ProJet MJP 2500W User manual

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

1/26

Quick Start Guide

ProJet MJP2500W/ IC

Quick Start Guide

p/n 33-D130 Rev C

Original Instructions

Please refer back tohttp://infocenter.3dsystems.com/projetmjp2500w/quick-start-guidefor the most up-to-date quick start guide

Introduction

ProJet MJP 2500W

The ProJet®MJP2500W3D printer system is a Multi-Jet Printer (MJP) printer. The solid imaging 3D printer produces wax casting patterns

from 3D solid Computer-Aided Design (CAD) models and through the 3D printer system client software. The parts are generated in a rapid

prototype (RP) environment. The primary features of the printer are the user interface, build chamber including the print engine, and the material

delivery module (MDM), which contains the materials and waste bag.

VisiJet® Materials for ProJet®MJP 2500W

ProJet®MJP 2500W VisiJet®M2 Cast(PW - Part Wax)

VisiJet® Wax Jewel Red(PW - Part Wax)

NOTE:The ProJet® MJP 2500W is a wax printer and thus has no UV lamps installed.

®

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

2/26

ProJet MJP 2500 IC

The ProJet®MJP2500 IC3D printer system is a Multi-Jet Printer (MJP) printer. The solid imaging 3D printer produces wax casting patterns

from 3D solid Computer-Aided Design (CAD) models and through the 3D printer system client software. The parts are generated in a rapid

prototype (RP) environment. The primary features of the printer are the user interface, build chamber including the print engine, and the material

delivery module (MDM), which contains the materials and waste bag.

VisiJet® Materials for ProJet®MJP 2500 IC

ProJet®MJP 2500 IC VisiJet®M2 ICast

(PW - Part Wax)

NOTE:The ProJet® MJP 2500 ICis a wax printer and thus has no UV lamps installed.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

3/26

Safety Information

Safety Symbols and Denitions

ELECTRICAL SHOCK HAZARD: High voltage electricity is accessible in the vicinity of this sign or behind the access panel. High voltage

can cause severe burns or death, as well as res. Access panels are for service only and should be opened only by certied service

personnel or trained maintenance personnel.

HOT SURFACE HAZARD: A hot surface is accessible in the vicinity of this sign or behind the access panel. Avoid contact. Hot surfaces

can cause burn injury or re. Allow surface to cool before touching. Access panels are for service only and should be opened only by

certied service personnel or trained maintenance personnel.

KEEP FINGERS AWAY FROM FAN: Putting ngers in way of moving fan can cause serious injury.

KEEP FINGERS AWAY FROM SHARP OBJECTS: Putting ngers in way of sharp objectscan cause serious injury.

HARMFUL IRRITANT WARNING: Indicates that skin or eye irritation could result while exposed to a chemical composition.

CAUTION: Indicates the possibility of loss of data or damage to equipment.

WARNING: INDICATES THE POSSIBILITY OF INJURY OR DEATH TO PERSONNEL.

HAND ENTANGLEMENT WARNING:GEARS OR MOVING PARTS HAZARD IN THE VICINITY OF THIS SIGN OR BEHIND THE ACCESS

PANEL. ACCESS PANELS ARE FOR SERVICE ONLY AND SHOULD BE OPENED ONLY BYAUTHORIZED SERVICEPERSONNEL.

WEAR GLOVES: Wear the appropriate gloves when required. For example, when touching surfaces that may contain or have been

exposed to materials, wear nitrile gloves. Heat gloves are necessary when touching surfaces that may be hot to ensure burns don’t occur.

NOTE: A note signies important information but not information of a critical content.

Safety Guidelines

General

The 3D printer system is designed with built in safety features, improper use can cause injury to personnel.

Follow these safety guidelines when operating the printer:

Read and follow all 3D printer system instructions. Printer should only be operated by trained personnel.

Follow all safety rules and heed all cautions and warnings in this guide.

Do not attempt to open top door while printing.

