Promation Engineering P2-12PN4-DC User manual

Installation & Operation

Manual

This IOM is for the following

ProMation Engineering Products:

Valid for the following Options

-TS - Torque Switch equipped

-68 - IP68 compatible enclosure

-SS - Stainless Steel enclosure

P2S-12PN4-DC

P3S-12PN4-DC

P2S-24PN4-DC

P3S-24PN4-DC

P2-12PN4-DC

P3-12PN4-DC

P2-24PN4-DC

P3-24PN4-DC

Contents

2 . . . . . . . . . . . . . . . . . . . Product Specifications

3 . . . . . . . . . . . . . . . . . . . Shipping and Handling

3 . . . . . . . . . . . . . . . . . . . Product Mounting and Setup

3 . . . . . . . . . . . . . . . . . . . Installation Notes

4 . . . . . . . . . . . . . . . . . . . Wiring Diagram

4 . . . . . . . . . . . . . . . . . . . Torque Switches

5 . . . . . . . . . . . . . . . . . . . Layout of Controller

6 . . . . . . . . . . . . . . . . . . . Check End of Travel Settings

6 . . . . . . . . . . . . . . . . . . . Status Indicators

7 . . . . . . . . . . . . . . . . . . . Adjusting the actuator CW position

8 . . . . . . . . . . . . . . . . . . . Adjusting the actuator CCW position

9 . . . . . . . . . . . . . . . . . . . Adjusting the actuator Auxiliary Switches

10 . . . . . . . . . . . . . . . . . . Mechanical Data

11 . . . . . . . . . . . . . . . . . . Mechanical Data

12-14 . . . . . . . . . . . . . . . Commissioning

15 . . . . . . . . . . . . . . . . . . AutoCalibration Procedure

IOM Template Master.indd

Page 1 of 17 P2/3 Series HV-TS AdVanced Proportional Control

Page 1 of 17 P2/3 12 24 VDC Proportional Series

Product

Family

Torque Output Voltage Options

in lbs Nm 12DC 24DC 24AC 120AC 230AC

P2 800 90

P3 1,335 150

P4 3,500 400

P5 4,400 500

P6 5,750 650

P7 8,900 1,000

P8 13,250 1,500

P9 17,500 2,000

P10 22,000 2,500

P11 26,500 3,000

P12 31,000 3,500

P13 40,000 4,500

Field Manual

P(S)2,3 24(12)-PN4-DC

High Resolution

Proportional Control w Loop Feedback

ISO5211 F07/F10 8P22

Imperial Mount S 3.25in BHC, 0.75x0.5in DD

Imperial Mount L 3.25/5in BHC, 0.875x0.625in DD

Actuator Sizes and Voltage Opons

ISO 5211

Mount Imperial

Mount

Actuators In

This IOM

FM_P28 24 PN4-DC Ver E 080223

Introduction

This document provides necessary information for set-up, calibration, testing and use of the P Series quarter-turn

electric actuators stated on the cover page. Each unit is shipped from the factory with initial calibration of mechanical

stops, cams and switches completed for 0-90 degree operation. However, these are general settings and serve as

a starting point for proper calibration of the actuator in its real-world application.

Safety

Safety is a basic factor any time you maintain and operate mechanical equipment. Appropriate handling

methods and proper use of tools and personal protective equiptment (PPE) can help prevent serious accidents

which can cause injuries to you or a fellow worker. This manual was created to enable a trained user to install,

adjust and troubleshoot your ProMation actuator.

Only competent and trained personnel should install, maintain and operate ProMation actuators. Any work

related to this actuator must be carried out in accordance with this manual and related codes and regulations.

Local workplace health and safety rules must always be followed.

Duty cycle

Duty cycle is the percent of time that an actuator spends running as a fraction of the total time. Duty Cycle is

directly related to heat; excessively repositioning an actuator typically results in motor overheating which can

cause permanent damage and/or reduced service life.

Duty cycle can be calculated as follows:

(example P2 series actuator running 3 seconds ON and 30 seconds OFF)

Runtime = 3s, Total time = 3s + 30s = 33s, therefore this duty cycle would be 9% (3/33)

Additionally, ProMation P series actuators are designed for a maximum of 1200 starts per hour (one start every

3 seconds maximum).

These may be equipped with internal

torque switches (-TS) which protect

the gear train, motor and controlled

equipment from damage when high

torque conditions exist.

These protective devices are NOT

adjustable. More information on this

techology is found throughout this

manual.

Page 2 of 17 P2/3 12V 24DC Proportional Series

Actuator Specications P2 P3

Torque “lb/Nm 800”lbs/90Nm 1335”lbs/150Nm

Supply Voltage 24vac 24vac

Max Inrush Current 4.5A 5.0A

Running Current 2.2A 2.4A

Motor DC Brush Type

Runtime (90°@60Hz/vdc) 15 sec 22 sec

Runtime (90O@50Hz) 15 sec 22 sec

Duty Cycle Proportional: Managed (75% maximum)

Motor Starts 1200 per hour

Weight 26lbs/12kg

Mechanical Connections ISO5211 F07 8pt 22mm

Electrical Entry (2) 3/4” NPT

Electrical Terminations 12-16ga

Environmental Rating NEMA 4/4X

Manual Override 5” