Procom DGC-202 Series User manual

PR C MO O ®

Installation Guide

Rev.-01

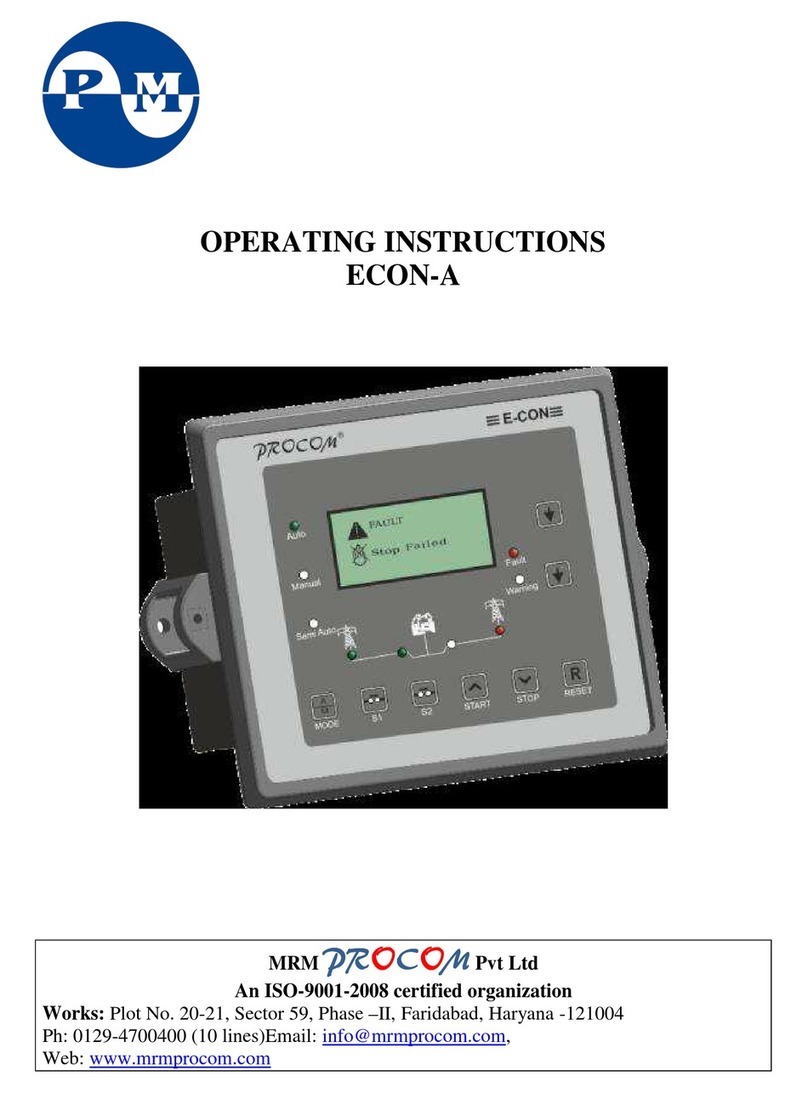

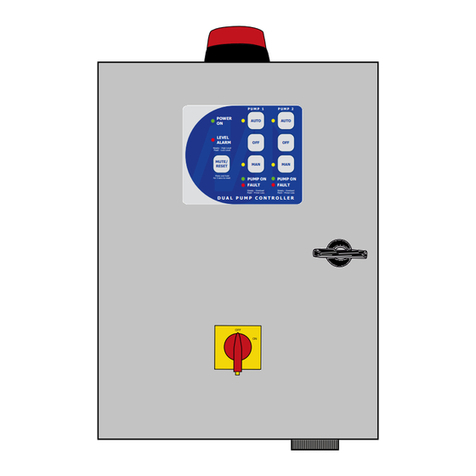

OPERATING INSTRUCTIONS

DGC-202X

INDEX

1.0. Introduction

2.0. Model selection

3.0. Specifications

4.0. Salient features, Measurement, Protection & Supervision

5.0. Digital Inputs Outputs

6.0. Modes of Operation

7.0. Analog Sensors in Details

8.0. Records

9.0. Installation

10.0. Display/ Front Panel

11.0. Icons

12.0. Keys and Leds Description

13.0. Lamp Test

14.0. Setting Procedure

15.0. In Built Parameter

16.0. Current Unbalance Calculation

17.0 Technical Specifications

18.0. Dimensions

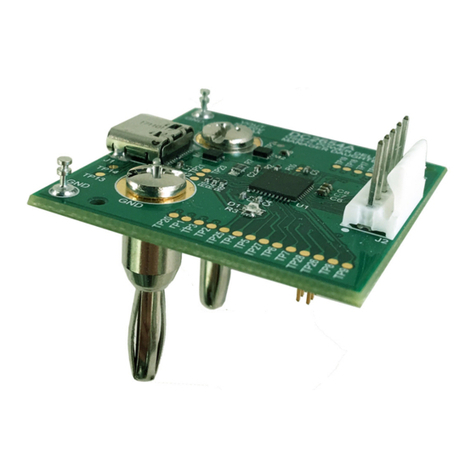

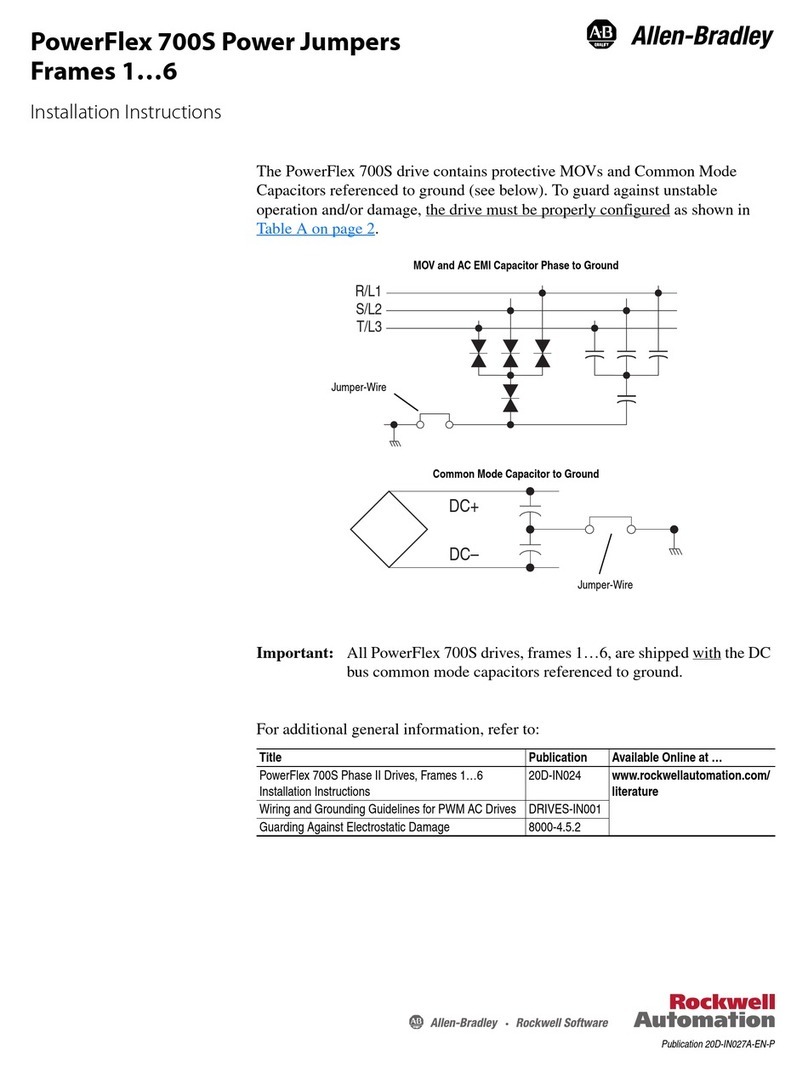

Connection type

Two-part connector.

•Male part fitted to module

•Female part supplied in module

packing case - Screw terminal, rising

clamp, no internal spring.

Example showing cable entry

and screw terminals of a 10

way connector.

1.0. Introduction

This document details the in-built features, operating procedure requirements of the DGC202X

Series modules. This document is subject to changes without prior notice.

DGC202X series is designed on a common platform and provided variants for different level of

functionality and economics. This allows system designers greater flexibility in the choice of

controller to use for a specific application.

The DGC202X series module has been designed to allow the operator to start and stop the

generator manually or automatically and transfer the load to the generator automatically.

DGC202X automatically starts and stops the generator set depending upon the status of the

mains (utility) supply. The user also has the facility to view the system operating parameters on

LCD display. Additionally, a special mode, Test Mode, is incorporated to facilitate easy debugging

during the building and testing a genset.