Do not use any material without reviewing the Global Harmonized Standards/Safety Data Sheet (GHS/SDS).

Dress power and communication cables behind printer to prevent tripping.

Do not attempt to access, service, or adjust printer components or perform procedures without reviewing the documentation for user

accessible maintenance routines unless specically trained to do so.

Only certied service personnel that have completed the 3D Systems service trainingmay perform tasks they are authorized and certied to

complete.

Do not ignore warning signs posted during 3D printer system service operations.If an error message appears on the 3D printer system’s User

Interfacerefer to “Troubleshooting Section” within this guidedepending on the error, before resuming operation.

To prevent potential skin irritation and sensitization due to contact with waste material or uncured Part Material, follow all guidelines in the

following sections.

Protective Equipment/First Aid

Follow recommendations for protective equipment and general rst aid procedures to minimize the risks from part material exposure. If

professional medical attention is necessary, take the Global Harmonized Standards/Safety Data Sheet (GHS/SDS) for the exact material

involved to the attending physician.

Always wear 100% nitrilegloves and lab coats when handling any part or waste material. Latex gloves are not chemical-resistant and

are not recommended.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

4/26

In the event of a leak or spill of uncured part material, wear safety glasses with side shields to provide eye protection.

Because of the 3D printer system’s built-in engineering controls, respiratory protection is not necessary during normal operation. A

NIOSH-approved (or equivalent) dust mask is recommended when dry sanding cured material parts.

Always wear protective sleeves or a lab coat when doing anything around the materials. When skin comes in contact with materials

they can cause an allergic reaction that can be harmful to skin.

Skin Contact

Uncured part material is a sensitizer, and can cause allergic reactions if skin comes into contact. When handling any part or waste material,

always wear 100% nitrile gloves and lab coats.

Should skin come into contact with uncured part material, wash thoroughly with soap and cold water and immediately remove contaminated

clothing and shoes. Do not use hot water or solvents to wash hands, as it will result in absorption through the skin. If skin is irritated, seek

medical attention. Dry-clean contaminated clothing and discard contaminated shoes and leather products in accordance with applicable

regulations.

Eye Contact

Safety goggles with side shields should be worn to prevent accidental splashes into the eyes. If material comes in contact with the eye, ush

immediately with large amounts of cold water for 15 minutes, avoid sunlight, uorescent light, and other ultraviolet light, and obtain immediate

medical attention. Eye wash facilities and a rst aid kit should be readily available and close to the 3D printer system.

Contact Lenses

Wearing contact lenses is not recommended if handling liquid materials. If material splashes into eyes when contact lenses are worn, ush eyes

immediately with water. Verify that ushing has removed the contact lens from the eye(s). Protect eyes from light and obtain immediate medical

attention. Discard contact lenses that come into contact with liquid material.

Fume Inhalation

Under normal operation, inhalation is not an expected route of entry. Always work in a well ventilated area when using materials and avoid

breathing vapors. If inhaled, remove the personalto fresh air. Give articial respiration or cardiopulmonary resuscitation (CPR) if required. If

breathing is dicult, give oxygen. Obtain immediate medical attention.

Ingestion

Uncured part material is toxic if ingested. Obtain immediate medical attention.

Hygienic Practices

Because uncured material is toxic if ingested, it must not be present where food and drink are stored, prepared, or consumed. After handling

materials, wash hands with soap and cold water before consuming meals, breaks, smoking, applying cosmetics, using toilet facilities, and after

work.

Employees should be alerted of the need to clean and rinse off any contacted surface promptly in order to prevent further contamination. Ensure

a convenient washroom location is provided with access to soap, water, and disposable paper towels.

Tools contaminated with part material should be cleaned prior to reuse. Solvents such as denatured alcohol or Isopropyl Alcohol (IPA), are

normally required to clean equipment and tools. Wash with soap and water to remove any traces of excess part material or solvent.

