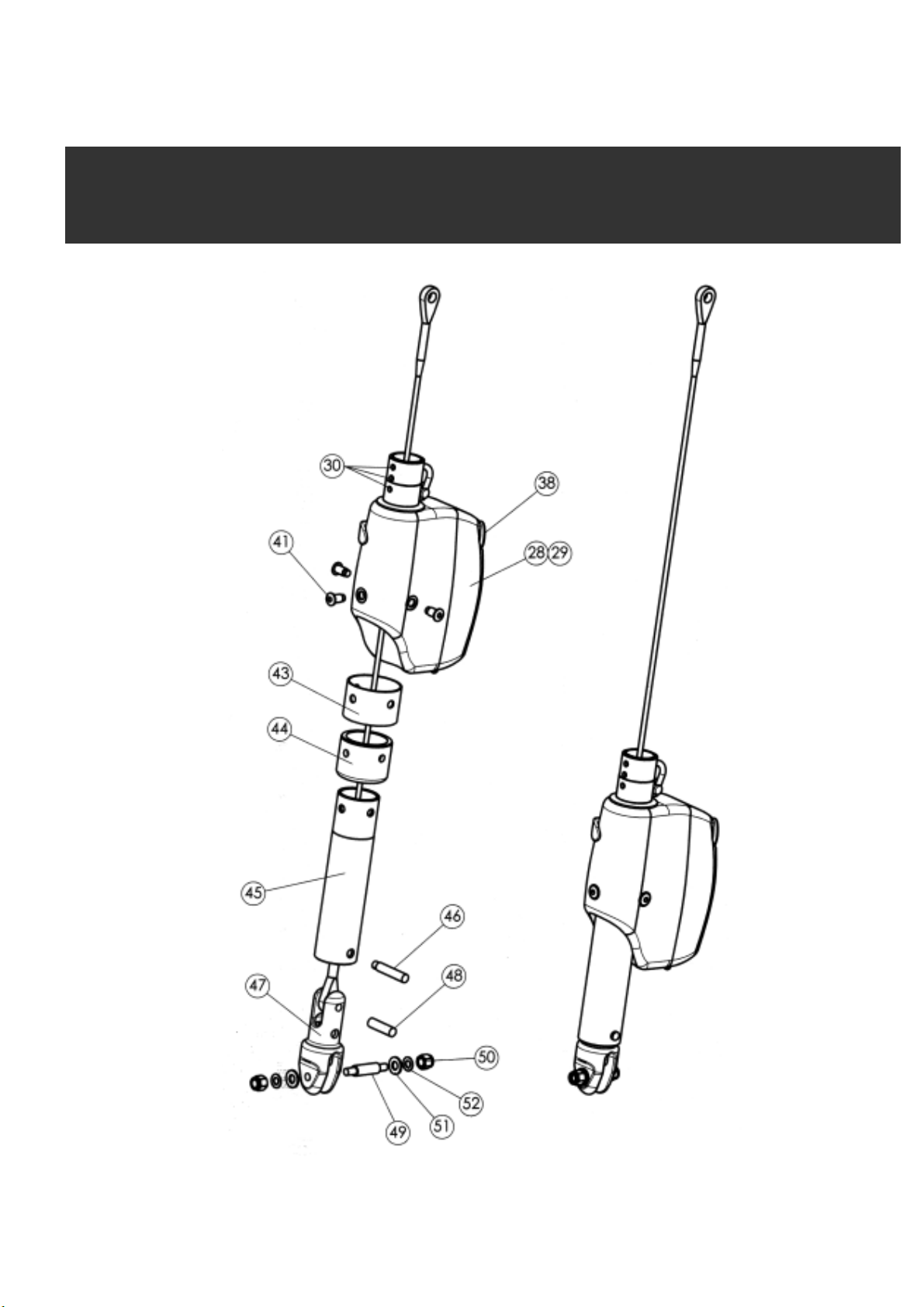

FITTING THE GEAR MOTOR

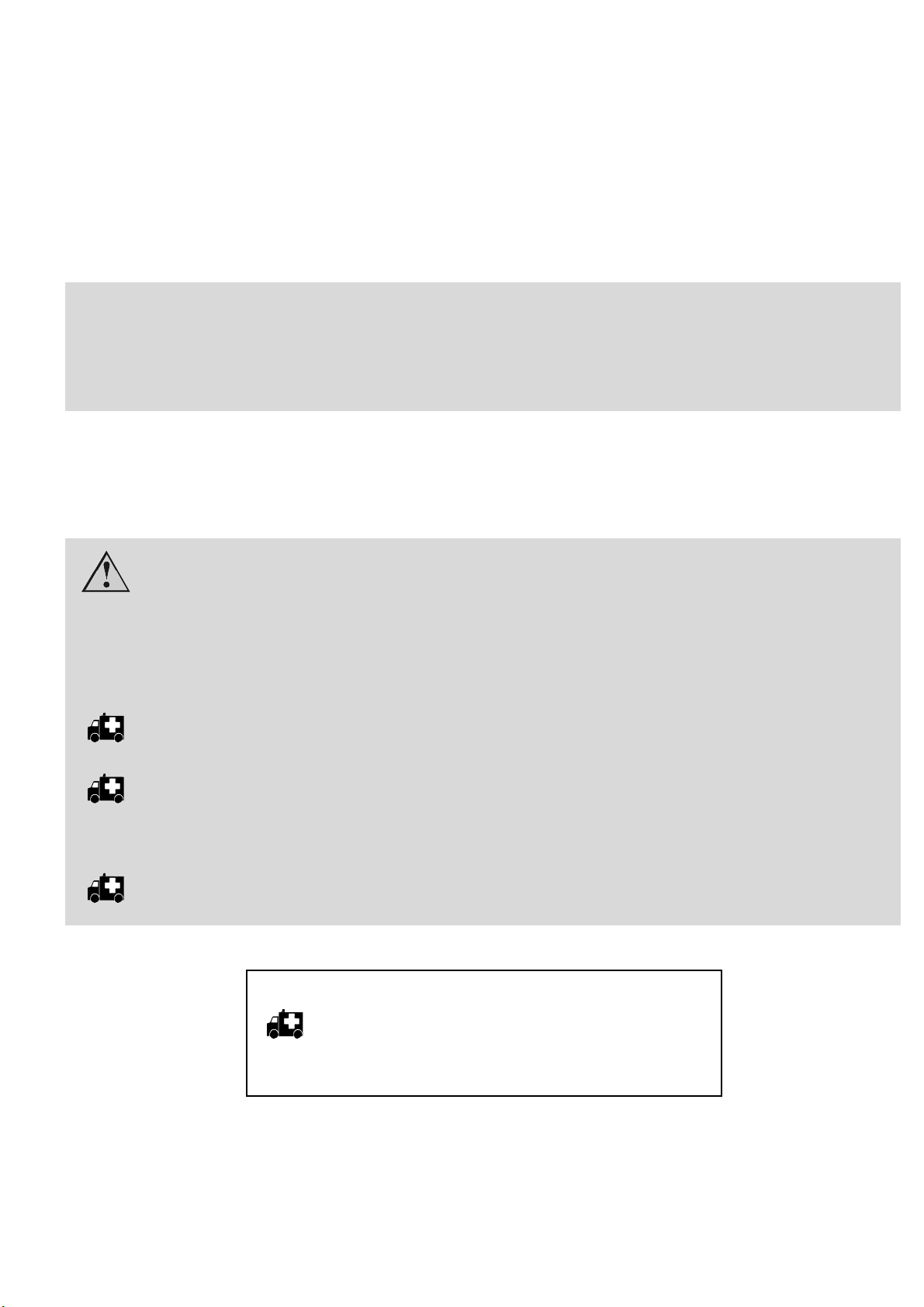

1 - For models 42 only, if t e system as been delivered wit a turnbuckle cylinder (52) - optional “I”

version:

• remove t e s ape adapter * (32) from t e gear motor,

• fit it at t e top of t e turnbuckle cylinder (52), align t e 3 oles in t e s ape adapter wit t e 3

corresponding t readed oles in t e cylinder.

• fit t e turnbuckle cylinder (52) at t e top end of t e gear motor, and screws (54).

* T e inside s ape of t e s ape adapter s ould matc t e outside

s ape of t e extrusions (round C 42, or foiled R 42).

