1

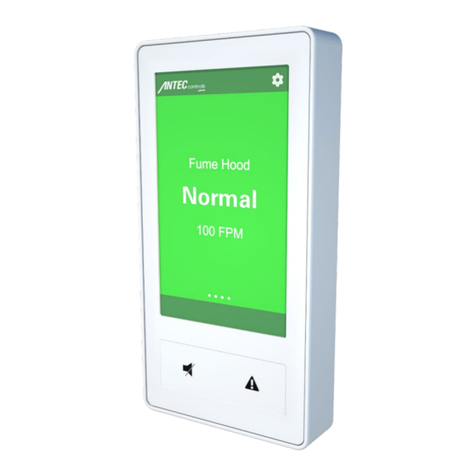

FUME HOOD CONTROLLER / MONITOR

SECTION 1 - INTRODUCTION

FUME HOOD CONTROLLER / MONITOR - Manual |pricecriticalcontrols.com

Product Overview

Laboratory fume hoods serve as

ventilation systems that efficiently

exhaust chemical vapors, mist, and

fumes. Fume hoods also provide a

barrier protecting occupants from

certain reactions, spills, and even fires.

In most cases special fans exhaust the

fumes outside, which greatly dilute their

concentration and reduce their harmful

effects. In some cases a specialized

scrubber is also required to remove the

vapors from the exhaust air.

Fume hoods require constant exhaust

airflow to ensure that none of the air

entering the fume hood ever escapes

back into the laboratory space. This

ensures the safety of the user and of

any other occupants of the room or

building. The exhaust airflow, measured

in cubic feet per minute (CFM), creates

a face velocity across the sash opening.

This is the industry standard measure

of fume hood safety. Typically the

face velocity of a fume hood must be

between 80 – 100 feet per minute

(FPM), but this can vary based on local

codes or the fume hood design. It is

important to note the required face

velocity for the hood being used.