Material Handling and Safety

Prior to using the ProJet® MJP 2500 and 2500

Plus

, users should be aware of potential hazards which may result in exposure to uncured part

material, such as removal of the material waste bag and handling part material cartridges.

Emergency (GHS/SDS)

Chemtrec USA (800) 424-9300; Europe +1-703-527-3887

Consult the materials Global Harmonized Standards/Safety Data Sheets (GHS/SDS) for information on specic materials. For further

information on this and related topics, consult the 3D Systems - Materials website at http://www.3dsystems.com/support/materials/msds.

Packaging Inspection

The material cartridges are packaged in shipping cartons. Upon receipt of materialshipments, inspect cardboard carton exterior for signs of

damage and leakage. Ifleakage is observed, DO NOT open carton, and contact 3D Systems’s TechnicalSupport Hotline.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

5/26

ProJet® MJP 2500W ProJet® MJP 2500 IC ProJet® MJP 2500W

ProJet® MJP 2500W ProJet® MJP 2500 IC

Material

(Part/Support)

VisiJet®

M2

Cast(Part)

VisiJet® M2 SUW(Support) VisiJet®

M2 IC

(Part)

VisiJet® M2 IC SUW(Support)

VisiJet®

Wax Jewel

Red(Part)

Shelf Life 2 Years 2 Years 2 Years 2 Years

Climate Cool, dry area with adequate ventilation

Temperature Range 60°F (16°C) to 80°F (27°C)

Maximum Storage

Temp

95°F (35°C)

Environmental

Conditions

No direct sunlight, heat, ames, or UV energy. Do not expose materials to heat at or above 230°F (110°C) , ames,

sparks, or any source of ignition.

Storing a Partially Used Material Cartridge

It is important not to lay material cartridges that are partially used on their side. Doing so will cause material to seep through the vent cap and

clog cap. This will cause damage to the material cartridge if used for a later print.To store a partially used Material Cartridge, place it upright in

a ProJet® 2500 Cartridge Holder and tighten the vent cap.

Recertication Date

Always check material "Recertication Date" before use. If the cartridge has reached its Recertication Date, your 3D Systems certied Partners

or 3D Systems Technical Support can assist with questions on materialrequiringrecertication.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

6/26

Disposal

Support Material

Support material has no known regulatory requirements and may be disposed of in ordinary oce waste.

Spilled Material

Spills of material are unlikely, and should NOT occur in normal operation of the 3D printer system.

Spills of support material can be cleaned without the use of protective gear, and disposed of as oce waste.

Promptly remove spilled materials, dispose of waste materials, and clean up materials per local regulatory requirements.Small spills of uncured

liquid part material can be cleaned up using disposable towels, non-reusable rags, or absorbent materials to clean spills outside of the

printersuch as sawdust, clay, diatomaceous earth, or activated charcoal and placed into containers for transfer to an approved waste disposal

site.

Caution: Never put sawdust, clay, diatomaceous earth, or activated charcoal inside the printer, doing so will damage the printer.

If spilled material is hot (liquid), wait until it cools before wiping up. Use of heat above 65° (149°F) may prove helpful in removing spilled support

material from carpet. After wiping up the spill, wipe surface with denatured or isopropyl alcohol and clean thoroughly with soap and water.

Some cleaning solvents are highly ammable such as denatured alcohol and isopropyl alcohol. Before using solvents to clean and remove

uncured part material, be sure read and follow thesolvent suppliersafety precautions and recommended usage.

Flammability Hazards

Though the U.S. Department of Transportation does not consider VisiJet materials a "ammability hazard," they do classify them "combustible"

based on ash points. Material containers may rupture when exposed to extreme heat. Use National Fire Protection Association Class B

extinguishers such as carbon dioxide, dry chemical, or foam.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

7/26

At A Glance

The three dimensional solid partsconsist of two materials (support material and part material). The support material is a wax based material

providing adhesion to print platform, as well as, providing material used to produce supports required to build the your part.

