1. WARNING:.......................................................................................................... 4

2. INSPECTION OF THE MATERIAL UPON RECEIPT OF THE EQUIPMENT: ................ 1

2.1 LIST OF COMPONENTS .................................................................................................... 1

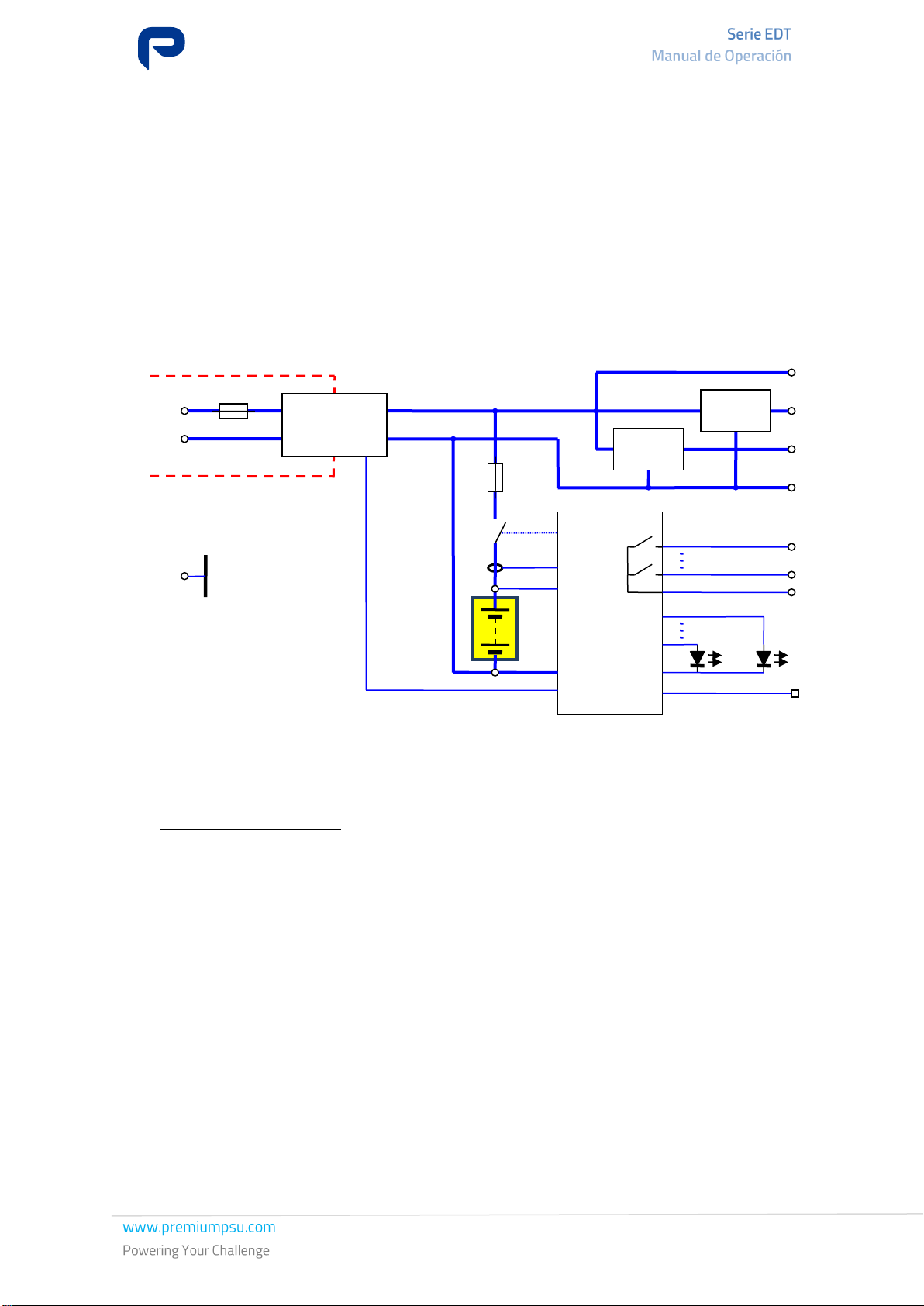

3. EDT-150-5191 SYSTEM DESCRIPTION................................................................ 2

4. CHARGER FUNCTION .......................................................................................... 4

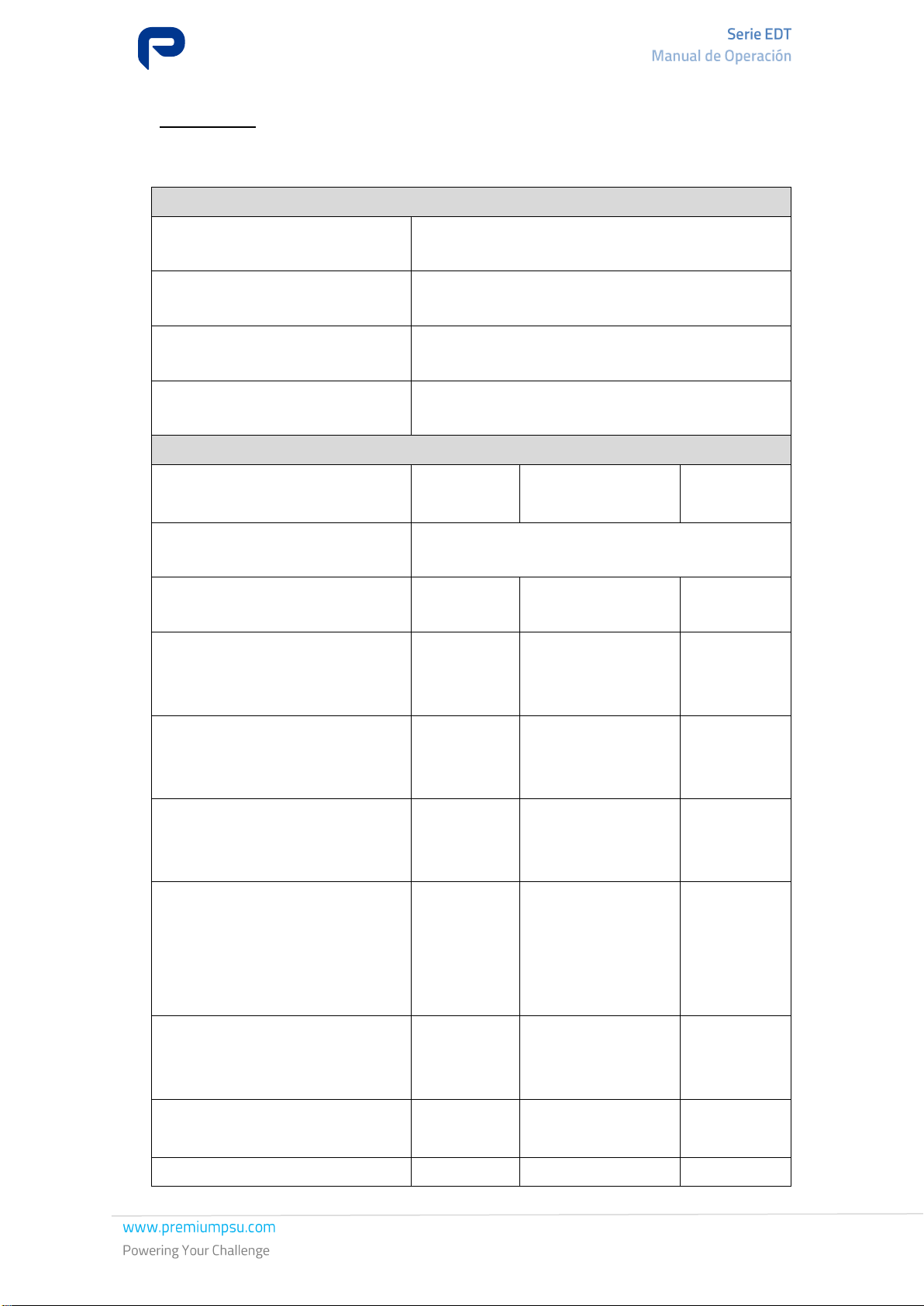

5. FEATURES:.......................................................................................................... 6

5.1 ELECTRICAL, ENVIRONMENTAL AND MECHANICAL CHARACTERISTICS: .................................. 6

5.2 ELECTRICAL BEHAVIOUR: ............................................................................................... 8

5.3 PROTECTION................................................................................................................. 8

5.4 SIGNALLING ................................................................................................................10

5.5 ALARMS.......................................................................................................................11

5.6 WIRING AND SIGNALS:..................................................................................................12

5.6.1 TERMINAL BLOCKS AND SIGNALS:...................................................................................12

5.6.2 BUTTON: .....................................................................................................................15

5.7 TEMPERATURE SENSOR .................................................................................................16

5.8 CONFIGURATION: .........................................................................................................16

5.9 COMMUNICATIONS: ......................................................................................................17

6. INSTALLATION:................................................................................................ 18

6.1 INSTALLATION REQUIREMENTS ......................................................................................20

6.2 BATTERY INSTALLATION ................................................................................................20

7. WIRING............................................................................................................ 21

