Procom ECON-F User manual

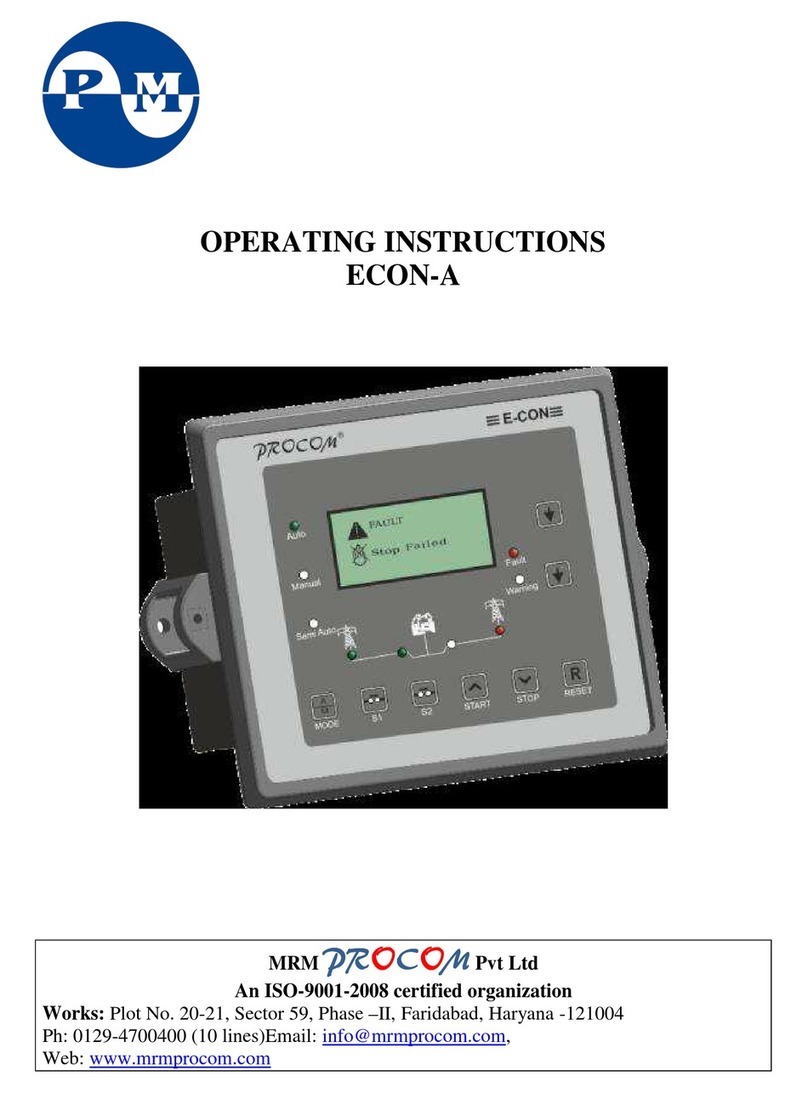

OPERATING INSTRUCTIONS

ECON-F(GC)/F(4C)

Operating Instructions Page - 1

INDEX

1. Introduction

2. Protection, Supervision Salient features

3. Digital Output

4. Digital Input

5. Indication

6. Front Panel Switch

7. Setting Procedure

8. Technical Specification

9. Analog Channel Data

10. Wiring Diagram

11. Dimensional Drawing

1.0 Introduction

lECON- F(GC)/F(4C) is an Engine Control / Protection Unit for engines

used for NON DG applications.

lThe controller can measure signals from either MPU or charging

alternator to calculate RPM.

lECON provide choice of Varity of sensor selection from predefined

selection chart

lIn critical operation it is possible to disable or debar tripping of engine via

an external digital input.

l128x64 pixel graphical display enhance convenience in configuration of

controller.

