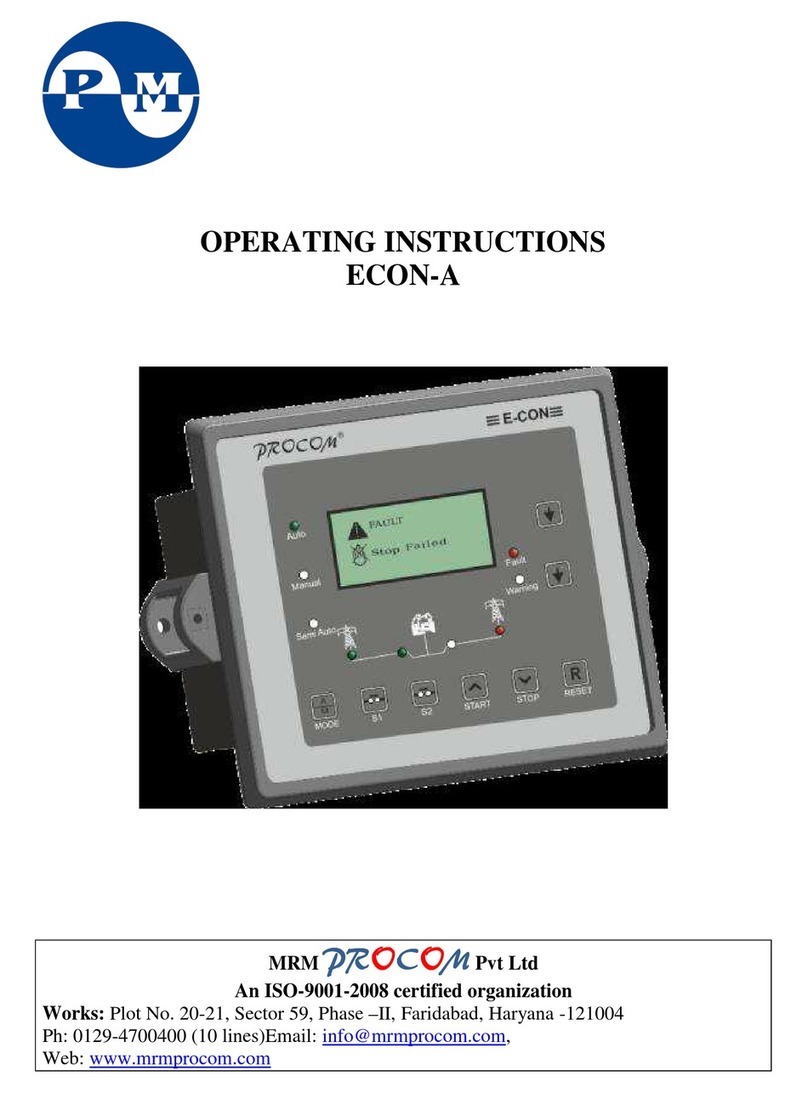

Procom DGC-7RR User manual

OPERATING INSTRUCTIONS DGC-7RR

START

MON

GON STOP

-

Fail to Start Fail to Stop

VIEW / PROGRAM

RESET

PROCOM

Emergency

Low Fuel

HWT/HCTLLOP

V-Belt

Canopy oCD Voltage

D Freq

Battery

D C-7R

Over speed

O/C Crank Solenoid

R

Auto

Man.

Test

Off

MRM

PROCOM

PROCOMPROCOM

PROCOM

Pvt Ltd

Plot No. : 20-21, Industrial Estate,

Sector - 59, Phase-II, Faridabad (Haryana)

Ph.: 0129-4700400(10 Lines)

Email: pankajgupta@mrmprocom.com

Web: www.mrmprocom.com

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 2/18

Index

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 3/18

1.0 Introduction

2.0 Protection, Supervision Salient features

3.0 Measurement & Display

4.0 Annunciations

5.0 Contacts

6.0 Timers

7.0 Switches Description

8.0 Annunciations Description

9.0 Lamp Test

10.0 Operating Mode

10.1 Auto Mode

10.2 Manual Mode

10.3 Off Mode

10.4 Test Mode

10.5 Remote Mode

11.0 Programming mode

11.1 Parameter Mode

11.2 Annunciation Mode

11.3 Programming Solenoid Mode

12.0 Faults

12.1 Internal Faults

12.2 External Faults

12.3 Fault Reset

13.0 Communication

14.0 Model Selection

15.0 Terminal description

16.0 Specifications

17.0 Connection Diagram

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 4/18

1.0 Introduction

•16 Bit RISC, state of art,

microcontroller based System.

•True RMS measurement of all

measured parameters with 1% accuracy

of measured value (Not full scale)

Backlit LCD Display for easy reading

and parameter settings. No need to

consult the manual while programming

the unit.

•All the inputs, such as Mains, Generator

and Battery voltages are fully isolated,

providing the freedom to design a

totally isolated system. This avoids and

prevents malfunctioning/ burning of the

unit.

•Fully operational up to 4V. Can

withstand a voltage dip up to 0V for

1sec.

•Many variants are available to suit

various system requirements. See model

selection chart

•23 window annunciation

•All system parameters are user

programmable

•Suitable for all types of engines

including the one requiring choke.

•Easy selection of modes by a simple

press of a switch

•All digital inputs are optically isolated

for enhanced reliability

•All outputs are through potential free

contacts for system stability and

reliability

•All contacts are protected by TVS to

strengthen the EMI/EMC capabilities of

the unit.

