7

Read Instruction Manual before operating the machine for your own safety.

1. Make sure the power voltage is for the machine. Before connecting the plug to socket, it is necessary

to check the power spec. to avoid any damage occurring.

2. If the machine is not used for a long time, the plug should be disconnected.

3. Never put the power cable near the fire or water environment, to break or press the power cable is

not allowed.

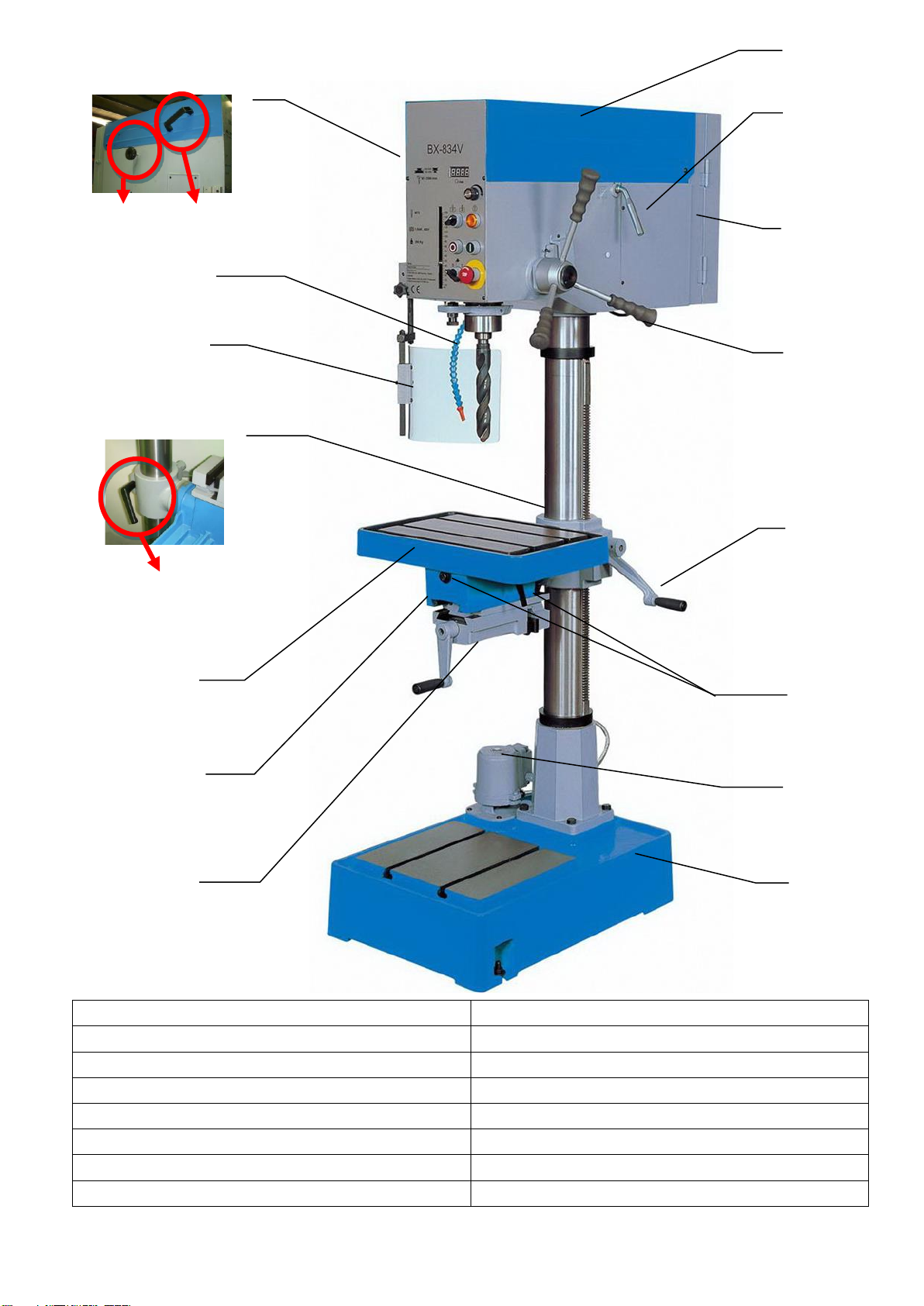

4. It shall be stable and securely fixed in machine installation procedure for the machine to be used

safely.