2.0 Protection, Supervision Salient Features

Protection

Low Lube Oil Pressure(LLOP)l

High Water Temp. (HWT)l

Fuel Level l[In ECON-F(4C)only]

Emergency off l

Oil Temperature .l

Charging Alternator Fail/V-Belt failurel

Display and Measurement

Battery Voltagel

Engine Run Hourl

RPMl

Oil Pressure in KG/cm2l

Water Temp in degree centigradel

Oil Temp in degree centigradel

Fuel Level in % l[In ECON-F(4C)only]

Service Hourl

3.0 Digital Output

Seven digital output (Six negative and one positive) are available, four

output contacts programmable

.

Start/Crank (Battery Negative)l

Charging Alternator (Battery positive)l

Solenoid (Battery Negative)l

Annunciation 1 (Battery Negative)l

Annunciation 2 (Battery Negative)l

Annunciation 3 (Battery Negative)l

Annunciation 4 (Battery Negative)l

Hooter (Battery Negative)l

Page - 2

Operating Instructions

Page - 3

4.0 Digital Input

ECON can measure / detect three Analog, seven digital and one pulse

input. These inputs are as mentioned below.

1. Fuel Sensor : Resistive sensor can be connected to fuel sensor

terminal(1). Pre Programmed sensor value (Listed in TABLE 5.1) can

be assigned to fuel input [In ECON-F(4C)only]

2. LLOP Sensor : Resistive sensor can be connected to LUBE OI

PRESSURE terminal(2). Pre Programmed sensor value (Listed in

TABLE 5.1) can be assigned to LOP input

3. HWT Sensor : Resistive sensor can be connected to Water

Temperature terminal(3). Pre Programmed sensor value (Listed in

TABLE 5.1) can be assigned to WT input

4. Oil Temp sensor : resistive sensor can be connected to Oil Temp

sensor terminal (4). Pre Programmed sensor value (Listed in TABLE

5.1) can be assigned to Oil Temp input

5. LLOP Switch : Oil pressure switch can be connected to LOP switch

terminal (8) . The input is activated on connection of DC negative at

terminal no. 8. on activation stop command is issued to the engine and

the fault is indicated on front LED.

6. HWT Switch : Water Temperature switch can be connected to HWT

switch terminal (9) . The input is activated on connection of DC negative

at terminal no. 9. on activation stop command is issued to the engine

and the fault is indicated on front LED

7. Oil Temp Switch : Oil Temp level switch can be connected to Oil Temp

level switch terminal (10) . The input is activated on connection of DC

negative at terminal no. 10. on activation stop command is issued to the

engine and the fault is indicated on front LED

8. Emergency Off : The input is activated on connection of DC negative

at

terminal no. 11. on activation stop command is issued to the engine and

the fault is indicated on front LED

9. Protection Debar : The input is activated on connection of DC negative

at terminal no. 12. on activation ECON disable trip function on all the

faults.

10. Remote Start : ECON issues start command to engine on receipt of

DC negative at remote start terminal

11. Remote Stop : ECON issues stop command to engine on receipt of DC

negative at remote stop terminal

5.0 Indication

Listed below are the two LED indication available on front of ECON-F/P

Warning : Blinks in case of sensor open or on low fuel warning

Operating Instructions

Page - 4

6.0 Front Panel Switch

ECON – F/4C has four switch provided on its front panel. Switch can h

more than one functions assigned to them. The table below describes the

operation of these

7.0 Setting Procedure / Menu

ECON is user/site configurable. User can view all parameters, fault history,

events no. of start/stop and can also edit, system parameter (password

protected), engine / generator parameter, annunciation setting,RS485

parameter clock and password. Following is the sequential procedure to

edit. view all the menu and submenus

Press “R” & “Enter“ switch simultaneously.

The LCD shall display, “System Parameter”

1. System Parameter

lSystem parameter are password protected.

lTo enter “system parameter” press “Enter”.

lECON will request for password, LCD will display “ Enter Password”

lSystem parameter can be edited by entering correct password or else

can be viewed by entering “0” as password.

2. Engine / Generator Parameter

lTo go to next menu after system parameter, press “Increment”.

lThe LCD shall display “Generator Parameter”.

lGenerator parameter can modified / viewed by pressing “Enter”.