The part material is a wax material. After a layer of material is deposited onthe build plate, the part is immediately solidied by cooling of the

molten wax. When the build is complete, the part (consisting of the two materials) is adhered to the print platformby means of the support

material).

The material delivery module consist of four material cartridge holders; the two left side holders are for the support material (white) cartridges.

The right side of the module are for two part material (grey) cartridges. Once materials are heated, they are fed to the printhead. Material waste

is generated by two processes; cleaning the printhead array plate and planarization. The cleaning process involves purging jets and wiping the

printhead array plate. The planarizer removes excess material during the print process.The combined waste materials are then periodically

emptied into the waste bag. The printhead cleaning process is invoked automatically prior to starting a build.

.

After the build is complete, the print platformand the part arethen removed from the printer. A secondary operation, known as post processing,

is required to provide anished/cleaned part. Refer to yourPost Processing Guide for more information.

ProJet® MJP 2500W/IC Printer System

Print Engine : The Print Engine contains major systems such as the Printhead, andPlanarizer.

Build Chamber: TheBuild Chamber is the area where the print platform can be found. All print jobs are built on the print platform. For more

information see Printing Area.

User Interface (UI): This is the built-in touchscreen which allows the user to interface with the printer. The touchscreen allows the user to check

printing status, material levels, as well as power printer off. For more information on what user can access through the UI go to the User Interface

section of this manual.

Power Cord and Power Switch:The electrical power cord is plugged into the printer here. There is also a Power Switch located next to the power

outlet.

Material Drawer Module (MDM): The MDM drawer is a push/push type mechanism. To open the drawer push in, drawer should pop open allowing

you to pull it open the rest of the way. The MDM contains the part and support materials and the waste bag.

Printing Area

The actual area that you can print a job consists of the x-axis (left-to-right)times (x) the y-axis (front-to-back) times (x) the z-axis (max height).

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

8/26

English (X x Y x Z) Metric(X x Y x Z)

11.6" x 8.3" x 5.6" 294mm x 212mm x 144mm

3D Printer System Components

Material Delivery Module (MDM)

ProJet® MJP 2500W/ IC

Support Material Containers 1 and 2: These containers hold the VisiJet® M2 SUW or VisiJet® M2 IC SUW (Printer specic)support material

that is used for the build. The support material is housed on the left side of the MDM in the white receptacles.

Part Material Containers 1 and 2: These containers hold the cartridges of the VisiJet® part material, which are used to build parts on the 3D

printer system. The part material is housed on the right side of the MDM in the black receptacles.

Smart Cartridge Technology:All cartridges incorporate smart cartridge technology that enables the ProJet® MJP 2500W/ IC to verify that the

user does not use the wrong material, use material incorrectly, or use empty or expired containers, ensuring the material is safe to use.

Waste Bag Receptacle

Behind the Support Material cartridges there is a waste bag receptacle area containing a disposable bag and rigid liner. The waste bag and liner

will need to be changed periodically. See Changing Waste BagSection of this manual to change waste bag.

NOTE: With every material cartridge delivered, two waste bags will be supplied. If more waste bags are required, they can be ordered

separately.

Power

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

9/26

Power Supply: In the rear of the printer there is an outlet to plug in the power supply cord and a switch to turn the system on. This is the only

way to power the printer on from a complete shutdown state. Do not use this switch to shutdown printer. Printer should be shutdown through

the UI and brought back up by toggling the power switch on the back. (A)

CAUTION: It is advised to never pull the plug or use the switch as a means to power down the printer, always power off through the

Shutdown process on the UI.

NOTE: Unless the printer will not be used for a substantial period of time (>60 days), it is best to leave it powered on, as a result, the

printer will automatically go into a Standby state.

Additional Documentation

The following documents will help you to achieve maximum prociency with your ProJet® 2500W/ IC Series printer.

