Procom DGC-6D User manual

Cat/DCG-6D1I/07-08/03/Ver 1 Page 2/10

Index

1.1 Introduction

1.2 Salient Feature of the DGC-6D

1.2.1 Protection & Supervision

1.2.2 Measurement & Display

1.2.3 LED Indications

1.2.4 Timer

1.3 Function

1.4 Engine solenoid

1.5 Display

1.6 Programming Mode

1.6.1 Setting Table

1.7 Annunciation LED Functions

1.8 Switch Description

1.9 Fault

1.9.1 Internal Fault

1.9.2 External Fault

1.9.3 Fault Reset

1.10 Specification

1.11 Connection Diagram

Cat/DCG-6D1I/07-08/03/Ver 1 Page 3/10

DGC-6D

Automatic Engine Controller

1.1 Introduction

•The Microprocessor / microcontroller based DGC-6D automatic generator

start and supervisory device is designed keeping in view the ease of operation.

•Housed in 96 x 96 flush mounted enclosure, is an ideal replacement of logic

based AMF.

•The functions of the discrete logic based AMF units are built in to one single

compact device, resulting in simplified panel wiring and size reduction.

1.2 Salient features of the DGC-6D

1.2.1 Protection & Supervision:

•3 phase Under & Over voltage protection for EB supply (True RMS

measurement)

•Phase under & over voltage protection of Generator supply (True RMS

measurement)

•User programmable Cranking attempt.

•Generator over speed supervision

•DC Battery Voltage supervision (Under & Over voltage)

•External fault detection (2 digital inputs)

•External engine running signal

•DG Fail to Start supervision and indication

•DG fail to Stop supervision and indication

•Unit remains fully operational even if battery voltage falls to zero volts for one

sec.

1.2.2 Measurement & Display.

DGC-6D, equipped with four seven segment display, displays:

•

••

•

EB voltages of RYB phase

•

••

•

Generator voltage

•

••

•

Generator Current (Only in model DGC-6D1I)

•

••

•

DC battery voltage

•

••

•

Generator frequency

•

••

•

RPM

•

••

•

Cumulative Run Hour five digit

•

••

•

Set values

1.2.3 LED Indication

•Status Indication of Mains Supply (R,Y,B)

•Status Indication of Generator Voltage (G)

•Status indication of Battery Voltage (Vb)

•Generator frequency (Hz)

•Load on generator (GCB)

Cat/DCG-6D1I/07-08/03/Ver 1 Page 4/10

•Load on EB (MCB)

•Auto / Manual (Auto)

•Emergency fault (Emer)

•DG Fail to Start (FST)

•DG Fail to Stop (FSP)

•High Water Temperature (HWT)

•Low lube Oil Pressure (LLOP)

1.2.4 Timers

Following timers are incorporated in the DGC-6D1I:

•DG Start delay (variable)

•Generator Voltage Supervision (variable)

•Max. cranking time (variable)

•Crank gap time (variable)

•No of crank attempts (variable)

•Mains restoration time (variable)

•DG recooling time (variable)

•High Water temperature (Variable)

•Low lube Oil Pressure (Variable

•Generator over speed delay timer (Variable)

•Timer for stop solenoid (Variable)

1.3 Function

Auto/ Manual mode selection:

Press A/M button for 4 sec. On pressing the button the unit selects Auto or

manual mode. Auto LED glows when the unit is in auto mode. LED turns off I

manual mode.

Auto Mode

DGC-6D monitors the Mains supply, if Mains supply varies beyond set limit of

Under and Over voltage for more than Mains supervision time, DGC-6D starts the

genset.

To start the genset DGC-6D gives a cranking signal via potential free contact to

crank motor. On detection of engine start, started either by external engine start

input or by build up of generator voltage, the Crank command is withdrawn.

Max duration of crank command is user settable.

The maximum number of cranks is user programmable. Failure of starting of

generator after maximum-programmed crank attempts, result into blinking of FST

LED, indicating Fail to Start fault and the hooter is switched on.

While the genset is running, DGC-6D monitors the genset for external fault

LLOP, HWT, Emergency and voltage healthiness.

On detection of any fault, Gen-set is stopped by the DGC-6D after set time delay

& hooter is switched on.