7.1 ELECTRICAL MAINS AND EARTH CONNECTION:..................................................................22

7.2 OUTPUT AND BATTERY CONNECTION: ..............................................................................23

7.3 BATTERY TEMPERATURE PROBE CONNECTION:..................................................................24

7.4 ALARM RELAYS CONNECTION: ........................................................................................25

7.5 ETHERNET NETWORK WIRING CONNECTION: ....................................................................25

8. COMMISSIONING ............................................................................................. 27

9. OPERATION ...................................................................................................... 28

10. PROCESSES: ..................................................................................................... 29

10.1 ALARMS: .....................................................................................................................29

10.2 BATTERY CONSUMPTION:...............................................................................................31

10.2.1 STATE OF CHARGE: .................................................................................. 31

10.2.2 EQUIPMENT TOTALLY TURNED OFF: ........................................................ 33

10.2.3 EQUIPMENT TURNED ON AND WITHOUT MAINS INPUT:.......................... 33

10.3 CONFIGURATION: .........................................................................................................33

10.4 POWER-UP:..................................................................................................................33

10.5 VARIATION OF FLOAT VOLTAGE WITH TEMPERATURE: ........................................................34

10.6 CONNECTION AND BATTERY CHARGING: ..........................................................................36

10.7 BATTERY DISCHARGE AND DISCONNECTION: ...................................................................37

10.8 RECOVERING BATTERY: .................................................................................................37

10.9 BATTERY TEST:.............................................................................................................39

10.10 BATTERY CHANGE: ....................................................................................................40

10.11 POWER DISTRIBUTION: .............................................................................................40