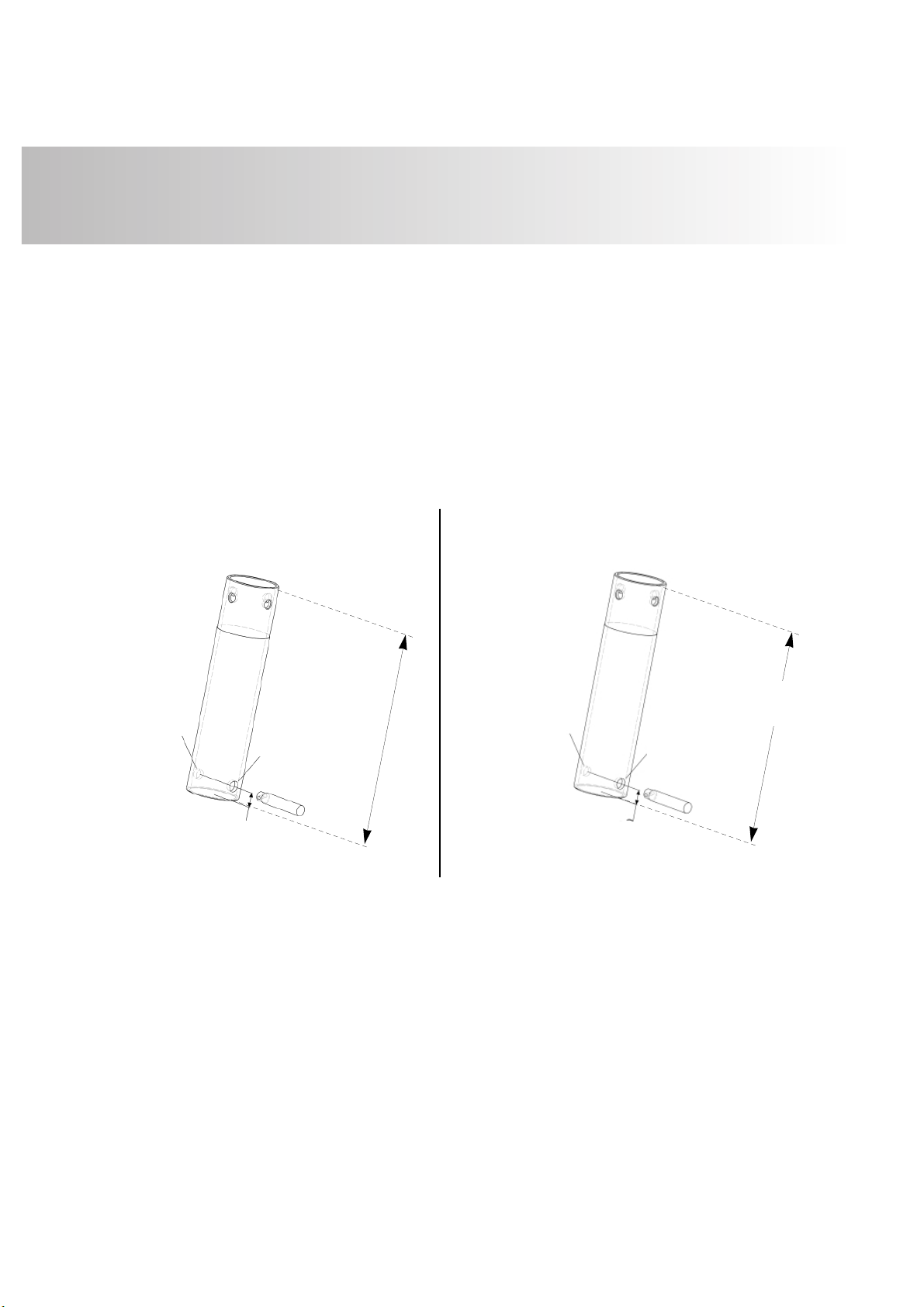

2 - Depending on boat’s design t e stem ead c ainplate may ave been

constructed in eit er at wart -s ips or longitudinal direction. T e stainless steel

tube (45) s ould be fitted into t e gear motor in t e correct position in order

to ensure t at t e andle socket (38) in t e gear motor is facing backwards.

3 - Slide up t e gear motor over t e bottom of t e stay until t e bottom

forestay terminal is easily accessible.

4 - Slide up over t e bottom end of t e stay in t is order :

• T e stainless steel ring (44) fitted over t e anti corrosion bus ing (43)

• T e stainless steel tube (45)

5 - Take t e forestay bottom terminal t roug and out of t e bottom end of t e

stainless steel tube, and fit t e bottom eye onto t e upper ole of t e toggle (47).

