MK 0

4

I- GENERAL DESCRIPTION

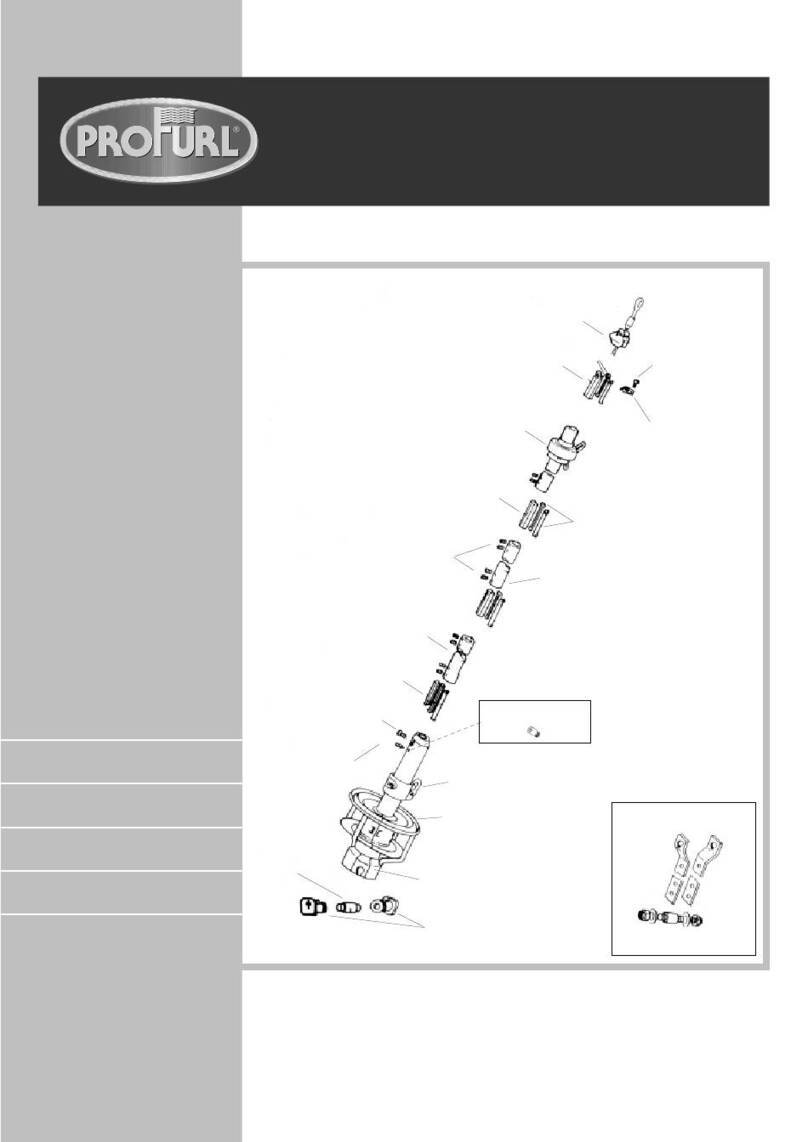

Note : names in bold refer to parts shown on the exploded view (next page)

The PROFURL MK0 in-boom furling system includes :

1. One set of luff profiles (1 and 2) articulated on the aft face of the mast.

There are 2 different kinds of luff profiles: one 0.40 m long feeder profile (1) on which the

feeder (21) is attached, and several 2 meters long normal luff profiles (2) depending on the

mainsail’s luff length. One of these 2 meters long normal luff profiles (2) will be re-cut to

length at its upper end to match the expected luff length of the mainsail. The different luff

profiles (1 et 2) are connected to each other by mean of connectors/articulations (4),

which are fitted to articulation brackets (5) that will be attached to the mast track.

2. Articulation brackets (5) attached to the mast with 2 slide screws (7) slipped in the mast

groove. Every slide screw (7) has a thread and a flat end going through a hole of the

articulation brackets (5). The thread of the slide screws (7) receives a washer (33) and a

locknut (8) for attachment.

3. Connectors/articulations (4) are also used to connect the different luff profiles (1 and 2),

held by set screws (9). The lower end of the 0.40 m long feeder profile (1) will be

connected onto the gooseneck articulation (10), thus allowing the luff profiles (1 and 2) to

rotate together with the boom.

4. A sheave box (11) through which the original mainsail halyard is passing. The sheave box

(11) will be fit at the top of the luff profiles (1 and 2). It is assembled on the end brackets [2

times 5a], themselves being attached by mean of slide screws (7) washers (33) and

locknuts (8) and pin (66).

5. A gooseneck (12) fit on the mast with 2 slide screws (7), and two gooseneck plates (13)

cambered at the mast shape while fitting, and which will be riveted onto the mast with the pop

rivets (14) supplied.

6. A boom profile (15) which has been delivered in 3.20 meter (10’ 6”). It may be necessary to

re-cut the boom profile to length when fitting to match the expected boom length.

7. A mandrel (16) turning on bearings (17) fit on a bearing holder (19) at the rear end of the

boom, and on the drum-bearing holder (24) front, turning around a pin inserted in each of

the boom end fittings (22 and 23). When re-cutting the boom profile (15) to length, the

mandrel (16) should also be re-cut by the same amount.

8. A drum boom end fitting (22). It includes the drum-bearing holder (24) fit on the mandrel

(16): the drum being loaded with the furling line, pulling on the furling line while releasing the

mainsail halyard will rotate the mandrel (16), which will furl the sail.

9. 2 adjustable mainsheet bails (25).

10. A special boomvang (26). It is attached :

- to the mast by mean of a boomvang attachment, including an gooseneck (12)

attached onto the mast with 2 slide screws (7) washers (33) and locknuts (8) and two

gooseneck plates (13) which will be riveted to the mast with the pop rivets (14)

supplied. The boomvang lower end will be attached onto an articulation fitting (48)

rotating in the boomvang gooseneck.

- onto the boom with an adjustable boomvang hound (28).