends installing a pressure gauge to measure the pressure drop

across the filter system. When the filters become clogged, the ventilation system may not be able

to overcome the pressure drop, and the airflow though the room will rapidly decrease.

TIP: To improve test result repeatability, use a special duct to direct air from outside the test cell

but inside the building into the engine intake. Drawing air for the engine from inside the

building reduces temperature variations throughout the year. Air for the test cell can then be

brought in from and exhausted to outside the building without filters or conditioning,

substantially reducing heating and cooling expenses.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 9

Heat Extraction

Chassis dynamometer testing produces a significant amount of heat that is for the most part

released to the test room air. Ventilation is required to evacuate this heat from the room. If the

room temperature increases during the test or exhaust gas recirculates into the engine inlet, your

test results will vary in an unpredictable manner. Both the quantity and direction of airflow are

critical for repeatable test results.

In chassis dyno testing, about 40% more energy is released into the air than the engine tested in

the vehicle produces. This energy is in the form of heat from the vehicle’s engine and exhaust as

well as heat from the various drivetrain components and their corresponding drivetrain frictional

losses. So for every 100 hp of engine flywheel power, you must assume it releases 140 hp in the

form of heat and then size the ventilation system so it is capable of removing the heat. If your

system is not capable of removing all of this heat effectively, your testing will suffer as a result of

excessive temperatures in the room, or you will be forced to run limited duration tests with a cool-

down period between tests.

Generally, for every 1 hp of engine power produced for 1 minute, the temperature of 2,313 cubic

feet of air in a room (at sea-level standard conditions of 60°F, 0% relative humidity, and 29.92 inHg

barometric pressure) will be heated 1°F.1A room ventilation system must be designed with the

capability to maintain a temperature at the rear of the vehicle that will not exceed the temperature

rating of the extraction system. Without adequate ventilation, on a nice 70°F day the temperature

in your test cell will be intolerable within minutes.

Example:

If the test vehicle is rated at 400 hp (at the flywheel) and you want to limit the temperature increase

in the room to 25°F, you need a ventilation system that flows more than 50,000 cfm.

• 1.4 is 40% increased heat load

• 2313 ft.3 is the volume of air affected by a 1° increase in temperature in 1 minute by 1 hp.

In a 30ft. x 12ft. x 8ft. (2,880 ft.3) test cell, 50,000 cfm is almost 17 air exchanges per minute

(50,000 divided by 2,880).

If a separate exhaust extraction system is in place, room

ventilation airflow can be decreased to a rate equaling 10 to

12 air exchanges per minute. Regardless of the test cell

design, the room ventilation fans should be sized to provide

enough air to the room to prevent an excessive buildup of

heat in the room and remove any dangerous fumes not

captured by the exhaust extraction system.

SuperFlow recommends using tube-axial fans for ventilation

of any closed-room test cells. The air should enter the room

at the front of the vehicle and be directed rearward. Ducting

can be used to direct the air at the radiator level of the

vehicle. Air can exit out the rear door of the room or through

the rear ceiling or rear sidewalls.

Figure 5. Room Ventilation Fan

1. Thermodynamics, J.P. Holman, McGraw-Hill College, 4th edition, ©1988

400hp 1.42313ft3

25F

-------------------------------------------------------------------51811cfm=

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 10

It is advisable to locate the fans at the rear of the test cell to extract air out of the room and

therefore create a slight negative pressure in the room to help prevent fumes and heat from the

test cell from entering other areas of your building or collecting in the corners. It is also advisable

to locate the fans or use duct work as necessary near floor-level to assist in directing airflow along

the path the vehicle will normally experience on the road.

The large fans required to provide the necessary airflow are noisy, so install them in a location

where the noise causes minimal disturbances for your employees and neighbors. You may need to

take additional protective measures such as enclosing the fans and ducts in sound-dampening

material. Self-closing shutters on the air outlets (and inlets if applicable) are advisable so the duct

openings can be sealed off when the dynamometer is not in use.

Vehicle Cooling

The main room ventilation system should evacuate heat released by the vehicle cooling system,

engine block, transmission, and exhaust. However, in many cases the airflow patterns resulting

from the room ventilation system do not adequately cool certain vehicle components. The engine

compartment and undercarriage exhaust system are usually the most troublesome areas.

Figure 6. Vehicle Cooling

To compensate for this deficiency, SuperFlow recommends spot cooling fans. Although these fans

do not increase the overall airflow through the room, they modify the local patterns and speeds of

the airflow to accomplish specific goals. High-speed fans are commonly used for these tasks.

