1-800-255-5387 • www.premier-mfg.com

premier manufacturing company Page 6

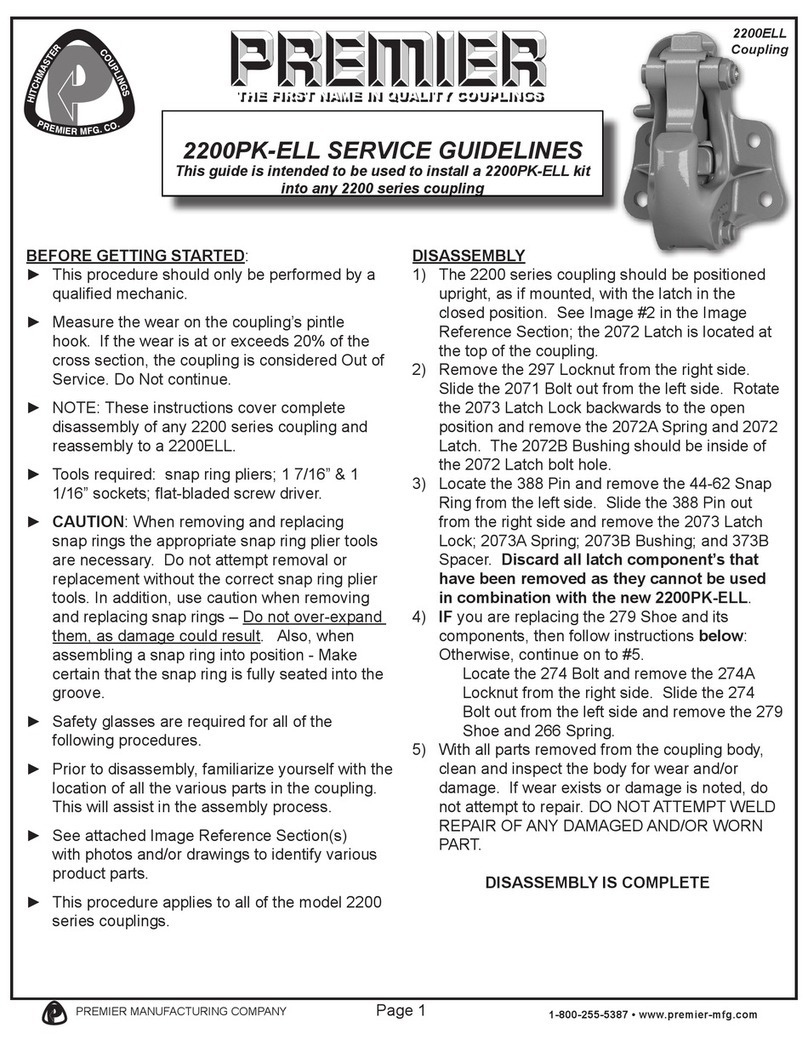

Model 2200ELL Coupling

INSTALLATION

The 2200ELL Coupling is only to be used and

maintained with Premier parts listed in the

Replacement Parts Information section. Any

substitution or use of non-Premier parts in a

2200ELL Coupling will VOID ALL PRODUCT

WARRANTY.

Installation Procedure:

1. The 2200ELL Coupling must be installed to

comply with the Federal Motor Carrier Safety

Regulations. Specifically, Section 393.70,

Paragraph C: “Towing of Full Trailers.” Prior

to install or operation, consult with local,

State and Federal agencies, as there may

be additional applicable laws governing

installation and use of this product.

2. Make certain that the cross member the

2200ELL Coupling is to be mounted on is of

sufficient strength to withstand the load rating

of the coupling.

3. If using the 2200ELL Coupling with a 281

Air Chamber, a 267 Air Chamber Bracket

and a 271 Thimble, measure the mounting

structure thickness and cut the pushrod on

the air chamber to a length of 3 5/8” plus the

mounting structure thickness (i.e. 1/2” thick

mounting structure would equate to:

3 5/8” + 1/2” = 4 1/8” pushrod).

4. Using the Standard Installation Drawing,

measure and layout the cross member and

then drill the holes for the mounting bolts (and

pushrod if used with an air chamber).

5. Mount the 2200ELL Coupling using either

Premier’s 501 Bolt Kit and provided torque

value, or four other 3/4” grade-8 bolts and

grade-C locknuts. Only use new fasteners

when mounting couplings or drawbar eyes

and torque to SAE specifications. If using the

2200ELL Coupling with a 281 Air Chamber,

mount the chamber, 267 Air Chamber Bracket

and 271 Thimble as shown in the Standard

Installation Drawing. The two longer (2

3/4”) mounting bolts in the bolt kit are used

for mounting the coupling and air chamber

bracket to the cross member. WARNING:

Never use an air chamber on a Premier

coupling without a 271 Series Thimble.

6. Once mounted, check the latch components

for proper operation and clearances (see the

Inspection/Operation/Maintenance section

for opening and closing the latch). If the

operation of the latch components is sticky,

lubricate via the zerk fittings on the 2074EL

and 2071EL with a pump or two of grease.

Also apply a light penetrating oil to the 2075

lever rotation point. Work the latch assembly

several times to distribute the lubricants evenly

and remove any excess with a rag. Do not

apply lubricant to the pintle/hook or saddle

area of the 2200ELL Coupling.

7. Plumb the air line to the 281 Air Chamber

from the vehicle’s emergency side air supply.

NEVER use the service side air supply.

8. WARNING! Keep hands clear of the 2200ELL

Coupling during this test. Activate the

emergency side air supply by releasing the

emergency brake and visually verify that the

279 Shoe fully rotates toward the pintle.

9. If the 279 Shoe does not move, verify that

the air chamber has been connected to

the emergency side air supply and that the

pushrod length is correct.

Optional Accessories:

- 282 Air Chamber (Type-30): Larger chamber diameter provides greater shoe force compared to the 281 Air

Chamber.

- Air Chamber Brackets: 267H (3/4 in. / 19 mm), 267F (4 5/8 in. / 117 mm)

- Thimbles: 271B (4 3/8 in. / 111 mm), 271C (5 1/2 in. / 140 mm)

- 438 Drawbar Guides: Helps guide drawbar eye into coupling.

- 14014 Wear Gage (2 1/8 in.): To determine hook wear limits.

- 14026 Latch Gage: To determine latch gap limit.

- 501SPL Bolt Kit: Mounting bolts and nuts used for non-air application.

ACCESSORIES