Progres diesel controll 100 User manual

1

INSTRUCTION

MANUAL

INDICE

Sec. THEME Page

1. FUNCIONAL DESCRIPCION 1

2. TECHNICAL CARACTHERISTICS 3

3. INSTALLATION 3

3.1. Wall mounting 3

3.2. Connections 3

3.3. Inputs 3

3.4. Activation by external order 4

3.5. Outlets 4

3.6. Supplementary relays 5

3.7. Option with preheating 5

3.8. Option for petrol engines 5

3.9. Option start-up of electric

generator for net failure detection

6

3.10. Miscellaneous notes 6

4. BREAKDOWN GUIDE 6

5.

CONNECTION SCHEME OF

MISCELLANEOUS OPTIONS 7

PRESENTATION

We wish to express our thanks for the confidence

in us which you have demonstrated by your interest in

our purchase of the DIESEL-CONTROL 100.

For us, this confidence inspires us to work harder

every day to deserve it, and thus, to justify the tradition

of quality which our products have.

This manual will allow you to see the capacity of

the unit as well as its installation and use.

However, if any doubts should remain, let us know

and we will happy attend to them.

1. FUNCIONAL DESCRIPTION

This is an electronic unit for the automatic

starting and stopping of diesel and petrol engines,

with breakdown detection.

STARTING

Starting can be carried out:

a) By means of a programmable clock which

can be built into the unit.

b) By signals from external elements (level

sensors, another programmer, etc.).

c) Manually ( “MANUAL START” button).

The activation time of the starter motor can be

adjusted between 1 and 12 seconds (“START”

button).

In case of a failure in the starting, the unit will

make up to 4 attempts, with 2 minute pauses between

them. If all attempts fail, there is an illuminated

indicator which warns of the occurrence (“START

FAIL”).

The unit will detect the starter failure by means

of the oil pressure.

There is a illuminated warning light for engine

working order (“WORKING”).

STARTER FUNCTIONING THEORY

On receiving a start order, be it from the builtin

clock, the manual start or external elements, the unit

activates the starter relay for the prefixed time set by

the corresponding adjustment. On finishing, it waits

for 1 and a half minutes to detect the working of the

engine through the oil pressure.

If it has failed to start, it will carry out up to 4

attempts, separated by a fixed timing of two minutes.

If all these attempts fail to start the engine, the

“START FAIL” indicator will be activated

The contact relay and the “WORKING” indicator

remain activated from start to stop.

If the engine is working and the pressure gauge

input is disconnected, the unit not obey start orders.

There is a CONTACT outlet which remains

2

activated from when the first attempt at starting is

made until the stop.

An electrovalve for irrigation can also be

connected to the contact outlet.

Optionally, the unit can be supplied with a

warm-up function. In this case, it will have a button for

programming the warm-up timing on the front, which

will function before the activation of the starter motor.