Some racing vehicles require air speed through the radiator at near road-speed. Achieving high

flows at high speeds requires tremendous power which explains why many high-performance

chassis dyno rooms resemble wind tunnels containing fans of several hundred horsepower.

As an example, to blow air at 100 mph [160 km/h] through a standard size radiator would require a

fan capable of about 50,000 CFM [90,000 m3/hr]. The motor required for a fan of this size could

exceed 50 HP [37 kW]. If your requirements do not quite reach these levels, you should purchase a

set of mobile high-speed fans of 5000–10000 cfm [8500–17000 m3/hr] which can be positioned in

critical areas.

TIP: SuperFlow data acquisition and control systems are capable of supplying a 0–10VDC control

signal based on engine speed to a variable speed fan controller. This allows more realistic

test simulations where the vehicle will experience airflow in near-real-world road conditions.

In some cases you may want to install an under-car ventilation system. These provisions should

be made at the time of installation. Perforated in-floor rails or ducts can be installed below floor

Spot fan High-capacity fan

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 11

grade. Incorporating a pressure blower in this system helps you more easily control exhaust and

undercarriage temperatures.

Exhaust Extraction

WARNING: A proper exhaust extraction system is critical for the safety of your employees

and customers both inside and outside the test room. If the room ventilation is good, a

separate engine exhaust collection may not be necessary. However, to ensure the safety of

all personnel in your building, exhaust from the vehicle must be completely removed.

Many test cells are built with the idea they will have enough airflow with a room ventilation fan to

extract the exhaust without any help from duct work or auxiliary fans. If the cell is small and the

airflow is many thousands of cfm (exchanging all air in the room at least 12–15 times per minute),

this is possible. However, very few test cells achieve this goal. Sometimes the best solution is to

use hoses or flexible metal with a fan on the other end to suck out the exhaust (see Figure 7).

Consider that for every 100 hp of engine power, roughly 17 pounds of exhaust is produced per

minute which is equivalent to 223 cfm of airflow. In addition to noxious gases, a significant

amount of heat is released through the exhaust system, especially with the engine at wide-open

throttle and at full load. The exhaust system must be able to handle both the flow and temperature

of the exhaust gas. Most ventilation ducts and fans only handle temperatures up to 250 deg F (110

deg C). Therefore, exhaust ducts, hoses, and fans should be rated for high temperatures. The

extraction fan can be rated for a lower temperature if the exhaust is diluted with cooler air prior to

reaching the fan.

IMPORTANT: Hoses typically used in service garages are not applicable for dynamometers as

they are only rated for slightly above idle temperatures.

It is much easier to build a system with higher flow capacity than one that can handle exhaust-

level temperatures. In addition, sealing the exhaust pipe can influence engine performance by

increasing the exhaust back pressure. With a high-flow extraction system, exhaust gas can be

diluted with ambient air to reduce the overall temperature in the exhaust system. Leave some

space between the vehicle exhaust and the duct inlet so the fan pulls room air into the pipe. This

will dilute the exhaust gases by about 2 to 1 and help prevent overheating the fan.

Figure 7. Exhaust Extraction

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 12

Alternately, connect directly to the exhaust pipes and integrate an air inlet near the pipe entrance

to provide dilution air from inside or outside the test cell. Dilution air can even be introduced

from outside the building. The piping prior to the dilution point must be rated for high

temperatures.

As with spot cooling fans, the exhaust fan is usually a centrifugal type, high-speed fan. Proper

temperature-resistant ducting should be installed to capture the exhaust gas close to the vehicle

tailpipe.

For an exhaust extraction system, SuperFlow recommends selecting a fan capable of flowing 1,500

cfm for every 100 hp of engine power. Ensure that the duct system is capable of providing the

required flow with the fan you plan on using. A system capable of 1,500 cfm per 100 flywheel hp

will provide a 7:1 dilution ratio which should keep the temperature of the diluted air in the ducts

below 250°F. Due to incomplete mixing at the collection point, it may be desirable to use metal

ducting for the first 10 ft. of the collection system.

If relying on the room ventilation to remove the exhaust from the vehicle, you must assume that

for every 100 hp of engine power, roughly 140 hp releases as heat into the room. Therefore, the

specifications for a ventilation system to handle both room ventilation and exhaust extraction

should be increased by 40% over the standard requirements.

For more information on exhaust extraction and system design suggestions, contact SuperFlow

Sales or Customer Service and ask for the document “Chassis Dyno Exhaust Extraction” PDF.

