ProJet 60 Series User manual

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

1/14

Quick Start Guide

ProJet x60 series

ProJet 160, 260C, 260Plus, 360, 460Plus

Quick StartGuide

Rev A

Note: Please refer back to http://infocenter.3dsystems.com/projetcjpx60/ for the most up-

to-date Quick Start Guide

Familiarization ProJet® CJP 160, 260C and 260Plus

This Guide is intended as a reference for users who are familiar with their ProJet®CJP X60

Series printer, and are ready to start their rstbuild.The3DPrint Software should

beinstalled and ready to run. Ensure that the software is properly congured for your printer

and print style. For more-detailed instructions, please refer to the Projet®CJP X60

SeriesUser Guide.

®

TM

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

2/14

A - Control Panel F. Vacuum Hose K - Service Station

B - LCD Display G - Fast Axis L - Deck

C - Control Knob H - Build Bed M - Front Overview

D - Binder Cartridge I - Fast Axis

E - Debris Separator J - Build Bed

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

3/14

Familiarization ProJet® CJP 360 and 460Plus

(460

Plus

is depicted)

1. Control Panel

2. Control Knob

3. LCD Display

4. Deck

5. Build Bed

. Service Station

7. Binder Cartridge (Shown removed)

. Fast Axis

9. Heater (460

Plus

Only)

10. Debris Separator(Shown removed)

11. Vacuum Hose

12. Arm Holes

13. Vacuum Accessory Storage Compartment

(460Plus Only)

14. Air Wand

15. Cleaning Station

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

4/14

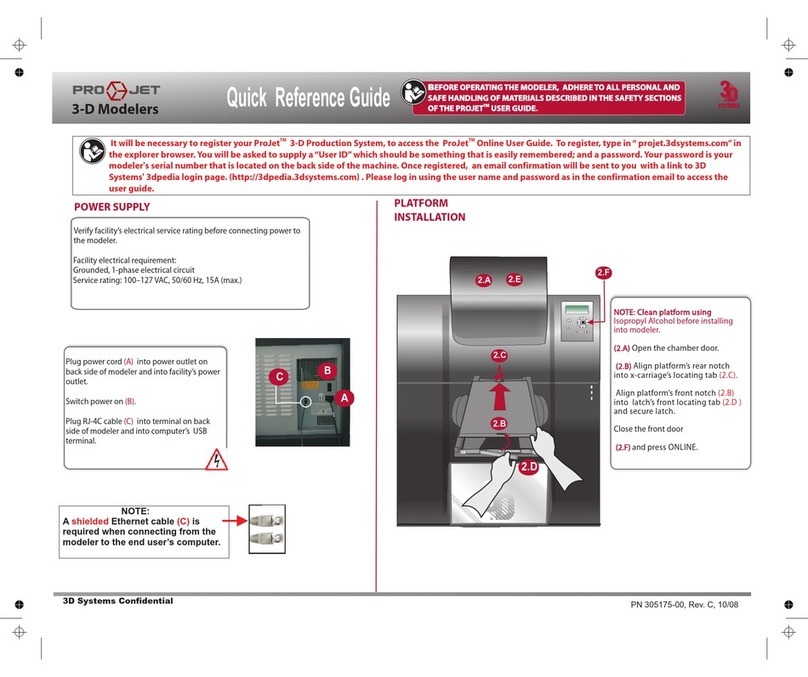

Power Supply

Verify facility's electrical service rating before connecting power to the printer.

Electrical Requirement:

Printer in operation

100-120V~, 50-60 Hz, 5.5 Amps.

230V~, 50-60 Hz, 2.75 Amps.

Printer in Sleep Mode - 48 W

100-120V~, 50-60 Hz, 0.4 Amps.

230V~, 50-60 Hz, 0.2 Amps.

1. Plug power cord into power outlet (A)

(located at the backside of printer) and into

facility's power outlet.

2. Plug one end of theEthernet cable into

Ethernet port (B) and the other end intoyour

PC's network port.

3. Switch power on (C)

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

5/14

Once the LCD display shows online;

Push the Control Knob (D) once to:

Bring up the printer menu

Select a menu command

Start/Stop/Cancel a menu function

Turn the Control Knob left/right to highlight

menu items. When selecting the

Raise/Lower Platform commands, hold the

Control Knob down to raise/lower the

platform.