•Up to 6 potential free annunciation

contacts. These contacts can be

configured, in any combination, for

announcing any one or more of the 19

possible conditions

•Housed in 92X192mm Din Standard

housing.

•Over 80 Variants

2.0 Protection, Supervision Salient features

•Mains 3 phase monitoring for

under/over voltage, under/over

frequency and Phase voltages

unbalance.

•Generators single phase monitoring and

protection for under/over voltage,

under/over frequency and over

speeding.

•DC Battery Voltage supervision (Under

& Over voltage)

•8 digital input for system protection

•DG Fail to Start supervision

•DG fail to Stop supervision

•User programmable engine warm up

time, before the load is switched to

generator.

•Mains Restoration supervision

•User programmable Cranking attempt.

•User programmable Crank Time and

delay between two successive cranks

•External engine running signal

•External signal for remote operation

•Programmable option for Choke

3.0 Measurement & Display

16 segment 2 line LCD displays the following parameters. Some of the parameters are model

dependent and are available in only those models.

•Mains 3 Phase voltage

•Mains Frequency

•Generator Voltage

•Generator Frequency

•Battery Voltage

•Generator Run Hour

•RPM

•Programmed settings

•Room/Canopy Temperature (Select

Model)

•BTS Voltage (Select Model)

•Current 1 Phase (Select model)

•LLOP through Sensor

•HWT/HCT through Sensor

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 5/18

•Fuel through Sensor

Normally the display auto scrolls and displays a set of parameter for 10 seconds, but any time the

Next key (

) can be pressed to select the next parameter window.

4.0 Annunciations

DGC-7R is equipped with the following annunciations for system status and faults

•Load on generator (GON)

•Load on Mains (MON)

•Mains : Healthy/Unhealthy

•Generator On

•DG Fail to Start (fault)

•DG Fail to Stop (fault)

•Emergency (Shut down Command)

•LLOP (Fault)

•HWT(Fault)

•Fuel (Fault)

•DG frequency(Fault)

•DG Voltage (Fault)

•DG Over Speed (Fault)

•V-Belt (Fault)

•Canopy Temperature (Fault)

•Over Current (Fault)

•Battery (Warning)

•Crank (Annunciation)

•Fuel Sol (Annunciation)

•Auto (Annunciation)

•Manual (Annunciation)

•Test (Annunciation)

•Off (Annunciation)

5.0 Contacts

The following potential contacts are provided. Annunciation contacts are available in models

requested with Annunciation features.

•Mains Contactor: MCB (NC)

•Generator Contactor: GCB (N0)

•Crank (NO)

•Fuel (NO)

•Hooter (NO)

•Choke (NO). This contact can be used

as a general purpose annunciation

contact if the choke function is not used

•Optional 5 contacts(NO) for

annunciations. The choke contact can

be used as annunciation contacts in

engines not requiring choke.

6.0 Timers

DGC-7R is equipped with the following timers:

•Mains voltage supervision timer

(variable)

•Mains frequency supervision

timer(variable)

•Mains voltage unbalance supervision

timer (variable)

•Generator voltage supervision timer

(variable)

•Generator Frequency Unhealthy

supervision timer (variable)

•Generator over speed supervision timer

(Variable)

•Choke pre start timer (Variable)

•Choke post start timer (Variable)

•Max. crank duration timer (variable)

•Crank gap timer (variable)

•No. of crank attempts (variable)

•DG warm up timer(variable)

•Mains restoration timer (variable)

•DG re-cooling timer (variable)

•Stop Solenoid on time (variable)

•Fuel supervision time (variable)

•LLOP supervision time (variable)

•HWT supervision time (variable)

•Auxiliary Supply Under/Over voltage

supervision & warning timer (Fixed)

•Canopy supervision timer(variable)

•Over Current supervision

Timer(variable)

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 6/18

•V-Belt supervision timer (variable)

•Delay between GCB to MCB switching

(Variable)

•Hooter Reset Time(variable)

7.0 Switches Description

DGC-7R has 12 switched are provided on its front panel. The table below describes the operation of

these.

S.No. Switch Symbol Switch Function Description

1

Next Normal operation mode: In this mode, it is

used to change the parameters being displayed

on LCD.

Programming Mode: Next key is used to

select the next parameter to be programmed.

2

Increment This key is only active during Programming

Mode and is used to increment the value of the

parameters under programming.

3

-

Decrement This key is only active during programming

mode and is used to decrement the value of the

parameter under programming.

4 R Reset Reset key resets the Hooter and Fault signals.

The first press shall reset the hooter and next

shall reset the faults. A long press of 1 Sec shall

reset both.

5

&

-

Programming

Mode Entry

If both the keys are pressed simultaneously the

unit will enter in Programming Mode.

6 START To start Generator in Manual Mode.

7 STOP To stop Generator in Manual Mode.

8 MCB In Manual Mode this toggles the mains

contactor, On/Off

9 GCB In Manual Mode this toggles the generator

contactor, On/Off

10 Auto To select Auto Mode.

11 Man. To select Manual Mode.

12 Test To select Test Mode.

13 Off To select Off Mode.

Auto, Man., Test & Off are Radio buttons and only one can be active at a time.

8.0 Annunciations Description

DGC-7R has 23 annunciations on its front panel. These either announce the faults or indicated the

status of the system.