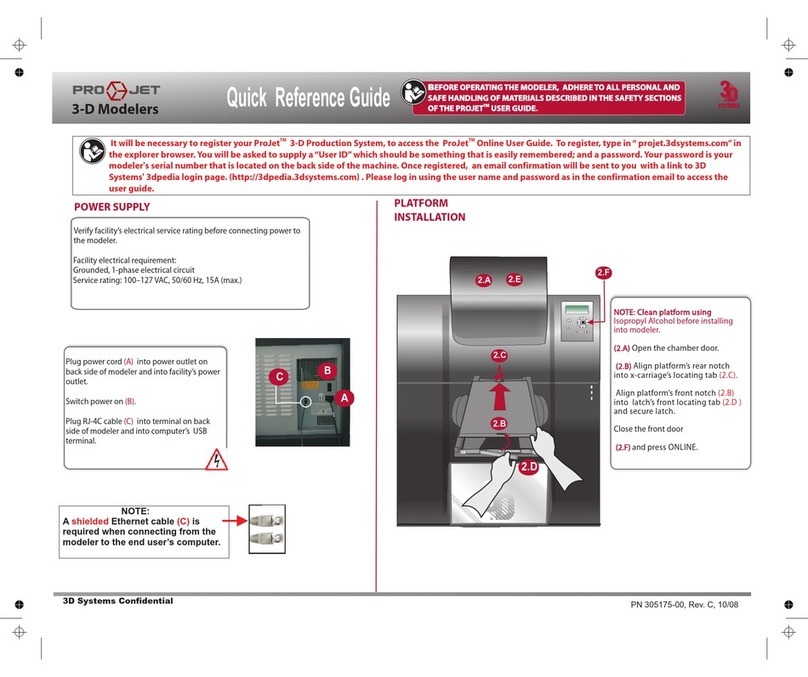

ProJet® MJP 2500W/ IC Facility Requirements Guide

The Facility Requirements Guide details the requirements necessary to install the ProJet® MJP 2500W/ IC 3D Printer. Details include the

necessary facility dimensions, electrical and pneumatic resources, and any equipment that may be needed for installation. An electronic version

of this document is available at http://infocenter.3dsystems.com/projetmjp2500w/facility-requirements-guide.

ProJet® MJP 2500 Series Installation Guide

The Installation Guide details the procedures required to properly install and set up the ProJet® MJP 2500 Series3D Printer at the customer’s

site. Only a 3D Systems Certied Field Service Engineer or a Certied Reseller is allowed to install the 3D printer system. An electronic version of

this document is available at http://infocenter.3dsystems.com/product-library/projetmjp2500-service.

ProJet® MJP 2500W/ IC Material and Post Processing Guide

The Material Guides detail the use of materials that have been certied for use in the ProJet® 2500W/ IC. Each material has its own Material

Guide. Information specic to each material is included in these guides. An electronic version of this document is available at

http://infocenter.3dsystems.com/projetmjp2500w/post-processing-guide.

ProJet® MJP 2500W/ ICQuick Start Guide

The Quick Start Guide gives the user a quick overview of the 3D printer system and the procedure for printing a part with theProJet® MJP

2500W/ IC. An electronic version of this document is available at http://infocenter.3dsystems.com/projetmjp2500w/quick-start-guide.

ProJet® MJP 2500W/ IC Global Harmonized Standards/Safety Data Sheets (GHS/SDS)

Each material has its own GHS/SDS. The user must be familiar with all information contained in these documents before handling the materials.

Every material shipment includes a paper copy of its GHS/SDS.

Electronic versions of the GHS/SDSs are available on our website at http://infocenter.3dsystems.com/materials/

NOTE: All of the documentation listed here is available by following links listed in the descriptions above.

Electronic Documentation

3D SPRINT Help

The 3D SPRINT printer application provides a complete on-line help guide for understanding how to utilize and manage the client software used

for part layout and job submission to your new printer.

User Interface

User Interface

The User Interface is located on the top of the printerto the right. There are ve main screens that contain sub menus that allow the user to

perform a variety of functions to control the printer. These vescreens and their menus are:

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

10/26

Status Tab (A)

The rst tab on the UI. The following features are accessed under the Status Tab (A). Refer to 1-7 for information that appears on this

screen.The left side tiles describe job status, the right side tiles describe printer status.