Retain t e pin (48) in t e ole of t e toggle (45) wit ad esive tape.

6 - Keep t e gear motor raised (wit a alyard if t e system is fitted on a standing stay).

7 - Fit t e toggle (47) over t e c ainplate wit t e t readed clevis pin (49) supplied,

fit t e was ers (51) and t e locknuts (50).

8 - Adjust tension of turnbuckle (if fitted).

9 - Lower t e stainless steel tube (45) over t e toggle, and fit t e clevis pin (48) supplied (t e one wit

a ead) to connect t e stainless steel tube (45) onto t e lower ole of t e toggle (47).

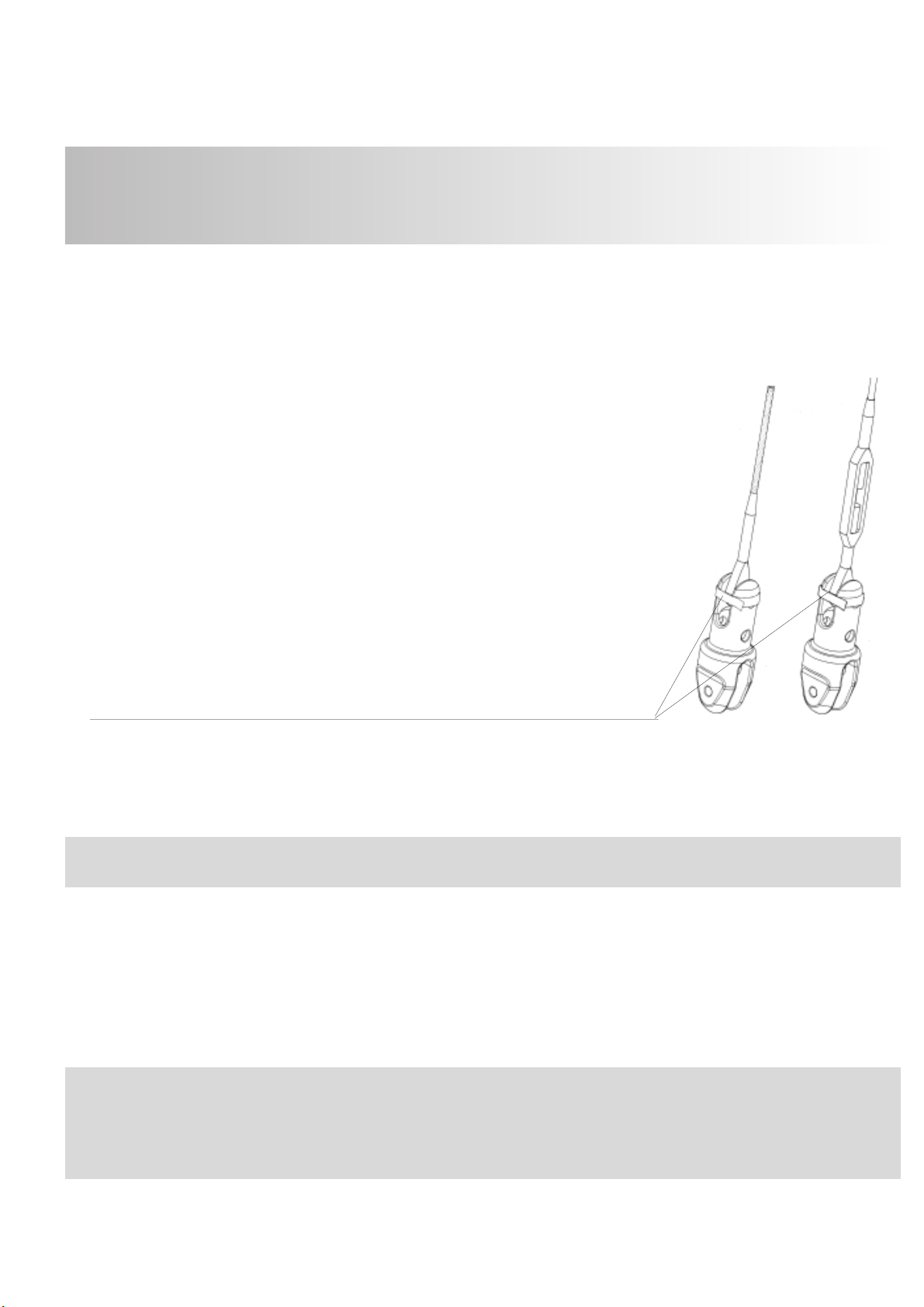

10 - Lower t e gear motor over t e stainless steel tube (45) and fit t e 3 screws (41) to attac t e gear

motor onto t e stainless steel tube.