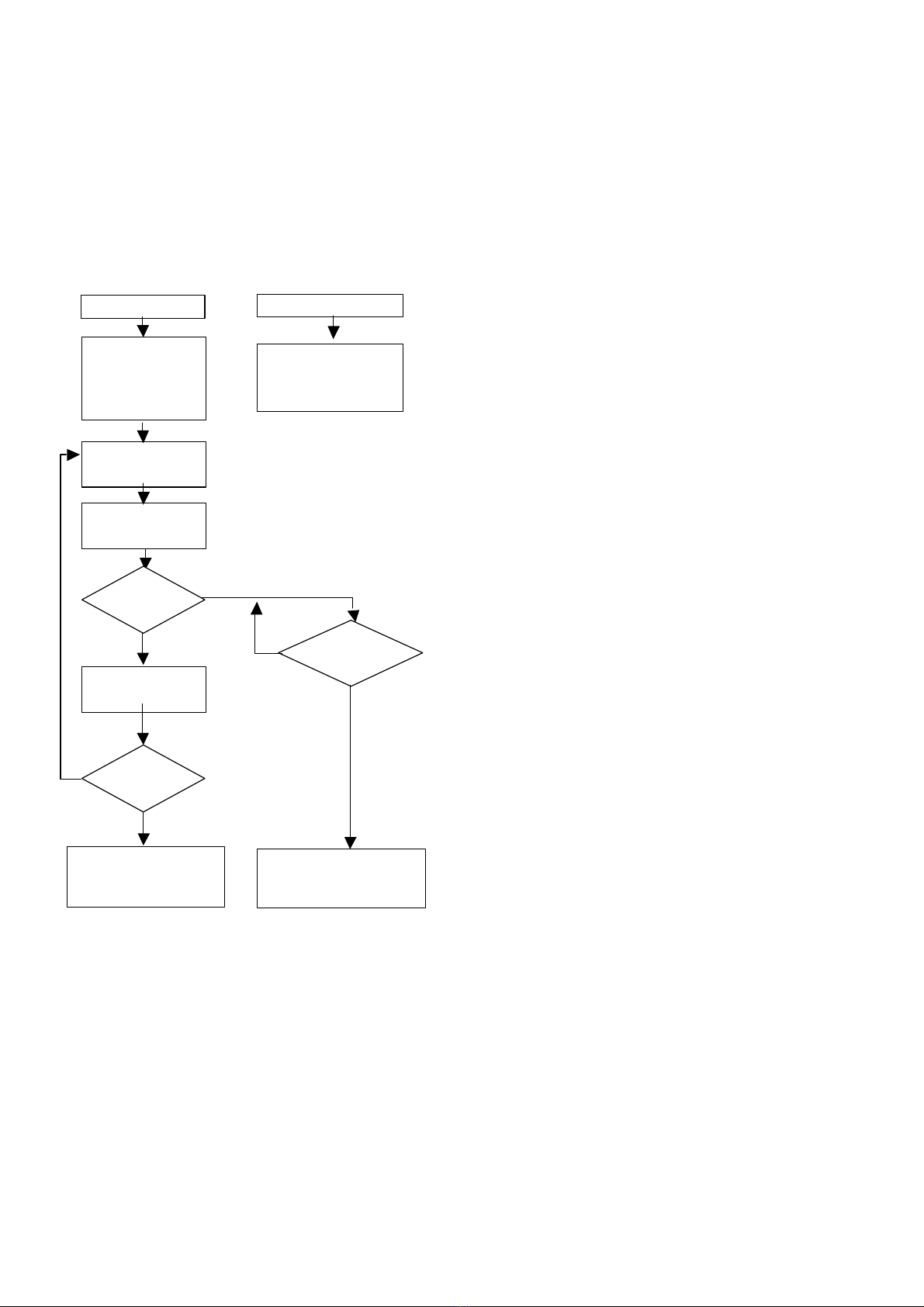

FUNCTION DIAGRAM

STOP

The stop can be caused:

a) By the end of the timing programmed on

the clock.

b) By obeying external elements such as,

for example, level sensors, irrigation

programmers, etc.

c) Manually (“MANUAL STOP” button).

d) By the detection of a breakdown by a

sensor connected to the corresponding

input (motor overheating, oil pressure,

lack of water, etc.), this being recorded

by the illuminated indicators (“SENSOR

BREAKDOWN”).

STOP FUNCTION THEORY

The stop is carried out by the activation of an

outlet, for a short period of time, which can be

connected to an electro-valve (cut in the fuel supply)

or an electro-magnet (choking the engine).

It is advisable to mount the electro-valve, for the

stop, on the engine, between the filter and the injector.

Stop time is adjustable from 6 to 90 seconds

(“STOP” button).

The setting for the stop timing should be left at

least 30 % longer than the time the engine actually

takes to stop.

BREAKDOWN DETECTION

Breakdowns will only be detected from one and

a half minutes after the engine has actually started.

On detecting a breakdown through the sensors

or in the oil pressure, the unit will automatically

activate the stop relay, also keeping the “SENSOR

BREAKDOWN” indicator lit although the breakdown

disappears. This will only go out on restarting. engine

again. However, if the breakdown continues, the unit

stop the

OPTIONS

WITHOUT CLOCK. In this option, the unit

incorporates a start/stop input for possible connection

to programmers or other external elements.

WITH ONE DAY CLOCK, which repeats the

programmes every day. In this option, 15 minute

intervals between orders are possible.

WITH WEEKLY CLOCK, which repeats the

programmes daily or weekly.

In this model, the intervals between orders are two-

hourly.

WITH DOUBLE SPHERE CLOCK, which repeats

the programmes daily or weekly, as in the “WEEKLY”

version, but with 30 minute intervals between orders.

