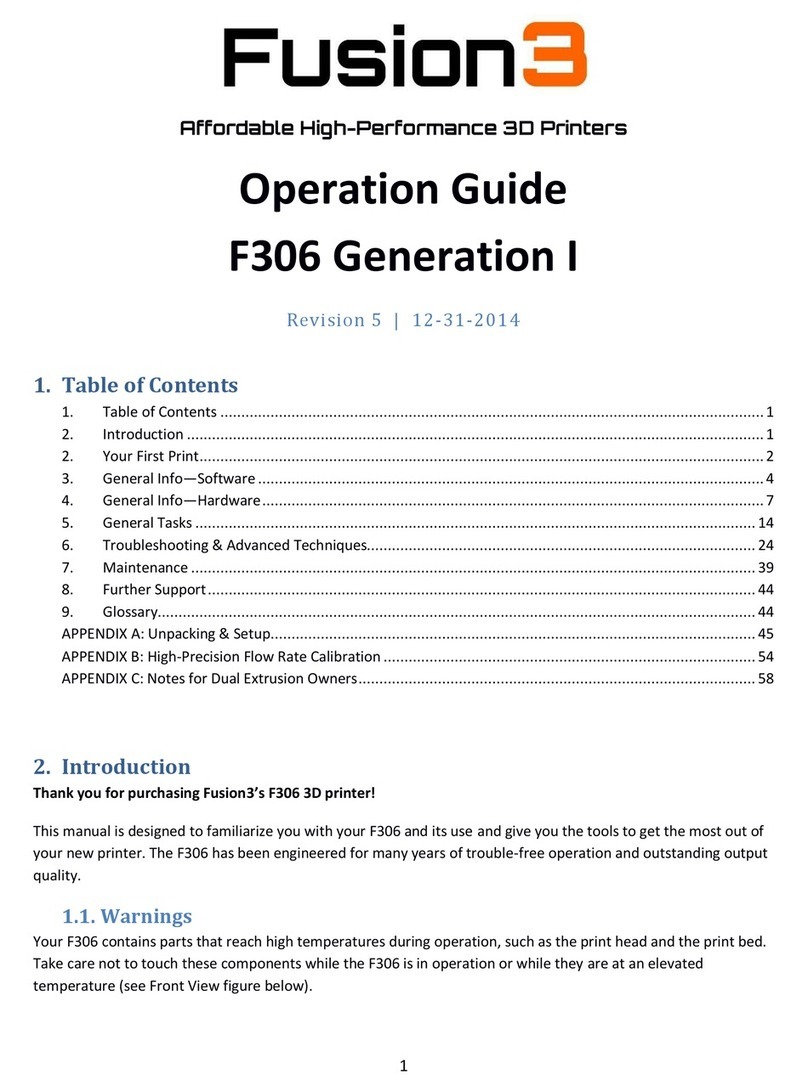

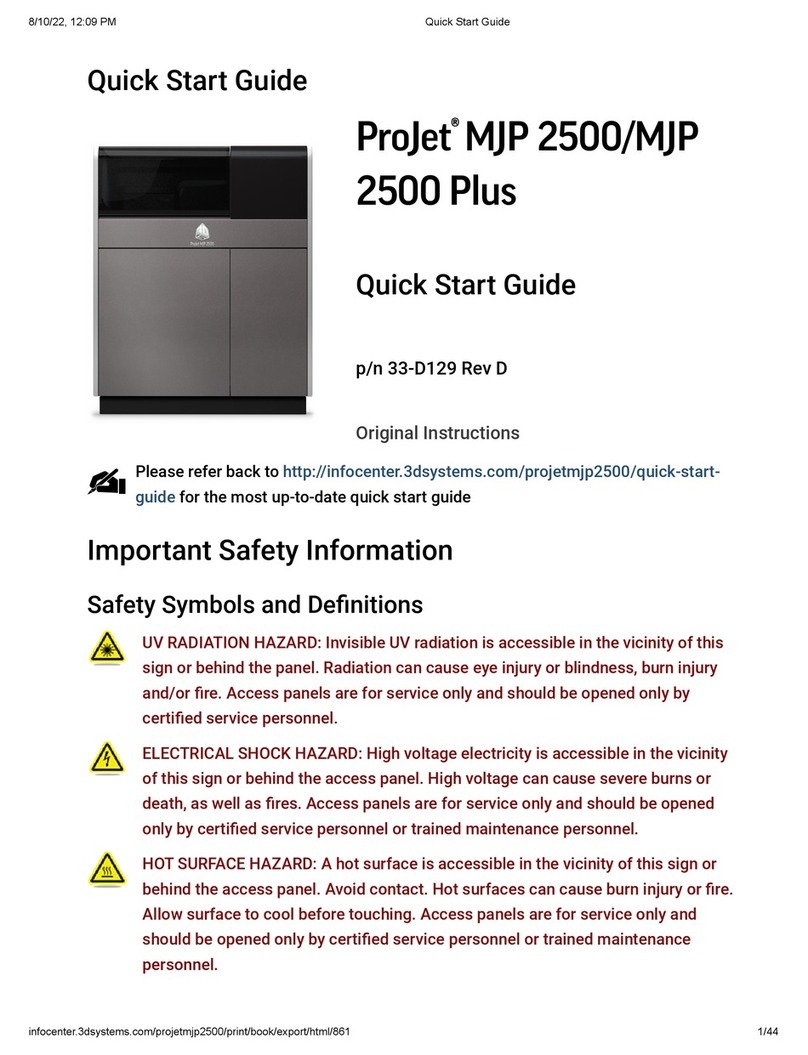

ProJet MJP 2500 User manual

Facility Requirements Guide

ProJet MJP2500,MJP 2500 Plus &

MJP 2500W

Facility RequirementsGuide

p/n 33-D131Rev C

Original Instructions

Please refer back tohttp://infocenter.3dsystems.com/projetmjp2500/facility-requirements-guidefor the most up-to-date facility

