Section 1 - General

Warning Page............................................................................

PowerMate Description.............................................................

Delivery and Warranty Registration..........................................

Operator Training Guideline......................................................

Section 2 - Safety

Hazard Graphical Symbols........................................................

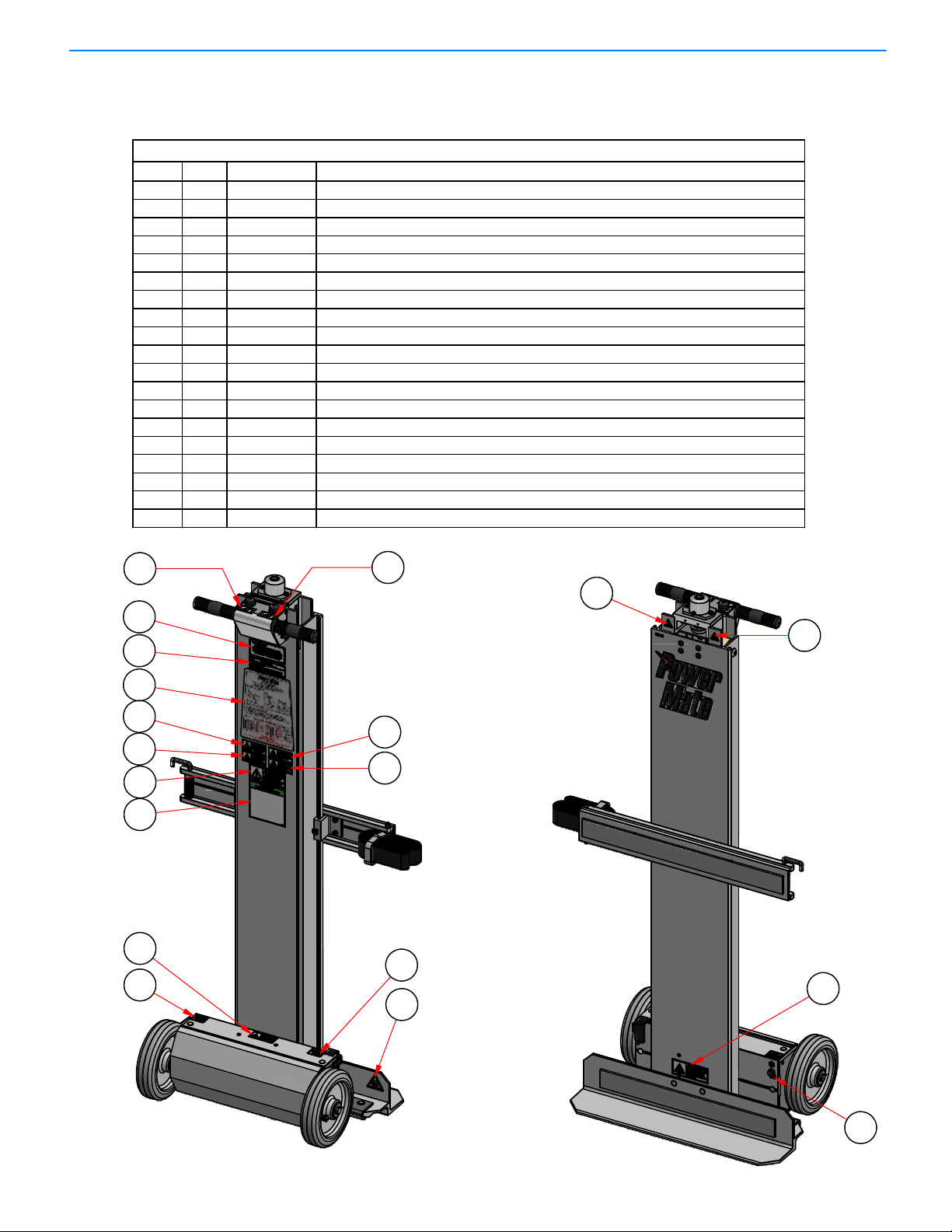

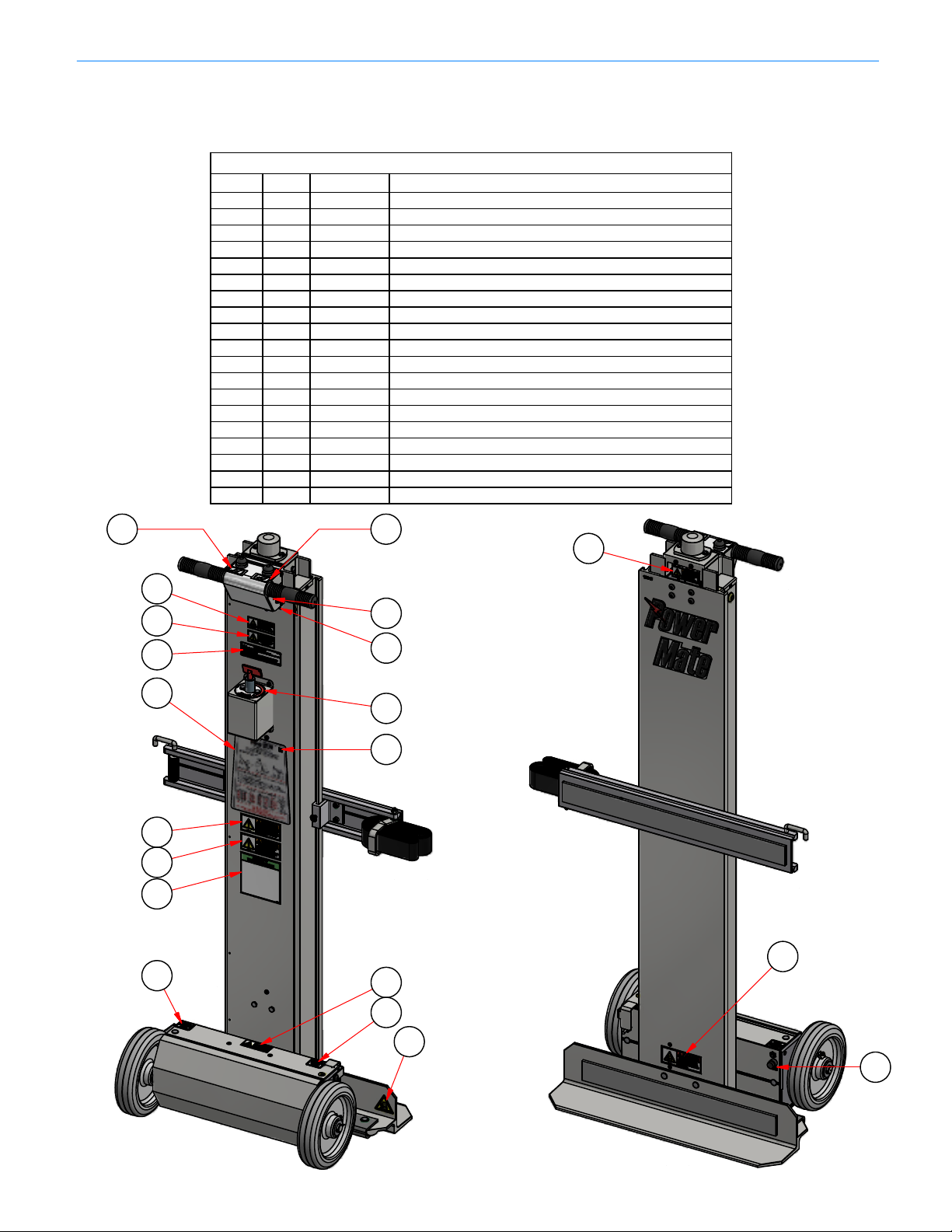

Mandatory Safety Decal Placement...........................................

Safety Precautions....................................................................

Safety Inspection......................................................................

Environment Safety.....................................................................

Loading Safety..........................................................................

Safety in Motion........................................................................

Battery Safety...........................................................................

Battery Charging Safety...........................................................

Section 3 - Instructions

L-Series PowerMate Charging Instruction..............................

Loading Instruction...................................................................

Vehicle Loading.......................................................................

Stairclimbing.............................................................................

Storage Procedure and Battery Care......................................

Section 4 - L-Series PowerMate Component Identification

Model L-1 Exploded View.........................................................

Screw Assembly L-1................................................................

Screw Assembly L-2................................................................

Brake Assembly Kit..................................................................

Bearing Override Kit.................................................................

Section 5 - Maintenance

Maintenance After Every Year of Operation.............................

Procedure for Repairing Drive Screw Assembly......................

Ballnut Removal and Replacement........................................

Installation of Sealed Batteries..............................................

Bottom Rubber Guard Replacement........................................

Push Button Switch Replacement............................................

Strapbar Assembly for L-Series..............................................

Replacement Strap Installation.................................................

L-Series Wiring Diagrams........................................................

L-Series Motor Replacement Instruction………………………

Section 6 - Specifications

L-Series Specifications............................................................

Solidstate Controller.................................................................

Battery Specifications...............................................................

Section 7 - Accessory Installations

Battery Charger Remote Installation.........................................