1. Access Platform - Pressing this button provides access to the print platform.

2. Start Print Job - Select to start the next print job in the print queue.

3. Printer State - This area identies what state the printer is in at any given time. See below for the various Printer States.

Ready - Printer ready toaccept print jobs.

Load Print Platform - Printer is ready for a clean print platform to be installed

Printing - Printer is printing a job

Preparing Build - Printer is setting up to begin printing

Busy - Printer is performing maintenance

Standby - Printer is in a low power state

Paused - Current print is paused and can be resumed by selecting the button

Complete - Current print is completed and the part can be removed from the printer

Remove Print Platform – Job is complete; access the print platform to remove the part

Aborting / Aborted- Current print isaborting / aborted

Warming- Printer is warming up to a Ready state

Cartridge Warming Up - Printer cartridge(s) warming up to a Ready state

Waiting - Chamber Cooling Down - Printer is waiting for the build chamber to cool down before continuing printing

Initializing - Printer is powering on and going through initialization

Shutting Down - Printer is powering down and will notify the user when it is safe to power off the printer

Recovery - Printer has a fault and is attempting recovery

Diags - Printer is in Diags mode and may require a service call

Error - Printer is in an Error state and may require a service call

Top Door Open - Close the top door in order for maintenance or printing to occur

Material Needed -the printer needs more material in order to print

4. Part Material Installed- Displays material type installed and status (tile changes color if material needs attention). Click on the tile to bring up the

Materials tab.

5. Material Drawer - Displays the state of the Material Drawer - Closed, Locked, Open to help user quickly identify when it is accessible.

. Waste Bag / Maintenance Status- Displays thepercentage and statusof the waste bag and other maintenance items. Click on the tile to bring up the

Operator Maintenance tab.

7. Print Mode, Layer - This area displays the current layer and print mode information.

. Start Time, Estimated Time, Completion Time - Displays the print job printing time information.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

11/26

Prints Tab (B)

Second Tab on the UI.

1. Opens up the Print Queue to manage the print queue of jobs for the printer.

NOTE: Clicking on the Info button brings up print job information; reorder jobs in queue using the arrow buttons.

VisiJet® M2 Cast VisiJet® M2 ICast Vi

Materials Tab (C)

Displays information about the Part and Support materials loaded in the printer.

Material Status -Displays the level of material in both the Support and Part Cartridges.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

12/26

Material Information - Clicking on the material level in any one of the four of the material status screens will bring up an information box about

that particular cartridge of material. Information listed here is:

Material- Type of material in cartridge

Level- Percentage of material remaining in cartridge

Weight- Weight of material in cartridge

Status- Current information about materials

Active– current cartridge in use for printing

Inactive– cartridge available, but not currently in use

Unusable– cartridge has a fault and cannot be used, contact service for assistance

Missing– no cartridge installed

Near Empty–cartridge is almost empty

Empty–cartridge is empty

Expired–cartridge is expired and needs to be replaced

Warming Up– cartridge is warming up to print ready temperature

Temperature – Status of material for printing

Color/Type- Description of what material is, for example color, and characteristics

Expiration date- Date material expires on

Note:When an expired cartridge is inserted, the printer will reject it. If a job is printing when the cartridge expires, it will to continue to

complete the job before declaring the cartridge is no longer available for use.

Batch - Date batch of material was made

Order Number - The order number of the material

More Information - Additional status on the cartridge

Make Active - Sets cartridge as the current one in use for printing

Tools Tab (D)

The following information can be accessed under the Tools tab.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

13/26

1. Printer Info - Displays printer and version information.

2. Customer Usage- Displays customer’s printer usage.

3. Material Usage – Displays the material and amount using in the printer

4. Diagnostics - Many diagnostic procedures can be run under the Diagnostics button. See Diagnostics Menusbelow for more information.

