PRONET

PRONET soware has been designed by Proel’s Research & Development Department to easily control a single unit or a network of devices, like

acve loudspeakers or speaker processors, equipped with the C-AUDIO CORE digital processing plaorm.

PRONET has been developed in collaboraon with sound engineers and sound designers, in order to offer an “easy-to-use” tool to setup and

manage your audio system. With PRONET you can visualize signal levels, monitor internal status and edit all the parameters of each connected

device.

Download the PRONET app from the PROEL website at hp://www.proel.com clicking on support secon.

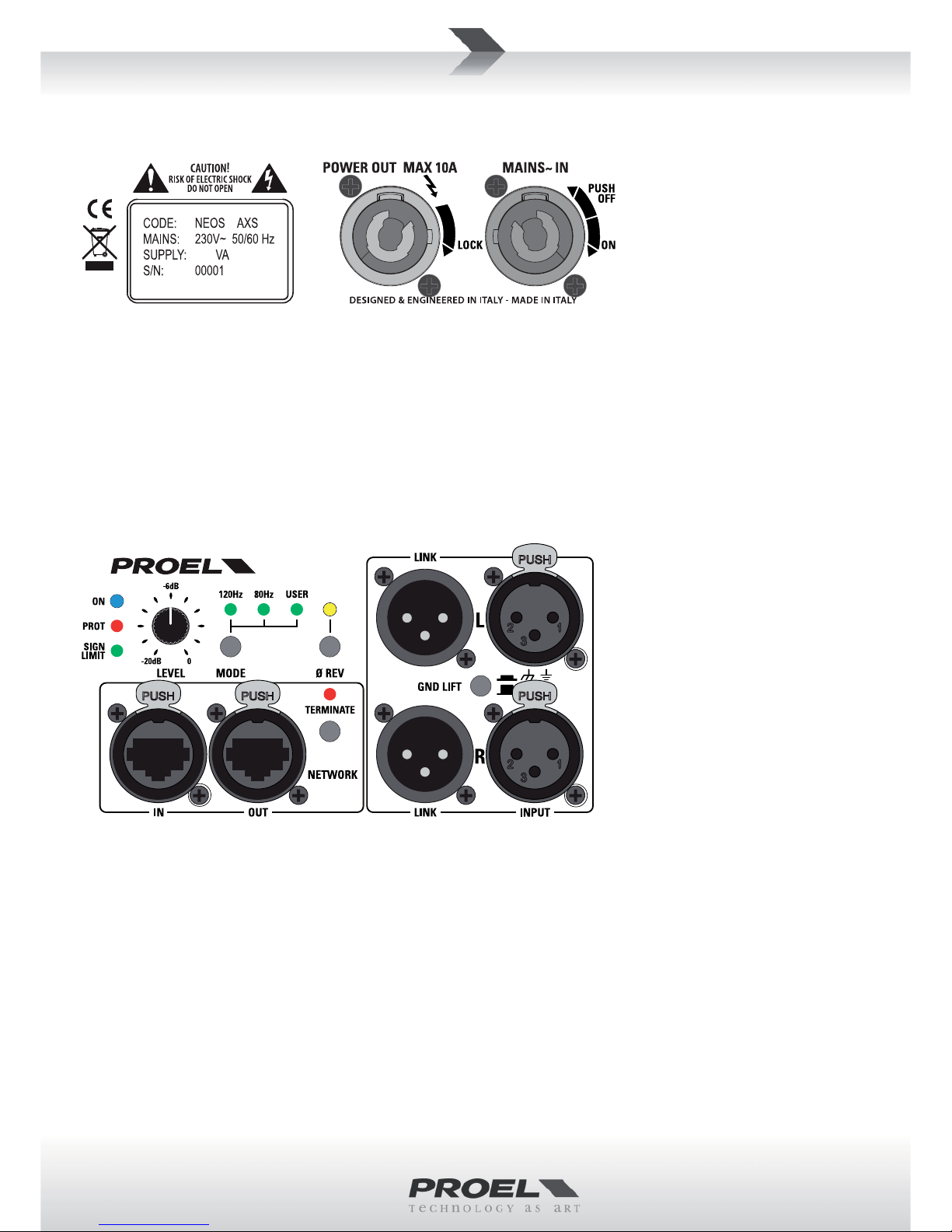

The NEOS AXS loudspeaker devices can be connected using the network connecon, in this case the PROEL USB2CAN converter oponal accessory

is needed. The first me you connect a device with the USB2CAN converter, Windows O.S. will ask you to install the driver files, which you can

find in the Driver folder within the Pronet applicaon folder (by default is C:\Program Files\Proel\Pronet\Driver, or if you changed it <your path>\

Driver). Please refer also to “Installaon” and “Drivers” paragraphs in the Pronet documentaon.