WITH DOUBLE OUTLET DIGITAL CLOCK,

which allows orders by minutes and with daily or

weekly frequency. It has 2 outlets for, per example,

working with two different irrigation sectors, or with

only one but with independent fertilizer application.

WITH PRE-HEATING. With this option, the unit

preheats the engine before each attempt at starting.

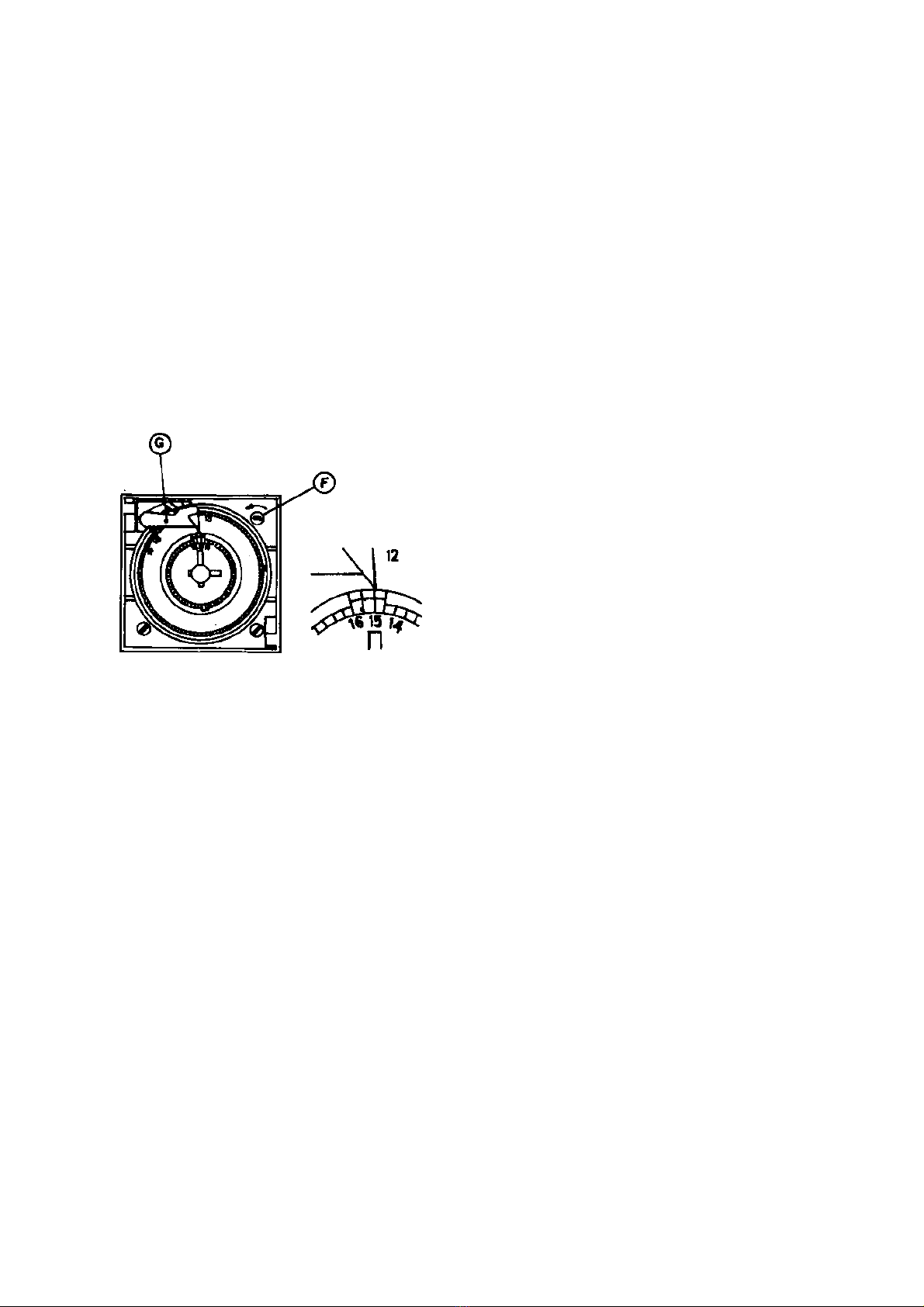

CLOCK

The Diesel Control can incorporate different

kinds of clocks. If they are digital, moreover of this

manual, there is one about the clock. If they are

analogical (of gantries) you can follow these

instructions:

ACTIVATION STOP

RELAY.

