Full Description of Push Button Functions

PWhile this button is pushed the rate

display will show the input current in

mA, or as a percentage of the

instrument span depending upon how

the instrument has been configured.

When the button is released the normal

display in engineering units will return.

The function of this push button is

modified when optional alarms are fitted

to the instrument.

▼While this button is pushed the

instrument will show the calibrated rate

display with 4mA*input - usually zero

for flow applications. When the button

is released the flow rate will again be

displayed.

▲While this button is pushed the

instrument will show the calibrated rate

display with 20mA*input. When the

button is released the flow rate will

again be displayed.

EWhile this button is pushed the Rate

Totaliser will display the time in hours,

minutes and seconds since the

instrument was powered or the total

display was reset. The elapsed time is

not saved when power is removed.

E+▼While these buttons are pushed the

total display will show the least

significant eight digits of the grand total,

and the grand total annunciator will be

activated.

E+▲While these two buttons are pushed the

total display will show the most

significant eight digits of the grand total

and the grand total annunciator will be

activated.

After the two buttons have been pushed

for ten seconds ‘CLr no’ with the ‘no’

flashing will be displayed. If no action

is required, pressing Ewill return the

instrument to the operating mode.

Operating the ▼or ▲button will toggle

the display to ‘CLr YE5’ with ‘YE5’

flashing, operating the E button will then

clear the grand total and ‘Gt CLrd’ will

be displayed to confirm the operation.

The instrument will then automatically

return to the operating mode.

Selectable function in the configuration

menu. See section 5.17

Note: Totalisation will continue until

‘CLr no’ or ‘CLr YE5’ are displayed.

▼+▲Resets the total display to zero

when these two push buttons are

operated simultaneously. Selectable

function in the configuration menu.

See section 5.17

P+E Provides access to the configuration

menu via optional security code.

Note: *If the Rate Totaliser has been

calibrated using the CAL function,

calibration points may not be 4 and

20mA.

