CAVA - MANUAL

1 | CAVA – Manual | AntecControls.com

INTRODUCTION

General

In this manual, you will find:

•Cava™ technical specifications

•Cava™ mechanical and electrical installation

•Fume hood accessories

•Cava™ interface navigation and configuration

•Troubleshooting information

Please refer to the project specifications, mechanical and electrical

plans, and the Antec Controls project submittal documents for project-

specific wiring and configuration details.

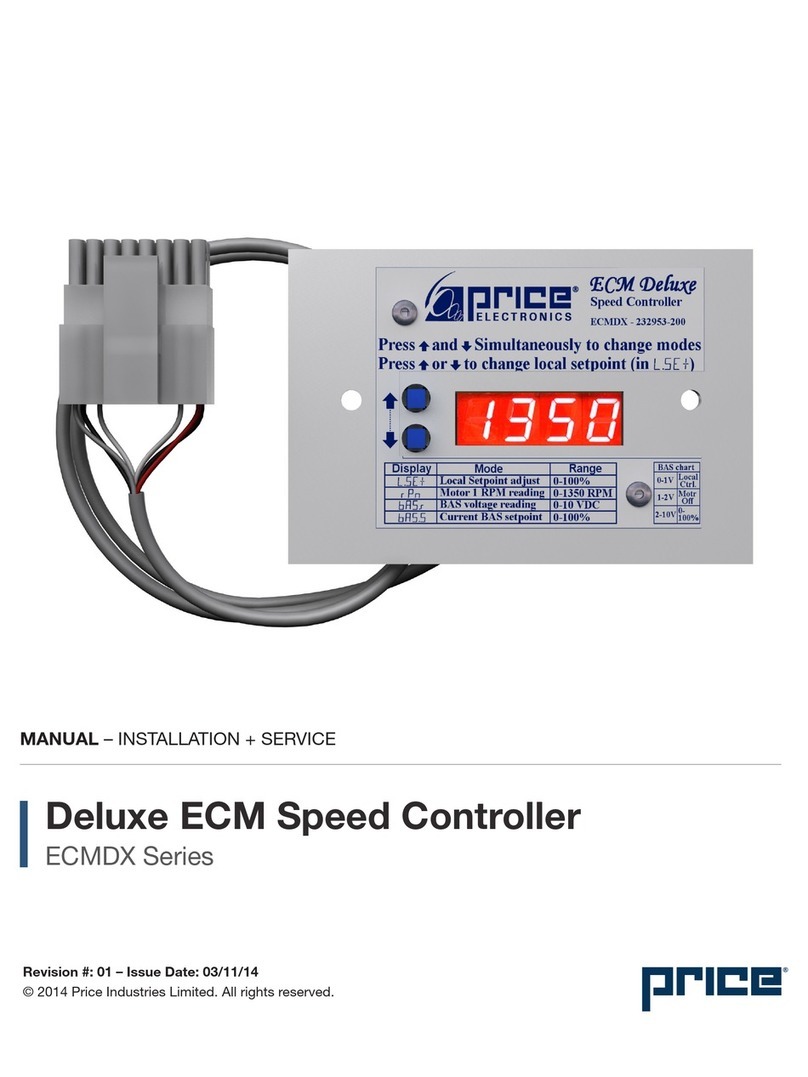

Product Overview

Cava™ is an exceptionally versatile fume hood controller that precisely

monitors and controls fume hood face velocity. Designed specifically

to meet the needs of all fume hood types, Cava™ provides assurance

that required fume hood face velocity is satisfied and the work

environment is safe, while eliminating unnecessary energy usage.

Cava™ delivers effective control using Venturi Valves, Venturi FX

Valves, or terminal units on fume hoods and biosafety cabinets.

Cava™ is intended for continuous, 24-hour fume hood face velocity

control and monitoring, and will automatically resume upon restart

after losing power.

Cava™ displays critical fume hood details through its interface, where

users can effortlessly view real-time information and update a variety

of display parameters. Fume hood status is clearly indicated through a

colored display with an excellent viewing angle, along with

programmable audible alarms ensuring the safety of all users through

immediate notification of changes in fume hood status. Cava™ has

two physical buttons, including one that allows users to quickly enter

emergency mode without having to remove any protective wear.

