1-800-255-5387 • www.premier-mfg.com

PREMIER MANUFACTURING COMPANY Page 7

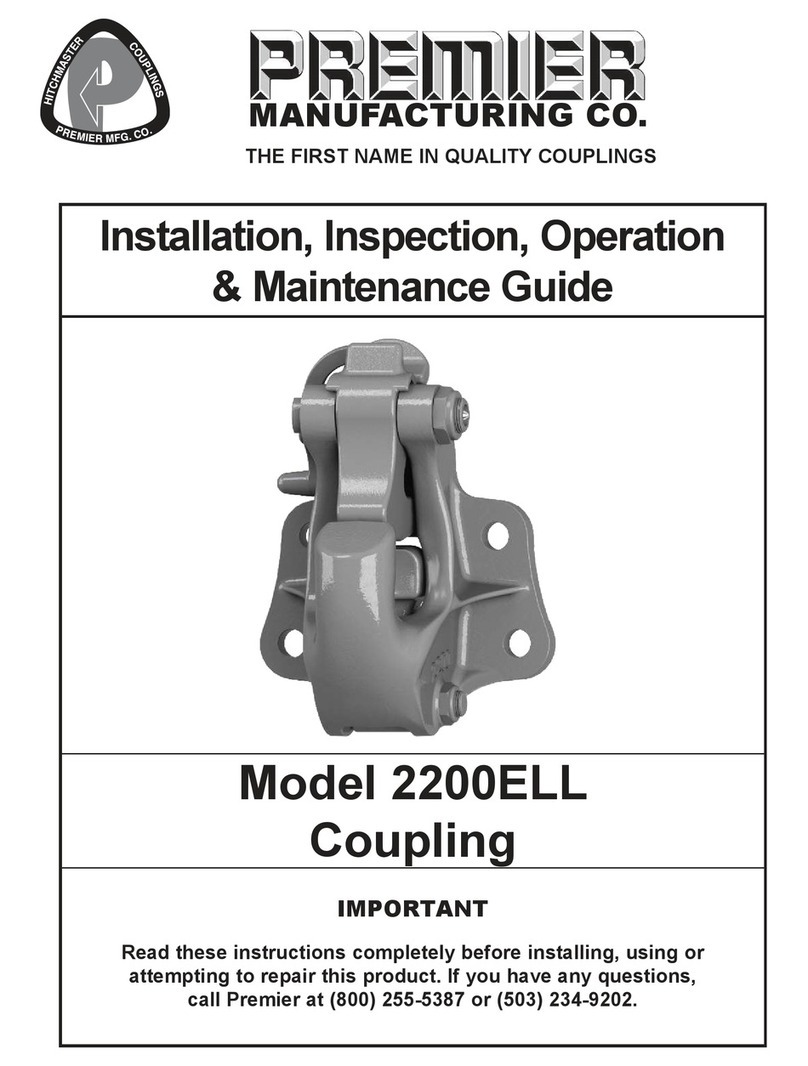

Model 2200 / 2200L Coupling

INSPECTION / OPERATION / MAINTENANCE

Operation:

OPENING Coupling Latch: (See specific model of

coupling for proper opening instructions)

2200:

1. While facing the mounted 2200 Coupling, push

the 2073 Latch Lock toward the mounting plate

(away from you) until full rotational travel is

reached. While holding the latch lock in this

position, grasp the top of the 2072 Latch and

pull out toward the pintle, rotating the latch until

full rotational travel is reached.

2. Holding the 2072 Latch in place, slowly release

the 2073 Latch Lock until it has rotated into the

latch.

3. Release the 2072 Latch and the 2200 Coupling

is now open and ready to couple or uncouple.

2200L:

1. While facing the mounted 2200L Coupling,

grasp the knob on the 2075 Handle and pull

away from the mounting plate (toward you) until

full rotational travel of the 2073 Latch Lock is

reached (Fig. 2). While holding the handle in

this position, grasp the top of the 2072 Latch

and pull out toward the pintle, rotating the latch

until full rotational travel is reached (Fig. 3).

2. Holding the 2072 Latch in place, slowly release

the 2075 Handle allowing the 2073 Latch Lock

to rotate into the latch.

3. Release the 2072 Latch and the 2200L

Coupling is now open and ready to couple or

uncouple (Fig. 4).

CLOSING Coupling Latch: (See specific model of

coupling for proper closing instructions)

2200:

4. Rotate the top of the 2072 Latch toward the

pintle until full rotational travel is reached and

hold in place. Push the 2073 Latch Lock

toward the mounting plate as far as it will go.

5. While holding the 2073 Latch Lock in this

position, slowly release the 2072 Latch. Next,

release the latch lock making sure it seats fully

down in the slot on top of the latch. The 2200

Coupling is now closed.

6. To test for proper latching, apply a force toward

the coupling body to the front of the 2072

Latch (down near the top of the pintle). THE

LATCH SHOULD NOT OPEN! If the latch does

not stay closed, do not use until it has been

repaired or replaced.

7. This product is designed to be operated within

its free rotation limits. It is the responsibility of

the vehicle designer/end user to ensure that

these limits are not exceeded (do not bind-up/

jackknife).

8. WARNING: Prior to towing, make certain that

adequately rated safety chains have been

properly connected.

2200L:

4. WARNING: Keep fingers away from the top

of the pintle/hook during this operation as the

2072 Latch will automatically rotate into the

Inspection and Maintenance:

1. Visually inspect the coupling body and latch

components for cracks, impact damage and/

or deformation before each and every use. Do

NOT use if any of these conditions exist.

2. Check the gap between the 2072 Latch and

the top of the pintle/hook on the coupling body

before each and every use. A gap of 3/8” or

more means the coupling must be taken out of

service and repaired or replaced.

3. If the wear area on the pintle/hook has worn

20% or more from its original cross-section, the

coupling is considered out-of-service and must

NOT be used.

4. Lubrication of the latch components must

be performed at 90-day intervals or sooner

depending on the operating environment.

Lubricate the latch components with a spray-

type lubricant to evenly coat all rotation points.

Rotate each latch component several times to

evenly distribute the lubricant.

5. Remove any excess lubricant with a rag. Do

not apply lubricant to the pintle/hook or saddle

area of the coupling.

6. Never weld on any Premier part in order to

repair damaged or worn areas. Field and/or

shop welds are inadequate and may further

weaken the coupling.

7. WARNING: Other inspection and maintenance

procedures are also required prior to the

operation of combination vehicles. Consult

and follow all Federal Motor Carrier Safety

Regulations as well as local, state and federal

guidelines.