Seakeeper 5 GYRO User manual

Other Seakeeper Boating Equipment manuals

Seakeeper

Seakeeper 26000 GYRO User manual

Seakeeper

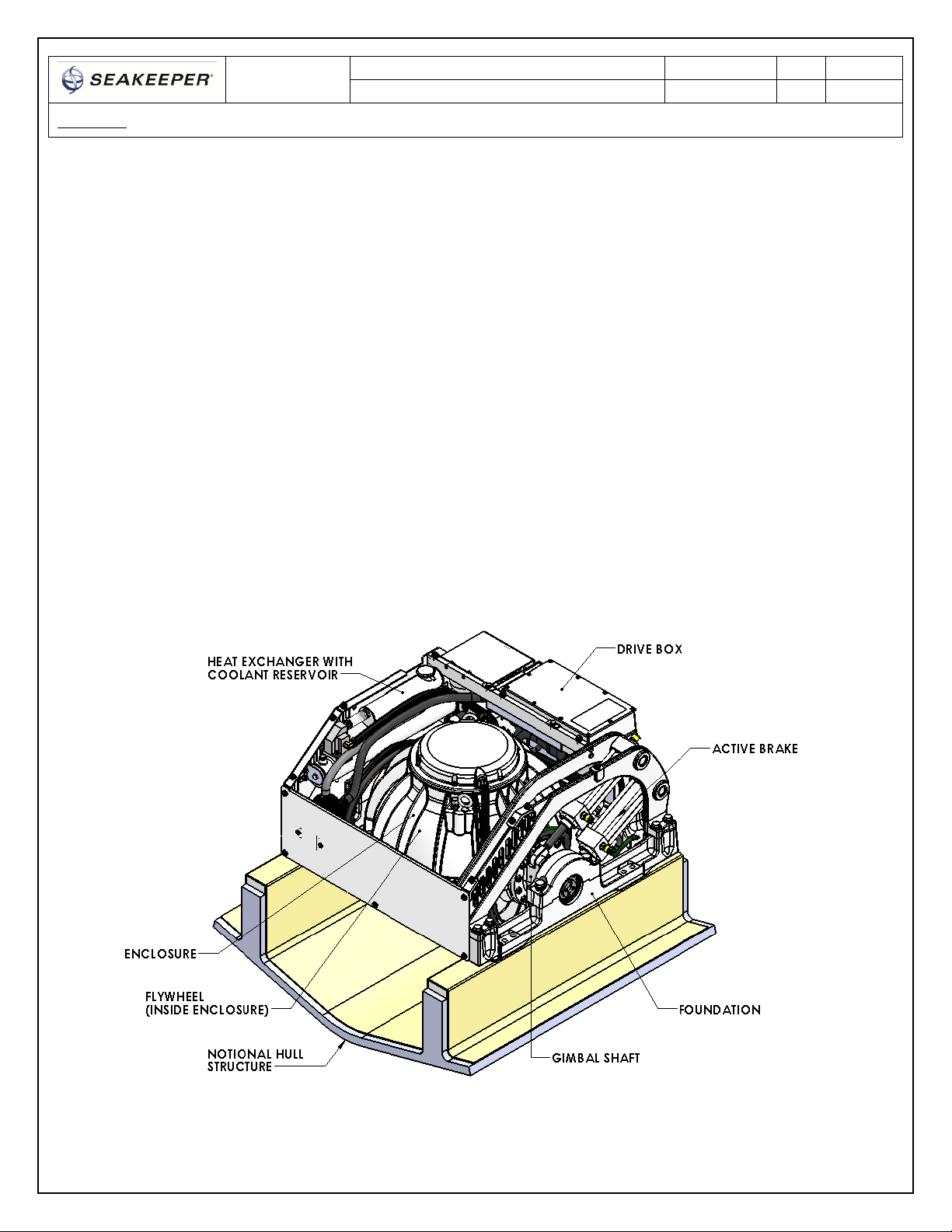

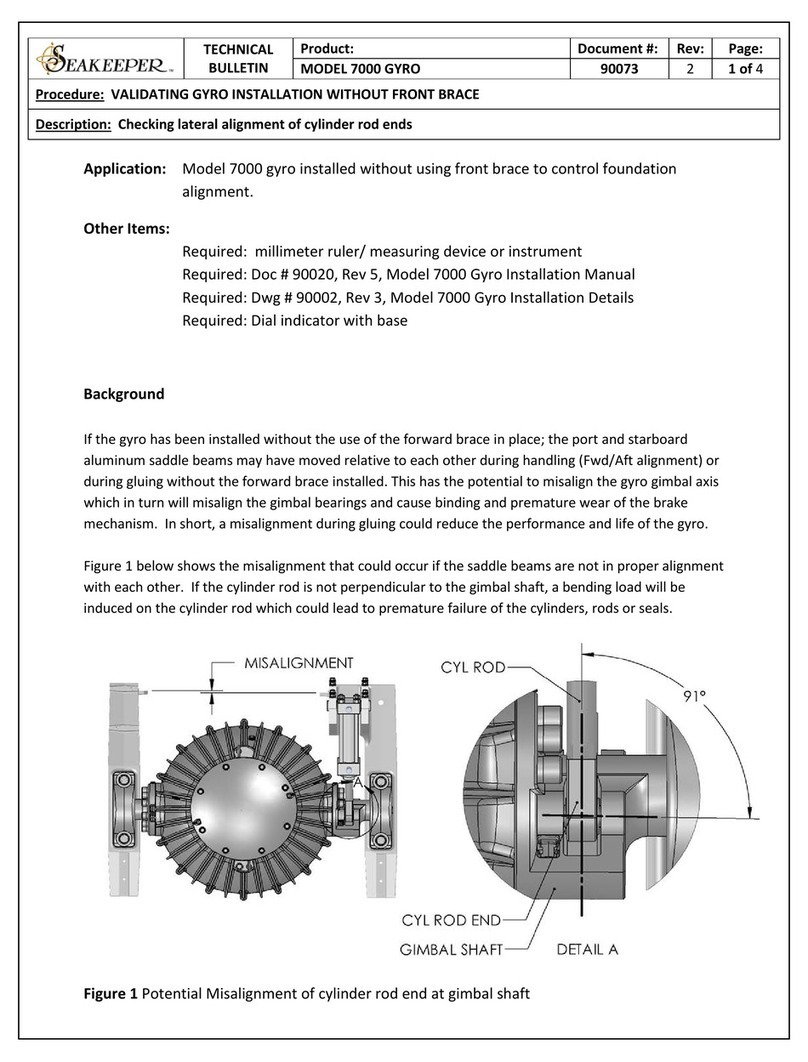

Seakeeper 7000 User manual

Seakeeper

Seakeeper 1 User manual

Seakeeper

Seakeeper 26 GYRO User manual

Seakeeper

Seakeeper 7000A GYRO User manual

Seakeeper

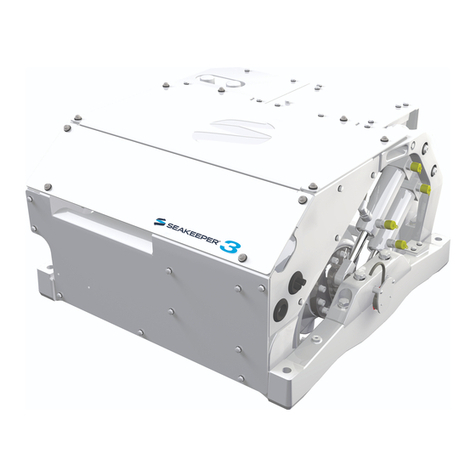

Seakeeper 3 User manual

Seakeeper

Seakeeper 7000 GYRO Service manual

Seakeeper

Seakeeper 1 User manual