(for setting details pls refer table 5.1)

Switch

Symbol

Switch

Function

Description

Increment

/Start

Programming Mode: It is used to increment

the value of the parameters under

programming. & it is used to issue the crank/

start command to DG

Decrement

/Stop

Programming mode: It is used to decrement

the value of the parameter under programming

&. It is used to issue the stop command to DG

Next

Normal operation mode: In this mode, it is

used to change the parameters being displayed

on LCD.

Programming Mode: Next key is used to

select the next parameter to be programmed.

Reset

Either to reset the fault / Or press enter and

reset together to select programming mode.

Operating Instructions

3. Annunciation Setting

l To go to next menu after generator parameter, press “Increment”.

l The LCD shall display “annunciation setting”.

l Annunciation settings can modified / viewed by pressing “Enter”.

(for setting details pls refer table 5.1)

4 RS-485 Parameter In ECON F (4C) only

l To go to next menu after Annunciation Setting, press “Increment”.

l The LCD shall display “ ”.RS-485 parameter

l can modified / viewed by pressing “Enter”.RS-485 parameter

(for setting details pls refer table 5.1)

5. Display History

l To go to next menu after annunciation press “Increment”.

l The LCD shall display “Display History”.

l Trip record / history can be viewed by pressing “Enter”.

l ECON keep a record of last 32 tripping with date and time stamp.

l Tripping records are updated on first in first out basis

6. Display Event

l To go to next menu after history press “Increment”.

l The LCD shall display “Display Event”.

l Display Event can be viewed by pressing “Enter”.

l ECON keep a record of last 32 event with date and time stamp.

l Event record is updated on first in first out basis.

7. Display Start Stop

l To go to next menu after event press “Increment”.

l The LCD shall display “Display Start / Stop”.

l Start Stop can viewed by pressing “Enter”.

l ECON keep a record of last 100 start and stop event with date and time

stamp.

l Start/ stop record is updated on first in first out basis.

8. Reset Service Alarm

l To go to next menu after Start-Stop press “Increment”.

l The LCD shall display “Reset Service Alarm”.

l Service due hour can be reset by pressing start button after entering in

to this menu.

9. Adjust Clock

l To go to next menu after Service Alarm press “Increment”.

l The LCD shall display “Adjust Clock”.

l Time can be modified / viewed by pressing “Enter”.

Page - 5

Operating Instructions

Page - 6

10. Reset Password

l To go to next menu after annunciation press “Increment”.

l The LCD shall display “Reset Password”.

l Password can be modified by pressing “Enter”

l ECON will request for the present password, after feeding correct

password change password will be requested and the password will be

replaced by new password on pressing start button..

Parameter Mode

Parameter

Options/Limits

Description

Default Setting

A. System Parameter

System parameters are the parameters which are programmed once

during initial installation and does not require frequent changes. As these

are critical parameter and hence are password protected. It is possible to

view system parameter without knowing the password but editing is

possible only after entering correct password

All system parameters are listed below along with their default value and

minimum / maximum variation range. Values can be increased or

decreased by pressing up/start and down/stop button respectively . Next

parameter can be selected by pressing next button

Solenoid

Type

1: Pull to Start

2: Pull to Stop

Pull To Start

In this mode fuel solenoid

contact changes from Open

to Close at the time of

cranking and remains close

till the genset is running. For

stopping the generator this

contact opens.

Pull To Stop

In this mode fuel solenoid

contact remains open at the

time of cranking and till the

genset is running. For

stopping the generator this

contact closes for a user

programmed time.