On restoration of healthy EB supply for the set time duration the Gen-set is

stopped after recooling it for the user set recooling time.

Load change over is automatically performed by DGC-6.

Cat/DCG-6D1I/07-08/03/Ver 1 Page 5/10

Manual Mode / Test

In manual /Test mode the DG can start or stop by pressing Start and stop button

respectively. The main contactor can be switched on and off by pressing MCB

button and generator contactor can be switched on / off by pressing GCB button.

1.4 Engine solenoid Engine solenoid contact (Terminal 15 & 16) can be configured

in two modes

a. Mode 0: In this mode fuel solenoid contact changes from NO to close at

the time of cranking and remains close till the Genset is running. For

stopping the Generator this contact opens.

b. Mode 1: In this mode fuel solenoid contact remains open at the time of

cranking and till the Genset is running . For stopping the Generator this

contact closes for a user programmed time.

For changing the solenoid mode first press Reset button, than simultaneously

press GCB button . It’s a good practice to switch off and than switch on the

battery supply after changing the mode.

1.5 Display

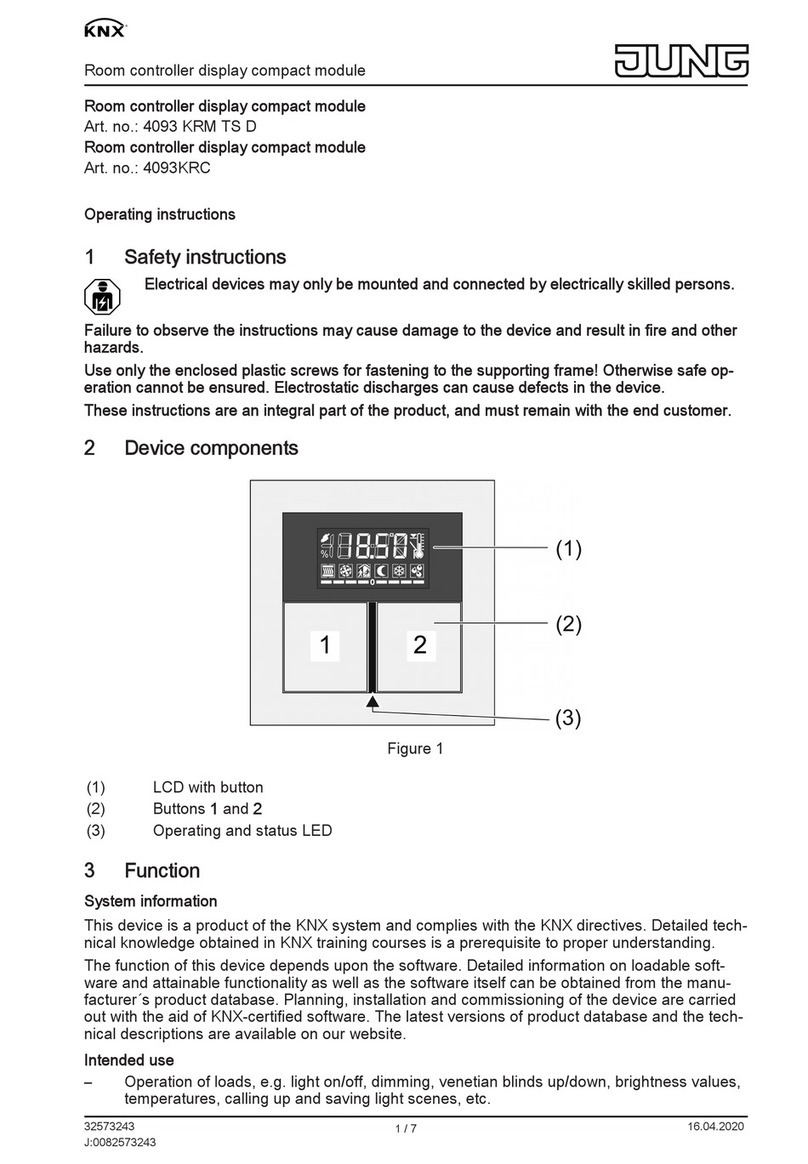

α) It LCD display, to display voltages. Beside the numeric display there are 14 LEDs

for annunciations

1.6 Programming mode

Programming mode can be entered any time by simultaneously pressing Reset & A/M

keys. The following table details the various programmable parameters:

1.6.1 Setting table

Sl.

