4

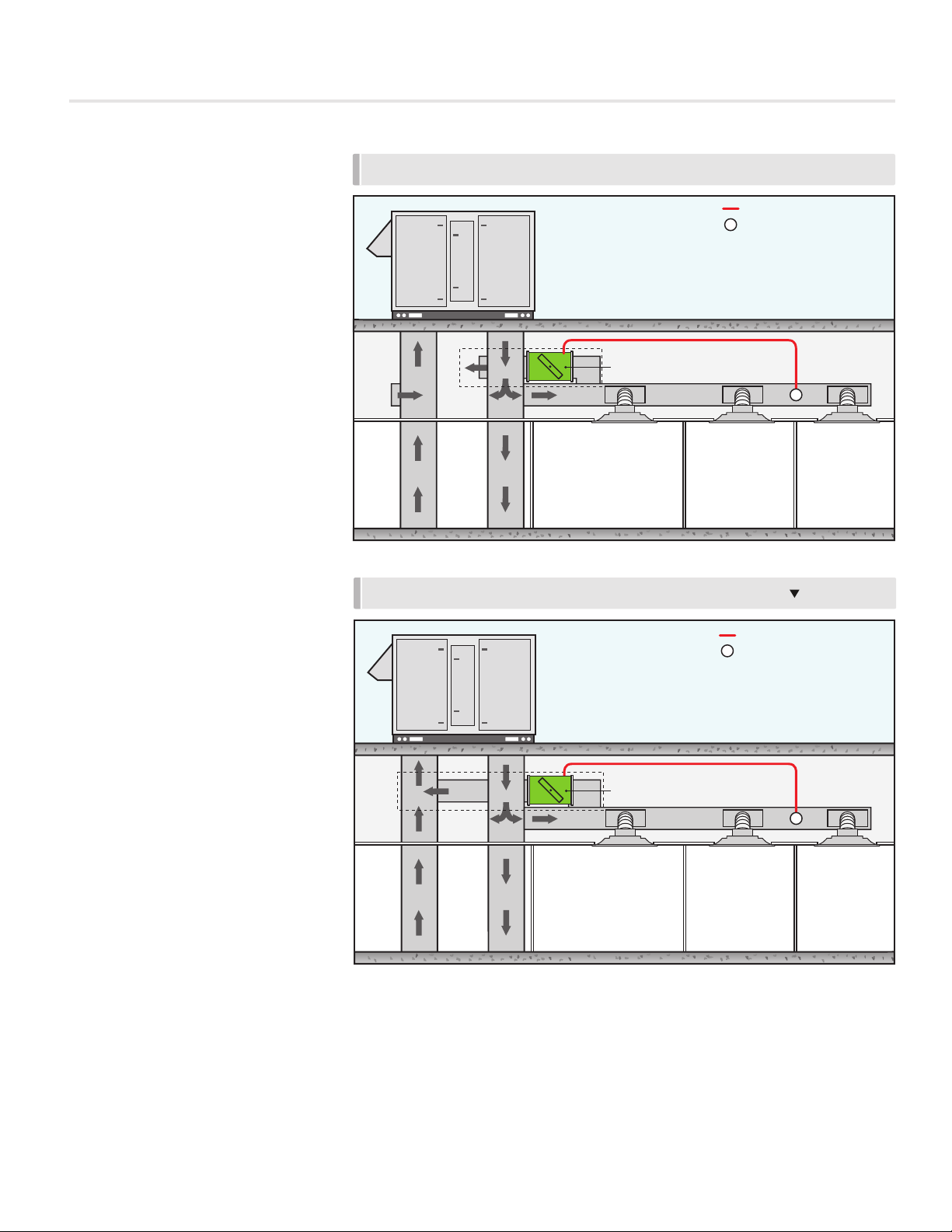

PRESSURE CONTROL VALVE

INSTALLATION

PRESSURE CONTROL VALVE - Manual |priceindustries.com

Installing the PCV Unit

1. The PCV consists of a damper (often a Price model RDV)

and a PIC controller that is programmed for pressure

control. The PCV should be installed on the supply duct

running off of the rooftop unit. For bypass applications, the

PCV will go in between the supply and return duct (return

may be open and return directly to the ceiling plenum).

For downstream throttling applications, the PCV should

be installed directly in the supply duct, before the first VAV

box or VAV diffuser in the branch being served.