requirements guide

About This Manual

This document includes the overall facility requirements that will be needed to have a successful installation when our authorized 3D Systems

representatives arrive to install your 3D printer system.

®

What is a Facility Requirements Guide

This guide provides important information on selecting a facility location and planning for the installation of 3D Systems’ ProJet® MJP 2500

Professional Printing System. It also presents planning guidelines to facilitate fast, convenient installation and operation of your 3D printer system.

What’s Inside:

Descriptions of hardware, software, part material, networking components, and documentation that comprise the ProJet® MJP 2500

Professional Printing System.

An overview of the site requirements in typical engineering and design work spaces. These involve basic access, electrical, and environmental

conditions for conguring a safe and ecient work area.

A checklist is included to ensure that the facility is adequately prepared for installation of your 3D printer system.

Information on how to obtain assistance from 3D Systems Customer Support Team.

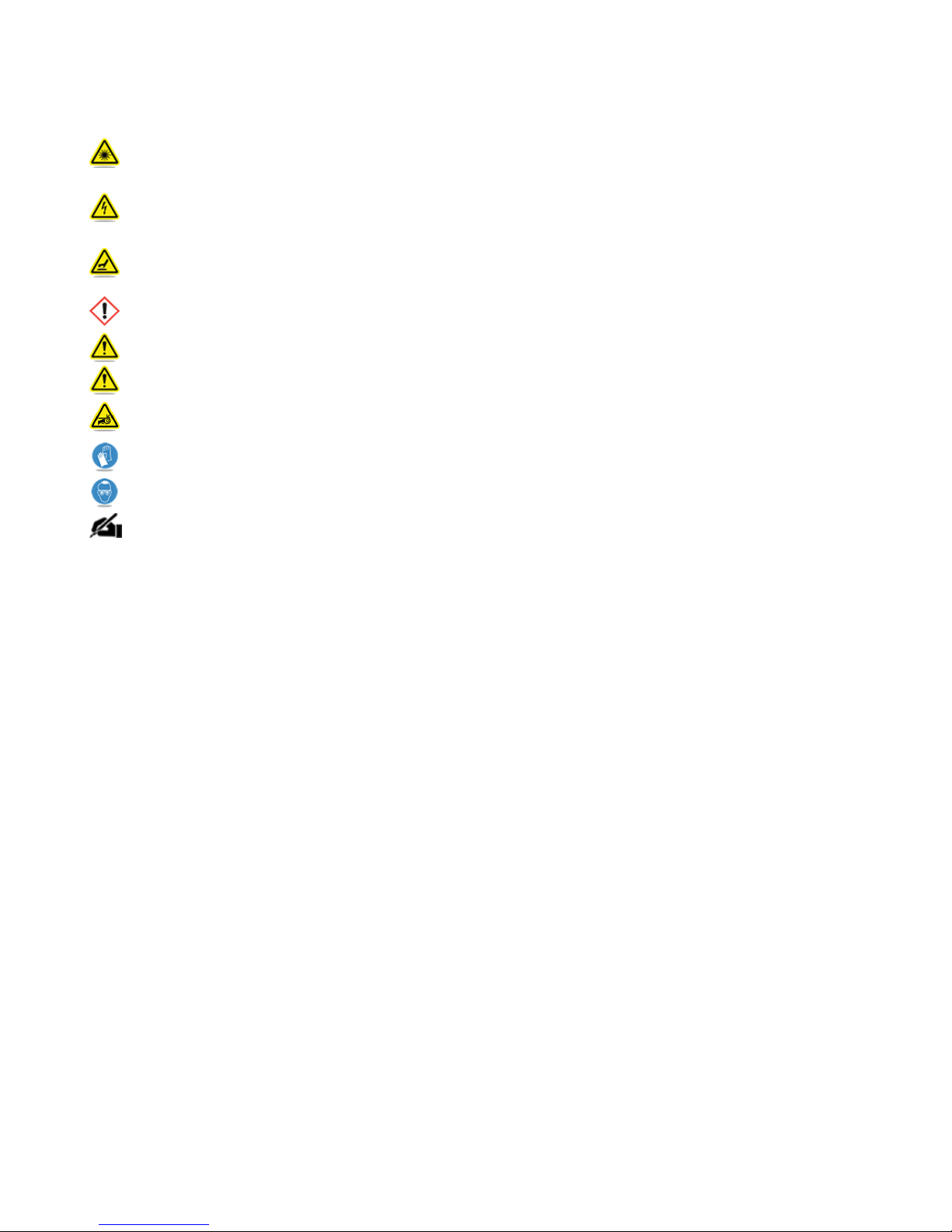

Common Symbols Used Throughout 3D Systems Manuals

The ProJet® MJP 2500 Professional Printing System is part of 3D Systems’ Multi-Jet-Printing (MJP) product line.