No Parameter Explanation of parameter Default

setting Setting

Range

1 Mains Over

Voltage Max. permissible voltage, above this the

voltage is treated unhealthy & Genset is

started.

270V 80-300V

2 Mains Under

Voltage Min. permissible voltage, below this the

voltage is treated unhealthy & Genset is

started

180V 80-300V

3 Mains voltage

supervision time Time for which the mains voltage has to be

unhealthy (Under or Over voltage as

defined above in 1 & 2) before starting the

Generator.

10Sec 0-999Sec

4 Generator Start

Delay After opening the Mains MCB, Generator

starting is delayed by generator start delay

time

Disable 0-

999Sec.

5 Generator Over

Voltage Max. permissible voltage, above this the

voltage is treated unhealthy & the

Generator is stopped by releasing fuel

solenoid.

Generator contactor is released and mains

contactor is closed. Hooter shall be

activated .

270V 80-300V

6 Generator Under

Voltage Min. permissible voltage, below this the

voltage is treated unhealthy & the 180V 80-300V

Cat/DCG-6D1I/07-08/03/Ver 1 Page 6/10

Generator is stopped by releasing fuel

solenoid.

Generator contactor is released and mains

contactor is closed. Hooter shall be

activated

7 Generator

Supervision Time The time for which the Generator voltage

should, continuously be unhealthy to

generate a fault condition.

10Sec 0-999

Sec.

8 Generator O/S If the generator frequency goes beyond this

limit, genset shuts down immediately 65 Hz 40-80

Hz;

Disable

9 No. of Crank

Attempt The maximum number of Cranks that shall

be issued to start the Generator 3 1-10

10 Crank Time Maximum Crank time 10Sec 0-25Sec

11 Crank Delay The delay between two successive Cranks 5 1-100Sec

12 Gen. pickup

Voltage This is the ignition voltage of the genset 100V 80-150V

13 Generator warm up

time After switching on the genset the load is

put on the genset on elapse of generator

warm up time

10 Sec 0-999

Sec.

14 Mains Restoration

Time The time for which mains should be

continuously healthy before stopping the

Generator.

30Sec 0-999Sec

15 Generator

Recooling Time The time for which Generator is allowed to

run on no load before switching off 30 sec 0-999Sec

16 Stop solenoid time The time for which stop solenoid will be

kept active while stopping the engine 30Sec 0-100Sec

17 Low Fuel time

delay Time delay before this fault can be

activated.

Faults are described in details.

5 Sec 0-999Sec

18 LLOP Time delay Time delay before this fault can be

activated.

Faults are described in details.

5 Sec 0-999Sec

19 HWT Time delay Time delay before this fault can be

activated.

Faults are described in details.

5 Sec 0-999Sec

20 GCB to MCB time

delay Changeover time delay from generator to

mains 2Sec 1 –5 Sec

21 Hooter Reset Time Time for which the hooter is switched on

after fault 30 Sec 0-999

Sec.

22 Over Current If the Current increase beyond this setting

the genset shuts down after the O/C delay

(Available only in DGC-6 with single

phase mains monitoring)

25 1 –70

Amp

23 O/C Delay Time for which the current has to be above

overcurrent setting before initiating shut

down process

(Available only in DGC-6 with single

10 0-999

Sec.

Cat/DCG-6D1I/07-08/03/Ver 1 Page 7/10

phase mains monitoring)

24 CT Ratio Current Transformer ratio

(Available only in DGC-6 with single

phase mains monitoring)

10 1-199

1.8 Switches Description:

S.No. Switch

Symbol Switch

Function Description

1

OR A/M Next Normal operation mode: In this mode, next is used

to select the voltages on the display. The default

voltage is mains R Phase voltage. Y Phase, B Phase.

Generator voltage & Battery voltage can be selected

by pressing next. The corresponding LED shall light

up to indicate the parameter that is displayed.

Programming Mode: Next key is used to select the

next parameter to be programmed.

When pressed for more than 4 sec. It toggles the

mode from auto to manual and vice versa.