The DGC202X module monitors the engine, indicating the operational status. On detection of

faulty conditions, it automatically shutting down the engine. The LCD display indicates the fault

and warning.

The powerful microcontroller contained within the module allows for incorporation of a range of

complex features:

• Icon and Description based LCD display

• True RMS Voltage, Current monitoring

• USB Communications

• Engine parameter monitoring.

• Fully configurable inputs for use as alarms or a range of different functions.

• CAN bus for Engine ECU interface.

• Isolated and Protected RS485 with Modbus.

• Canopy Fan Current Monitoring for Air Cooled Engines.

A robust plastic case designed for front panel mounting houses the module. Connections are via

locking plug and sockets connectors.

All parameters can be changed from the module’s front panel, USB or RS485 communication.

Access to Program/Modify the parameter, through front keys, is protected through a password.

Model

RS485

Fan Current

DGC2020

x

x

DGC2021

√

x

DGC2022

x

√

DGC2023

√

√

2.0 Model selection

3.0. Specifications

3.1 Terminal Specification

3.2Power Supply Requirements

Minimum supply voltage

8V continuous

Cranking dropouts

Able to survive 0V for 400mS providing the

supply was at least 10V before the dropout and

recovers to 5V afterwards.

Maximum supply voltage

35V continuous

Maximum operating current

• BackLightOn

58mAat12V

60mAat24V

• BackLightOff

48mAat12V

52mAat24V

• DigitalInputsConnected

60mAat12V

62mAat24V

• AllSensors Connected

72mAat12V

74mAat24V

Maximum standby current. LCD

Back Light Off

47mA at 24V

51mA at 12V

Maximum Current when in Sleep Mode

35mA at 12V

32mA at 24V

3.3 Battery Voltage Display

Range

0V-40V DC (note Maximum continuous operating voltage of 35V DC)

Resolution

0.1V

Accuracy

1% of Reading +1Least Count (At 12V 0.2V)

3.4 Generator Voltage/Frequency Sensing

Measurement type

True RMS conversion

Harmonics

Up to 11

Input Impedance

300K Ph-N

Phase to Neutral

30V to 330V AC (Measurement Range)

Phase to Phase

50V to 570V AC (Measurement Range)

Common mode offset from Earth

100V AC (max)

Resolution

0.1V

Accuracy

±1% of Reading phase to neutral

±1% of Reading phase to phase

Minimum frequency

15.0Hz

Maximum frequency

75.0Hz

Frequency resolution

0.1Hz

Frequency accuracy

±0.05Hz

3.5 Generator Current Sensing

Measurement type

True RMS conversion

Harmonics

Up to 11th

Nominal CT secondary rating

5A

Maximum continuous current

10A

Absolute maximum overload

50A for 1 second

Burden

0.25VA (0.01E current shunts)

Resolution

0.5% of 5A

Accuracy

±1% of Nominal (excluding CT error)

3.6 CT Polarity:

DGC202X has inbuilt CT polarity correction system. Measurement of Power, Energies etc are

independent of Polarity of connected CT, but it must be ensured that the CT are connected to

right phase. Eg. R Phase CT must go to R Phase CT terminal on the controller.

Number

6 fully configurable

Arrangement

Connection to Ground

Polarity

Programmable as Normally Open or Closed

Low Level Threshold

<0.7 V

Max Input Voltage

+40V

Min Input Voltage

-40V

Contact Wetting Current

1ma

Open Circuit Voltage

3V

3.7 Inputs

3.7.1 Digital Inputs

Measurement Type

Resistance measurement by measuring voltage across sensor

with a fixed current applied

Arrangement

Differential resistance measurement input

Measurement Current

13 mA independent of System Voltage

Full scale

600 Ohms

Resolution

Fuel 1%

Temperature 1°

Accuracy

<1% of Full scale ± 4 Ω excluding transducer errors

Max Common Mode Voltage

0.5V

Display Range

Depends upon the sensor selected.