Pull to Stop

Operating Instructions

LLOP

Sensor

1: Type A

2: Type B

3: M&M

4: MNEPL

5: VE

6: TMTL

7: HUAFANG

8: TATA

9: GC(VDO)

10:

GC(Murphy

11: MVD

12: Disabled

Select the installed sensors. If

no sensor is installed select

“Disabled”

Type A

Oil Temp

Sensor

1: Type A

2: Type B

3: M&M

4: MNEPL

5: VE

6: TMTL

7: HUAFANG

8: TATA

9: GC(VDO)

10:GC(Murph

y

Select the installed sensors. If

no sensor is installed select

“Disabled”

Type A

Fuel

Sensor

1: Type A,

2: Sam-0,

3: Sam-1,

4: Disabled*

Select the installed sensors. If

no sensor is installed select

“Disabled”

Type A

HWT

Sensor

1: Type A

2: Type B

3: M&M

4: MNEPL

5: VE

6: TMTL

7: HUAFANG

8: TATA

9: GC(VDO)

10:GC(Murph

y

Select the installed sensors. If

no sensor is installed select

“Disabled”

Type A

Page - 7

Operating Instructions

Sensor

Open

1: Warning

2:Fault

3: Disabled

The action to be taken if the

sensor is found to be open.

Warning

Pulses/Re

volution

1-300

No of pulses, from Magnetic

Pickup unit or W point of

charging alternator, in one

revolution of the engine. This

shall be used to calculate the

RPM.

132

Page - 8

Operating Instructions

Start Stop

Config

1: Separate

keys

2: Only Start

key

This parameter decides as to

how the remote start and stop

shall be done. Option 1:

Separate keys is selected

than a single pulse on remote

start shall the engine and

another pulse on remote stop

shall stop the engine. The

duration of these pulses

shall be more than 200msec.

Option 2: In this option the

engine shall be stated and

kept working till Remote start

is pulled low. As soon as the

pin is released the engine

shall stop. To attempt a new

start cycle, after the engine

fails to start, the remote start

pin must be released for some

time and again pulled low.

* Option 2 should not be

selected if the start and stop

functions are to be executed

from front keys.

Separate

keys

B. Engine/Generator Parameter

All the Engine programmable parameters are listed below along with their

default value and minimum / maximum variation range. Values can be

increased or decreased by pressing up/start and down/stop button

respectively . Next parameter can be selected by pressing next button.

Maximum

RPM

600-4000

Maximum allowed RPM of

Engine. Engine running at speed

above this is treated as over

speeding and a fault

is registered and engine stopped.

1600

Minimum

RPM

600-4000

Minimum allowed RPM of

Engine.running at speed below

this is treated as over speeding

and a fault is registered and

engine Stopped.

1400

RPM

Delay

1-999 Sec

Duration for which engine is

allowed to operated outside the

set RPM limits. If it continues to

operate beyond the limits for

more than the

set time a fault condition is

registered and engine stopped.

5

Pick Up

RPM

80-1000

The engine stalling RPM. This

parameter defines the RPM

above which the engine will not

stall and

hence can be treated as running.

This is used to detect the engine

running condition after crank.

1000

Service

Due Hour

10-999Hrs

Service due warning is generated

after the engine has logged these

many hours.

250

Oil temp

Trip Level

40-250oC

The maximum OIL temperature

up to which the engine is allowed

to operate.

o

95 C

Oil temp

trip delay

1-999Sec

Monitoring time for the Oil temp

level to avoid false tripping of the

engine.

10

UUU

Page - 9

Operating Instructions

Fuel Warn

Level #

25 %

Monitoring value of fuel level below

which fuel level warning is

generated.

Disable*

11-80 %

Fuel Warn

Delay #

10 Sec

Monitoring time of fuel level after

which fuel level warning is

generated.

1-999Sec

Fuel Trip

Level #

15 %

Monitoring value of fuel level below

which fuel level trip is generated.

10-80 %

Fuel Trip

Delay #

10 Sec

Monitoring time of fuel level after

which fuel level trip is generated.

1-999 Sec

LLOP Trip

Level

0.4-

2

8.5Kg/cm

The minimum lubricant oil pressure

on which the engine is allowed to

operate. A drop of pressure below the

set limit shall trigger a fault condition

thereby stopping the engine

2

1.0Kg/cm

Page - 10

Operating Instructions

LLOP

Trip Delay

1-999

Sec

Duration for which the low lubricant

oil pressure can be tolerated.