DEACTIVATION OF

WORKING INDICATOR

STOP

WORKING

STARTER TIMING

ACTIVATION

CONTACT AND

WORKING

INDICATOR: 1ST

START ATTEMPT

1 ½ MINUTE WAIT

MOTOR HAS

STARTED

1 ½ MINUTE WAIT

IS IT THE

4TH

ATTEMP

T

ACTIVATION OF

STARTER BREAKDOWN

INDICATOR

BREAKDOWN

ACTIVATION OUTLET

ACTIVATION SENSOR

BREAKDOWN INDICATOR

SI

YES

NO

NO

NO

YES

3

PROGRAMATION

Adapt the gantries of programming moving

them out (for the time that you want the engine to be

active) or pressing to put them in.

SETTING IN TIME

Use the command “F” of working of spheres

and pointers, avoiding moving them directly. For the

setting in time, consider the index of operations “G” as

much as the pointers; thus, if we want to select 15

hours, the index of operations “G” should have to

indicate 15,00 and the pointers should be at the

position that the figure indicates.

In the double sphere clocks, have to be

programmed the internal and the external sphere.

WARRANTY

The unit is warranted against manufacturing

defects for two years.

Breakdowns caused by accidents, mis-

connection and unauthorised use are excluded from

this warranty.

2. TECHNICAL CHARACTERISTICS

PROTECTION

Protection against polarity changes in the feed

input.Protection against power surges.

Protection against the chance activation of the

starter when the engine is working.

UNIT CONSUMPTION

Stopped 0.0025 A (0,03 W).

Working 0,0600 A (0,70 W).

PERMITTED WORKING TEMPERATURES

From -5 º C to +45 º C.

COMPONENTS

C-MOS integrated circuits. 10 A relay outlet.

MOUNTING BOX

Metal with lock, 25x25x8.

3. INSTALLATION

3.1. WALL MOUNTING

4 pieces for wall mounting are supplied with the

unit, which are mounted, from the outside and without

need to open the unit, in the holes on the back of this.

Site the engine, battery and DIESEL-CONTROL

as close as possible to each other, bearing in mind

possible problems which might arise such as, for

example, a water leak from the pump wetting the unit,

engine vibrations, etc...

3.2. CONNECTIONS

To connect the unit, remove the “connection

housing” cover.

3.3. INPUTS

Feed the unit 12v DC (INPUT terminals 7 and 8)

respecting the polarity.

The connection should be made with 2.5 mm2

cross-section cables, with direct feed from the battery

terminals, without any other connection between these

two points.

On connecting the unit to the battery, wait about

3 minutes before beginning any working operation. If

any warning light stays lit, press the MANUAL STOP

button and the unit will be prepared to initiate the

starter sequence.

Input no. 5 (STARTER DETECTOR) must be

connected directly to the oil pressure gauge,

prescinding any other connection (for example, the oil

warning light). To make the connection, first

disconnect the pressure gauge and do not reconnect

it as, if not, the unit could be damaged. The cable

cross-section should be 1.5 mm2.

When the unit does not obey start orders, it will

4

normally be because of the oil pressure gauge, given

that if it fails to receive a signal from this gauge, the

unit will understand that the engine is already working.

3.4. ACTIVATION BY EXTERNAL ORDER

When the Diesel-Control is delivered without

clock, and thus, is destined for activation by other

units, it will dispose of an input (terminals 1 and 2) for

these.

In this case it will be necessary to leave the

outlet to be used by these external units free of

tension.

The Diesel-Control, on receiving a signal will

initiate the start and when the signal ceases it will

activate the stop. Because of this, it will keep the

engine activated while there is a contact on inputs 1

and 2.

Even when the unitincludes a clock, it can carry

out starts and stops obeying level sensors, or similar,

by way of inputs 2, 3 and 4. (External signals always

free of tension). In these inputs the cables can be of 1

or 1.5 mm2 cross-section.

These inputs, differently from number 1 and 2

before, are independent for starts and stops and,

furthermore, only function with the initial impulse of a

signal or contact.