S.

No.

Nomenclature Description

1 Fail Start This LED blinks when the engine Fails to Start.

2 Fail stop This LED blinks when the engine Fails to Stop.

3 Emergency This LED blinks when the engine is Stopped in emergency.

4 LLOP This LED blinks when the engine is stopped on LLOP fault.

5 HWT This LED blinks when the engine is stopped on HWT fault.

6 Fuel This LED blinks when the engine is stopped on Low Fuel fault.

7 Canopy This LED blinks when the engine is stopped on high canopy

temperature fault.

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 7/18

8 DG Freq This LED blinks when the engine is stopped on frequency fault.

9 DG Vol This LED blinks when the engine is stopped on voltage fault.

10 Over Speed This LED blinks when the engine is stopped on over speed fault.

11 V-Belt This LED blinks when the engine is stopped on V-Belt fault.

12 Battery This LED blinks when the Auxiliary supply is outside the limits.

Warning only.

13 O/C This LED blinks when the engine is stopped on over current fault.

14 Crank This LED lights up while the engine is being cranked..

15 Fuel Sol This LED lights up while the fuel solenoid is active.

16 Mains Steady while Main is healthy else starts blinking.

17 MCB Steady when MCB is engaged.

18 GCB Steady when GCB is engaged.

19 Generator Steady while generator is running.

20 Auto This LED is On if the unit is in Auto Mode.

21 Man. This LED is On if the unit is in Manual Mode.

22 Test This LED is On if the unit is in Test Mode.

23 Off This LED is On if the unit is in OFF Mode.

9.0 Lamp Test

Switching on the power of the unit with RESET switch pressed shall force the entire annunciation

LEDS to blink and display shall show the DGC-7R Model type along with the version number of

the software. This state shall persist till the switch is kept pressed and on release of the switch DGC-

7R shall start functioning normally.

10.0 Operating Mode

DGC-7R is equipped with 5 operation modes, namely Auto, Manual, Test, Off and Remote Mode.

The first four modes can be selected by pressing the corresponding switch, from the front panel. The

remote mode is selected by a digital signal at its terminal.

10.1 Auto Mode

DGC-7R monitors the Mains supply, if Mains supply varies beyond set limit of under/over voltage

or under/over frequency or voltage unbalance for more than their individual programmed

supervision time, DGC-7R releases the MCB contactor (to protect the contactor from failure

because of low input voltage) and attempts to starts the generator.

DGC-7R gives cranks the engine by activating the inbuilt, potential free, crank contact. Crank

command is withdrawn if the engine start is detected, either by external engine start input or by

build up of generator voltage. Max duration of crank command is user settable.

In case of non start of the engine DGC-7R re-cranks it till it starts or user programmed crank

attempts are exhausted. If generator fails to start after the maximum programmed crank attempts,

Fail to Start LED starts blinking, indicating start failure and the hooter is switched on.

After successful start of the generator, it is allowed to warm up for a user programmed time before

the load is transferred to generator.

While the generator is running DGC-7R monitors it for external fault (LLOP, HWT, Emergency,

Fuel, V-Belt, Over Current and Canopy temperature) and internal faults on voltage and frequency.

Over Current Fault could also be internal fault in models having provision to measure and

monitor the current.

On persistence of any fault for more than the programmed supervision delay, for that fault,

generator is stopped, corresponding fault is announced & hooter is switched on.

On restoration of healthy mains supply, continuously, for the programmed duration the load is

transferred to the mains and generator is stopped after expiry of re-cooling time. In case mains

again become unhealthy during the re-cooling period the load is switched to generator.

10.2 Manual Mode

DGC-7R, in this mode is under the manual control of the operator for starting and stopping of the

generator. Engine has to be started manually by manually pressing “Start” switch. The “Start”

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 8/18

switch shall not operate if GCB contact is closed, to provide protection to generator. Once the

generator is started the load can be switched to generator by pressing “GCB” switch or to mains

by pressing MCB switch. At any given time, either of GCB or MCB can be operational. Attempt

to switch on GCB while MCB is on will be ignored and vice versa. Both MCB and GCB key have

dual function of either switching ON or OFF the respective contactor. A press shall toggle the

state. Continuously pressing these keys shall keep toggling the status. To stop the generator,

switch off the GCB contactor and press “STOP” key. Any attempt to stop the generator, while the

GCB contact is engaged, shall be ignored.

While the generator is running DGC-7R protects the generator by monitoring all internal and

external faults.

10.3 Off Mode

This mode is selected to completely shut down the system. By default the load is transferred to

Mains, but Mains contactor can also be switched off/On manually.

10.4 Test Mode

This mode helps the engineer to test the health of the engine. The engine can be started, as in Auto

Mode, even when the Mains voltage is healthy. The load is not transferred to the generator. In case

of Mains failure, while in this mode, the load is automatically transferred to the generator. Please

note that the generator will not automatically switch off in this mode. To switch off the generator

select either Auto, Manual or Off mode. “GCB” & “MCB” keys are active in this mode. DGC-7R

protects the generator by monitoring all internal and external faults.

10.5 Remote Mode

Remote mode is a subset of Auto Mode. Till Remote Pin of DGC-7R is left open, the unit works

in Auto Mode. DGC-7R is put in Remote Mode by pulling Remote Pin low to battery negative. In

Remote Mode the unit shall not initiate the generator start process till the Remote Pin is held low.