5

HWT trip

level

o

40-250 C

The maximum coolant

temperature up to which the engine

is allowed to operate.

o

95 C

Page - 11

HWT Trip

delay

1-999 Sec

The duration for which the engine

is allowed to operate at

temperature higher than the

above set maximum temperature

5

ChgAlt-

Vbelt

1-999Sec

Disabled

While the engine is running and

the Charging alternator pin is not

pulled low for this duration it is

assumed that either the charging

alternator or V-Belt has failed

thereby generating a fault ondition

and stopping the engine.

Disabled

Crank On

Time

1-10 Sec

The maximum duration for which

the engine can be cranked

continuously. In case engine fails

to start another attempt to start

shall be attempted after some

time.

5

Hooter

On Time

1-999 Sec

Duration for which the hooter

shall be . This setting is only

available if the hooter is assigned

to an DO.

15

Solenoid

On Time

1-60 Sec

The duration for which the Pull

solenoid can be continuously

energized while trying to stop the

engine.

22

Operating Instructions

Auto

Scroll

1: Enabled

2: Disabled

Can be used to stop/start the

automatic scrolling of the display

parameters.

Enabled

C. Annunciation Setting

It is possible to freely assign digital outputs to different fault. There are four

(ANN1 , ANN2, ANN3 and ANN4) field programmable output.

It is also possible to assign same digital output to more than one fault( e.g.

ANN1 can be assigned to fuel fault and HWT fault both, in this case ANN1

will activate on both the faults.

Ann oil

temp

fault

1: No Annunciation

2:On DO Ann1

3:On DO Ann2

4:On DO Ann3

5:On DO Ann4

If desired, the oil temp fault can

be announced at one of the

annunciation Digital Output.

No

Annun-

ciation

Ann

Fuel

Fault

1: No Annunciation

2:On DO Ann1

3:On DO Ann2

4:On DO Ann3

5:On DO Ann4

If desired, the Low Fuel fault

can be announced at one of the

annunciation Digital Output.

No

Annun-

ciation

Ann

HWT

Fault

1: No Annunciation

2:On DO Ann1

3:On DO Ann2

4:On DO Ann3

5:On DO Ann4

If desired, the High water

temperature fault can be

announced at one of the

annunciation Digital Output.

No

Annun-

ciation

Ann

LLOP

Fault

1: No Annunciation

2:On DO Ann1

3:On DO Ann2

4:On DO Ann3

5:On DO Ann4

If desired, the LLOP fault can

be

announced at one of the

annunciation Digital Output.

No

Annun-

ciation

Ann

RPM

Fault

1: No Annunciation

2:On DO Ann1

3:On DO Ann2

4:On DO Ann3

5:On DO Ann4

If desired, the Over/Under

speed fault can be announced

at one of the annunciation

Digital Output.

No

Annun-

ciation

Announce

Unit

OK

1: No Annunciation

2:On DO Ann1

3:On DO Ann2

4:On DO Ann3

5:On DO Ann4

If desired, the healthiness of the

controller can be announced at

one of the annunciation Digital

Output

No

Annun-

ciation

D. RS-485 Parameter #

Device Id

Modbus device ID

1

1-247

Baud Rate

RS 485 Communication Baudrate

9600

1200

2400

4800

9600

19200

Page - 12

Operating Instructions

Parity

RS 485 Communication Parity Bits

None

Even

Odd

None

Stop Bit

RS 485 Communication Stop Bits

1

1

2

E Reset Service Alarm

Press INC to Reset

Press DEC to esc

F Adjust Clock

Automatic real time based DG Start

& Stop (Manual Controller

Configuration) RTC Time and Date

can be easily entered

00.00

00.00

DD/MM/YY

YY

G Reset Password

Three digit password protection for

system settings

Password can be change easily.

8.0 Technical Specification

AC voltage withstand 330 VAC, Continuously, (Phase to

neutral)

Frequency Range 40-70 Hz

Measurement Accuracy

Voltage & Current ± 2%

Frequency ± 0. 05 Hz.