PowerMate RT Cart Attachment Instruction...........................

Section 8 - Accessories

Accessories..............................................................................

Warranty...................................................................................

Declaration of Conformity.........................................................

Daily Maintenance Schedule....................................................

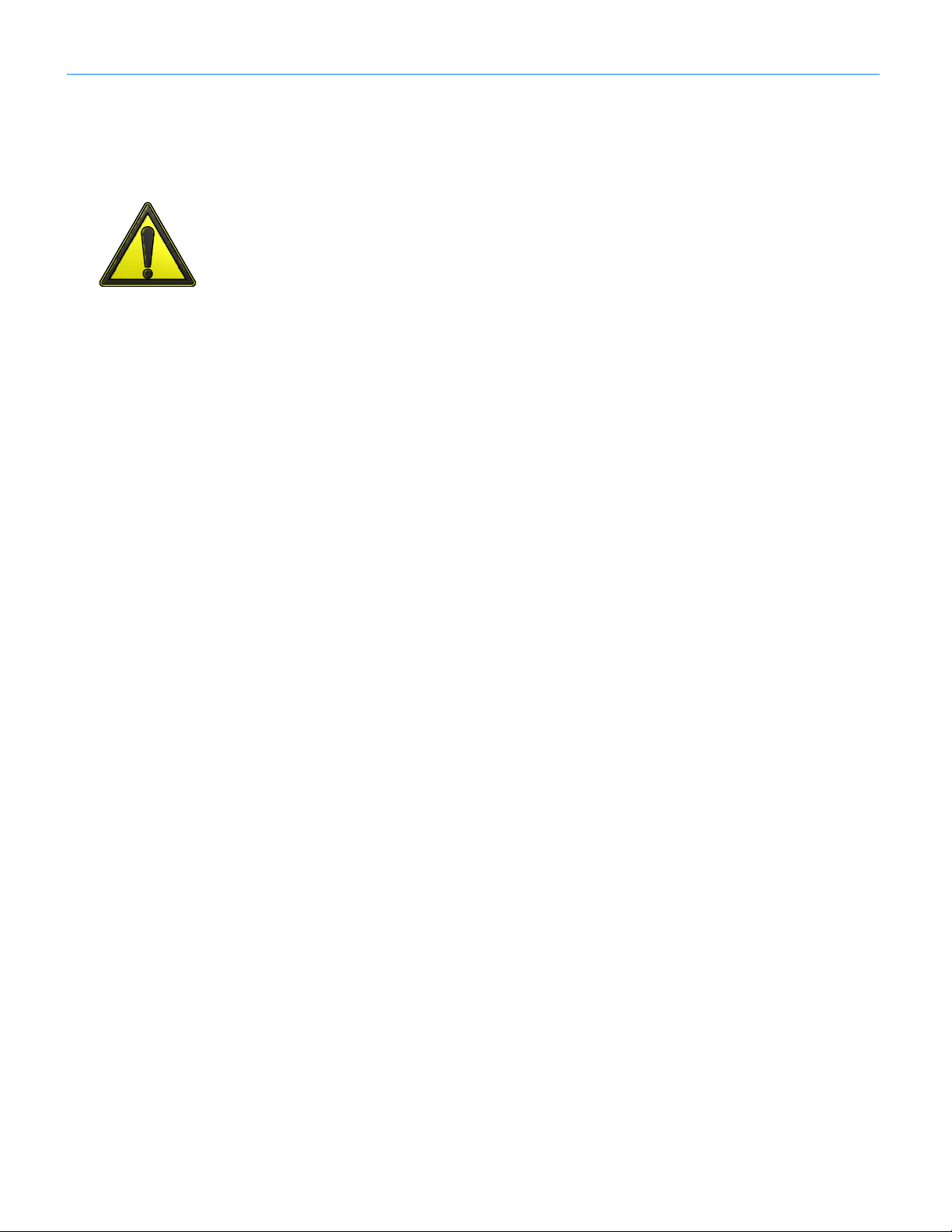

PowerMate

Operation Manual

TABLE OF CONTENTS

1.01

1.02

1.02

1.03

2.01

2.02

2.04

2.05

2.05

2.06

2.06

2.07

2.08

3.01

3.02

3.03

3.04

3.05

4.01

4.03

4.04

4.05

4.06

5.01

5.03

5.04

5.05

5.06

5.07

5.08

5.08

5.09

5.11

6.01

6.02

6.03

7.01

7.02

8.01

8.03

8.04

8.05

PN 011020 Rev. F

Eng. 11/ 16/ 15

i