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

6/14

Setting Up Your Printer

NOTE: Before starting your rst part, please ensure that the printer is clean and that it

is kept well-maintained. Please see the ProJet CJP160, 260C, 260

Plus

, 360 and

460

Plus

User Guide for further instructions on properly cleaning your printer.

Add Binder

To add binder, follow the steps below.

Before inserting the cartridge into the

housing, check the expiration date,

andensure the cartridge label is in the

correct orientation.

Insert cartridge into its housing. Ensure

it is pushed all the way in; you should

feel it gently snap into place.

Important: If a cartridge does not snap

into place,

do not force it

. Check the

orientation and that it is the correct type

of cartridge and try again.

If there is not enough binder in the

reservoir, 3DPrintdisplays BINDER LOW

in the Printer Status dialog.

Important: Do not add binder unless you

are prompted to in thePrinter Status

dialog.

Add Core

To add Core, follow the steps below.

Open the printer cover and vacuum Core

into the feeder by selecting VACUUM on

the display. Important: Never usethe

vacuum for any material other than

clean Core.Doing so will clog the

vacuum system.

3DPrint evaluates the geometry of the

part to determine if there is enough

Coreinthe Feeder to complete the build.

If there is not enough Core, 3DPrint

displays ADD COREin the Printer Status

dialog. Important: Do not add Coreto

the Feeder unless you are prompted to

in the 3DPrint Printer Status dialog.

The printer cannot start a print job when

the top cover is open; ensure cover is

closed before printing. Do not open the

cover while the machine is printing.

®

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

7/14

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

8/14

Startup Checklist

Startup Checklist:

Has air been purged from binder line? (1 print)

Ensure the Deck, Fast axis and Build bed are clean of Core or other contaminants

Ensure the debris separator is empty

Ensure the carriage and rails are clean

Ensure the service station is clean

After emptying it of any remaining Core, raise the build platform to the top of the build bed

Ensure there is nothing inside the printer that will obstruct the fast axis as it moves (especially

the vacuum hose – rotate it out of the way if necessary)

st

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

9/14

Setting Up a Build to Print

NOTE: Before starting your rst part, please ensure that the printer is clean and that it

is kept well-maintained. Please see the ProJet CJP X60 SeriesUser Guide for further

instructions on properly cleaning your printer.

1. Open your 3D content in 3DPrint.

2. Under Settings tab, press "Materials."

3. Check your printer settings to be sure the

correct printer and material set are

displayed.

NOTE: If you need to change any

settings, refer to the Setup and

Print the Build section of the

User

Guide

4. In Home tab, press "Build" icon.

5. Check the Printer Status window. If all

the Print Head, Core™, and General items

display OK, the Print button is enabled.

NOTE:If any items need attention,

the Print button is disabled. Refer

to the Additional Operations

section of the User Guide for

details on how to get the printer

ready and clear any messages.

. Select any Print Options for this build. If

the part has delicate features, deselect

the option for Empty Build Piston After

Printing (ProJet 460

Plus

only).

7. Click Print to start your build.

. The Printing dialog opens and reports the

status of the print job as the build

progresses.

9. Click Pause to pause the current print

job. Click again to resume printing.

10. Click Cancel to cancel printing this job.

Important: Pausing for more than 10

minutes may cause print defects.

®

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

10/14

Finishing Build

Gross Core Removal

When the build is nished, you will need

to remove the Core around the part.

Automatic Core Removal (460

Plus

Only)

When the build is nished, the printer

starts an automatic heated drying cycle.

A counter on theprinter LCD counts

down the time remaining before the part

is dry.

If 'Empty Build Piston after Printing' is

selected prior to printing in the 'Printer

Station' window, the printer automatically

removes excess Core by vibrating the

Build Bed and vacuuming through the

bottom of the Build Bed.

Remove the part and carefully transfer it

to the Cleaning Station to clean the Core

from the part.

After all parts are removed, vacuum any

Corethat may remain in the Build Bed.

Manual Core Removal (160, 260C,

260

Plus

and 360)

When the build is nished, the printer

starts an automatic drying cycle (heated

on the 460

Plus

, unheated on the 160,

260C, 260

Plus

and 360). A counter on

the printer LCD counts down the time

remaining before the part is dry.

Select VACUUM & CLEANING on the

LCD menu. Open the cover. The

vacuum starts.

Vacuum Core from around the part.

Be careful around delicate sections.

Use the Control Knob to move the

Build Platform up as needed.