UV RADIATION HAZARD: Invisible UV radiation is accessible in the vicinity of this sign or behind the panel. Radiation can cause eye injury

or blindness, burn injury and/or re. Access panels are for service only and should be opened only by certied service personnel (ProJet

2500/2500 Plus only)

ELECTRICAL SHOCK HAZARD: High voltage electricity is accessible in the vicinity of this sign or behind the access panel. High voltage can

cause severe burns or death, as well as res. Access panels are for service only and should be opened only by certied service personnel

or trained maintenance personnel.

HOT SURFACE HAZARD: A hot surface is accessible in the vicinity of this sign or behind the access panel. Avoid contact. Hot surfaces can

cause burn injury or re. Allow surface to cool before touching. Access panels are for service only and should be opened only by certied

service personnel or trained maintenance personnel.

THIS GLOBAL HARMONIZED SYSTEM LABEL FOR LOW LEVEL TOXICITY. THIS INCLUDES RESPIRATORY, SKIN, AND EYE IRRITATION, SKIN

SENSITISERS AND CHEMICALS HARMFUL IF SWALLOWED, INHALED OR IN CONTACT WITH SKIN.

CAUTION: Indicates the possibility of loss of data or damage to equipment.

WARNING: INDICATES THE POSSIBILITY OF INJURY OR DEATH TO PERSONNEL.

HAND ENTANGLEMENT WARNING:GEARS OR MOVING PARTS HAZARD IN THE VICINITY OF THIS SIGN OR BEHIND THE ACCESS PANEL.

ACCESS PANELS ARE FOR SERVICE ONLY AND SHOULD BE OPENED ONLY BYAUTHORIZED SERVICEPERSONNEL.

WEAR GLOVES: Wear the appropriate gloves when required. For example, when touching surfaces that may contain or have been exposed

to materials, wear nitrile gloves. Heat gloves are necessary when touching surfaces that may be hot to ensure burns don’t occur.

ULTRAVIOLET RADIATION INSIDE: Exposure may cause eye damage. Do not operate without covers. Wear UV eye protection.

NOTE: A note signies important information but not information of a critical content.

The ProJet Professional Printing System

Your ProJet®MJP 2500 Series Printerships with the following:

One crated ProJet®MJP 2500 Professional Printing System containing the following accessories and materials.

Two Build Platforms (one on the printer and one in an accessory box)

Region-specic “country kit” consisting of one power cable

Two full cartridges ofVisiJetPart Material and two full cartridge ofSupport Material

One pack of nitrile gloves

10 Waste Bags

2 cartridge holders

SIM card (ProJet®MJP 2500 Plus only)

Preparation for Shipment Arrival

The following topics should be arranged PRIOR TO THE ARRIVAL OF THE SYSTEM, to simplify installation of the ProJet® MJP 2500 Professional

Printing Systems.

Make sure the following resources are available:

____ A forklift or similar, heavy-duty equipment required for unloading the 3D printer system crate from the truck to thede-crating location. (Forklift is

not required to move 3D printer system into where it will be installed once thecrate is removed.)

____ Network connection(s)

____ Power outlet(s) - a dedicated circuit to power the 3D printer system

____ Storage cabinetry for extra 3D printer system material containers and other consumables

____ At least one (1), networked graphics workstation or CAD/CAM/CAE terminal meeting the requirements described inClient Workstation

Requirements.

NOTE: Retain the shipping crate, ramps, brackets and hardware in the event the ProJet® MJP 2500 Professional Printing System needs to be

shipped in the future. These crates are designed to allow fast, easy removal and packaging of the product. If 3D printer system needs to be

shipped, contact 3D Systems Customer Support for shipping instructions.

Facility Guidelines

This section provides details relating to site selection, site preparation and readiness of the facility to accept and install the ProJet® 2500

Professional Printing System. Discuss the appropriate equipment locations with a 3D Systems' Certied Partner, so that the equipment is located in

a convenient, appropriate location based on your organization's needs. When planning an installation, consider.

Electrical Requirements Network Interface

Space Planning Post Processing Accessories (Oven and Freezer)