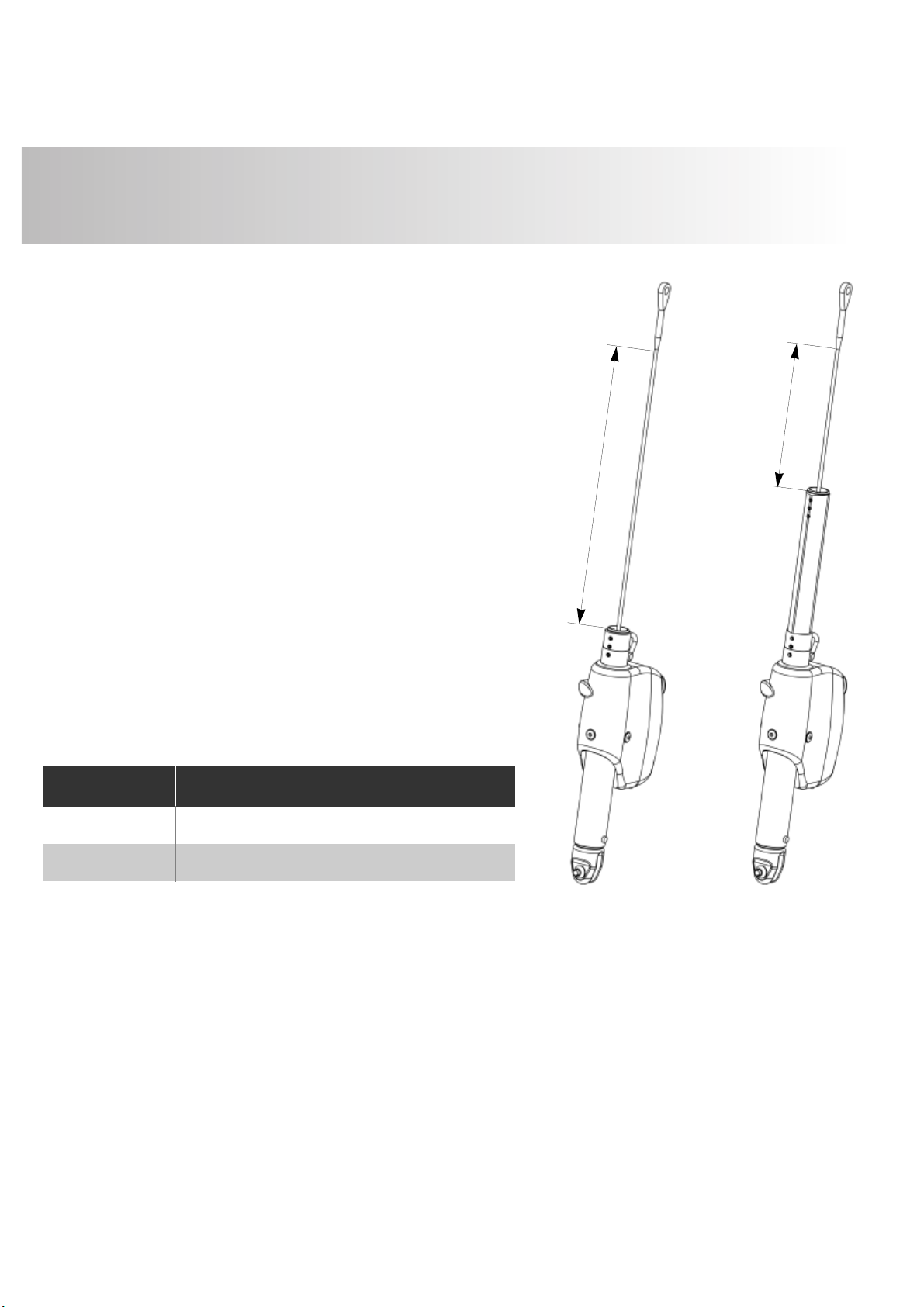

11 - During final assembly of t e extrusions, slide t em vertically into t e gear motor (or turnbuckle cylinder

if any) so t at t e black mark on t e lower extrusion is level wit t e top of t e s ape adapter (32). Fit

t e 3 set screws (30) to attac t e bottom end of extrusions.