Seakeeper

Seakeeper 26 User manual

Seakeeper

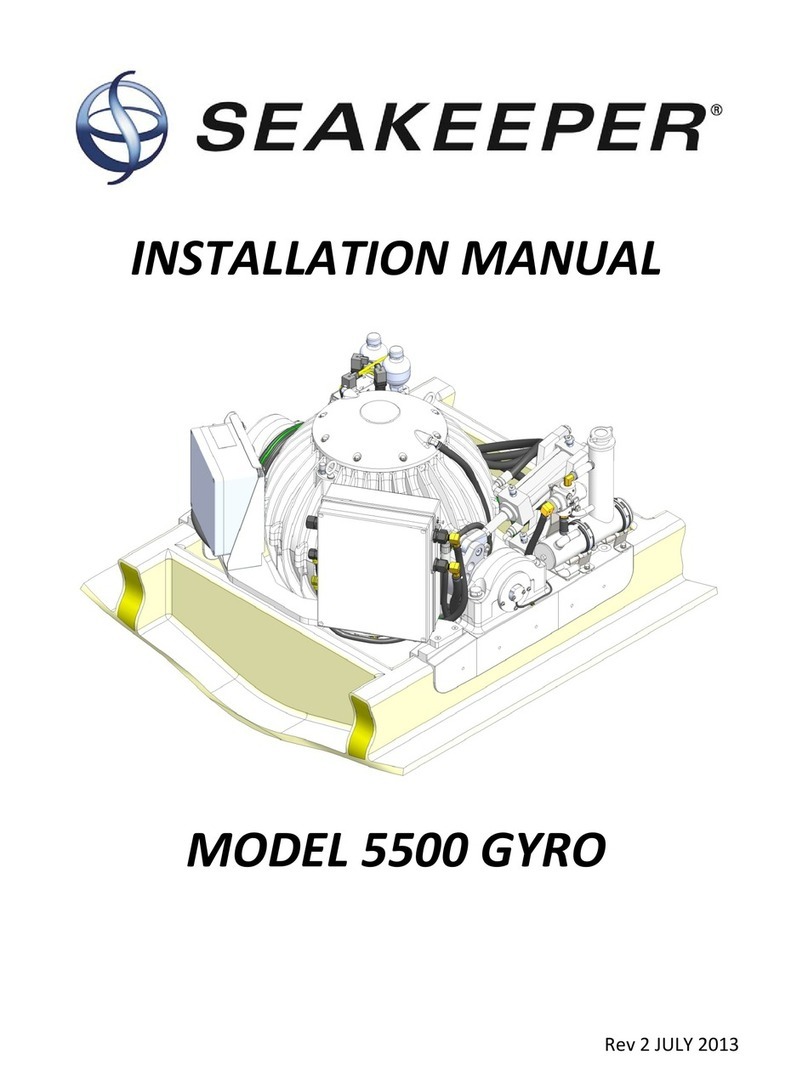

Seakeeper 5500 GYRO User manual

Popular Boating Equipment manuals by other brands

Humphree

Humphree HCS-5 installation manual

Vetus

Vetus BOW4512D Operation manual and installation instructions

Dock Doctors

Dock Doctors SLIDING BOARDING STEP Assembly instructions

Mastervolt

Mastervolt Mass Combi 12/2000-100 Quick installation

SeaView

SeaView PM5-FMD-8 installation instructions

Hobie

Hobie Mirage 360 manual