(Sensor can be selected from pre-programmed sensors or user

can program sensor data)

3.7.2 Analog Input

3.7.2.1 Coolant Temperature and Fuel

3.7.2.2 Pressure Sensor: Resistive type sensors or 4-20mA sensor interface

Measurement Type

Programmable

• Resistance measurement by measuring voltage

across sensor with a fixed current applied

• 4-20 mA output sensors

Arrangement

Resistive: Differential resistance measurement input

4-20 mA: Burden of 100 Ω

Measurement Current

Resistive: 13 mA independent of System Voltage

Full scale

600 Ohms

Resolution

0.1 bar

Accuracy

Resistive :<1% of Full scale ± 4 Ω excluding transducer errors

4-20mA: 2% of full scale excluding transducer error

Max Common Mode Voltage

0.5V

Display Range

Depends upon the sensor selected. (Sensor can be selected

from pre-programmed sensors or user can program sensor

data for resistive sensor)

3.7.3 Charging Alternator Interface

Excitation

• Magnetizing Current

220mA @12V (Typical)

110mA @24V (Typical)

Measurement

• Range

• 0-40V

• Accuracy

• 1% of reading

• Resolution

• 0.1V

Whenever the generator is required to run, the terminal provides excitation current to the charge

alternator field winding. When the charge alternator is correctly charging the battery, the voltage of the

terminal is close to the battery supply voltage. In a failed charge situation, the voltage of this terminal is

pulled down to a low voltage. It is this drop in voltage that triggers the charge failure alarm.

3.8 MPU Input

Freq Range

5Hz -7.5KHz

Load

10K Ω

Voltage Input Min

3V

Voltage Input Max

40V

Input Wave Form

Square

Input From

Magnetic Pickup Unit (MPU)

Charging Alternator W point (Should not be very noisy)

3.9 Digital Out Puts

No of Digital Out Puts

6

Out Put drive

To drive Relays

Out Put current

400mA

Out Put polarity

Delivers System Voltage

Protection

Over Temperature, Short Circuit, Over current and Load Dump

3.10 Communication Ports

USB

USB 2.0 Running on PC and can be used to:

• Program the Controller

• Read Instantaneous Parameters

• Read Fault History & Event Recordings

• USB Cable Type A to Type B

CAN

• J1939 Implementation at 250K

• Non-Isolated

• Internal Termination of 120 Ω

• Details on Request

RS485

• Fully Isolated and Protected against 200V between D+ & D-

• Isolation voltage 4KV

• Modbus Implemented

• Protocol on Request

• Internal Termination of 120 Ω

4.0. Salient Features, Measurement, Protection and Supervision

4.1 Salient Features

1. Fully field programmable either from front Keypad, through PC via USB or in field through

Modbus communication

2. Built in sensor data as well as provision to program a sensor data

3. Bright LCD with Icon and English Text Based Descriptions. No need to remember Icons or

consult the manual for understanding the displayed parameters, status, warning or fault

announcement.

4. 4-20mA Pressure Sensor can be interfaced

5. Fuel Solenoid can be configured as Pull to Start or Pull to Stop

6. System Configurable for:

a. Mains Single Phase Mains and Single-Phase Generator

b. Mains Three Phase and Generator Single Phase

c. Mains Three Phase and Generator Three Phase

7. SMPS Power Supply.

8. Heavily protected and isolated Rs485

9. Provision of measuring Fan Current and Protection against Fan failure for water

cooled engines

4.2 Measurement

4.2.1 Generator

• 1 Phase / 3 Phase Voltage • 1 Phase / 3 Phase Current

• Frequency • PF, KW, KVA, KWH

• Water Temperature • Oil Pressure

• Fuel Level • RPM

• Run Hour • Service Due Hour

4.2.2 Mains

• 1 Phase/ 3 Phase Voltage • 1 Phase/ 3 Phase Current

• Frequency • PF

• KW • KVA

• Phase Sequence Detection • Voltage Unbalance

4.2.3 Mains Monitoring/ Mains Unhealthy condition

• Mains Under/Over Voltage • Mains Under Over Frequency

• Mains Unbalance Voltage • Mains Phase Sequence

4.2.4 Supervision

• Generator Under/Over Voltage • Generator Under/Over RPM

• Generator Current Unbalance • RWL

• Generator Overload: Both Current and KW • LLOP

• Charging Alternator/V-belt • Emergency off

• Service Due • Fail to Start

• Fail to Stop • Oil Level

• Canopy Temp • Fire

• HET/HWT • Oil Temperature

• Low Fuel

5.0. Digital Input & Output:

5.1 Digital Outputs

No of Digital Out Puts

6

Programmable Output

1

Could be assigned to any one of these functions

• None

• Unit Healthy

• Glow Plug/Choke.