Access Area Surrounding 3D Printer System Material Storage

Unit Portability Material Bottle Disposal

Client Workstation Requirements PrinterWeights and Printer Dimensions

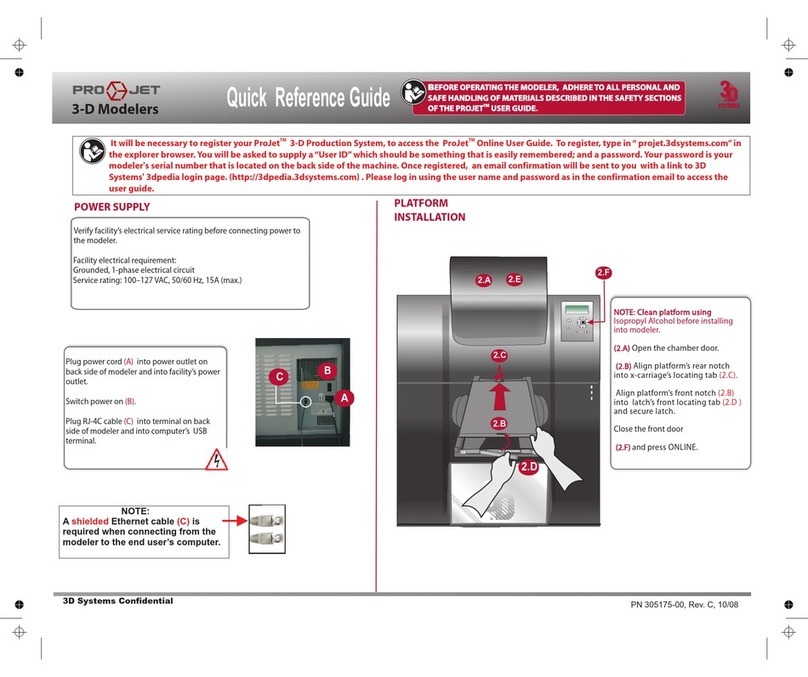

Electrical Requirements for the ProJet® MJP 2500 Series Printer:

Space Planning The outlet location must be near the 3D printer system and

remain accessible to the end user at all times.

An additional 100 or 220 VAC outlet is recommended for service

needs.

A phone near the 3D printer system is recommended to

facilitate 3D printer system support.

Each location of the 3D printer system requires a standard wall power

outlet or power drop to power the 3D printer system.

AC Voltage and Current Requirements:

Each 3D printer system requires use of a dedicated circuit that will allow for100-127 VAC, 50/60 Hz, 15A, single phase or200-240 VAC, 50 Hz,

10A, single phase Single C14 receptacle.

All ProJet® MJP 2500 series printers relies on a connection to the mains protective earth (ground). Thisprovides aone level of protection to the

user (Basic Insulation).

The installation of The ProJet® MJP 2500 Professional Printing System shall comply with the National Standards of the country in which it is

placed.

Protected Power/Un-interruptible Power

Many customers face AC power quality issues requiring the use of a UPS (Uninterruptible Power Supply) and generator to correct. The primary

function of a UPS is to hold up AC power for a limited period of time by using energy from rechargeable batteries. For brief power outages, a UPS is

sucient; the amount of holdup time may also be scaled with additional battery packs according to customer needs. For extended power outages,

some combination of UPS and on-site generator is required. The secondary benets of a UPS often include line conditioning (correcting for voltage

sags and swells) and line surge protection. A double-conversion, true sine-wave UPS is recommended as it provides additional immunity from

powerline perturbations.

3D Systems has tested the product with the following UPS models:

North America

Manufacturer Model Voltage

In

Voltage

Out

kW Input

Connector

Output

Connector(s)

APC SURTA3000XL 120 120 2.1 L5-30P 5-20R

North America

Eaton 9PX3000RT 120 120 2.7 L5-30P 5-20R, L5-30R

Liebert GXT4-3000RT120 120 120 2.7 L5-30P 5-20R, L5-30R

Worldwide

Manufacturer Model Voltage

In

Voltage

Out

kW Input

Connector

OutputConnector(s)

APC SRT3000XLW-IEC 208/230 230 2.7 C20 IEC C13, IEC C19

Eaton 9PX3000GRT 208/230 230 3.0 C20 IEC C13, IEC C19

Any UPS unit will impose additional facilities considerations including battery storage, oor space, interconnect and electrical receptacle

requirements. For example, the above North-America UPS models require an L5-30 receptacle.

If additional or substitute cordsets are required, the cordset shall be rated greater than or equal to the input current rating of the product at the

voltage applied. For example, a C13 to C14 cordset will be required if the UPS provides C13 receptacles (typical in markets outside North America).

Recognizing that customer needs and facilities differ greatly, 3D Systems encourages customers to contact one of the above UPS manufacturers for

a power protection solution tailored to the customer and site needs.

ProJet® XL Finisher (Optional) Power Requirements

The ProJet® XL Finisher must be hardwired andinstalled by a Certied Electrician. For more information about the ProJet® XL Finisher clickhere.

Client Workstation Requirements

Before a print can be printed on the printer, the print data le must be saved or exported to the industry-standard .stl le format, and submitted over

the network. 3DSPRINT client software is located on 3DS Central can be installed on each intended users’ workstation to allow them to select,

preview, and submit jobs; as well as manage the print queue.For more information onsending aleto the 3D printer system see the ProJet® MJP

2500 User’s Guide available on:

http://infocenter.3dsystems.com/projetmjp2500/user-guide(Acrylate)

http://infocenter.3dsystems.com/projetmjp2500w/user-guide(Wax)

Prior to installing the software, ensure that the initially selected workstation meets the following minimum specications. Although the ProJet®

2500 client software will run on less powerful computers, meeting the minimum recommended conguration will ensure acceptable performance. It

is recommended that this workstation be further enhanced with the recommended requirements for maximum performance, particularly with more

powerful processors and added memory.

System Requirements

OS Minimum

- Windows 7 (64-bit)

-Windows 8 (64-bit)

-Windows 10 (64-bit)

Recommended

CPU - Intel or AMD processor with

a minimum of 2.0GHz

- Multiple core processor

- Hyper threading and clock speeds above 3GHz

can be benecial but should be paired with a good

balance of cores.