The PRONET NETWORK is based on a robust, reliable and fast communicaon protocol called CANBUS. The devices in a PRONET NETWORK are

connected together with a “linear bus topology”. The USB2CAN converter must be connected to the network input of the first device, the network

output of the first device is connected to the input of the second and so on. For the network connecons simple RJ45 cat.5 or cat.6 ethernet

cables can be used (please don’t confuse a ethernet network with a PRONET network these are completely different and must be fully separated

also both use the same kind of cable).

The beginning and the end of a PRONET NETWORK must be terminated. One side is terminated by the USB2CAN converter, the other side must

be terminated pressing the TERMINATE switch on the last device. All devices between these two points must have the TERMINATE switch lied.

Assign the ID number

To work properly in a PRONET network each connected device must have a unique idenfier number, called ID. By default the USB2CAN PC

controller has ID=0 and there can be only one PC controller. Every other device connected must have its own unique ID equal or greater than 1:

in the network cannot exist two devices with the same ID.

An ID number is assigned automacally to each devices when they are turned on for the first me connected to a network.

In order to correctly assign a new available ID to each device for working properly in a Pronet network, follow these instrucons:

1. Switch offall the devices.

2. Connect them correctly to the network cables.

3. “TERMINATE” the latest device in the network connecon.

4. Switch on the first device keep pressed “RTA” buon on the control panel.

5. Leaving the previous device switched on, repeat the previous operaon on the next device, unl the latest device is turned on.

The “Assign ID” procedure for a device makes the internal network controller to perform two operaons: reset the current ID; search the fi

rst free

ID in the network, starng from ID=1. If no other devices are connected (and powered on), the controller assume ID=1, that is the first free ID,

otherwise it searches the next one lefree.

These operaons ensure that every device has it’s own unique ID, if you need to add a new device to the network you simply repeat the operaon

of step 4. Every device maintains its ID also when it is turned-off, because the idenfier is stored in the internal memory and it is cleared only by

another “Assign ID” step, as explained above. This means that if your network is made always of the same devices the assigning ID procedure must

be executed only the first me the system is turned on.

See the more detailed instrucon about PRONET on the documentaon downloadable from the web site: www.proel.com.

LIMITED WARRANTY

Proel warrants all materials, workmanship and proper operaon of this product for a period of two years from the original date of purchase. If any defects are found

in the materials or workmanship or if the product fails to funcon properly during the applicable warranty period, the owner should inform about these defects the

dealer or the distributor, providing receipt or invoice of date of purchase and defect detailed descripon. This warranty does not extend to damage resulng from

improper installaon, misuse, neglect or abuse. Proel S.p.A. will verify damage on returned units, and when the unit has been properly used and warranty is sll

valid, then the unit will be replaced or repaired. Proel S.p.A. is not responsible for any “direct damage” or “indirect damage” caused by product defecveness.

• This unit package has been submied to ISTA 1A integrity tests. We suggest you control the unit condions immediately aer unpacking it.

• If any damage is found, immediately advise the dealer. Keep all unit packaging parts to allow inspecon.

• Proel is not responsible for any damage that occurs during shipment.

• Products are sold “delivered ex warehouse” and shipment is at charge and risk of the buyer.

• Possible damages to unit should be immediately nofied to forwarder. Each complaint for package tampered with should be done within eight days from product

receipt.

SAFETY INSTRUCTIONS

– To reduce the risk, close supervision is necessary when the product is used near children.

– Protect the apparatus from atmospheric agents and keep it away from water, rain and high humidity places.

– This product should be site away from heat sources such as radiators, lamps and any other device that generate heat.

– This product should be located so that its locaon or posion does not interfere with its proper venlaon and heang dissipaon.

– Care should be taken so that objects and liquids do not go inside the product.

– The product should be connected to a power supply mains line only of the type described on the operang instrucons or as marked on the product. Connect the

apparatus to a power supply using only power cord included making always sure it is in good condions.

– WARNING: The mains plug is used as disconnect device, the disconnect device shall remain readily operable.

– Do not cancel the safety feature assured by means of a polarized line plug (one blade wider than the other) or with a earth connecon.

– Make sure that power supply mains line has a proper earth connecon.

– Power supply cord should be unplugged from the outlet during strong thunderstorm or when leunused for a long period of me.

CE CONFORMITY

Proel products comply with direcve 2004/108/EC (EMC), as stated in EN 55103-1 and EN 55103-2 standards and with direcve 2006/95/CE (LVD), as stated in EN

60065 standard.

PROEL S.p.A. (World Headquarter) - Via alla Ruenia 37/43 - 64027 Sant’Omero (Te) - ITALY

Tel: +39 0861 81241 Fax: +39 0861 887862 www.proel.com