1-800-255-5387 • www.premier-mfg.com

premier manufacturing company Page 3

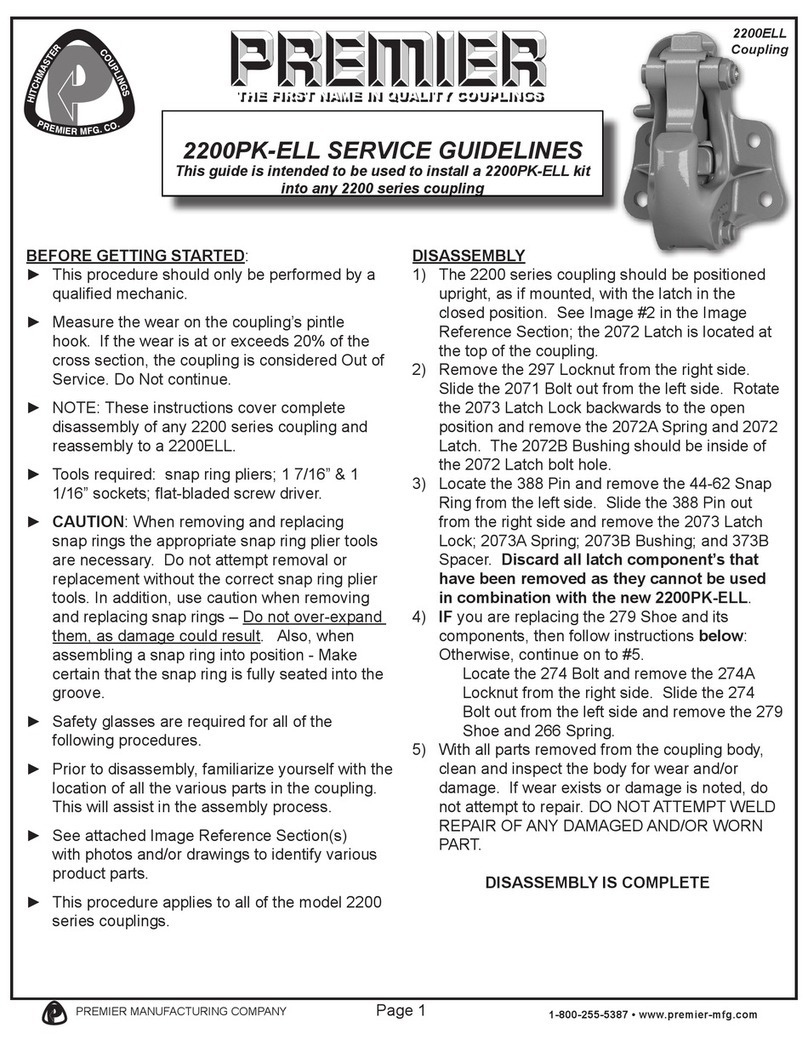

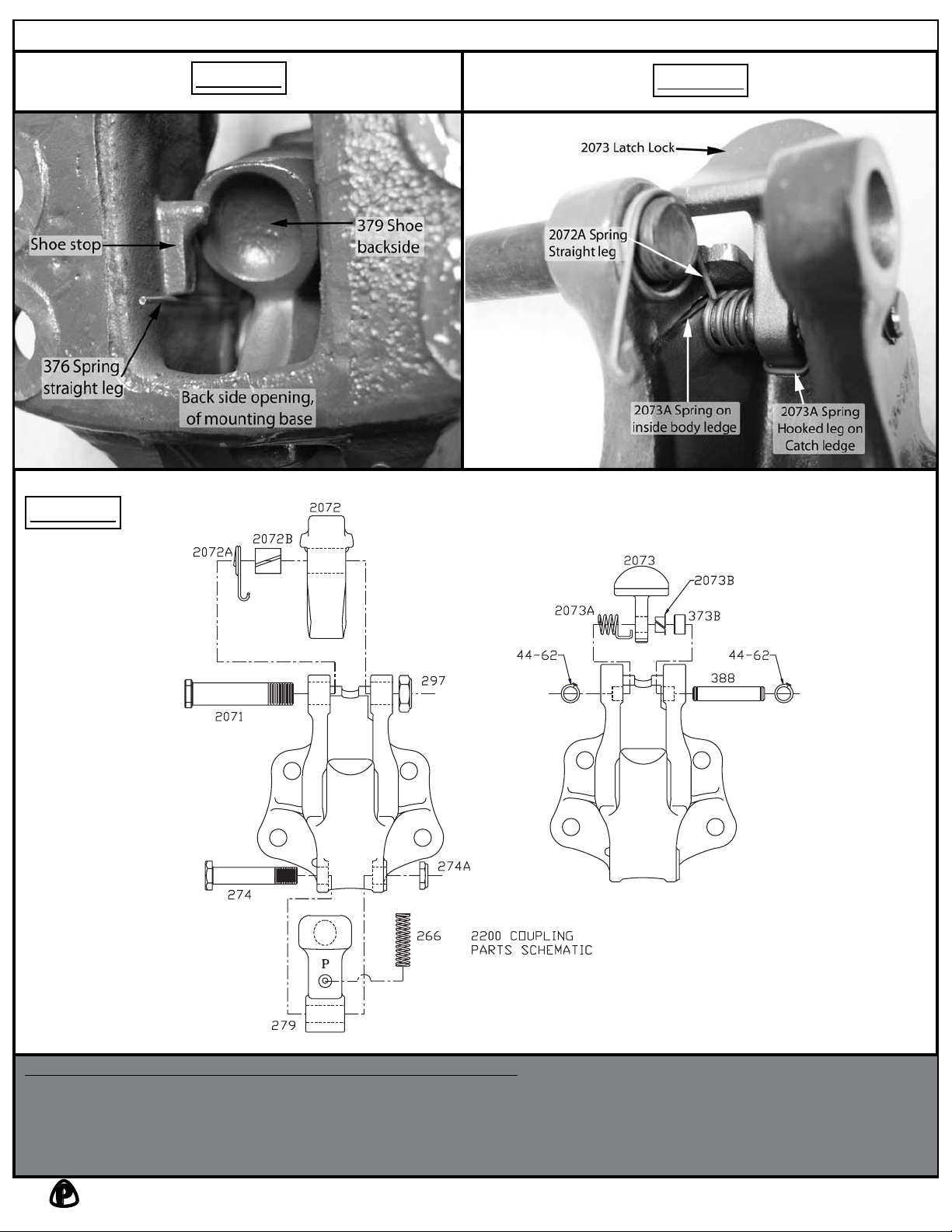

body sidewall. Rotate the 379 Shoe to verify

proper spring tension.

2) Take the 388 Pin and insert it into the right side

body hole, allowing approximately 1/2” to extend

past the right side interior wall surface. Place the

373B Spacer onto the extending end of the 388

Pin, within the body cavity.

3) Insert the 2073B Bushing into the right side of the

2073 Latch Lock hole (see Image #5), until the

bushing flange is tight against the outside edge.

Position the 2073 Latch Lock into the body,

adjacent to the 373B Spacer. Align the hole,

then slide the 388 Pin through to the left, until

flush with the left side of the 2073 Latch Lock.

If installed correctly, the flange on the 2073B

Bushing is up against the 373B Spacer.

4) Hold the 2073A Spring so that the straight leg is

pointing upward on the left side of the spring and

the hooked leg is on the right. Place the spring

on the left side of the 2073 Latch Lock, aligning

it with the body hole on the left side and the 388

Pin on the right. The straight spring leg should

be along the top ledge, pointing toward you.

5) Rotate the 2073 Latch Lock forward toward you

and capture the hooked end of the spring with

the front part of the catch ledge on the bottom of

the 2073 Latch Lock. Keeping the 2073 Latch

Lock in the forward position, push the 388 Pin

through the 2073A Spring and out the left side of

the coupling body.

6) Closely examine the left side’s interior body

sidewall, adjacent to the 2073A Spring, and

locate the catch ledge running at a 45 degree

angle. This is where the straight leg of the spring

needs to be placed. Using a flat bladed screw

driver, pry the straight leg away from the top

interior ledge of the coupling and rotate it until it

engages with the catch ledge. Please Note: Do

not over stress the 2073A Spring when engaging

either end and also MAKE CERTAIN both the

straight end and hooked end are completely

engaged with the catch site locations (see Image

#4).

7) Rotate the 2073 Latch Lock backwards, to the

opened position. If spring is installed correctly,