Diagnostics Menus - Selecting the Diagnostics button under theTools Tab will bring up the Diagnostics screen is where the User performs

routines that help run and maintain the printer.

1. Inspect PlanarizerWiper Blade

- Select this routine toinspect the planarizer blade for excess buildup. See Inspect PlanarizerBlade

procedure in theMaintenance section.

2. Inspect PlanarizerDucts

- This is a routine that will allow the user to inspect and clean the ducts in the planarizer. See Inspecting and

Cleaning Planarizer Ducts procedure in theMaintenance section.

3. Inspect Print Cartridge Home Sensor

- This routine will allow the user to access the optical home sensors for cleaning. See Clean Print

Carriage Optical Home Sensor procedure in the Maintenance section.

4. Head Maintenance Cycle

- Printhead maintenance routine used for basic jet recovery

5. Test Jets

- This is the routine that is used to verify that the jets are all jetting material properly. See Conrm Jets procedure in

theMaintenance section.

6. Check Part Test -

Diagnostic test routine. Run this test as requested by your service representative.

7. Check Support Test -

Diagnostic test routine. Run this test as requested by your service representative.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

14/26

8. View Fault Logs -

A history of fault codes is stored under the Fault History.

9. Unlock Top Door -

This button will allow the top door to unlock if the printer is in a Ready or Error State.

10. Save Job Files -

Allows for USB download of a job le in .mjpddd format

11. Recover Jets -

Advanced jetting recovery tool

5. Operator Maintenance - Selecting Operator Maintenance will bring up a maintenance schedule. Be sure to click on a maintenance item and

Reset the counter once the cleaning has been completed, otherwise a message will appear that the maintenance is over due. Before performing

any maintenance routines the printer must be in a Ready state and a clean print platform must be installed.

6. Save Log - Provides access to printer logs for service.

7.Power Options - Selecting the Power Options button provides access to Printer Shutdown, Printer Restart, Software Restart and Standby. For

shutting down the printer,the recommendation is that the printer always be shutdown through the UI. See Printer Shutdown section for

information.

8. Install Upgrade -Printer rmware can be updated using a USB thumbdrive.

Settings Screen (E)

1. Network- The network settings can be veried through Network Settings.

2. Email Alerts- Set up email alerts to be notied about printer events. Up to 5 email addresses can be added.

Note:Some email clients may block access to this application during email setup. If you experience issues setting up email alerts,

please verify your email provider has not blocked access.

4. Date Time- To change or setup the date and time click on Date Time Settings.

5. Language- Select language to display on UI.

. User Interface - Controls the UI brightness level andinformation about the UI itself.

7. Print Jobs -

Save completed jobs -Enable or disable this feature for the ability to reprint jobs

Part Placement Optimization - Part placement optimization is suggested for printers running a high number of single lane jobs. Enabling this

feature will yield the best print quality throughout the printer’s life.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

15/26

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

16/26

Printer Startup and Demo Build

The purpose of this section is to execute the following:

Power the printer on.

Installing new material cartridge.

Removing material cartridges.

Procedure to empty waste bag.

Procedure for installing and removing print platform.

Perform a successful Demo build.

Completion of this process will familiarize you with all of the “basic” printer operations needed to build parts on the ProJet® MJP 2500W/ IC

and provides a functional “run through” for a new installation. It is strongly recommended that you complete Section 5 before moving on to

larger more sophisticated builds.

POWER THE PRINTER

1. If the printer is not already on, turn printer on by ipping the power switch on the back of the printer. UI may take up to a minute or so to come on. After

about a minute the 3D Systems logo should appear and then the Status Screen will appear.

2. If printer has been shut down and is starting from a cold state,wait 2 hours for printer to warm up before startinga build job. UI display will show

Warming on the Status screen under Printer State (1).

NOTE: Build les can be submitted but will not start printing until printer is warm and ready.

Installing New Material Cartridge

NOTE: Cartridges cannot be installed into a cold printer. The printer must be warm before drawer will open and cartridges can be

installed.