On release of this pin and if the mains is unhealthy , the engine start process will be initiated. The

generator shall stop either on Mains becoming healthy or Remote Pin again going low. The

engine shall stop after the re-cooling time. While the generator is running DGC-7R protects the

generator by monitoring all internal and external faults.

11.0 Programming mode

DGC-7R has provision to program the operating parameters and annunciations separately.

Programming Mode can be entered any time by simultaneously pressing

&

-

switches. As soon as

DGC-7R enters the programming mode the Display Screen shall display “Select Pra/Ann +” in fist Row and

“Parameter Mode” in second row, ”Pressing “

” Switch will take the units in parameter programming

mode. To program the annunciation contacts scroll the screen by pressing

. The display shall now display

“Annunciator Mode”. Press “

” Switch to enter annunciation contacts programming mode. While in

Program Mode, the first row of LCD displays parameter/annunciation contact name/number under

programming and second row contains the parameter value. Please note that 20sec of inactivity will take the

unit back in normal mode and all the changes done shall be cancelled. The following tables gives the

detailed descriptions.

11.1 Parameter Mode

S.No Parameter

name on first

row of LCD

Explanation of parameter Factory

setting

Setting Range

Please note: Operating Mode cannot be changed if the unit

has stopped on a fault condition or the engine is cranking

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 9/18

Common to all Models

1 Mains O/V Max. Permissible voltage, above

this the voltage is treated unhealthy

& Generator is started.

270V 80-300V

2 Mains U/V Min. permissible voltage, below

this the voltage is treated unhealthy

& Generator is started

180V 80-270V

3 Mains Sup

Delay

Time for which the Mains voltage

has to be unhealthy (Under or Over

voltage as defined above in 1 & 2)

before starting the Generator.

10Sec 0-999Sec

4 Mains O/F Max. Permissible Mains

frequency, above this frequency

the Mains is treated unhealthy &

Generator is started.

55Hz 40-65Hz

5 Mains U/F Min. permissible Mains frequency,

below this frequency the Mains is

treated unhealthy & Generator is

started.

45Hz 40-65Hz

6 Mains Freq

Delay

Time for which the Mains

frequency has to be unhealthy

(under or over voltage as defined

above in 4 & 5) before starting the

Generator.

10Sec 0-999 Sec.

7 Mains Vol

Unbal

(Not available

In Single phase

version)

Max. Permissible voltage

difference between two phases of

mains. Above this the voltage is

treated to be unbalanced and

Generator is started.

Disable* 10-100 Disable*

8 Unbalance

Delay

Duration for which unbalance can

be allowed before starting the

Generator. This parameter is not

available if (7) is set to disabled.

10Sec 0-999Sec

9 Gen Start Delay The starting of generator is delayed

by this time after the mains

unhealthy timers have expired and

the mains contact has been

released. This is required in certain

applications where immediate

generator starting is not required

but the mains contactor are to be

protected. This timer is

automatically reset, if during this

duration the mains become

healthy for “Mains Restoration

Delay” (26)

Disable* 0-999

10 Gen Start Unit The generator start delay(9) can be

programmed in seconds or

minutes. This parameter is not

available if (9) is disabled.

Sec Sec-Min

11 Generator O/V Max. Permissible Generator

voltage, above this the Generator

voltage is treated unhealthy & the

Generator is stopped on voltage

270V 80-270V

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 10/18

fault.

12 Generator U/V Min. permissible Generator

voltage, below this the Generator

voltage is treated unhealthy & the

Generator is stopped on voltage

fault.

180V 80-270V

13 Gen Sup Delay Duration for which generator

Over/Under voltage condition can

be tolerated before stopping the

Generator.

30Sec 0-999Sec

14 Generator O/F Max. Permissible Generator

frequency, above this the

Generator frequency is treated

unhealthy & the Generator is

stopped on frequency fault.

55Hz 40-65Hz

Disable*

15 Generator U/F Min. permissible Generator

frequency, below this the

Generator frequency is treated

unhealthy & the Generator is

stopped frequency fault.

45Hz 40-65Hz

Disable*

16 Gen Freq Delay Duration for which Generator

Over/Under frequency condition

can be tolerated before stopping

the Generator.This setting is not

available if (12)&(13) are disabled

10Sec 0-999 Sec.

17 Generator O/S The maximum Generator

frequency beyond which over

speed is detected

65Hz 40-80Hz

Disable*

18 Gen O/S Delay Time for which over speeding is

allowed. This parameter is not

available if (17) is disabled.

2 Sec 0-999Sec

19 Choke Pre Time Activate the choke for this time

before cranking

Disable 1-100Sec

Disable*

20 Choke Post

Time

Keep the choke for this time after

the engine has started. This setting

is not available if (19) is disabled

Disable 1-100Sec

Disable*

21 No Of Crank The maximum number of cranks

that shall be issued to start the

Engine

3 0-10

22 Crank Time Maximum crank time 5Sec 0-25 sec

23 Crank Delay The delay between two successive

cranks

5Sec 0-100Sec

24 Gen Pick Vol This parameter specifies the

generator voltage at which the is

presumed to have started and crank

has to be terminated

100V 70-150V

25 Warm Up Time Generator warm up time. The load

is transferred to generator after

expiry of this time

0Sec 0-999Sec

26 Mains Rest

Delay

Mains restoration Delay:

The time for which Mains should

be continuously healthy before

stopping the Generator.