• Fuel Pump

• Load Warning. This contact will get activated if the load

cross a defined level.

• MCCBShuntTrip.WhentheAutoshutdowninmanual

modeisselectedthisoutputcanbeusedtotripthe

MCCBandlettheengineshutdownonnoloadafter

coolingdown.

5.2 Digital Inputs

There are six digital inputs and each one of them can be assigned to perform a task as indicated

in the list below:

Assignable

Functions

Descriptions

RWL

Radiator Water Level switch to trigger a fault in case of low coolant

Oil Level

Oil Level switch to shut down the engine on low oil level

Earth Fault

External switch input for earth fault protection

Canopy

Temperature

External switch input for high Canopy temperature protection

Emergency

Emergency Stop signal

Fixed Outputs

• Crank

• Fuel Solenoid (configurable as pull to start or pull to stop)

• Mains Contactor

• Generator Contactor

• Hooter

HET/HWT

High engine/coolant temperature switch. Though the unit has provision for a

temperature sensor. This input could be used to provide additional protection.

Fuel

Low fuel level switch. Additional protection along with the fuel sensor

LLOP: Low Lube

Oil Pressure

Low LLOP switch. Additional protection along with Pressure sensor

R. Start/Stop

If assigned this function to a digital input the input could be used to start/stop

the genset in manual mode.

Connection to ground: Start the Engine

Open: Stop the Engine

Note: Front Start/stop keys shall not work with this assignment.

R. Stop

Remote stop: If assigned this function to a digital input, the Digital input shall,

in manual mode, stop the engine, when connected to ground. This could just

be pulse of around 100ms

R. Start

Remote start: If assigned this function to a digital input, the Digital input shall,

in manual mode, start the engine, when connected to ground. This could just

be pulse of around 100ms

Auto/Manual

If assigned this function to a digital input, the input will select the mode of

operation.

Connection to Ground: Auto Mode

Open: Manual Mode

The front key can’t be used to select Auto or Manual mode but the test mode

can still be selected form front.

Note: There are some restriction on the assignment of the function to the Digital Inputs

a)R . Start/Stop can not be selected along with either of R.Stop or R.start

b)R .Start and R.Stop both must be assigned. Assigning only one is not allowed.

6.0. Modes of Operation

Mode

Description

Auto

The genset runs without any human interventions.

The engine shall be switched on when the Mains becomes unhealthy as per the user

defined settings.

The mains can be monitored for voltage levels, frequency, phase sequence and

voltage unbalance. The monitoring of frequency, phase sequence and voltage

unbalance can be disabled.

Once the Mains voltage is outside the limit, continuously for the programmed time,

the engine is cranked and load transferred to the genset after warmup time. The

engine keeps running till the Mains is restored and upon its restoration, the load is

transferred to the Mains and engine is shut down after cooling. This cycle keeps

repeating.

On detection of unhealthy conditions(faults) the engine shall be shut down and an

alarm (Hooter) is activated for the programmed time.

Manual

In this mode the starting and stopping of the genset is controlled manually. All other

functions like load transfer and protections are performed automatically

Starting the Engine: Depending upon the setting of the digital Input the engine could

be started by either:

• Front Start Key

• R. Start Key

• R. Start/Stop Key

Stopping Engine: The engine can be shut down either automatically on restoration

of Mains Voltage (Auto shut down) if the setting xxxxxxxxx is enabled in xxxxxx

Parameter else it’s shuts down by user depending upon the digital Input setting

• Front Stop Key

• R. Stop Key

• R. Start/Stop Key

Test

This is special mode meant for testing during building the system or trouble

shooting.

This mode allows the operator to manually start and stop the engine also the mains

contactor and generator contacts can be manually controlled from Front Keys

7.0. Analog Sensors in Details

Though three sensors one each for Temperature, Pressure and Fuel are installed but at times

systems have typical requirements. DGC202X is deigned to cater for all these possible

requirements and these can be programmed in System Configuration Settings:

Requirement

Description

Sensor/Sensors are not

installed

In such case the display shall not display the measured sensor value and

the protection shall not be activated on the sensor readings.

Sensor/Sensors Installed but

not to protect the engine

If system requires to have the engine protected only through the digital

Input but the sensor measured values have to be displayed.

Sensor/Sensors installed and

used for Protection

Normal Operation

Fault in Sensors

The following faults in sensors are detected and announced:

• Sensor Common Open.