smooth increasing spring resistance should be

felt when rotated. If no resistance or binding

is felt, the spring and/or parts are not installed

correctly.

8) Using snap ring pliers, install both 44-62 Snap

Rings into the grooves on the 388 Pin. Verify

that both snap rings are fully seated into their

grooves.

9) Insert the 2071 Bolt from the left side into

the coupling body until the threaded end is

approximately 1/8” past the left side interior

body sidewall. Place the 2072A Spring onto the

protruding 2071 Bolt’s threaded end. The hook

end of the spring should be pointing toward you

and the straight leg facing downward, captured

by the top interior ledge of the coupling (see

Image #4).

10) Place the 2072B Bushing into the hole in the

2072 Latch. With one hand rotate the 2073

Latch Lock back to the opened position and hold.

With the other free hand grasp the 2072 Latch

and lower into position, catching the hooked

end of the spring on the left side sidewall of

the 2072 Latch. Once in position, gently allow

the 2073 Latch Lock to rotate forward, into the

closed position. Now align the 2072 Latch hole

with the 2071 Bolt and slide the bolt to the right

until fully seated. Due to the snug fit caused by

the bushing, it is possible that while pushing the

bolt into place, you may have to twist the bolt

and wiggle the latch to get everything to line up

properly. Do not hammer or tap the bolt through.

This action could possibly damage the bushing.

Secure the bolt with the 297 Locknut on the right

side.

11) Rotate the 2073 Latch Lock to the opened

position and hold. Rotate the 2072 Latch to

the opened position. If the spring is installed

correctly, smooth increasing spring resistance

should be felt when rotated. If no resistance or

binding is felt, the spring and/or parts are not

installed correctly. Reassemble correctly.

12) Once the coupling is assembled it should be

opened and closed several times, testing for

smooth and correct operation. DO NOT use the

coupling if it does not operate properly. Call for

assistance.

13) Use only new fasteners torqued to SAE

specifications when mounting the assembled

coupling to its mounting structure.