30Sec 0-999Sec

27 Gen Recool The time for which generator is 30Sec 0-999Sec

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 11/18

Time allowed to run on no load before

switching off

28 Stop Sol On

Time

The time for which stop solenoid

will be kept active while stopping

the engine

30Sec 0-999Sec

29 Fuel Level in % Fuel Level in %. Below this level

the fuel fault shall be acivated

15% 10-100%

30 Fuel Delay Duration for which the Fuel level

should be continuously low to be

recognized as a fault and action

initiated. This fault is always

enabled.

2 Sec 0-999Sec

31 Lube Low

Pressure

The minimum acceptable pressure

in Kg/cm

2

. Below this level the

LLOP fault shall be activated

2.5Kg/cm

2

0-8.5 Kg/cm

2

32 LLOP Delay Duration for which the LLOP

signal should be continuously

active to be recognized as a fault

and action initiated. This fault is

only enabled while the generator is

running.

2 Sec 0-999Sec

33 HW

Temperature

The maxi. Temperature at which

the engine is allowed to operate

70

o

C 10-120

o

C

34 HWT/HCT

Delay

Duration for which the HWT

signal should be continuously

active to be recognized as a fault

and action initiated. This fault is

always enabled.

2 Sec 0-999Sec

35 O/C Delay Duration for which the external or

internal over current (for models

which have internal current

measurement) be recognized as a

fault and action initiated. This fault

is only enabled while the generator

is running.

2Sec 0-999

Disable*

36 V-Belt Delay Duration for which the V-Belt

signal should be continuously

active to be recognized as a fault

and action initiated. This fault is

only enabled while the generator is

running.

2Sec 0-999

37 Canopy Delay Duration for which the external or

internal (Models with canopy

temp. measurements) Canopy

Temperature fault should be

continuously present to be

recognized as a fault and action

initiated. This fault is only enabled

while the generator is running.

2 Sec 0-999Sec

38 GCB to MCB

Delay

User programmable delay when

the load is transferred from

Generator to Mains.

2 Sec 1-5 Sec

39 Hooter Reset

Tim

Duration for which the hooter shall

be ON, if not externally reset,

while announcing a fault.

30Sec 0-999Sec

40 DC O/V Max. permissible Auxiliary supply 30V 10-40V

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 12/18

voltage. If Auxiliary voltage is

higher than this for 10sec the

Battery LED starts blinking (only

warning).

Disable*

41 DC U/V Min. permissible Auxiliary supply

voltage. If Auxiliary voltage is

lower than this for 10sec the

Battery LED starts blinking (only

warning).

10V 10-40V

Disable*

42 Gen On Time Max. duration for which the

generator is allowed to work

continuously

Disable* 10-999Min

43 Gen Rest Time If the generator has run

continuously as per (39), the

generator is given rest irrespective

of the mains condition. In case of

mains unhealthy during this time

the mains contact is deactivated

but the generator is not started.

This is unavailable if (39) is

Disabled

This timer is automatically reset, if

during this duration the mains

become healthy for “Mains

Restoration Delay” (26)

Disable* 10-999Min

For models with internal Current Measurement

44 CT Ratio External CT Ratio 1 1-200

45 O/C The current above which the over

current fault monitoring has to

start. The timer for it is as

described in 33. Setting it to

disable will doesn’t disable the

external over current fault. This

fault is only enabled while the

generator is running.

6Amp 1-999Amps

Disable*

For models with BTS Voltgae Measurement

46 BTS Under Vol The min. permissible voltage of

BTS. The generator shall not be

started, even if the mains voltage

becomes unhealthy till the BTS

voltage is above this limit.

42V 18-70V

47 BTS Vol Delay BTS voltage has to continuously

below (43) limit for this duration

for starting the generator

5Sec 0-999Sec

For models with Room Temperaure Measurement

48 Room Temp The max. permissible room

temperature. The generator shall

not be started, even if the mains

voltage becomes unhealthy till the

Room temperature is below this

limit

27Deg 18-40Deg

49 Room Temp

Delay

Room Temperature has to

continuously above (45) limit for

this duration for starting the

generator

5Sec 0-999Sec

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 13/18

For models with Room Temperaure and BTS Voltage Measurement

Any of (43) or (45) condition being satisfied shall start the generator

For models with Canopy Temperaure Measurement

49 Canopy Temp Max. permissible Canopy

temperature before the engine is

shut down.

70 20-99

* This parameter can be disabled while programming

11.2 Annunciation Mode

When DGC-7R enters this mode, it allows programming of 6 contact free annunciations. Please

note that in case ANN1 shall not be available if in parameter mode Choke function is enabled. In

case it was, previously disabled and ANN1 has been assigned a annunciation, and later the

choke was enabled, the assigned annunciation to ANN1 shall be automatically disabled. In such

case the user is advice to reassign the annunciation contacts after enabling the choke