• Sensor Open

If Sensor Common Open is detected, non sensors shall be effective

If a Sensor Open on an individual sensor is detected, it renders that sensor

ineffective

Fault Records

Last 64 Faults with time stamping. This is a circular buffer with last 64 faults. Newer

fault shall replace the oldest fault(64th). These can be viewed on the LCD display or

downloaded either by USB or RS485.

The faults logged are as per the list in 3.2.4(Supervision)

Event Records

Last 64 Events with time stamping. This is a circular buffer with last 64 Events. Newer

Event shall replace the oldest event(64th). These can be viewed on the LCD display

or downloaded either by USB or RS485.

The events are:

1. Parameters Modified

2. RTC time changes

3. Password Changed

8.0. Records

9.0. Installation

For dimension details, see the section entitled Dimension latter in this document.

9.1 Terminal Description

9.1.1 DC Supply, Outputs and Inputs

PIN No

DESCRIPTION

NOTES

1

DC Supply Input (Negative)

Negative DC Supply

2

DC Supply Input (Positive)

Positive DC Supply

3

Programmable Output

Battery Positive to drive a Relay

4

GCB

BatteryPositivetodriveaRelayforGenerator

5

Charging Alternator

Magnetisingcurrentduringstartingoftheengineis

deliveredtoChargingAlternator.Thecharging

Alternatorvoltageismeasuredhereandusedfor

disconnectingthecrankaswellasdetectingV-

Belt/ChargingAlternatorfailure.

6

MCB

BatteryPositivetodriveaRelayforMainsContactor

7

Solenoid

BatteryPositivetodriveaRelayforSolenoid

8

Crank

BatteryPositivetodriveaRelayforcrankingthe

9

Hooter

BatteryPositivetodriveaRelaytodrivehooter

duringfaultannunciation.

10

Ground

Ground pin

11

Comm. Driver

Return feed for sensor. Should be connected to the body

where sensor is mounted (Engine Body)

12

LLOP

Connect to Oil pressure sensor

13

HWT

Connect to High Water Temperature sensor

14

Fuel

Connect to Fuel sensor

15

MPU/W-Point

InputofMPUorW-Pointfromchargingalternator

9.1.2 Configurable Digital Inputs

PIN No

DESCRIPTION

NOTES

16

Digital Input 1

Switch to negative

17

Digital Input 2

Switch to negative

18

Digital Input 3

Switch to negative

19

Digital Input 4

Switch to negative

20

Digital Input 5

Switch to negative

21

Digital Input 6

Switch to negative

9.1.3 Communications

PIN No

DESCRIPTION

NOTES

22

CAN P

For CAN communication

23

CAN N

For CAN communication

24

RS-485(D+)

For RS-485 communication

25

RS-485(D-)

For RS-485 communication

9.1.4 Generator/Mains Voltage Sensing

PIN No

DESCRIPTION

NOTES

26

Generator L1 Voltage monitoring

Connect to generator L1 (R) output (AC)

27

Generator L2 (Y) Voltage monitoring

Connect to generator L2 (Y) output (AC)

28

Generator L3 (B) Voltage monitoring

Connect to generator L3 (B) output (AC)

29

Generator Neutral (N) input

Connect to generator Neutral terminal (AC)

30

Mains L1 (R) voltage monitoring

Connect to Mains L1 (R) output (AC)

31

Mains L2 (Y) Voltage monitoring

Connect to Mains L2 (Y) output (AC)

32

Mains L3 (B voltage monitoring

Connect to Mains L3 (B) output (AC)

33

Mains Neutral (N) input

Connect to Mains Neutral terminal (AC)

9.1.5 Generator Current Transformers

PIN No

DESCRIPTION

NOTES

34

CT Secondary for Gen L1(R)

Connect to s1 secondary of L1 monitoring CT

35

CT Secondary for Gen L2(Y)

Connect to s1 secondary of L2 monitoring CT

36

CT Secondary for Gen L3(B)

Connect to s1 secondary of L3 monitoring CT

37

CT Common

9.1.6 Generator Fan Current

PIN No

DESCRIPTION

NOTES

38

Fan Current(S1)

Connect to s1 of CT

40

Fan Current(S2)

Connect to s2 of CT

9.1.7 Generator Fan Current

DESCRIPTION

NOTES

Socket for connection to PC with

software.

This is a standard USB type A to

type B connector.