Carefully move the part to the

Cleaning Station to clean the Core

from the part.

After all parts are removed, vacuum

any Corethat may remain in the Build

Bed.

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

11/14

Fine Core Removal

Any loose Core on the part must be removed before proceeding

withpost-processing.

160,260C& 260

Plus:

Open the printer's top cover and move the part to

the external Cleaning Station. Open the Cleaning Station's top cover and

place the part onto the bed; close the top cover. Select EXTERNAL

CLEANING on the LCD menu; the vacuum and compressor start.

360 & 460

Plus

Only: Open the printer's top cover and place the part into

the post-processing unitand close the top cover. Select VACUUM &

CLEANING on the LCD menu; the vacuum and compressor start.

Test the air ow from the air wandagainst your hand and adjust as

needed. Turn the Control Knob left to decrease pressure, orright to

increase pressure.

Using the Air Wand, remove all remaining Core on the part. Use caution on

delicate areas. A small brush may also be gently used.

Push the Control Knob once to turn the air compressor off. Return the Air

Wand to its clip. If possible, allow the part to dry for several hoursin the

post-processing unit.

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

12/14

Cleaning

It is very important that you keep your printer well-maintained. Please read the x60User

Guide to properly clean your printer. A clean, well-maintained printer produces better parts,

has less downtime, and needs fewer service calls.

Routine Cleaning After Every Build

After every build, it is important to clean your printer following the steps below.

Routine cleaning includes the following steps:

Vacuum Up Excess Core

Empty the Debris Separator

Clean the Rails and Carriage

Clean the Service Station

Vacuum Up Excess Core

Select VACUUM & CLEANING on the LCD menu. Open the top cover. The vacuum starts.

Vacuum the following areas:

The top of the Fast Axis; also reach inside to vacuum the Rails and the top of the

PrintheadCarriage.

TheBuild Bed (but not the Feeder side).

The deck around the Build Bed

Press the Control Knob once to turn off the vacuum.

Important: Do not vacuum the Service station. Use the vacuum only on clean, reusable

Core

Empty the Debris Separator

Pull the Debris Separator out of its housingon the printer.

Empty the contents into a trash receptacle.

Use the soft brush found in the Accessory Kit to brush caked Corefom the screen and into a

trash receptacle.

Return the empty Debris Separator to its housing. Be sure to push the Separator at against the

panel for a secure t.

Clean the Rails and Carriage

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

13/14

Pull the Fast Axis toward the front of the printer.

Using a paper towel dampened with distilled water, wipe the top and bottom Rails. Move the

Carriage back and forth as needed to clean the entire length of both rails. Using a clean, dry

paper towel, thoroughly dry both Rails.

Using a fresh paper towel, wipe the Carriage to remove any Core. Clean the Build Bed and Deck of

any water or damp Core.

Clean the Service Station

You will need several dry paper towels and a cotton swab, a squirt bottle lled with distilled water,

disposable gloves, and Pick and Syringe from the Accessories Kit.

Open the printer top cover and the Service Station cover.

Place paper towels around the Service Station as well as theFront Overow and the Build Bed.

Pull the Service Station wiper lever all the way forward until the rubber squeegees are fully

exposed. Use caution - Binder may ing off of the squeegees. Hold the lever and squirt water on

and around the squeegees.

Pay special attention to the underside of the squeegeescraper bar.Ensure it is fully cleaned.

Important: Don't get water in the front overow or on the build bed.

Wipe the front and back of the squeegees clean. Use the Pick to scrape away any excess Core.

Thoroughly clean and dry the Service Station, Deck, Build Bed, andFront Overow. Push the wiper

lever back to its original position.

8/11/22, 2:30 PM

Quick Start Guide

infocenter.3dsystems.com/projetcjpx60/print/book/export/html/861

14/14

Post Processing

Pleaserefer to the Post Processing Guidefor part post-processing instructions for your

ProJet CJP X60 Series printer.http://infocenter.3dsystems.com/projetcjpx60/post-

processing-guide

®

This manual suits for next models

5

Table of contents

Other ProJet 3D Printer manuals

ProJet

ProJet MJP 5600 Installation manual

ProJet

ProJet PJ 5000 User manual

ProJet

ProJet 5500X User manual

ProJet

ProJet 1000 User manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet 160 Guide

ProJet

ProJet 3-D Modelers User manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet MJP 2500 User manual