To place a material cartridge into the MDM, perform the following steps:

1. Obtain a new material cartridge ensuring that it is the same material as currently installed in the MDM.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

17/26

2. If drawer is not already open, push to unlock drawer.

3. Pull open the MDM drawer.

NOTE: The steps to install a support cartridge are the same as installing a part cartridge.

NOTE: To install cartridges into the MDM drawer properly ensure that the small cap be installed away from the user.

NOTE:It is important to verify the cartridges have been audibly clicked into place, have material in them, and the cartridge caps properly

ventilated; otherwise the printer may not be able to pull material from thebottles, potentially resulting in the following fault codes:

93-134 thru 137

4. Place cartridge in slot and push down until you hear it click in place.

5. Vent each cartridge by loosening the material cap (A) by a 1/2 turn counterclockwise.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

18/26

. Close the MDM drawer (B), by pushing in the dimple at the top until it’s latched securely.

7. Check the material level under the Materials tab (C)on the UI to ensure cartridge is seated properly into MDM and ready to print.

REMOVING MATERIAL CARTRIDGES

When a material cartridge is empty and needs to be replaced, or if a partially lled container needs to be replaced with a full container, perform

the following procedure.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

19/26

NOTE: It is important to verify the type of material currently in the MDM before proceeding with these steps.

NOTE: Cartridges cannot be removed from a cold printer. The printer must be warm before drawer will open and cartridges can be

removed.

The MDM drawer (A) is a push/push mechanism. Push to open drawer, push to lock drawer.

1. Open the MDM drawer by pushing in at the recessed dimple.

2. Pull the MDM drawer open.

3. Turn the material cap (B) a 1/2 turn to clockwise to tighten the vent cap.

4. Press the release button (C) on the front. You will hear the cartridge release. Pull the cartridge out of the slot.

5. Dispose of the empty cartridge according to local regulations.

. Wearing nitrile gloves and eitherprotective sleeves or a lab coat to protect arms, use a disposable paper towel and wipe all material from the container

seal assembly, if necessary you can use some isopropyl alcohol on the paper towel to wipe up the excess material.

NOTE: It is important to always wear nitrile gloves and either protective sleeves or a labcoat to protect arms when coming in contact with

materials to avoid getting materials on skin. Contact with skin may cause an allergic reaction.

8/10/22, 2:55 PM

Quick Start Guide

infocenter.3dsystems.com/projetmjp2500w/print/book/export/html/861

20/26

WASTE BAG REMOVAL AND INSTALLATION

NOTE: Even though the waste bag may not appear full when the user is notied to change it, it is highly recommended to replace the

waste bag when prompted to avoid unnecessary overow and mess. When waste bag has been changed ensure youconrm the level has

been reset to zero.

1. Verify that the printer is inREADY.

2. Select Materials tab.

ProJet® MJP 2500W ProJet® MJP 2500 IC

3. Select next to the Waste Bag status bar.

4. Wearing protective Nitrile gloves, open the MDM drawer.

5. Remove the waste bag and dispose of bag according to local regulations.

. Inspect the waste bin for any remaining waste. If necessary, wipe out any waste that exists with a lint free cloth and isopropyl alcohol.

NOTE: If the waste bag is stuck to the liner when you attempt toremove it, replace the entire liner and bag to prevent the bagfrom tearing and

causing material to leak into the receptacle.Waste bags can be ordered using part number 310248-00.With each order you will receive 50 bags.

7. Conrm on the printer UI when you have completed replacing the waste bag.

Table of contents

Other ProJet 3D Printer manuals

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet MJP 5600 Installation manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet HD3000 User manual

ProJet

ProJet PJ 5000 User manual

ProJet

ProJet 5500X User manual

ProJet

ProJet 3-D Modelers User manual

ProJet

ProJet MJP 2500 User manual

ProJet

ProJet 60 Series User manual

ProJet

ProJet 1000 User manual