9.2 Typical Wiring Diagram

Note 1: These ground connections must be on the engine block, and must

be to the sender bodies.

Note 2: All the digital inputs(DIN 1-DIN 6) are available in section 5.2.

10.0 Display / Front Panel

10.1 Front Facia

128x64 pixels Graphical LCD Display for ease of readout. Parameters are displayed in English

along with symbolic representation. Normally the display auto scrolls and displays a parameter for

10 seconds, but any time the Next key can be pressed to select the next parameter window.

Icons:

When displaying instrumentation, a small icon is displayed in the instrumentation area to indicate

what value is currently being displayed.

S.No

Description

1

Next Key. The preceding section describes the functions associated with all keys

2.

Reset Key

3.

Radio LED annunciation for the selected mode: Auto/Manual/Test

4.

Mode Key

5.

MCB/Back Key

6.

GCB/Forward Key

7.

Increment/Start Key

8.

Decrement/Stop Key

9.

Status Area: This area shall display the position of the Mains and Generator contacts or

will indicate operations status like Cranking, Eng Cooling etc.

10.

Fault and Warning Led. Fault Led blinks on a fault that resulted in engine shut down while

the warning will blink on a warning not resulting in shut down

11 & 12

Ms = Mains status. The area below Ms shall indicate the status of mains. If the mains is

healthy √ is displayed. Reasons of Mains being unhealthy such as Phase Sequence,

voltage unbalance, under/over voltage or under/over frequency shall be indicated by

respective Icon. In case of more than one unhealthy condition two Icon in the priority, as

written above, shall be announced.

13.

Parameter Window. All measure Parameter shall be displayed here.

14.

Icon to distinguish between Mains or Generator Parameter.

eg: Mains Icon with voltage display means its mains voltage and vice versa

15

Icon of the parameter being displayed

10.2 Backlight

Any event such as a front Key is pressed, Fault or Warning shall set the backlight to 100%

brightness. After 120 sec of expiry of the event the brightness of the backlight shall be reduced to

the programmed level. The level can be programmed from 10%-100%. During the cranking,

backlight shall be switched off.

11.0 Icons

11.1 Fault Icons

OilTemperature

Oil Temperature.

Earth Fault

Earth fault.

Canopy

Temperature

Canopy Temperature fault.

ICON

DESCRIPTION

NOTES

Start Failed

The engine has not fired after the programmed number of starts

attempts

Stop Failed

The controller has detected a condition that indicates that the

engine is running when it has been instructed to stop.

Engine High

Temperature

(HWT)

The controller detects that the engine coolant temperature has

exceeded the high engine temperature setting level and the Safety

On timer has expired.

Low Lube Oil

Pressure(LLOP)

The controller detects that the engine oil pressure has fallen below

the low oil pressure programmed level and the Safety On timer has

expired.

Under RPM

TheenginespeedhasfallenbelowtheprogrammedRPM

Over RPM

The engine speed has risen above the programmed RPM alarm

setting

V Belt/Chg Alt

The auxiliary charge alternator voltage is low

Low Fuel

The level detected by the fuel level sensor is below the low fuel level

setting.

Generator Under

Voltage

The generator output voltage has fallen below the programmed

setting after the Safety On timer has expired.

Generator Over

Voltage

The generator output voltage has risen above the programmed

setting and the Timer has expired.

Emergency Stop

The emergency stop button has been depressed. This fail safe

(normally closed to emergency stop) input and will immediately stop

the set should the signal be removed.

LLOP Sensor

Open

Oil pressure sensor has been detected as being open circuit.

HWT Sensor

Open

HWT sensor has been detected as being open circuit.

FUEL Sensor

Open

Fuel sensor has been detected as being open circuit.

RWL

RWL fault.

Oil Level

Oil level fault.

R P M

R P M

Over Load

The current or KW derived from the genset is above the

programmed limit.

Voltage Unbalance

The unbalance in the voltage between the phases.

Current Unbalance

The unbalance in the current between the phases.

11.2 Warning Icons

ICON

DESCRIPTION

NOTES

LLOP Sensor

Open

Oil pressure sensor has been detected as being open circuit

when sensor open is selected as warning.

HWT Sensor

Open

HWT sensor warning has been detected as being open

circuit when sensor open is selected as warning.

FUEL Sensor

Open

Fuel sensor warning has been detected as being open

circuit when sensor open is selected as warning.