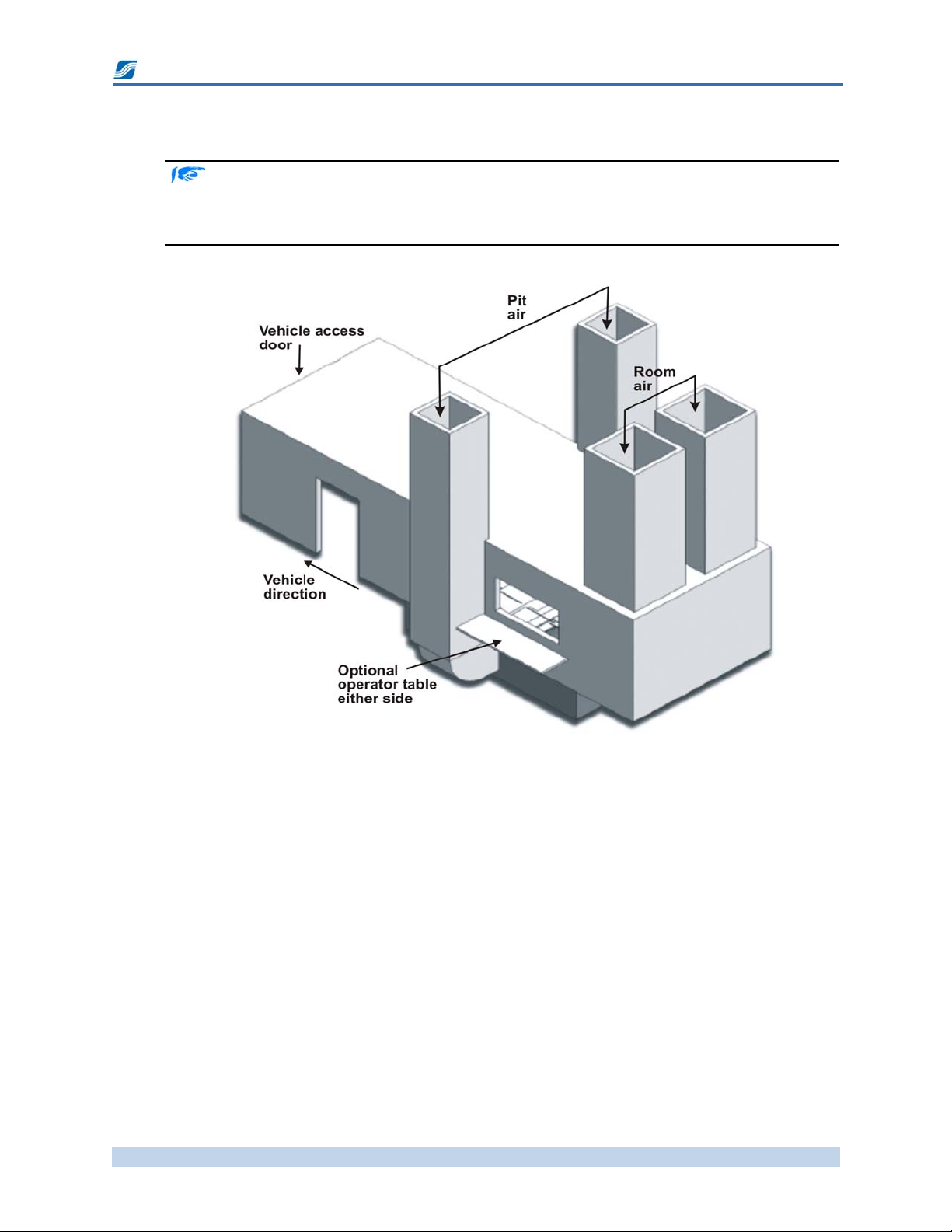

Absorber Cooling and Pit Ventilation

Pit ventilation is required for two reasons: to remove heat generated by the absorbers and to

evacuate potential explosive gases.

The eddy current Power Absorption Unit (PAU or absorber) in the pit absorbs power generated

by the vehicle and converts it to heat. Most tests on the AutoDyn are short and limited first by the

vehicle overheating when testing at full power and second by the eddy current absorber

overheating. Consequently, tests can be run for a longer period at much higher power levels if the

vehicle and absorber are kept cool. The vehicle temperature is maintained by the room air

ventilation whereas the absorber temperature is handled by a pit ventilation system.

The heat from the absorber is removed by supplying fresh air to the pit during vehicle operation.