RAM -4 GB - 8GB or more

- Virtual Memory: In Win 7, Win 8, Win 10, it is

recommended to use the defaultoption;

"Automatically manage paging le size for all

drives"

Hard Disk -30 GB of available hard-disk

space for cache

-Temporary le cache requires

about 3GB free disk space for

optimal print le transfers

-SSD or 10,000RPM HDD

Display/GPU -Open GL 2.1 and GLSL 1.20

enabled graphics card

-Screen resolution 1280x960

-NVidia or AMD GPU with 1GB of RAM or more

-Screen resolution 1280x1024 or higher

Other -Internet Explorer 9 or newer

-Microsoft .NET Framework 4.5

(installed with application)

-3 button mouse with scroll

-Keyboard

-Google Chrome or Internet Explorer 11

I/O -Either ethernet or wireless

connection

-Ethernet may be more stable depending on the

facility

Network Interface

The ProJet® 2500 Professional Printing System requires an Ethernet network connection to transfer print jobs from workstation(s) to the printer.

An established TCP/IP network is setup and enabled. An RJ45 Ethernet network connection for each printer to be installed at the delivery site must

be installed, tested and functioning. The printer can use either DHCP or a static assigned IP address. A DHCP server automatically programs an IP

address; otherwise, a network administrator can manually assign a permanent IP address for each printer that is to be connected to the network.

Write IP address(es) here:

___________________________________________________________________

Space Planning

Included in this guide is information and dimensions required to help plan installation of the printer.

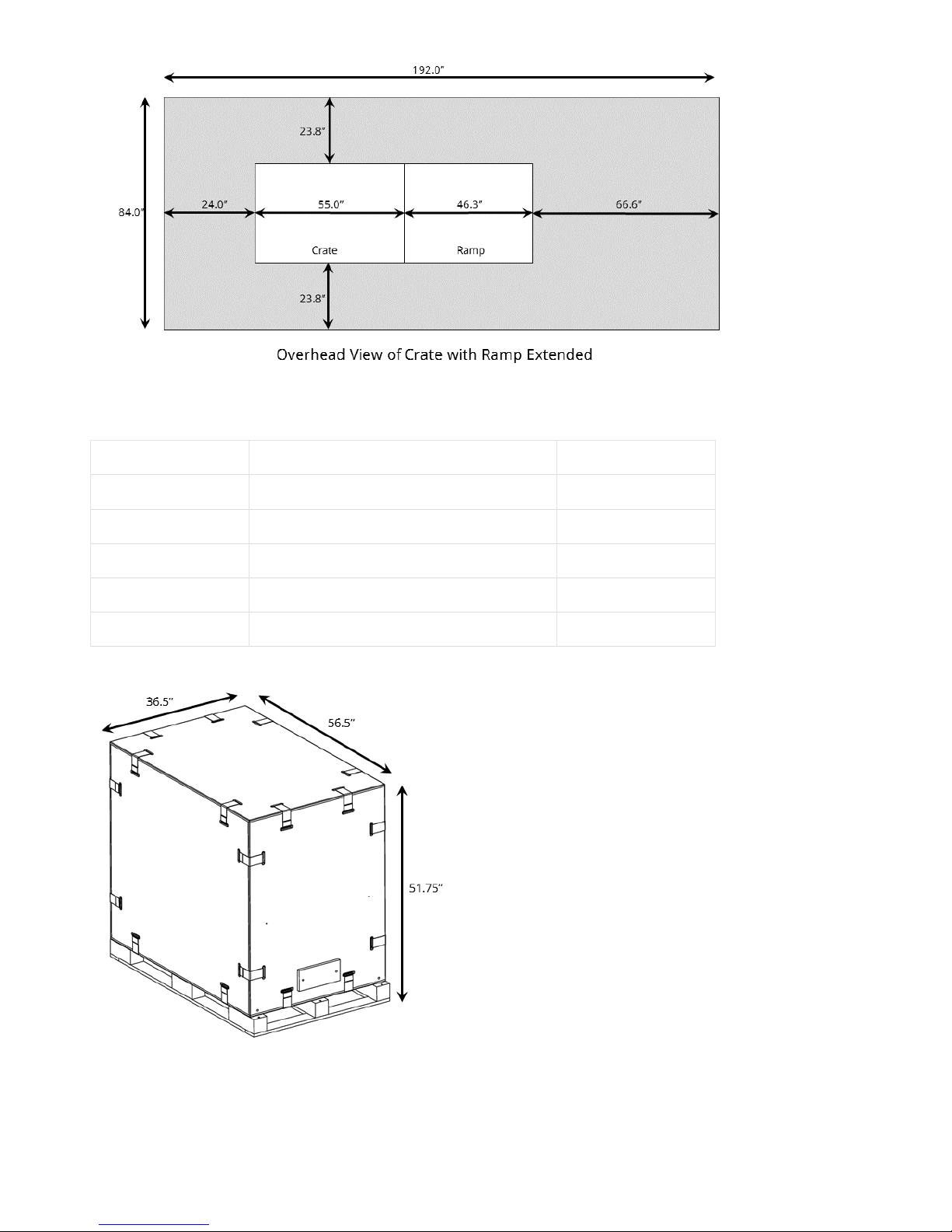

Crated Clearance

The 3D printer system is intended to be lifted from the shipping truck using a forklift. Have a forklift available for the 3D Systems Customer Support

Engineer (CSE) or reseller when installation occurs. The crate can then be removed, and the ramps placed as shown below. Store crate pieces where

it will be easy to access should the printer need to be sent back or shipped to another location. Based on the crate size, you must have at least

192”(488mm) (approx. 16’) to accommodate the pallet, ramps and printer, the required footprint to uncrate is approximately 7’ x 16’.(2.13x4.88m)

CAUTION: NEVER unpack, assemble, or connect any component of the shipment without the aid of a qualied, 3D Systems Customer Support

Engineer or certied partner. 3D Systems accepts no responsibility for damaged, defective, or incomplete systems uncrated by anyone other

than 3D Systems Customer Support Engineer or certied partner.