Features

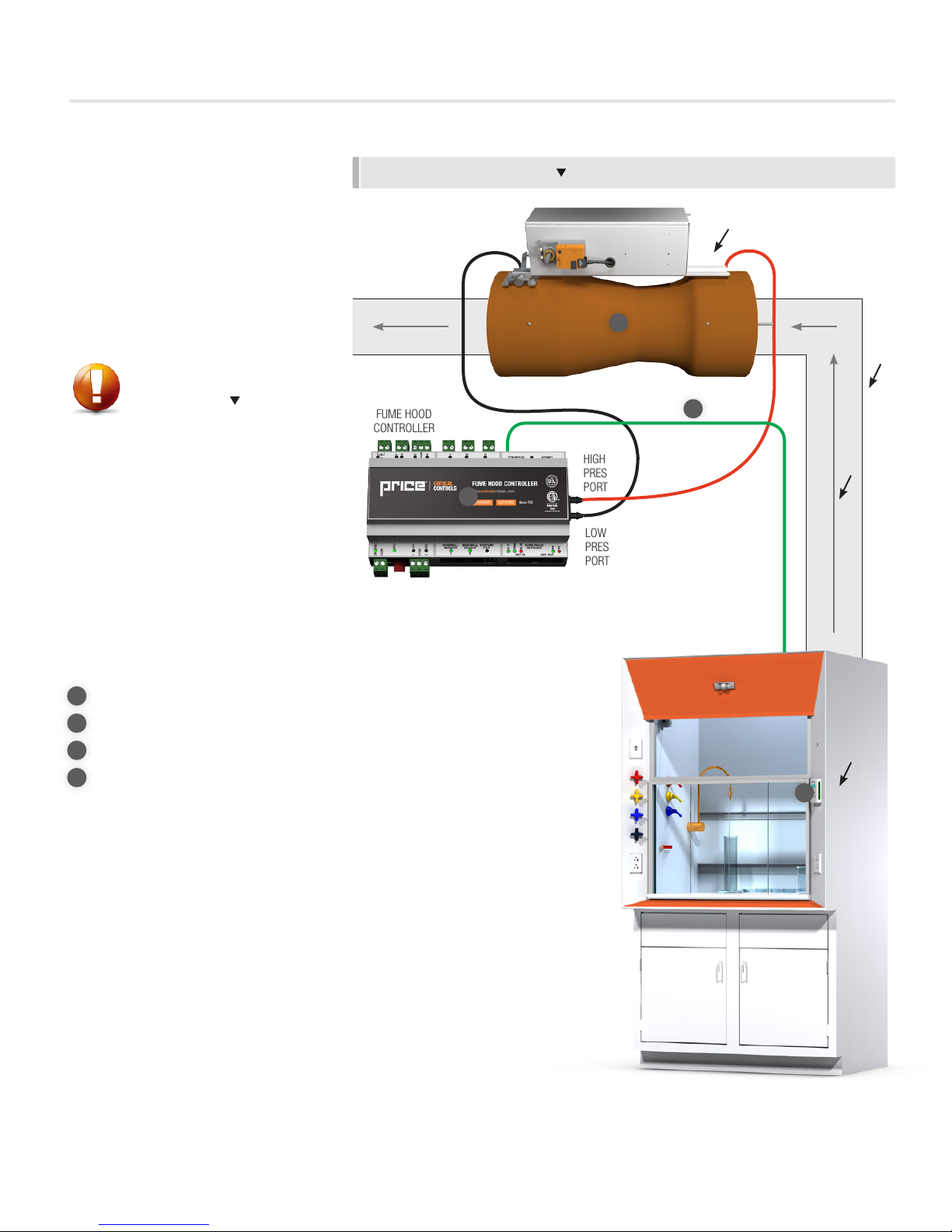

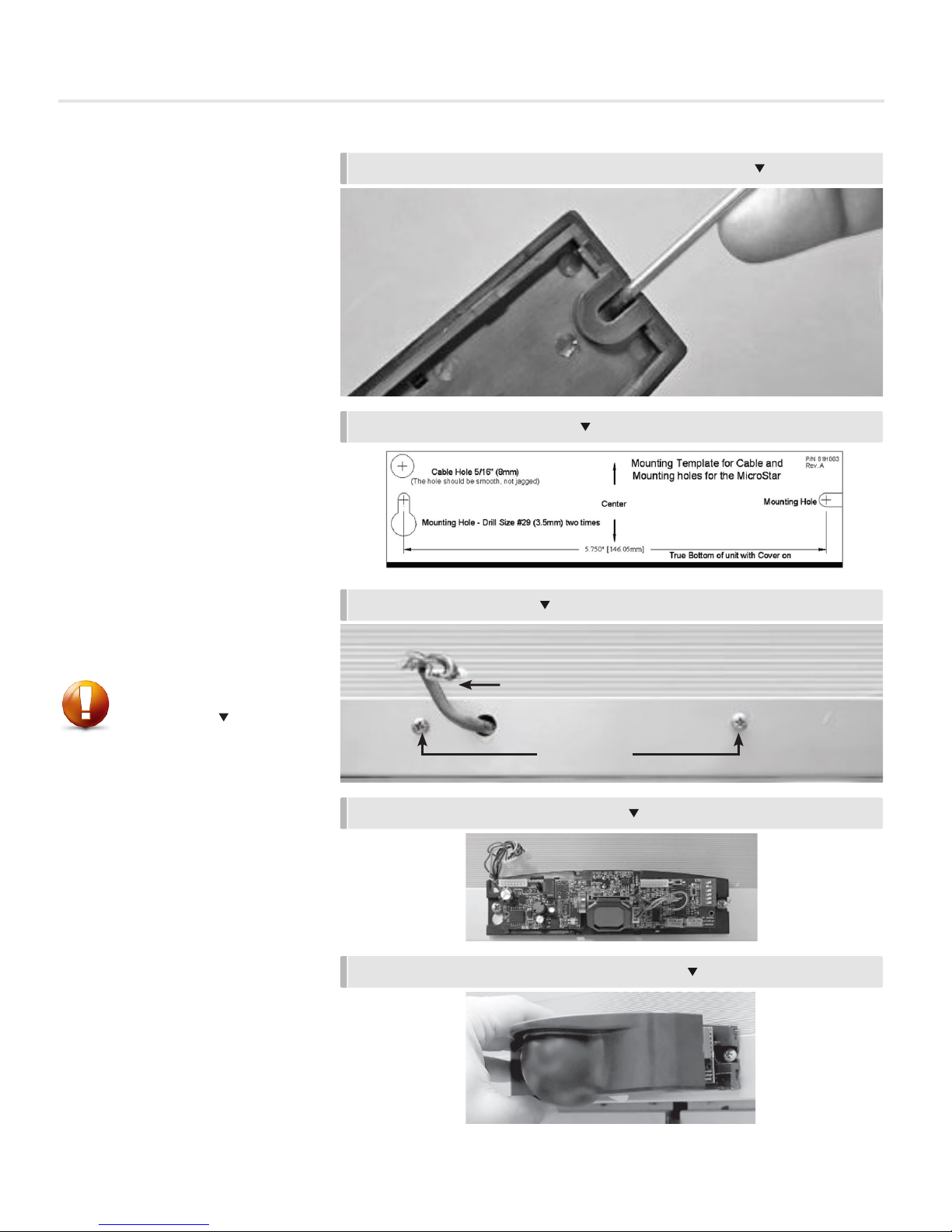

The Fume Hood Controller (FHC) can ensure a safe working environment by

constantly monitoring and adjusting the exhaust to maintain the correct face velocity.