S.No Parameter name on first

row of LCD

Setting Factory Setting and remark

1 Mains OK 0-ANN1-ANN6 0

2 Mains Not OK 0-ANN1-ANN6 6

3 DG Running 0-ANN1-ANN6 0

4 DG Not Running 0-ANN1-ANN6 0

5 Load on DG 0-ANN1-ANN6 0

6 Load on Mains 0-ANN1-ANN6 0

7 Fail to Start 0-ANN1-ANN6 1

8 Fail to stop 0-ANN1-ANN6 2

9 LLOP Fault 0-ANN1-ANN6 3

10 HWT/HCT Fault 0-ANN1-ANN6 3

11 DG Vol Fault 0-ANN1-ANN6 5

12 DG Freq Fault 0-ANN1-ANN6 5

13 DG O/S Fault 0-ANN1-ANN6 5

14 Low Fuel 0-ANN1-ANN6 4

15 O/C Fault 0-ANN1-ANN6 0

16 Canopy Fault 0-ANN1-ANN6 0

17 V-Belt Fault 0-ANN1-ANN6 0

18 Battery Unhelath 0-ANN1-ANN6 0

19 Room Temp High 0-ANN1-ANN6 0

20 BTS Vol Low 0-ANN1-ANN6 0

0 Means no contact. Room Temp, and BTS Vol Low are model dependent

11.3 Programming Solenoid Mode

For changing the solenoid mode first press (R) (reset) button, than simultaneously press +ve and –

ve button while the reset button is pressed. The first row of LCD shall display “ FuelSolType”.

There are two possible modes.

Mode 0 In this mode fuel solenoid contact changes from Open to Close at the time of cranking

and remains close till the genset is running. For stopping the generator this contact opens.

Mode 1 In this mode fuel solenoid contact remains open at the time of cranking and till the genset

is running. For stopping the generator this contact closes for a user programmed time.

Mode 2 Same as Mode 0 with additional feature of deactivating the crank when the Lube Oil

Pressure is build(LLOP Fault is removed).

Mode 3 Same as Mode 1 with additional feature of deactivating the crank when the Lube Oil

Pressure is build(LLOP Fault is removed).

Don’t change the mode while generator is running. It’s a good practice to switch OFF and than

switch ON the battery supply after changing this mode.

12.0 Faults

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 14/18

There are two categories of faults

oInternal Faults

oExternal faults

12.1 Internal Faults

Internal faults are the faults, which do not need any external signals and are detected by the system

itself. They are:

oGenerator Fails to Start.

oGenerator Voltage Unhealthy

oGenerator Frequency Unhealthy.

oGenerator Over Speed.

oGenerator Fails to Stop.

oOver Current ( In models with built in Current measurements)

oLLOP

oHWT

oFuel

oBattery Under or Over voltage (Warning only).

12.2 External Faults

Those faults which cannot be sensed by the unit itself (these faults are not reflected by the

generator voltage) and are to be provided externally. They are:

oCanopy Temperature

oEmergency

oOver Current (External)

V-Belt

12.3 Fault Reset

oInternal Faults & LLOP fault: All internal faults and LLOP fault can be reset by pressing (R)

switch after the generator is stopped.

oExternal Fault except LLOP & V-Belt faults: These faults cannot be reset till the engine is

running and/or fault conditions persist. Once the faults are rectified, the fault can be reset by pressing

Reset switch (R). In case the engine fails to stop “STOP KEY” can be pressed for manual attempt to

stop engine

13.0 Communication

Half Duplex, RS485 communication running in slave mode: The communication can be used for the

following:

•Programming the parameters

•Reading instantaneous parameters

•Reading system conditions

•Reading fault status.

•Remote Operation

14.0 Model Selection

The nomenclature for selecting the model is as follows:

DGC-7R

-1P/3P for Single Phase /3 Phase Mains monitoring

-A for Annunciation Contacts are required

-B for BTS Vol

-N for Canopy Temperature

-T for Room Temp

-I for Current single Phase

-C for Communication

S.No Desired Features Model Name

1 Current, Room Temp, Communication, 3 phase

mains

DGC-7R-I-T-C-3P

2 Annunciation, BTS Voltage, Room Temp,

Single Phase mains monitoring

DGC-7R-1P-A-T-B

Please note:

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 15/18

a) Only one temperature measurement out of Room and Canopy can selected at a time

b)

Out of BTS Voltage, Room/Canopy Temperature and Current only 2 parameters can be selected

at the same time.

c)

Single Phase unit can have provision for KW, PF and KWhr

15.0 Terminal description

Terminal Number Description

1 Mains R Phase Voltage

2 Mains Y Phase Voltage

3 Mains B Phase Voltage

4 Mains Neutral

5 Generator Voltage

6 Generator Neutral

7 These connections depend upon the models. Please see Table A in

15.1 for details.

8

9

10

11 Remote

12 Engine Running( Started)

13 HWT Sensor

14 Fuel Sensor

15 Canopy Temperature

16 Emergency

17 LLOP Sensor

18 V-Belt

19 External Over Current digital Input

20 Auxiliary supply +ve

21 Auxiliary supply -ve

22,23 Mains Circuit Breaker

24,25 Generator Circuit Breaker

26,27 Crank

28 Hooter

29 Common for hooter and fuel

30 Fuel

31 ANN1 or Choke

32 ANN2 (Optional)

33 Common for ANN1 & ANN2

34 ANN3

35 ANN4

36 ANN5

37 ANN6

38 Common for ANN3 – ANN6

15.1 Table A

Parameters in models Pin 7 Pin8 Pin9 Pin10

Basic Model -- -- -- --

Current CT+ CT- -- --

BTS Voltage -- -- BTS+ BTS-

Room Temperature Temp+ Temp- -- --

Canopy Temperature Temp+ Temp- -- --

BTS Vol + Room/Canopy Temperature Temp+ Temp- BTS+ BTS-

BTS Vol + Current CT+ CT- BTS+ BTS-

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 16/18

Current + Room/Canopy Temperature CT+ CT- Temp+ Temp-

16.0 Specifications

AC voltage withstand 330 VAC (Phase to neutral)

Measurement Accuracy 1%

Surge 1.2/50Usec 2.5KV

Battery Voltage Suitable for 12V/24 VDC System

Min. voltage to power on 9V

Min Running Voltage after

Power on 4V

Max. Battery Voltage 35V

DC Interruption time 1 Sec.