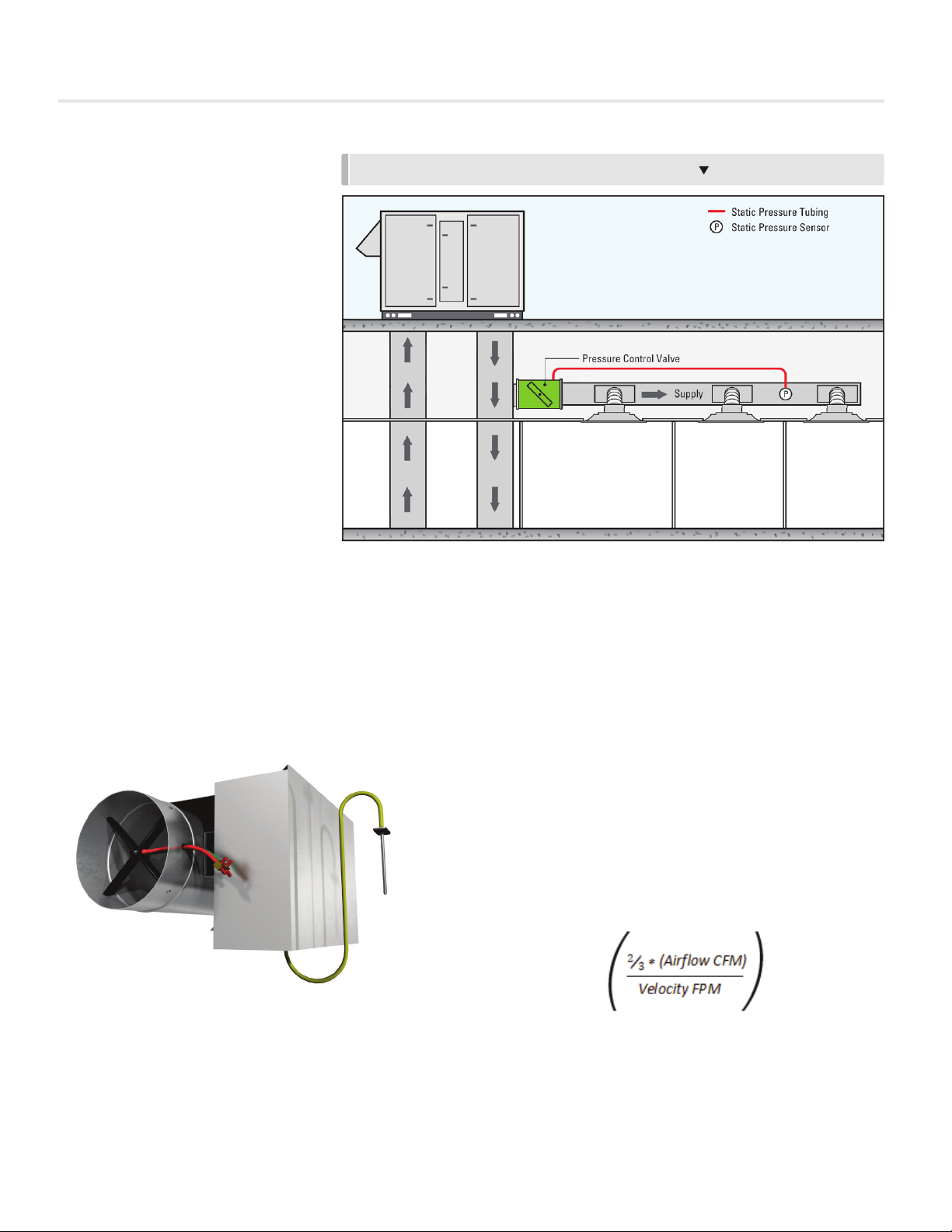

2. Static Pressure Probe – the PCV will come with a static

pressure probe. This probe needs to be installed about

2/3 of the way down the main supply duct run. Do not

mount this directly after the main fan, as the transducer

would read a very high static, rather than the average duct

static pressure. The probe then needs to be connected to

the HI side port of the transducer on the PIC board with

field provided ¼” pneumatic tubing. Leave the LO side

port of the transducer open to the atmosphere.

3. Power up the PCV controller. If a transformer is supplied,

then apply the appropriate line voltage to the transformer.

If a Price Power Module (PPM) is being used, plug in

the provided RJ12 cable into the power jack on the PIC

controller. The secondary of either transformer must be

earth grounded!

LCD Set-up Tool

The balancer will require an LCD-SETUP tool to set the static

pressure setpoint on the PCV controller, and to change any

parameters if needed. To connect the LCD-SETUP tool, the

balancer must connect to the PIC controller on the bypass

terminal in the ceiling, using the Service Port. (Note** the PCV

does not come with an LCD stat, so the LCD Set-up Tool is

required). If an LCD Set-up tool was not ordered for the job, an

existing LCD stat from a zone controller can be used as well;

you just require a CAT-5E (NETC35) cable to connect the tstat

to the controller

See page 16 for details on how to set the static pressure

setpoint.

1/4" TUBING

PCV CONTROLLER STATIC PRESSURE PROBE IN

THE SUPPLY DUCT

INSTALL 2/3 OF THE WAY DOWN MAIN DUCT

LCD CONNECTION EXAMPLE

LCD OR

LCD-SETUP RJ12 GREY CABLE

COMES WITH LCD-

SETUP TOOL

NOTE: When using CAT-5E (NETC35), connect to ethernet port on the back of the LCD thermostat.

CAT-5E (NETC35) BLUE CABLE

USING EXISTING LCD STAT

ONSITE