PROKIT’S INDUSTRIES CO., LTD

https://www.prokits.com.tw

Email: pk@mail.prokits.com.tw

©2023 Prokit’s Industries Co., LTD. All rights reserved 2023001(C)

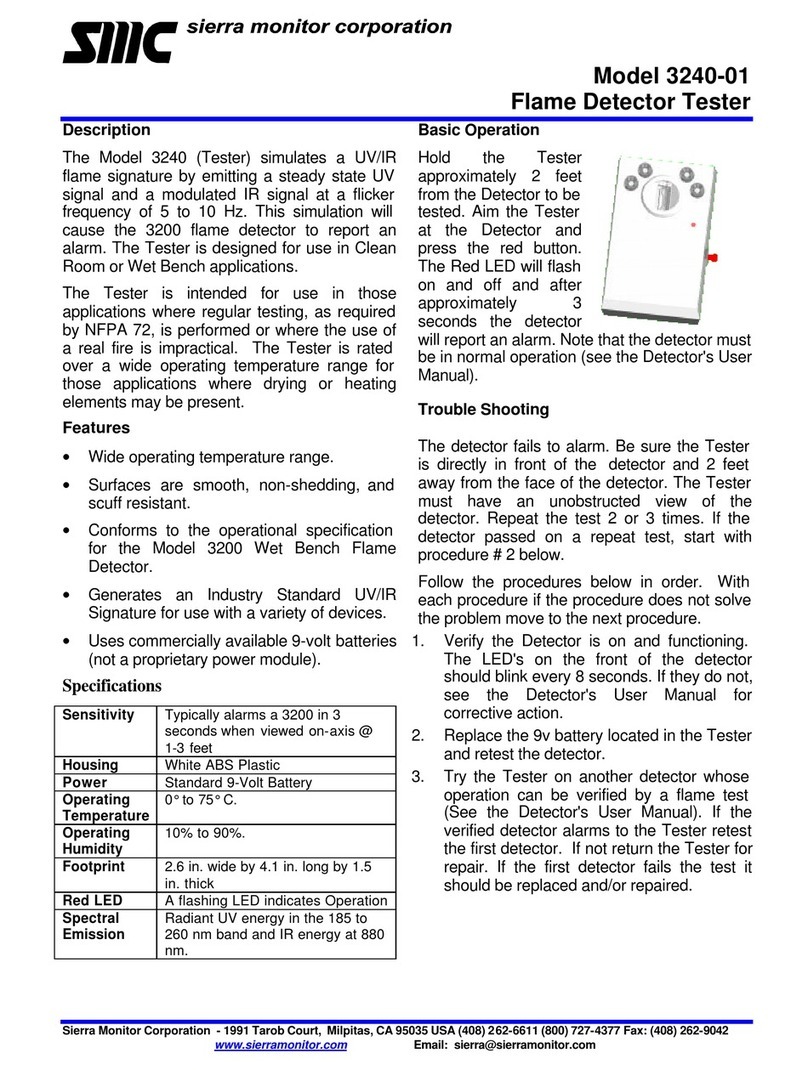

TE-8202A-W / TE-8202F-W series Fiber Optic Fusion Splicing Machine

Operation Manual

Main Features:

5 inches high resolution colorful LCD display, image can be

turned according to position

Average splice time: 10 second

Average tube-heat time: 30 second

Lithium battery: Rechargeable and up to 180 times of continuous

splice and heat after fully charged

Separately X or Y axis views with 500 times magnification and

Cutting-edge technology for image processing

New core alignment technology, the core alignment is more

accurate

New developed technology providing strong wind and dust

resistance

Working mode:Auto & Manual & Full-Auto

Micro USB Port

Storing 10,000 groups of latest splice results.

Storing 100 groups of splice images

Multipurpose optical fiber fixture ( 3-in-1 fixture and SC/LC/FC

connector fixture, patented technology)

Specifications:

0.02dB(SM),0.01dB(MM),

0.04dB(NZDS), 0.04dB(ED)

Suitable for cutting

optical fiber length

Suitable for optical fiber

core

Cladding diameter:80-150μm,

Coating diameter:100-1000μm

500 times for single X or Y view;

250 times for X and Y view

10000 groups of splice results

100 groups of splice images

5 “high resolution colorful LCD

Lithium battery: 10.95V/6Ah

Adapter: INPUT AC 100~240

50/60Hz; OUTPUT: DC15V/5A

1.98Kgs (include battery)

1.6Kgs(not include battery)

Package:

1. Machine x 1pc

2. AC Adaptor x1pc

3. Optical fiber splicing fixture (3-in-1)x1set

4. Battery x1pc

5. Spare electrodes x 1set

6. Protection sleeve(60mm) x 25pcs

7. Cooling tray x 1pc

8. Operation manunal x 1pc

9. Carrying belt x 1pc

10. Carrying case with carrying strap x 1pc

11. Disk (with communication program, driver and Instructions )

Quick Reference Guide

The guide is for the basic operation. For the detailed information,

please refer to http: www.prokits.com.tw.

1. Power Supply: Two ways of supplying power to the fusion

splicer: a. internal battery;b. AC power supply. Please turn off

fusion splicer before operation.

1.1. Insert battery: Insert the battery into the battery groove.

Make sure it is properly fixed.

1.2. Remove battery: Push the battery out

1-3. Using AC Adaptor : Put the plug into socket as matching

the anchor point.

2. Turning on Splicer Power

Press power button to switch ON/OFF device.

3. Setting Fiber in Splicer

3.1. Open the windproof cover ;

3.2. Open the left and right sheath

clamps;

3.3. Put the stripped fiber on the V-groove,

and make sure the fiber end between

groove edge and electrode (as pic).

3.4. Holding the fiber and close the sheath

clamps carefully. If the fiber is not properly set, please

adjust it;

3.5. Repeat the steps 3.3 and 3.4 for second fiber;

3.6. Close the windproof cover.

4. Splicing Operation

4.1. Mode:Manual /Auto / Full-auto you can choose the

operation model in operation menu.

Manual: Fusion splicing operate step by step controlled

by the operator via the keypad.

Auto: Press the button, it will automatically core to

core alignment and fusion splicing.

Full-auto: Automatically operation after closed the

windproof cover

4.2. Fiber type: SM/MM/NZDS/ED

5. Pause function :

5.1. Turn on the pause function: under auto and Full-auto

mode, after core to core aligning the fiber, splicing

machine will stop, then press button, the splicer

began to fuse.

Turn off: no effect any splicing mode operation.

6. Take out the fiber and heat the fiber

1)Open the heater cover;

2)Open the windproof cover ;

3)Open the right and left sheath clamps;

4)Take out the fiber and move the fiber protection sleeve to

the splice point. Make sure the splice point in the center of

the fiber protection sleeve tube

5)Put the fiber protection sleeve on the heater, close the

heater cover;

6)Press button, and red indicator light will light up;

7)When the indicator light off , it means that the heating is

finished;

8)Open the heater cover, check if there are air bubbles in

protection sleeve;

9)Put the fiber on the cooling tray, until it cooling down

Please scan QR code or visit https://www.prokits.com.tw

for detail manual download