2

OR Start Increment

or start This key is only active during programming mode

and is used to increment the value of the parameter

under programming.

In manual mode this key may be used for ignition /

crank command to DG

3

-

OR Stop Decrement This key is only active during programming mode

and is used to decrement the value of the parameter

under programming.

In manual mode this key may be used to stop the

DG.

4 Reset Reset Reset key resets the Hooter and Fault signals.

The first press shall reset the hooter and next shall

reset the faults. A long press of 1 Sec shall reset

both.

5 MCB Mains

contactor on

/ off

Mains contactor can be switched on or switched off

by pressing this key.

6. GCB Generator

contactor on

/ off

Generator contactor can be switched on or switched

off by pressing this key.

1.9 Faults

There are two categories of faults

1) Internal Faults

2) External faults

1.9.1 Internal Faults

Internal faults are the faults, which do not need any external signals and are detected by

the system itself. They are:

Cat/DCG-6D1I/07-08/03/Ver 1 Page 8/10

i) Generator Fails to Start. Corresponding LED blinks and hooter is activated

ii) Generator Voltage Unhealthy. Corresponding LED blinks and hooter is

activated

iii) Generator Fails to Stop. Corresponding LED blinks and hooter is activated

iv) Over-Speed. Corresponding LED blinks, hooter is activated & Genset stops.

v) Battery Under or Over voltage. Corresponding LED blinks.

1.9.2 External Faults:

Those faults which cannot be sensed by the unit itself (these faults are not reflected by the

generator voltage) and are to be provided externally. The external faults could be Low

Lube Oil Pressure, High Water Temperature, emergency stop etc.

There is provision to connect three such faults externally.

i) LLOP: This fault can only be activated while the generator is running. If the

genset is off because the Mains is available or some other fault have switched

off the generator this fault shall be inactive.

ii) HWT & Low fuel: This fault always remains active irrespective of Generator

condition (ON or OFF).

This fault is also provided with variable timer, and is generated after the

expiry of programmed ” HWT / Emergency Time delay”. This fault can be

used for emergency stop or it can be used for High Water Temperature

19.3 Fault Reset

ι) Internal Faults: All internal faults can be reset by pressing reset Key.

ιι) LLOP: This fault can be reset by pressing reset Key.

ιιι) HWT /Low fuel: This fault cannot be reset till the conditions creating this

fault are not cleared. Until this fault is cleared the Generator shall not start.

Contacts after the fault conditions: Immediately after activation of any

faults the Generator is stopped. The Generator Circuit Breaker contact is

released, and after 125millsec delay the load is transferred to Mains Supply.

The hooter is active for 30 second if not reset during this period.

Type of Contacts: All contacts are normally open (NO) type except the

Mains Circuit breaker contact which is Normally Closed (NC) type.

1.10 Specifications

AC voltage withstand 330 VAC continuously (Phase to neutral)

Measurement Accuracy 1%

Surge 1.2/50Usec 2.5KV

Battery Voltage Suitable for 12V/24 VDC System

Max. Battery Voltage 35V

DC Interruption time 1 Sec.

Out Put Contact 5 NO

Contact Rating 230V / 6A

Cut out Dimensions 90mm X 90mm

Cat/DCG-6D1I/07-08/03/Ver 1 Page 9/10

Depth 120mm

Digital Input Level Battery Voltage (Negative)

1.12 Connection Diagram dgc-6d

1.13 Connection Diagram dgc-6d1I

It is our endeavour to constantly upgrade our products, hence specifications are subject to change without any notice.

Cat/DCG-6D1I/07-08/03/Ver 1 Page 10/10

Cran

k

Fuel

Hooter

Mains

Gen

Batt +

Batt - Vr

Vy

Vb

Sup- N

Vg

LLOP

HWT

Low fuel

1

2

3

5

7

9

8

18

17

15

14

13

11

10

V+

V-

_-

12

16

4

Gen-N

6

Cran

k

Fuel

Hooter

Mains

Gen

Batt +

Batt - Vr

Sup-N

CT1

CT2

Vg

LLOP

HWT

Low Fuel

1

2

3

5

7

9

8

18

17

15

14

13

11

10

V+

V-

_-

12

16

4

Gen-N

6

This manual suits for next models

1

Other Procom Controllers manuals