Surge 1.2/50Usec 2.5KV

Auxiliary Voltage 8-35V/DC OR 50-300 V AC/DC

Contact Rating 230 VAC, 5A

Humidity 95 %

Page - 13

Operating Instructions

• 9.0 Analog Channel Data

9.1 High Water Temperature Sensors Data :

Continues on Next Page

Temp.

Resistance in ohms

In °C

Type A

Type B

M&M

MNEPL

VE

Huafang

TATA

GC

(VDO)

GC

(Murphy)

TMTL

Water

0

3282

1525

3282

3282

2363

2900

3192.6

3417

10613

3512

5

2765

1319

2765

2765

1873

2199

2461.1

2609

7764

2707

10

2247

1112

2247

2247

1383

1684

1914.6

2011

5743

2106

15

1730

906

1730

1730

1111

1301

1502.7

1564

4292

1653

20

1212

700

1212

1212

839

1015

1189.2

1227

3240

1308

25

1036

570

1036

1036

683

798

948.4

970

2469

1043

30

860

440

860

860

527

632

762.1

773

1898

838

35

684

365

684

684

434

505

616.7

621

1472

678

40

508

287

508

508

340

406

502.5

520

1050

552

45

426

260

426

426

283

327

412

438

885

453

50

343

232

343

343

226

247

340

356

720

374

55

291

205

291

291

190

214

282.1

288

560

310

60

238

178

238

238

154

187

235.5

220

410

259

65

203

151

203

203

131

154

197.6

183

360

217

70

167

123

167

167

107

120

166.6

145

300

183

75

144

96

144

144

92

101

141.2

128

240

155

80

120

69

120

120

76

85

120.2

110

193

132

85

104

62

104

104

66

74

102.8

95

160

113

90

88

54

88

88

55

62

88.3

80

145

97

95

77

46

77

77

48

55

76.2

71

120

83

100

66

38

66

66

41

47

66

61

100

72

105

58

35

58

58

36

41

57.4

52

90

63

110

50

31

50

50

30

36

43.8

45

80

55

115

45

27

45

45

27

31

38.5

40

70

48

120

39

23

39

39

23

27

33.9

34

55

42

125

34

19

34

34

21

24

30

30

45

37

130

30

15

30

30

18

21

26.6

27

38

33

135

27

11

27

27

16

18

23.7

23

33

29

140

25

0

25

25

14

15

21.1

21

29

26

145

23

0

23

23

12

12

18.9

18

25

23

150

21

0

21

21

10

10

16

22

20

Operating Instructions Page - 14

9.1 High Water Temperature Sensors Data :

S.No

.

Temperature in °C

Resistance in ohms

TMTL AIR3C

TMTL AIR1C

1

80

300

300

2

85

279.3

273.1

3

90

258.5

246.2

4

95

237.8

223.8

5

100

217

208.5

6

105

201.3

193.1

7

110

185.5

177.7

8

115

169.8

162.3

9

120

154

146.9

10

125

138.3

131.5

11

130

122.5

116.2

12

135

106.8

100.8

13

140

91

85.4

14

145

76.3

70

15

150

61.5

57.3

16

155

46.8

44.7

17

160

32

32

18

165

30.3

30.3

19

170

28.5

28.7

20

175

26.8

27

21

180

25

23.6

22

185

22.3

20.2

23

190

19.5

16.8

24

195

16.8

13.4

25

200

14

10

26

205

13

27

210

12

28

215

11

29

220

10

Operating Instructions Page - 15

9.2 Low Fuel Sensors Data :

Operating Instructions Page - 16

S.No.

Fuel in %

Resistance in ohms

Type A

Sam_0

Sam_1

Electronics

Linear

1

0

0

14

10

10

10

2

5

5

18

18.5

19.5

18.5

3

10

10

22

27

29

27

4

17

17

29.5

35.5.