Features

•4.3” capacitive touchscreen display

•Large tactile buttons for ‘glove-handed’ use

•Audible and visual configurable alarms

•Works with Venturi Valves, Venturi FX Valves, and terminal units

•Sash position sensing, sidewall face velocity sensing, or hybrid

sensing configuration

•Less than 1 second speed of response defined by ANSI Z9.5

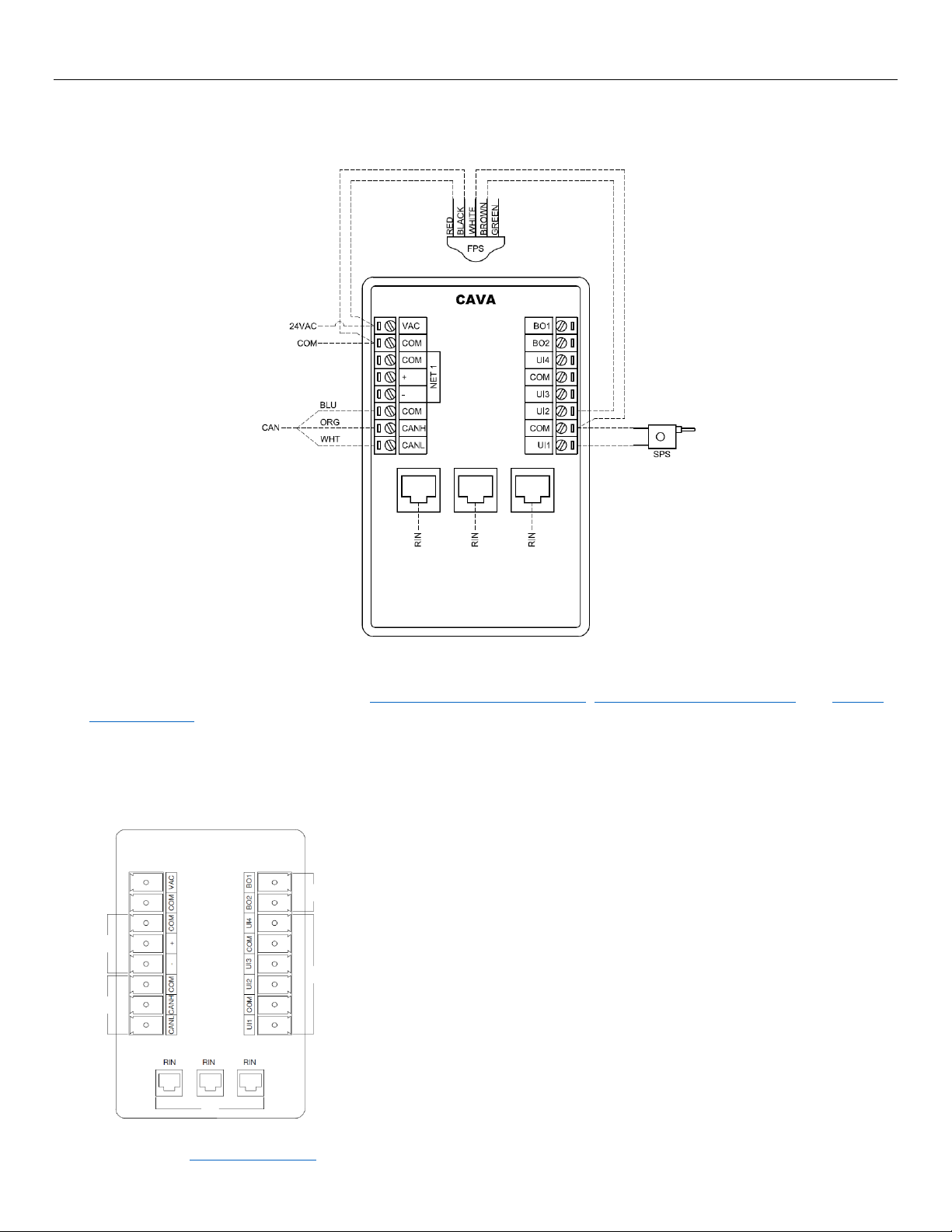

•Controller Area Network (CAN) for communication between

fume hood-level devices

•High-speed Room Information Network (RIN) for communication

between all room level and fume hood controllers

•BACnet MS/TP

•Fast, intuitive start-up and balancing software

•User defined fume hood modes

•Commissioning port at every Cava™ that allows for simple fume

hood and room level setup

Installation & Service

1. A qualified person must perform installation

and electrical wiring in accordance with all

applicable codes and standards, including

fire-rated construction practices.

2. Do not damage electrical wiring and other

hidden utilities while installing this device.

3. Disconnect power at the service panel

before performing wiring or maintenance

on this device.

4. Intended for indoor installation only, in

areas with Pollution Degree 3.

5. Not designed for use in industrial, farming,

or humid environments.

6. Not designed for use in residential

environments and may not have adequate

protection to radio interference.

7. Not designed to operate in a construction

environment. Use in these environments

may lead to excess or unintended wear,

reducing product life and/or performance.

This mark indicates an important point for

the proper function of Cava™ and any of its

accessories. Pay close attention to all

caution points throughout this manual.

For support and in-depth

training on this product and

other associated system

components, please

contact your local Antec

Controls Representative.

For more information visit