Requirement Metric English

Crated size 1435mmx 927.1mm x 1314.5mm(L x W x H) 56.5” x 36.5” x 51.75”

Crated weight 324kg 715 lbs.

Uncrated size 1117.6mm x 741.7mm x 1061.7mm (L x W x H) 44” x 29” x 41.8”

Uncrated weight 211kg 465lbs.

Floor Flatness / Level 2.5cm over 12m 1” over 3’

Crate Dimensions and Weight

Unit Portability

The ProJet® 2500 Printing System is equipped with four caster-type rollers and four leveling feet. Leveling can be adjusted by locking the casters in

place while adjusting leveling feet as required until 3D printer system is level.

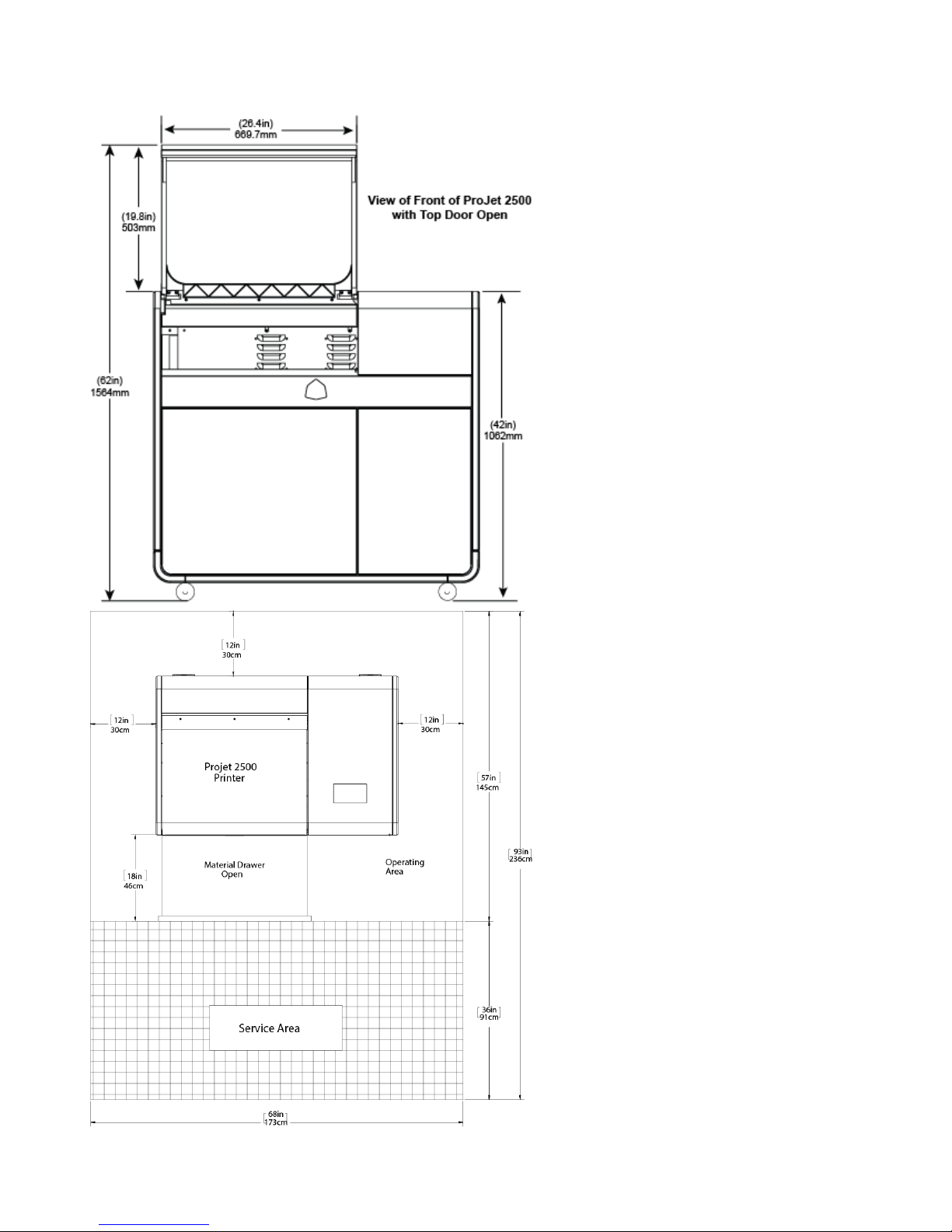

Access Area Surrounding Uncrated 3D Printer System

At least 12" (30cm) of unobstructed oor space is recommended behind and on either side of the printer for airow with 18" (46cm) in front of the

printer to be able to open the material drawer. It is recommended that 36" (91cm) either behind or in front of the printer for service access. Behind

would allow service to obtain access from the back, if the space is left in front, the printer will need to be moved out away from wall using that space

in front to do so.