38.5

35.5

5

20

34

37

44

48

44

6

25

51

55.5

52.5

57.5

52.5

7

30

68

74

61

67

61

8

35

85

92

69.5

76.5

69.5

9

40

102

110

78

86

78

10

45

110.5

124.5

86.5

95.5

86.5

11

50

119

139

95

105

95

12

55

127.5

149

103.5

114.5

103.5

13

60

136

159

112

124

112

14

65

144.5

165

120.5

133.5

120.5

15

70

153

171

129

143

129

16

75

157.7

172.5

137.5

152.5

137.5

17

80

162.3

174

146

162

146

18

85

167

176

154.5

171.5

149.5

19

90

171.7

178

163

181

153

20

95

176.3

181

171.5

190.5

166.5

21

100

180

184

180

200

180

9.3 Low Lube Oil Pressure Sensors Data

Operating Instructions Page - 17

Pressure

Resistance In Ohms

2

In Kg/cm

Type A

Type B

M&M

MNEPL

Volvo

TMTL

Huafang

TATA

GC

(VDO)

GC

(Murphy)

0

10

10

10

10

15

10

10

10

10

240

0.5

16.5

20

16.5

20.5

19.5

21

20

20.5

20

214

1

23.5

30

23.5

31

24

32

30

31

30

189

1.5

30.2

40

30.2

41.5

28.5

43

40

41.5

41

166

2

37

50

37

52

33

54

50

52

52

147

2.5

49.5

58.7

49.5

70

40.5

62.7

58.7

61

61

129

3

62

67.5

62

88

48

71.5

67.5

70

70

115

3.5

74.5

76.2

74.5

106

54.5

80.2

76.2

79

79

102

4

87

85

87

124

61

89

85

88

88

91

4.5

96

93.5

96

142

63.5

97.7

93.5

97

97

81

5

105

102

105

160

66

106.5