SuperFlow recommends two tube-axial fans for pit ventilation: one fan pushes the air into the pit,

and one fan extracts air from the pit. One fan alone does not normally have enough pressure

capability to overcome the duct flow losses. These fans can be mounted on the roof, an outside

wall, or anywhere within the ducts. It is best to install the exhaust fan at the end of the duct to

ensure all air (possibly contaminated) is exhausted from the building. SuperFlow recommends a

pit ventilation system capable of flowing 1,500 cfm per 100 hp of engine power of vehicle to test.

This limits the temperature rise in the dyno pit to 80°F. A system with less flow than this will limit

the length of the tests being performed and requires a cool-down period between tests.

For efficiency, airflow should be directed across the absorbers. Therefore, the ventilation ducts

should be placed on opposite sides of the pit and in line with the absorber which is about four feet

from the back wall of the pit.

• Ducts may be round or rectangular as long as the cross-sectional area is sufficient to manage

the airflow.

• Make sure the fans and duct system are compatible in providing the required airflow.

• The pit ventilation ducting should extend to the side walls of the test cell or at least far

enough to clear a vehicle mounted on the dynamometer.

• If the fan motors are actually located in the pit, they should be rated as explosion-proof.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 13

• Place the master control for the ventilation fans inside the room within easy access for the

dynamometer operator and an emergency cutoff switch outside the room.

Figure 8. AD30-AWD Pit Ventilation

An option is to replace the pit covers on one side of the absorbers and closest to the pit edge with

metal grates so air is drawn from the test room into the pit and out the exit ducts. One fan may

suffice with this design. If replacing solid metal covers with grates, make sure the grating is

supported sufficiently to support the weight of a vehicle that may possibly drive over the grating.

NOTE: The fans must deliver the required flow against a pressure of at least 1.25” (3 cm) of water

pressure to overcome the duct flow losses. The fans listed in “Equipment Recommendations” on page

17 here meet that requirement. Do not try to substitute a lower velocity fan design.

TIP: Placing the AutoDyn next to an external wall makes it easier to route ventilation ducts

outside the building.

Vehicle Restraint Requirements

Vehicles must be carefully and securely restrained when testing on a dynamometer, more so on an

all-wheel-drive dynamometer. Because the vehicle is sitting on free-turning rolls, the only

restraint comes from straps securing the vehicle to the test cell floor. Three or four restraining

straps are required at each end of the vehicle. In some applications, straps are needed along the

sides of the vehicle. Front-wheel-drive vehicles are particularly susceptible to sideways movement

because the testing primary load is on the steering axle.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 14

Figure 9. Vehicle Restraint – AWD

The straps are attached to the floor with flush-mounted floor anchors. Floor anchors can be

integrated in the room floor when the concrete is poured or special anchor pods are inserted into

holes bored into the concrete floor and wedged in place. Chains or load hooks can be attached to

the anchor points.

Figure 10. Tie-down Anchor and Straps

Use adjustable-length, ratcheting restraining straps with at least a 5000-lb. (2200-kg) load-working

capacity. Straps with ends terminated in J-hooks or eye loops are the most useful. You will need at

least four side straps, each at least 8 ft. (2.5 m) long and four front/rear straps, each at least 12 ft.

(3.5 m) long.

SuperFlow recommends installing at least 12 tie-down points as shown in Figure 7, “Vehicle Tie-

down Points,” on page 47. If you are testing specialty vehicles, you may want to add more tie-

down points. At least three points must be used at each end during testing. Add wall-mounted

hooks for storage when the straps are not in use.

NOTE: If using the anchor pods purchased from SuperFlow (part number 3420P-1300), install them

with the long slot pointed toward the vehicle.

Electrical Requirements

WARNING: All electrical installations must adhere to your local codes and regulations.

SuperFlow cannot advise as to the proper installation of electrical devices and wiring for

your area. The recommendations in this section are suggestions only. Consult a local,

certified electrical contractor for assistance with lighting and electrical installation.

Floor anchor pod

Ratchet strap

Axle strap Sling strap

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 15

Dynamometer Chassis

The AutoDyn power absorber requires 25 amps of 208 to 240 VAC power wired from a power

distribution box through a 1” (25 mm) diameter conduit in the pit or a trench cut in the side wall to

the rollset power junction box on the AutoDyn. The junction box is located on the front side of the

rear rollset just to the right (looking forward) of the eddy current absorber (see Figure 32,

“Electrical Controls,” on page 35).

This power operates the eddy current absorbers and the hydraulic pump that moves the front

rollset. Both devices can be run on the same circuit because both should never be on at same time.

In addition to the power cable, a control cable is routed from the AutoDyn through a trench or

conduit to the SuperFlow Data Acquisition System (sensor box). The connection for this cable is an

interconnect panel on the left side (looking forward) of the rear rollset.