There use will be useful when the start has to be

by clock and the stop by level indicator (inputs 2 and

4); or when the activation is by sensor (inputs 2 and 3)

and the stop by clock; or when their is external

activation and deactivation by way of differentiated

impulses for start and stop.

In input 6 (breakdown) any kind of sensor with a

normally open contact, free of tension can be

connected. The cross-section of the cable can also be

either 1 or 1.5 mm2.

3.5. OUTLETS

Terminal no. 1 (common outlet) must be

connected directly to the positive battery terminal. The

cross-section of this cable can be 2.5 mm2.

The outlet for activating the starter motor

(terminal 2) has a relay with a maximum intensity of

10ª (as have the remaining outlets).

However, it is necessary to install a

supplementary relay between this outlet and the

starter motor. Follow the instructions which appear

later. This terminal has to be connected to one pole

of the supplementary starter relay winding. The other

pole has to be connected directly to the negative.

These cables can be of 1.5 mm2 cross-section.

The starter relay common outlet must be

connected directly to the positive with a direct 6 or 8

mm2 wire. The other contact must be connected to

the distributor with a similar wire.

There are engines which need to work with

double injection by way of a small electro-magnet

which will be connected in parallel with the starter.

The stop outlet (terminal 3) can act directly

without a relay in between, through an electro-valve

(which will temporarily cut the fuel supply) with a

1.5mm2 cable.

The stop electro-valve will be installed between

the filter and as close as possible to the injector input

and will normally be open and at 12v DC.

The engine can also be stopped by way of an

electro-magnet (which chokes the engine).

If the electro-magnet system is chosen, a

supplementary relay must be installed. The

connecting up of the Diesel-control and the relay and

that of this to the electro-magnet will be carried out in

the same way as in the case of the start. It being

possible to bridge the negatives of the relay windings

and the positives of the common outlets of the

contacts, with the same sections as specified above.

The contact outlet (terminal no. 4 will remain

activated from the moment of starting until the stop.

The contact outlet gives positive whenever the

unit is working (“WORKING” LED illuminated). This

outlet will only be used in case we need to activate a

general aperture electro-valve, or when the engine

needs the contact signal to charge the battery.

In this case it can be connected directly to the

contact position of the starter key.

At the contact outlet, an electro-valve for

irrigation can be connected if necessary.

Use 35 mm2 cross-section cable as normally

used in the motor industry from the battery negative to

the engine chassis. This section should be increased if

the distance between the battery and the engine is

greater than 3 metres.

The connection to the engine or the support

must be good. An adequate place could be where the

rectifier negative connects to the earth 9.

The cable from the positive to the starter motor

terminal should have a cross-section of 20 mm2, for a

distance not greater than 4 metres, so that the tension

drop on starting the engine is minimum; this way the

battery charge will also be used to its maximum by the

alternator.

For the connection of Diesel-control, it would be

convenient if all the cables had terminals, by which a

greater degree of security and a better appearance

would be achieved in the connections, thus also

avoiding poor connections which occasionally causes

false contacts.

Avoid producing short-circuits in the cables

given that the unit does not contain fuses (to avoid

tension drops in the same).