Contact(MCB) NC, 230V / 6A

Contact(GCB) NO, 230V / 6A

Contact(Hooter) NO, 230V / 6A

Contact(Fuel) NO, 230V / 6A

Contact(Crank) NO, 230V / 6A

Contact ANN1 NO, 230V / 6A

Contact(ANN2-ANN 6 ) NO, 230V / 1A

Cut out Dimensions 186mm X 90mm

Depth 120mm

Digital Input Level Battery Voltage (Negative)

DGC-7R Digital Genset Controller

Cat_DGC-7R-04-08-VERB1-0.doc Page 17/18

It is our endeavour to constantly upgrade our products, hence specifications are subject to change without any notic

DG

Main

1 Main R Phase Remote Start 11

2 Main Y Phase HWT 13

3 Main B Phase Low Fuel 14

4 Main Neutral Canopy Temp. 15

18

MCB Check Back

Emergency 16

22

MCB NC Contact LLOP 17

23

MCB NC Contact Crank NO 26

7 Not Connected Crank NO 27

8 Not Connected Hooter 28

19

GCB Check Back Common 29

9 Not Connected Fuel 30

10

Not Connected ANN1- NO 31

24

GCB NO Contact ANN2-NO 32

25

GCB NO Contact Common 1-2 33

5 Generator R

phase

ANN3-NO 34

6 Generator Neutral ANN4-NO 35

21

Battery Negative ANN5-NO 36