If the conduit or trench is placed about one foot from the rear wall and about one foot below the

top edge of the pit, it will be very close to being in line with the interconnect panel. Otherwise,

place it no closer than 4 feet [1.2 meters] or farther than 8 feet [2.4 m] from the rear wall. This will

put the cable and air hose between the rollset frames making access much easier. Conduit should

be no less than 18” [45 cm] from the pit floor.

• A 3” [75 mm] conduit is required for the control cable and air line for easy passage of the

large connector on the control cable.

• The power cable and the control cable should not be routed together in the same conduit or

trench.

•A a master disconnect switch for the VAC power should be within sight of the rollset.

• Do not combine the dynamometer power with any other devices such as fans or pumps.

Data Acquisition System

The AutoDyn sensor box, computer, and printer requires a 110 VAC, 15-amp or 240 VAC, 8-amp

supply using approved GFI plug receptacles. SuperFlow recommends using an Uninterruptible

Power Source (UPS) or a good surge suppressor for these devices.

Miscellaneous

Additional power is required for the fans, sump pump, room lights, and any power tools or

devices that may be used in the room.

• Use only Ground Fault Interrupter (GFI)-protected power outlets in the test cell.

• Install two-way switches inside and outside the test room for the lights.

• Place the master control for the ventilation fans inside the room within easy access for the

dynamometer operator and an emergency cutoff switch outside the room.

Air Requirements

Compressed air at 100 psi (600 kPa), must be supplied to the AutoDyn to operate the AutoDyn roll

lock. This line is routed into the pit through a conduit or a trench cut in the side wall of the pit

edge. The connection is on the left rear side (looking forward) of the rear rollset chassis next to the

control cable panel. The air line can be routed alongside the AutoDyn control cable or the power

cable.

• Provide an easily accessible air shutoff valve.

• Install a regulator, filter, and water trap where they can be easily monitored.

SuperFlow Product Information

AD-30 AWD Pit Installation 3.30.2020 Page 16

• In situations where high concentrations of water may be in the air supply, install an

automatic water drain in the pit at the lowest level of the air supply line.

Suggested air supply equipment is shown in “Equipment Recommendations” on page 17.

Static Electricity

An ungrounded vehicle on a chassis dynamometer will create a very high static charge as the tires

turn. This charge normally dissipates fairly quickly after the vehicle is stopped if an alternative

ground path is not provided.

However, the alternative ground path can be the handheld controller (wired model) or the

operator while stepping out of the vehicle. The back plate of the handheld is metal and is

connected to earth ground through the sensor box. If the handheld backing plate is laid on a metal

part of the vehicle or the operator is in contact with the backing plate and touches a metal part of

the vehicle, a static discharge can occur. A discharge can also occur when the operator steps down

from the vehicle and contacts the ground. Such a discharge can cause severe damage to the system

electronics or give the operator a mild electric shock.

The best way to prevent any static buildup and subsequent discharge is to provide a positive

ground path. The easiest and most efficient method is to connect a ground strap from the vehicle

frame to a positive earth ground. This strap can be flat metal braid, welding cable, battery jumper

cables, or a length a thick, solid copper wire. With one end permanently attached to an earth

ground point and a alligator-style clip on the other, it only takes a few seconds to ground the

vehicle and prevent damage or injury.

The AutoDyn pit design has a copper grounding rod through the pit floor. A wire or strap is

connected from the AutoDyn frame to this rod. Therefore, a vehicle ground strap can be attached

to the AutoDyn frame that will provide a discharge path for static electricity.

Convenience Issues

Based on experience gathered while installing and visiting countless test facilities, SuperFlow

suggests making these enhancements to your facility:

• Wide-angle mirrors positioned in front of the driver so all parts of the test room are visible

during tests.

• A video computer monitor or projector to display WinDyn data screens on the front wall

during the tests.

• Wireless two-way communication link between driver and system/computer operator or

an intercom between the test room and the control room.

• Digital camera for pictures of the vehicle while tested. The pictures can be downloaded to

the test system computer to display and store with the test data files. Additionally, pictures

provide a quick method to record the vehicle configuration and cooling blower

arrangement for the test, improving test repeatability.

• A microphone in the test room and driving speakers in the control room (and customer

viewing room). Because of the test room’s noise insulation, it may be difficult to hear

abnormal engine or drive line sounds from the control room.

• A telephone line for communication. A wireless telephone is convenient. When requesting

assistance from SuperFlow Customer Service, the dynamometer operator must be near the

system.

Table of contents