Freezer

A freezer is recommended but not mandatory for easy part removal. If you decide to include a freezer as part of your post processing equipment

ensure that it will accommodate the maximum build size of 12” x 6” x 8” (L x W x H). Any standard freezer capable of accommodating this size will

be sucient.

Material Storage

VisiJet® part and VisiJet® support materials should be stored in a conveniently located storage cabinet in proximity to the printer. A cabinet is

recommended to protect against long term exposure to external UV light sources, including sunlight, overhead lighting, or other UV light sources.

Storage temperature of the material should not exceed the specied maximum of 35°C (95°F). VisiJet® part material should be stored away from

strong oxidizing agents, such as hydrogen peroxide, bromine, or chromic acid.

NOTE: When storing material cartridges that have been used but still have materials in the cartridges, do not lay the cartridges on their side in

storage. Store box with side spacers installed. *DO NOT rest on nose of cartridge. Also, in the case where used cartridgeswith materials are

removed from the MDM and are still warm, it must be stored with the cap vented. If the warm cartridge is not vented, the wax will contract during

cooling and the cartridge's bottom may become at which will prevent re-engagement in the MDM.

More detailed information on the VisiJet® build material and VisiJet support material, relevant applicable safety precautions and remediation, and

specic storage and disposal requirements, can be found in the Global Harmonized Standards / Safety Data Sheets(GHS/MSDS). Your

organizations' Facilities Manager (or equivalent) should maintain a copy of the two GHS/MSDS documents, and provide ready, convenient access to

these documents. To obtain the VisiJet® material GHS/MSDS from 3D Systems, go to www.3dsystems.com/support/materials/msds. If further

information is needed, please contact 3D Systems' Customer Hotline within the U.S. at (800) 793-3669 (or from outside the U.S.A. at +49 (0) 6151

357357), or by visiting 3D Systems’ website.

Material Cartridge Disposal

Used part material cartridges must be disposed of in a manner consistent with local and other applicable laws and regulations governing such

materials. Refer to the VisiJet® materials' GHS/SDS Global Harmonized Standards/Safety Data Sheets prior to shipment of the printer. Discuss your

organization's methods for disposing or recycling of such material with your facilities manager, or for more information, contact 3D Systems'

Customer Support Hotline.

Operating Environment

Locate the 3D printer system in a convenient location meeting the requirements specied in this document. To ensure optimum performance, it is

important that the printer be installed in a clean, dry, air-conditioned room. Avoid placing the printer in any environment with airborne contaminants,

including cigarette smoke, fumes, and mechanical particulates that can adversely affect the long term functioning of the equipment.

Each 3D printer system undergoes an operational test at the factory, and is shipped with (2)full cartridges of part material and (2) fullcartridges of

support material.

Caution: Estimated printing times can be off if ambient temperature exceeds what is required.

Using VisiJet® M2G-DUR(ProFlex) and VisiJet® M2G-CL (Armor)

The (2)engineering materials,VisiJet M2G-DUR (ProFlex) andVisiJet M2G-CL (Armor) use advanced chemistry that produces a stronger odor that

may not be suitable for all oce environments.There are no safety hazards in the odor but thiscould be a nuisance, especially to people who are

generally hypersensitive to strong odors.

Air Conditioning

A number of the ProJet® MJP 2500 System’s internal electronic components as well as the part material, are sensitive both to ambient temperature

and, to some extent, humidity. In addition, the build process itself can be temperature-sensitive within certain limits. The operating temperature range

should be between 18-28°C (64-82°F); optimal temperatures being 18-24°C (64-75°F).

The facility air conditioningsystem where the printer is operating should be capable of dissipating 1.0 kW (3412 Btu or 0.28 ton U.S. refrigeration) of

heat or equivalent to temperature requirements. Ensure that any air conditioning ducting does not vent directly onto the 3D printer system. Its is

recommended to place the machine in a room that has (4) air turnover cycles per hour.

Humidity

Humidity should be maintained at 30 to 70% RH.

Lighting

The 3D printer system is equipped with its own internal light build chamber, and back lit operating panel control with display. Normal area lighting is

necessary for operation and service of this system. Indoor lighting such as uorescentor LED is the best lighting for the system.Do not place the

printer next to a window that receives partial or direct sunlight.

Vibration and Shock

The printer consists of many precision mechanical and sensing systems that are sensitive to vibration during the build process. To maximize the

quality and accuracy of the build, it is required that the unit not be near heavy machinery or any source causing high vibration or shock (i.e. exterior

walls near train tracks or airports).

Location

Do not place the printer next to a window that receives partial or direct sunlight.

Noise

< 65 dBa estimated (at medium fan setting)

Thank You

3D Systems is condent that you will be very satised with the purchase of your ProJet® MJP 2500 Professional Printing System. Enjoy the ability to

produce high quality parts from your 3-D digital data. We are dedicated to developing a relationship that extends beyond the terms of the sale. Please

take the time to contact 3D Systems with questions, comments or suggestions aboutyour ProJet® MJP 2500 Professional Printing System, or other

products or services. 3D Systems strives for higher quality, better products, and comprehensive services to benet our customers.