20

Battery Positive ANN6-NO 37

12

Engine Start Common 3-6 38

M

This manual suits for next models

1

Table of contents

Other Procom Controllers manuals

Popular Controllers manuals by other brands

Atomic Workshop

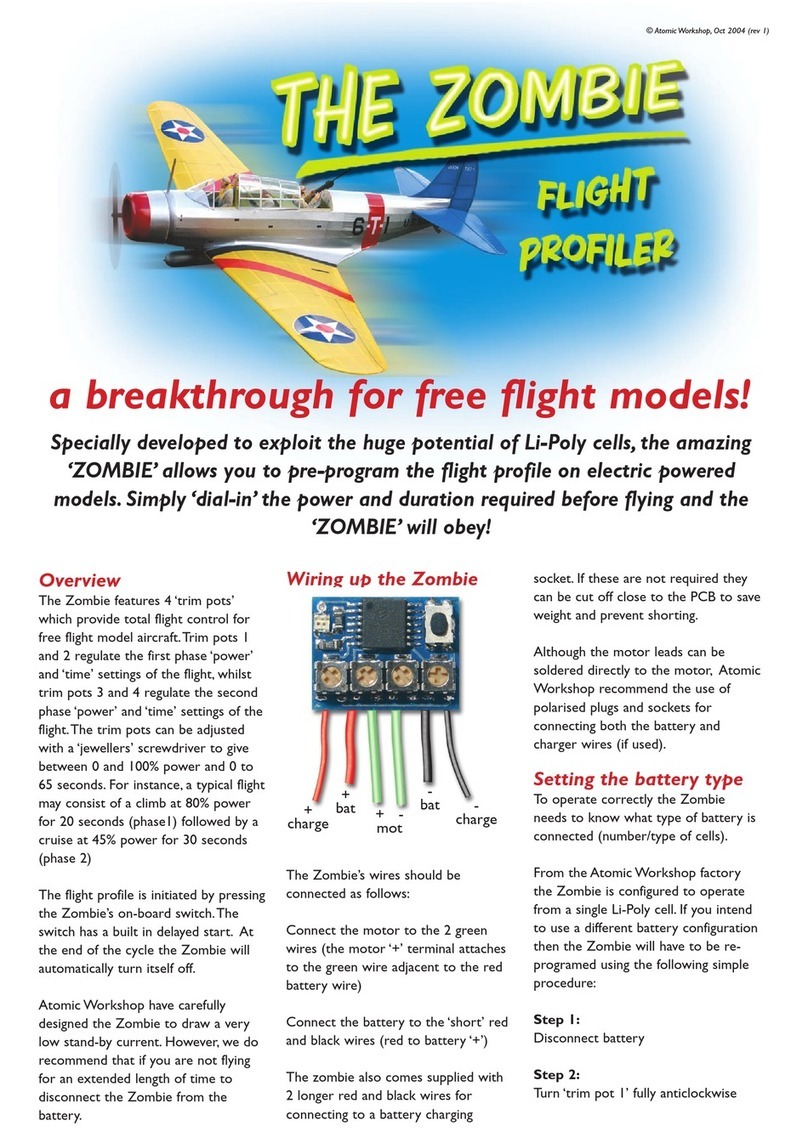

Atomic Workshop Zombie Leaflet

Cass Technology

Cass Technology CASTLE S SERIES Technical operation guide

Controlli

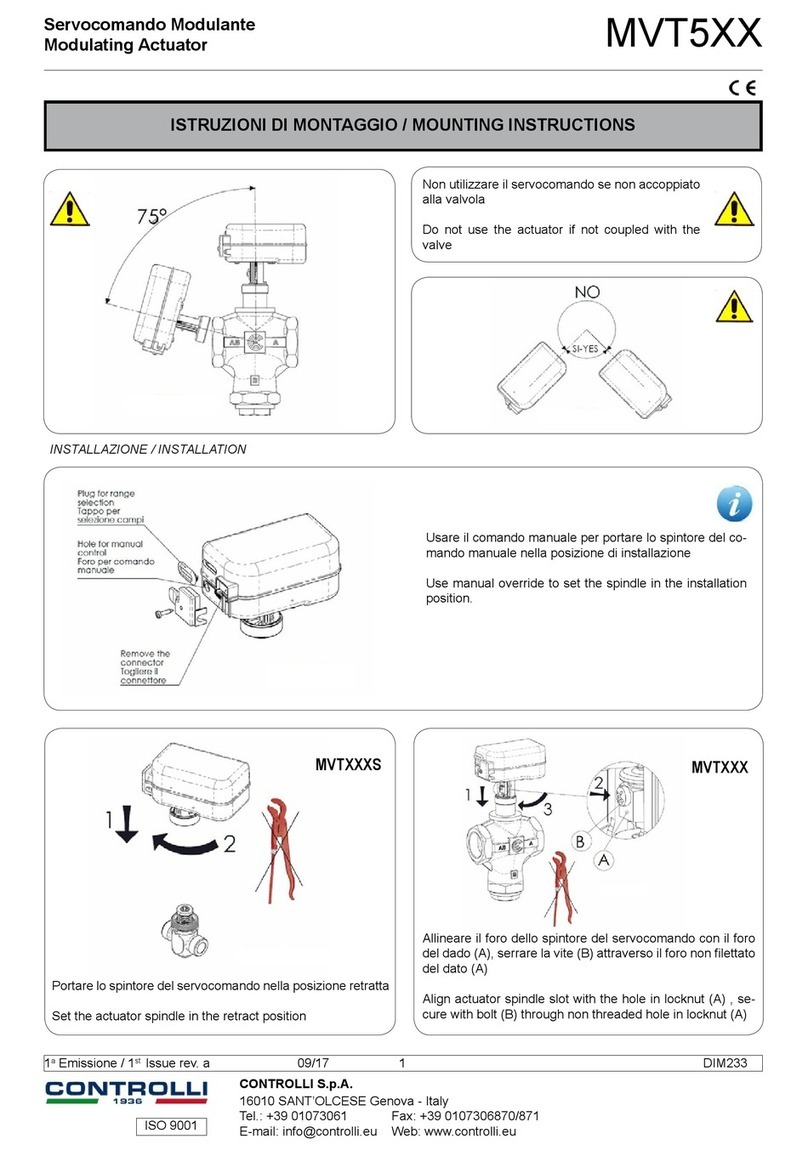

Controlli MVT5 Series Mounting instructions

Wiznet

Wiznet WizFi360 Series quick start guide

Aprimatic

Aprimatic ST450N Fitting instructions

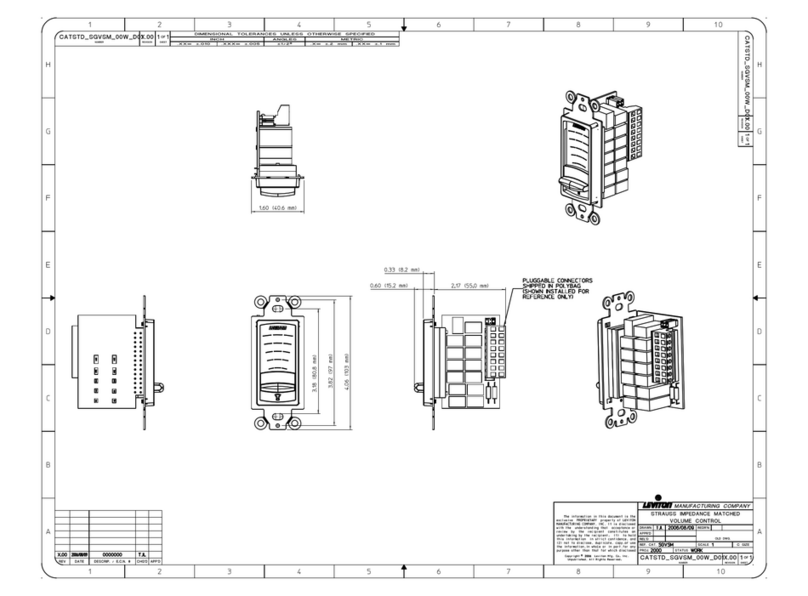

Leviton

Leviton SGVSM-00W Dimension Guide

SECOP

SECOP 101N07 Series operating instructions

Cisco

Cisco 2504 Getting started guide

Johnson Controls

Johnson Controls VMA1617 installation guide

SMC Networks

SMC Networks AR20S 02E-Y 15V Series Operation manual

Compur Monitors

Compur Monitors Statox 501 Operation instructions

IEI Technology

IEI Technology VWBOX-E133 user manual