8

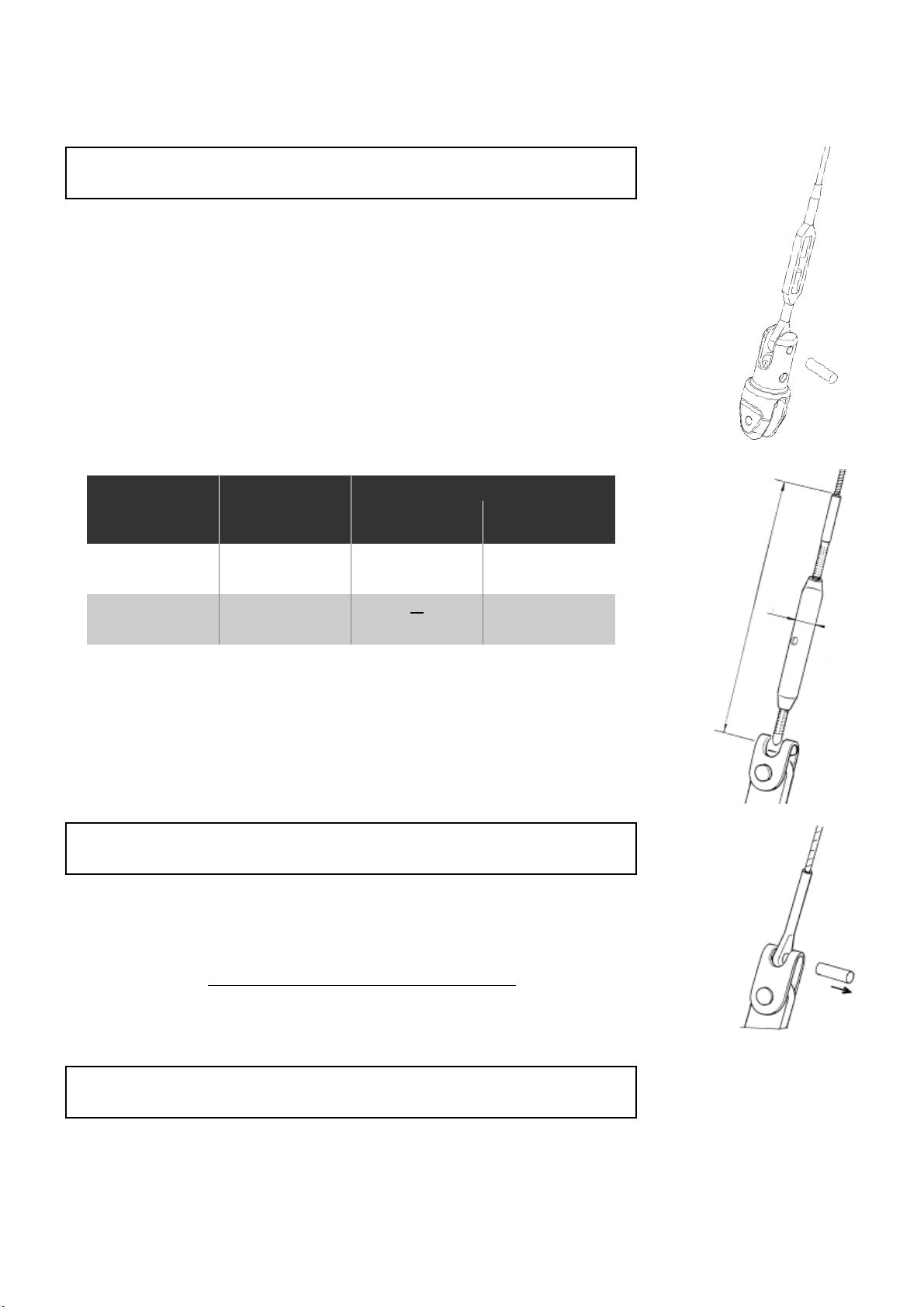

Properly secure t e turnbuckle to ensure t at it will NOT unwind w en operating t e system.

CAUTION!

W en adjusting your turnbuckle more open, please do not unwind and extend t e turnbuckle

longer t an t e maximum allowed lengt . Remind in case t e stainless steel tube as been s ortened,

ìNî dimension will be reduced accordingly. Please refer to eadboard 1.