Sensor Common

Open

Sensor Common Open warning has been detected when

sensor common pin is open.

Battery

The DC supply has fallen below or risen above the low/high

volts setting level.

KVA Warning

When power of generator in KVA reaches to set value, then

KVA warning occurs.

Mains

Thisiconindicatesthattheparametersshownonthescreenareof

Generator

Thisiconindicatesthattheparametersshownonthescreenareof

Generator.

Voltage

Voltage of Mains or Generator.

Frequency

Frequency of Mains or Generator.

RPM

RPM of Generator.

Current

This icon shows the current of Mains or Generator. When Mains contactor

is connected, it shows Mains current. When Generator contactor is

connected, it shows Generator current.

Active Power

This icon shows the active power of Mains or Generator. When Mains

contactor is connected, it shows Mains active power. When Generator

contactor is connected, it shows Generator active power.

11.3 Operation Icons

A

A

Hz

P

Apparent Power

This icon shows the apparent power of Mains or Generator. When Mains

contactor is connected, it shows Mains apparent power. When generator

contactor is connected, it shows Generator apparent power.

Power Factor

This icon shows the power factor of Mains or Generator. When Mains

contactor is connected, it shows Mains power factor. When Generator

contactor is connected, it shows Generator power factor.

Total Power

This icon shows the total power of Mains or Generator. When Mains

contactor is connected, it shows Mains total power. When Generator

contactor is connected, it shows Generator total power.

Battery Voltage

battery voltage.

Chg. Alt Voltage

Charging Alternator Voltage.

Service due Hour

Remaining hours for servicing the generator.

Run Hour

Run Hour of generator.

Energy

KWhr of Genset

LLOP Sensor

This icon shows the low lube oil pressure of generator.

HWT Sensor

This icon shows the high-water temperature of generator.

Fuel Sensor

This icon shows the fuel of generator.

Oil Temperature

Sensor

This icon shows the oil temperature of generator when CAN is enabled.

RTC

This icon shows the current date and time.

12.0 Keys & LEDs Description

DGC202x has seven Keys provided on its front panel. The table below describes the operation of

these.

S

E

Keys Symbol

Keys Function

Description

Next

Normal operation mode: It is used to scroll forward the

parameters being displayed on LCD.

Programming Mode: Key displays the next parameter to be

programmed.

Increment

/Start

Programming Mode: It is used to increment

the value of the parameters being modified.

Manual mode: it is used to issue the crank/ start command to

DG. Crank is disabled while in Programming Mode.

Decrement /Stop

Programming mode: It is used to decrement the value of the

parameter being modified program.

Manual mode: It is used to issue the stop command to DG. Stop

is disabled while in Programming Mode.

Reset

Normal Operation: Reset key resets the Hooter and Fault signals.

The first press shall reset the hooter and next shall reset the

faults. A long press of 1 Sec shall reset both.

Programming Mode: Go a level up.

Programming

/History

Fault Mode Entry

If both the keys are pressed simultaneously, the unit will enter in

first Level of the Programming Mode. Here Edit/View of the

Parameters or View history, events and CAN status could be

selected.

MCB

Test Mode: Toggles then mains contactor, On/Off

Programming Mode: Scrolls the parameter back

GCB

Test Mode: Toggles then generator contactor, On/Off

Programming Mode: Scrolls the parameter forward

MODE

Toggle between Auto, Manual and Test Mode

Please refer to Digital Input section for more clarity

LED Annunciations Description: DGC202X has 5 annunciations on its front panel. These either

announce the faults or indicate status of the system.

Nomenclature

Symbol

Description

Auto

Auto

Led lights up when unit is in Auto mode

Manual

Manual

Led lights up when unit is in manual mode

Test

Test

Led lights up when unit is in Test mode

Fault

Fault

This LED blinks in case of a fault

Warning

Warning

This LED blinks in case of a warning

M

13.0. Lamp Test:

If the DGC202X is switched on while the reset switch is pressed, all the LEDs start blinking till

the reset switch is kept pressed. This state shall persist till the switch is kept pressed and on

release of the switch DGC202X shall start functioning normally.

14.0. Setting Procedure:

DGC202X has provision to program the operating parameters. It is user/site configurable. User

can view all parameters, fault history, events, adjust clock, reset password and also edit the

parameter.

This manual suits for next models

4

Table of contents

Other Procom Controllers manuals