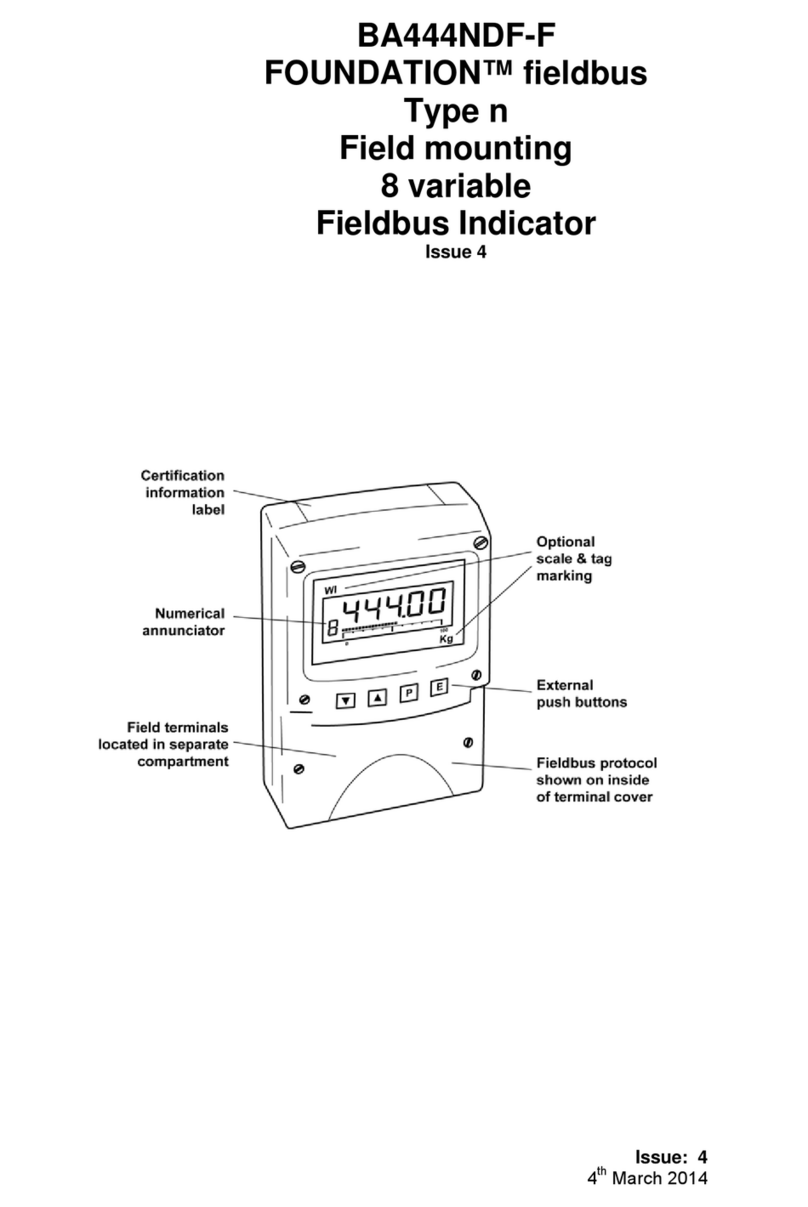

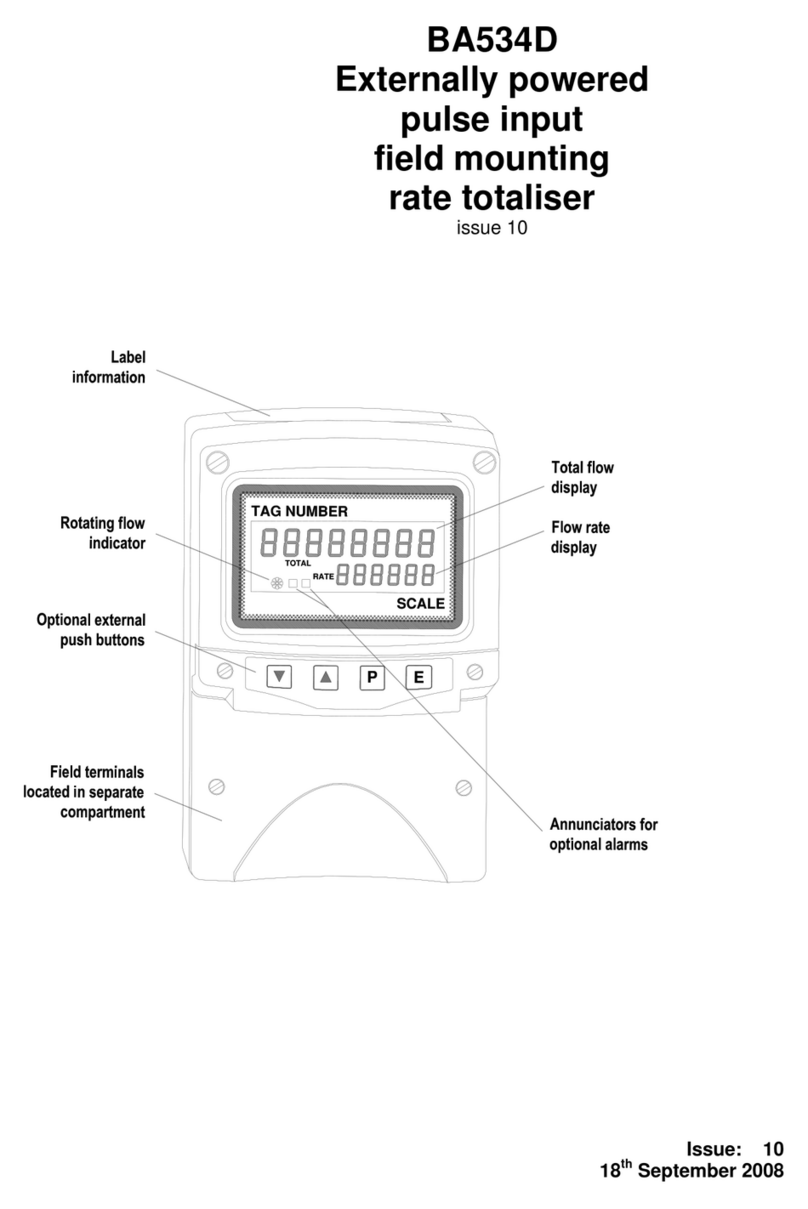

2.2 Displays

The BA558E has two digital displays and

associated annunciators, plus a flow indicator as

shown on page 1.

Upper Shows the flow rate on the five digit

display plus sign 12mm high display.

Lower Shows the total flow on the eight digit

display (seven with negative sign) 18mm high

display which may be reset to zero by

operating the ▼+ ▲instrument push

buttons or by an external contact

closure.

The rate and total displays may be interchanged,

see section 6.7

Flow This disc on the lower left hand

indicator side of the display rotates when the

input current exceeds 4.000mA,

indicating that flow is being detected by

the Rate Totaliser. For bi-directional

flow, the disc rotates when flow

exceeds ±0.05% of span.

Annunciators

Reset Activated when total display is reset to

zero by operating the ▼+ ▲buttons

simultaneously or by connecting the

reset terminals together.

Hold Activated when flow rate falls below the

clip-off value and totalisation is

inhibited.

4