5. The working piece must be tightly fixed on table by vise or clamp.

6. Use recommended cutting liquid; consult the owner’s manual for recommendation.

7. Feed speed should be executed under safety scope, please refer to manual 3-3.

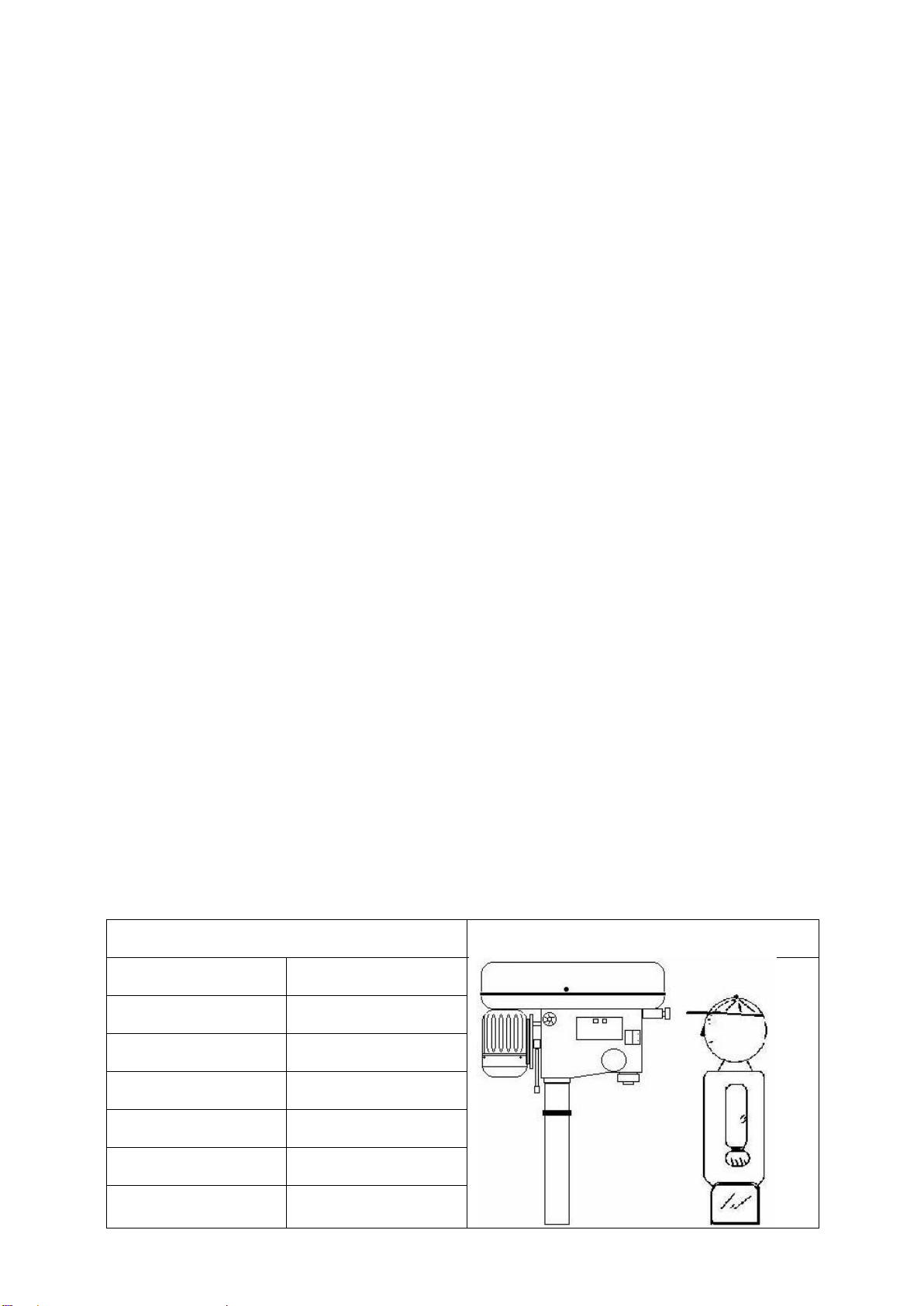

8. Wear proper apparel, no loose clothing, gloves, neckties, ring, and bracelet during operation. Always

wear safety glasses, cap and specific clothes.

9. Check all parts are in place and securely locked before transportation. Bump and crash are

prohibited.