The main control inputs are sash sensors and sidewall sensors. Sash sensors use a

potentiometer attached to the sash to measure the current height. Face velocity in

feet per minute (FPM) is calculated in real time. Sidewall sensors use an extremely

sensitive, low pressure sensor to measure the negative pressure in the hood

compared to the lab space. The Fume Hood Monitor (FHMX) constantly monitors

the fume hood face velocity and can provide real-time fume hood information to

operators and to the building management system (BMS) over BACnet.

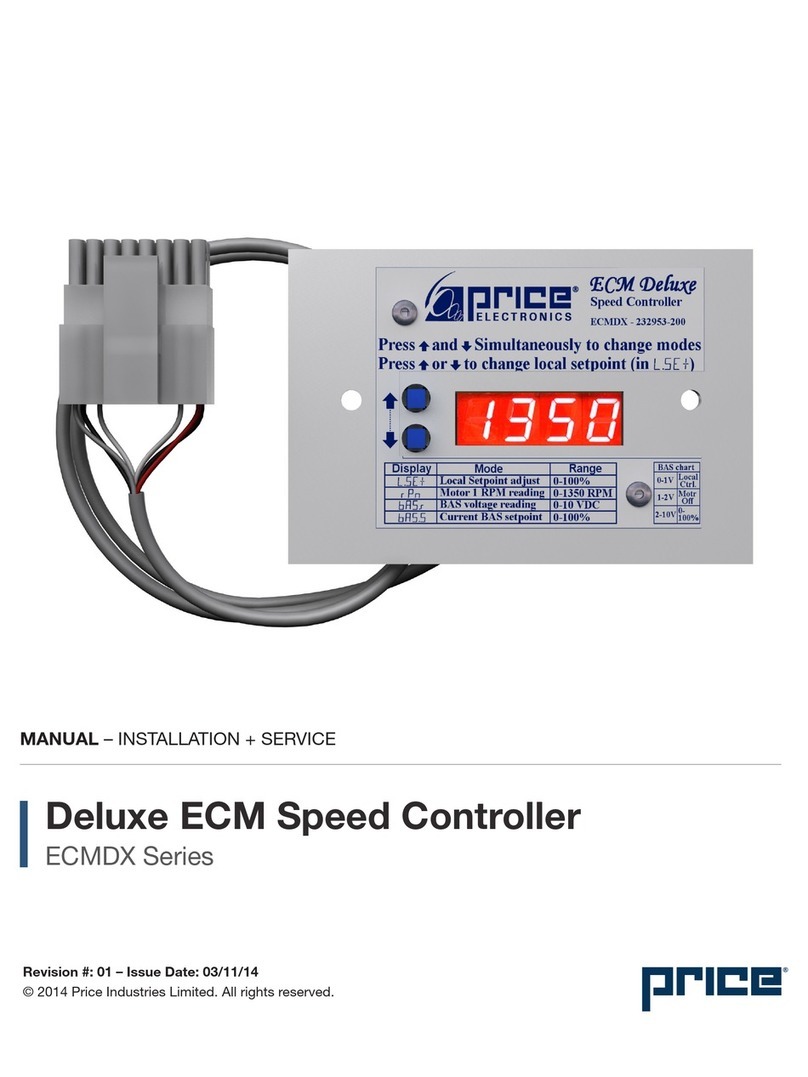

• 16 bit – high speed flash based microprocessor with watch dog timer, brown

out reset

• Multi-stage surge protection against voltage spikes on 24 VAC input

• 2 simple connections to sidewall sensors using RJ-12 jacks

• 3 Sash position inputs (10kΩ)

• 2 binary outputs rated at 0.5 amps each, protected with thermal fuse

(RED LED on trip)

• 1 binary output (dry contact)

• 2 analog outputs (0-10 VDC)

• 2 binary inputs

• Pluggable terminal blocks

• Mnet high-speed fume hood network port

• 1 potentiometer input

• 1 pressure port input

• LED’s for Mnet/Lnet data TX/RX, Mnet/Lnet wiring fault, and RS-45 termination

A higher face velocity is not always

safer. Turbulence in the fume hood

can be created by high face velocities

causing issues with spillage/blowback.

CAUTION