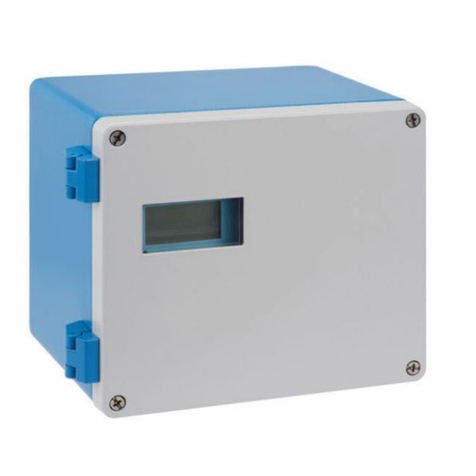

High Accuracy, Wide Range LCR Meter

Z9216

SPECIFICATIONS

30

Measured Components

L (inductance)

C (capacitance)

R (resistance)

Measured Circuit Configurations: series and parallel

Measurements

Resistance

Measured Parameter: R + Q

Measurement Ranges: R: 0.0001 Ωto 2000 MΩ

Q: 0.00001 to 50

Inductance

Measured Parameter: L + Q

Measurement Range: L: 0.0001 µH to 99999 H

Q: 0.0001 to 50

Capacitance

Measured Parameters: C + D and C + R

Measurement Range: C: 0.0001 pf to 99999 µF

D: 0.00001 to 10; R: 0.00001 KΩto 9999 KΩ

Display: Values, % deviation, or bin number

Test Environment

Test Frequencies: 100Hz, 120Hz, 1kHz, 10kHz and 100kHz

Frequency Accuracy: #±100 PPM

Drive Voltages: Fixed: 0.10, 0.25, 1.0 V RMS;

Vernier: 0.1 to 1.0 V RMS (50 mV resolution)

Drive Voltage Accuracy: ±2%

Measurement Rates:

(For test frequencies of 1kHz or greater):

Slow: 2 measurements/Sec

Medium: 10 measurements/Sec

Fast: 20 measurements/Sec

(For test frequencies of 100Hz and 120Hz):

Slow: 0.6 measurements/Sec

Medium: 2.4 measurements/Sec

Fast: 6 measurements/Sec

Bias Voltage: Internal: +2.0 V DC ±2%;

External: 0 to +40 V DC

Input Protection: 0.25A/250V Fuse

Ranging: Auto or manual

Triggering: Continuous, manual or remote (from the RS-232,

GPIB or handler interface)

Measurement Accuracy

Basic Accuracy: ± 0.2% with the following conditions:

1. An ambient temperature of 23°C ±5°C after a 30 minute

warm up period.

2. The short and open Cal has been performed.

3. D < 0.1 for capacitance, Q < 0.1 for resistance and Q > 10 for

inductance.

The component value, measurement rate and frequency

determine the actual measurement accuracy. (See the user

manual).

Zeroing Correction: Open and short circuit compensation

Remote Operation: Interfaces: RS-232 (25 pin D female

conductor) Standard GPIB and Handler (25 pin D male

connector optional)

General Specifications

AC Voltage Input: 120/220 Volts

Frequency: 50/60Hz

Power Consumption: 20 Watts

Operating Temperature: 0 to 50°C at < 80% Relative Humidity

Size: 4.3" H × 14.3" W × 14.5" D

Weight: 18 lbs.

Supplied Accessories: Manual, Line cord, Axial lead adapter

Optional Accessories: GPIB and Handler interface, Kelvin

clips, SMD tweezers

0.2% basic accuracy

Wide measurement range over13 orders of magnitude

Store and recall 9 instrument setups

Measurement rates to 20 times per second

Test frequencies are 100Hz, 120Hz, 1kHz, 10kHz and 100kHz

Displays component value and Q or Dissipation factor

Averaging for 2 to 10 measurements

RS-232 and optional GPIB and Handler interface

Open and short circuit compensation for accurate zeroing

Easy to use and calibrate

Built-in calibration procedures

Binning capabilities

K

K

K

K

K

K

K

K

K

K

K

K

Z9216

CE

Protek Test & Measurement

40 Boroline Road, Allendale, NJ 07401 Tel: 201-760-9898 Fax: 201-760-9888