3D Printer System Advance Preparation Checklist

NOTE: Unless governed by prior arrangement, 3D Systems is not responsible for loading the ProJet® MJP 2500 client software on the

user’s workstation(s). Thus, BEFORE THE 3D PRINTER SYSTEM ARRIVES, ensure that your workstation is capable of supporting the

requirements of both the client software and communication with the printer via your network.

Review this list with a network administrator, IT department, facilities manager or other responsible person within your organization. Complete and

place a check mark next to each item. Once everything is complete, photocopy this page, and fax it to the number checked or provided on the last

page of this document. If no number is provided or relevant, then fax to +1 970-257-4601 (U.S.A).

Please complete the following (if making a copy to ll in, please print):

Company Name:_________________________________________________________________________Telephone (with area

code)___________________________________

Contact (Print full name): ___________________________________________________________________________ Date faxed:

______________________________________

Email: ___________________________________________________________________

Please place a check in each box once that item is complete.

Final installation site selected. The intended physical location for each ProJet 2500 Professional Printing System(s) should be selected in

advance, and checked for adherence to the guidelines set out in this guide.

If required by the shipper, a method of removing the crate from the shipper’s truck has been arranged (forklift is required) and is available to

transfer the crate(s) to the de-crating location.

Operating system and workstation congurations are compatible and meet the minimum requirements as stated in the “Client Workstation

Requirements” section.

NETWORK CONNECTION IS INSTALLED. An RJ45 (UTP, female connection jack) Ethernet network connection for EACH 3D printer system

that is to be installed at the delivery site must be installed, tested and functioning.

TCP/IP is installed and enabled.

DCHP or Static IP

Dedicated material storage space selected.

Material disposal information in place according to local regulations.

Static IP address(es) has/have been allocated for each 3D printer system ordered. A permanent IP address on the network is assigned (presumably

by a Network Administrator) to each 3D printer system that is to be connected to the network. Write IP address here:

_______________________________________________________

Test each IP address by pinging it, or by temporarily connecting a network resource (such as a workstation or a 3D printer system) and “pinging”

from another workstation on the network.

Dedicated line, with a surge-and-spike-protected electrical power circuit for each 3D printer system, meeting one of the following specications

(Place check mark beside the appropriate specication: _________115 VAC, 50/60 Hz (dedicated 20 amp breaker) _________230 VAC 50/60 Hz

(dedicated 15 amp breaker)

Provide un-interruptable power (active battery back-up)

Before the printer is installed into this facility, we acknowledge that the installation site complies with the specications stated in the ProJet 2500

Facility Requirements Guide. Once the printer is installed, we agree not to alter any of therequired specications listed in this manualwithout

consulting with a 3D Systems’ Customer Service Representative or certied partner. If alterations are made without consulting 3D Systems, it may

void the system’s warranty.

Customer Signature: ____________________________________________________________________________________________ Date:

_____________________________________________

Please return a copy of the check listby FAXING it to the appropriate fax number provided in Contacts.

Contacting 3D Systems

The rst point of contact should be your Customer ResellerCertied Partner Attached below is your partner information.

ACCOUNT REPRESENTATIVES Place Business Card here and staple to document.

STAPLE CARD HERE

If you should need to contact 3D Systems headquarters:

3D Systems Corporation 333 Three D Systems Circle Rock Hill, SC 29730 Toll-Free Number: (800) 889-2964

Phone Number: (803) 326-4080 Web: www.3dsystems.com Email: more info@3d systems.com

For Customer Support:

Region Telephone Email

North America (800) 793-3669 3DWW-MJM Customer [email protected]

Europe +49 (0) 6151 357357

For localized service or support, contact the appropriate 3D Systems regional facilities listed below:

Region Telephone

France

Fax Number

+33 1 69351717 +33 1 69351718

Email

Germany

+49 6151 357 357

+49 6151 375355 [email protected]

Hong Kong

+852 2923 5077 +852 2574 4200

Contact the following Account Representative:

Name: _________________________________________________________________________________________

Address: _______________________________________________________________________________________

Italy

+39 039 68 904 00 +39 039 68 811 56

Japan

+03 5451 1690 +03 5451 6630

Portugal

+33 1 69 35 17 17

Spain

+33 1 69 35 17 17

UK

+44 1442 282600 +44 1442 282661

Tel: ___________________________________________________Fax: __________________________________________________

Returning the Advance Preparation Checklist?

Return the completed checklist via the method chosen below:

Fax to the Account Representative’s fax number (above):

Fax to the ___________________________________________________________ oce fax number (see above)

Fax or mail to: _______________________________________________________

Limitation of Liability

3D Systems is not, in any event, liable for any damages, including lost prots, cost of cover, or other special, incidental, consequential, or indirect

damages arising from the use of this document, however caused and on any theory of liability. This limitation will apply even if 3D Systems or an

certied partner or representative has been otherwise advised of the possibility of such damage. This document, in whole or in part, may be changed

or modied at any time at the sole discretion of 3D Systems, without notice.

Other manuals for MJP 2500

1

This manual suits for next models

2

Table of contents

Other ProJet 3D Printer manuals

ProJet

ProJet MJP 2500 User manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet 1000 User manual

ProJet

ProJet HD3000 User manual

ProJet

ProJet 5500X User manual

ProJet

ProJet 60 Series User manual

ProJet

ProJet MJP 2500W User manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet MJP 5600 User manual

ProJet

ProJet MJP 5600 Installation manual