10. Regular maintenance and repaired should be executed in accordance with the rules of manual.

11. Use the industrial suction to clean the chip is recommended.

12. Use carrier to move the working piece which the weight is more than 10 kg is recommended.

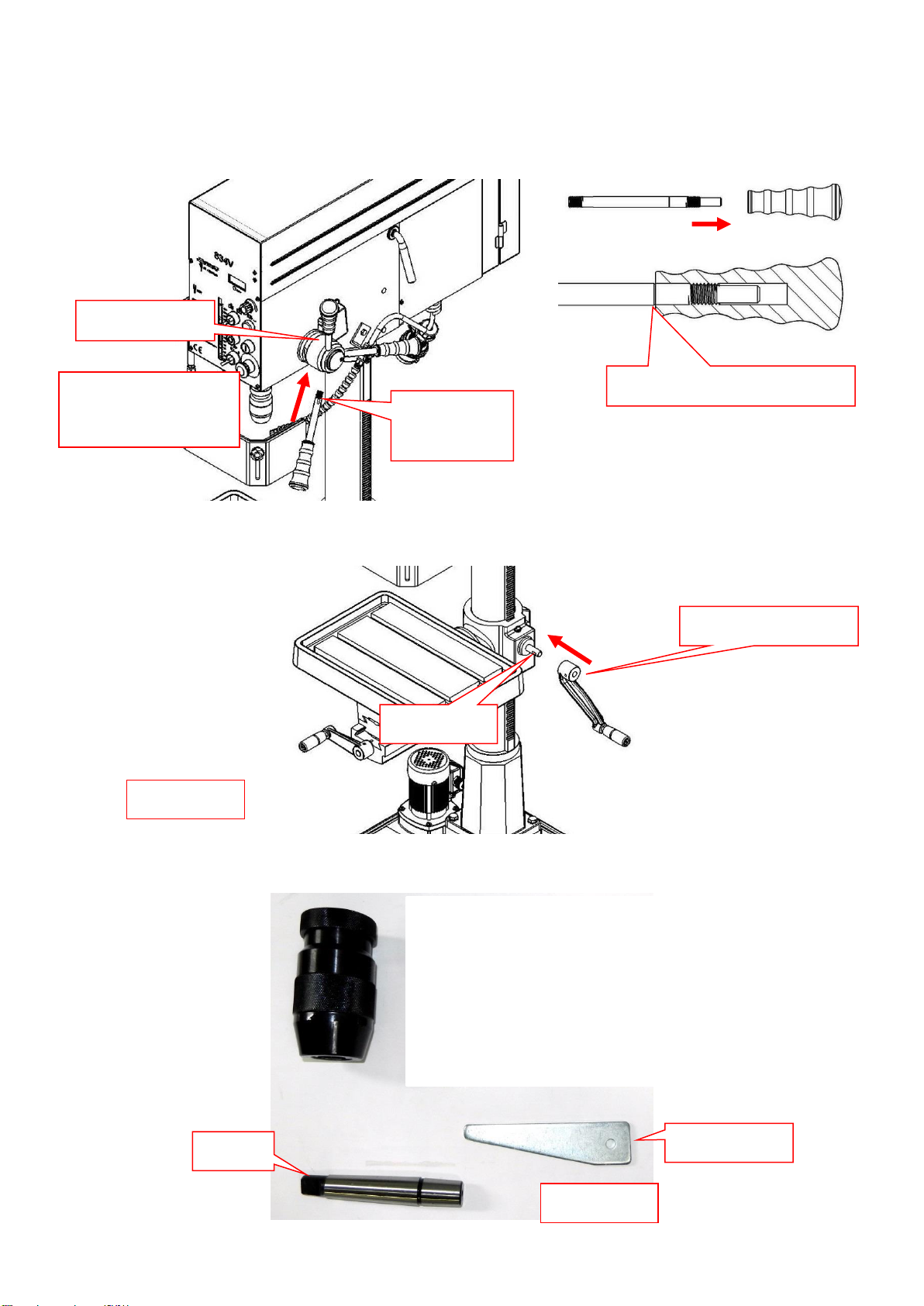

13. Wear safety gloves when install the drilling bit or tooling to avoid hurting your hand is

recommended.

14. This machine only be used following material brass, cast iron, steel, iron, aluminum .

15. It is prohibited to open the pulley cover during operation.

16. It is prohibited to use damaged or cracked parts

17. It is prohibited to remove the guard cover away during operation.