5

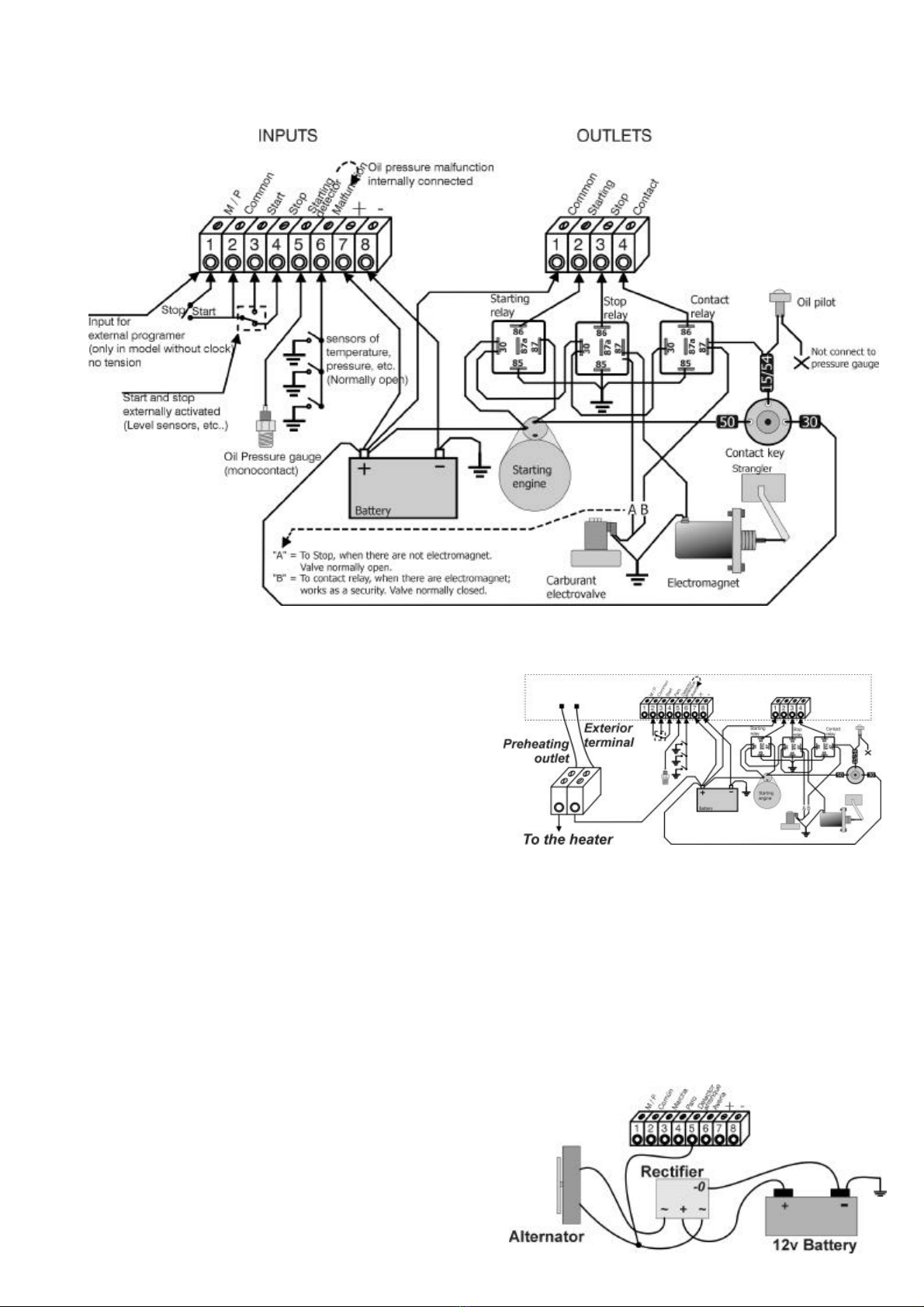

CONNECTIONS SCHEME

3.6. SUPLEMENTARY RELAYS

The supplementary relays on the start and stop

outlets will protect the Diesel-control from possible

anomalies from problems arising from the high power

which the distributor or electro-magnet needs for its

correct working.

The relays used will be 12v, with a shorting

capacity of 20 or 30ª. These relays are the type usually

used in the motor industry.

The supplementary relays can be placed inside

a sealed box of the type used in electrical installations,

which will be mounted as close as possible to the

engine.

The cables (1.5 mm2 sections) which govern

the supplementary relays will come out of terminals 2

and 3 (start and stop). These cables carry the positive

to the pole of the winding.

3.7. OPTION WITH PREHEATING

The units delivered with this option incorporate

another button on the frontpiece where the timing (in

seconds), of the preheating to be carried out before

the attempt at starting, can be programmed.

To connect the heater, in the connection housing

there will be a loose terminal which comes from the

positive. Place a relay like those described above

here.

CONNECTIONS SCHEME

3.8. OPTION FOR PETROL ENGINES

Only for the units that they have this option.

In petrol engines, which generally do not have

oil pressure gauges, the detection of the start is

determined by the moment when the alternator begins

to generate electrical tension.

For the connection of the unit it is sufficient to

take one of the poles of the alternating current

generated by the alternator to input terminal no.5

before it enters the rectifier. (See the following

diagram).

Table of contents

Other Progres Industrial Equipment manuals