102

106

106

71

5.5

114

110.5

114

178

72.5

115.2

110.5

115

115

61

6

123

119

123

196

79

124

119

124

124

51

6.5

133.5

127.2

133.5

214

82

132.7

127.2

132

132

41

7

143

135.5

143

232

85

141.5

135.5

140

139

31

7.5

152.5

143.7

152.5

250

87.5

150.2

143.7

148

146

24

8

162

152

162

268

90

159

152

156

152

20

8.5

171.5

159

171.5

286

95

167.7

159

164

159

16

Page - 18

10.0 Wiring Diagram

Operating Instructions

11.0 Dimensional Detail

Table of contents

Other Procom Controllers manuals

Popular Controllers manuals by other brands

Atomic Workshop

Atomic Workshop Zombie Leaflet

Cass Technology

Cass Technology CASTLE S SERIES Technical operation guide

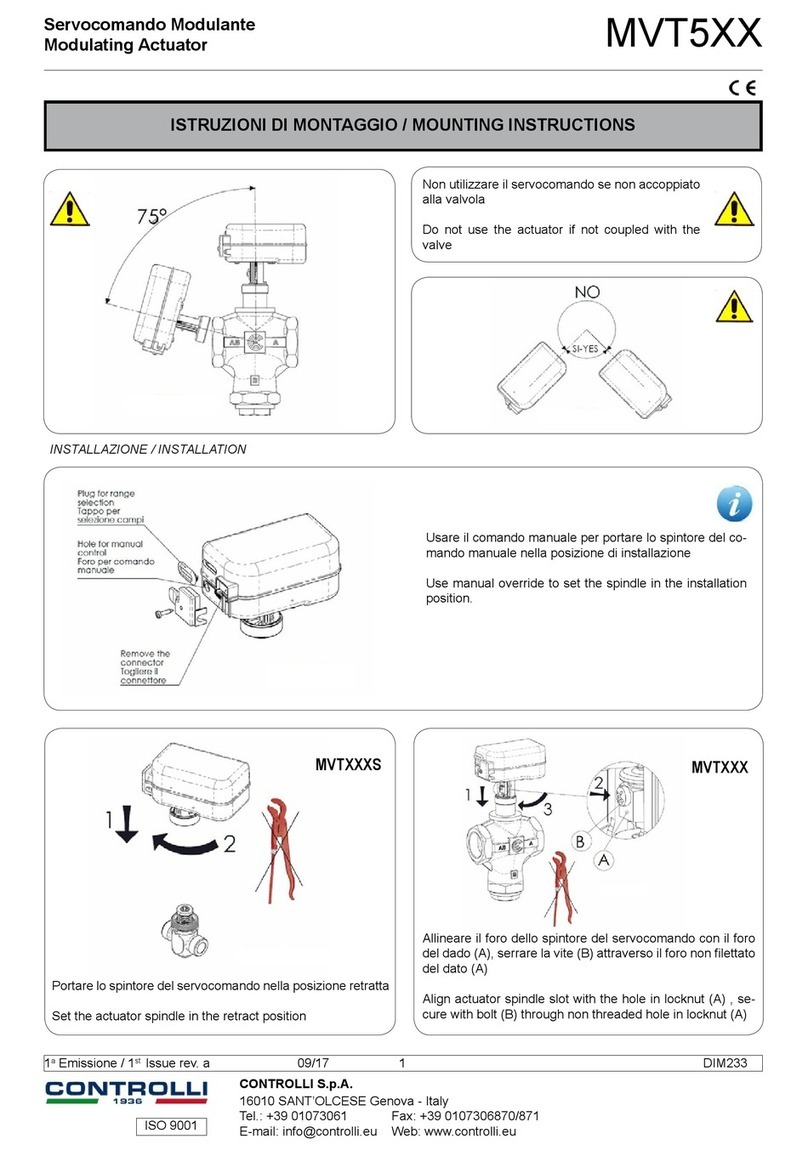

Controlli

Controlli MVT5 Series Mounting instructions

Wiznet

Wiznet WizFi360 Series quick start guide

Aprimatic

Aprimatic ST450N Fitting instructions

Leviton

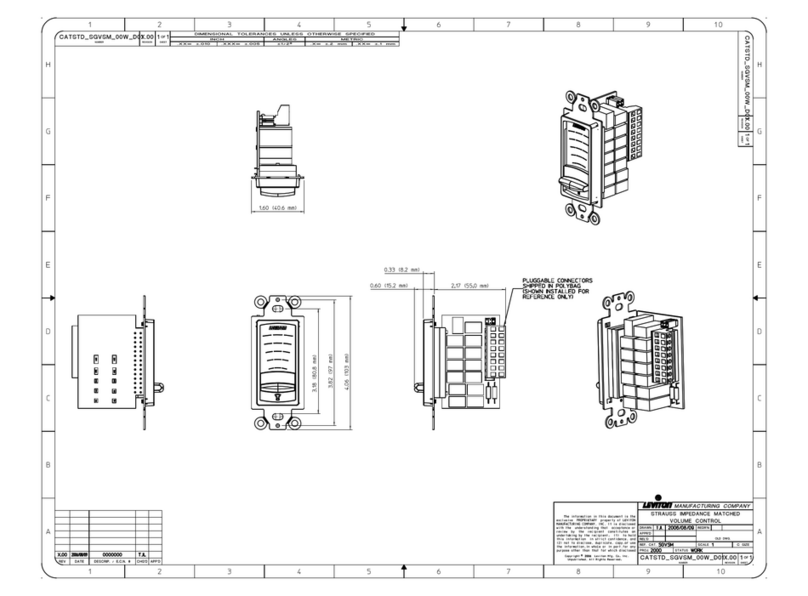

Leviton SGVSM-00W Dimension Guide

SECOP

SECOP 101N07 Series operating instructions

Cisco

Cisco 2504 Getting started guide

Johnson Controls

Johnson Controls VMA1617 installation guide

SMC Networks

SMC Networks AR20S 02E-Y 15V Series Operation manual

Compur Monitors

Compur Monitors Statox 501 Operation instructions

IEI Technology

IEI Technology VWBOX-E133 user manual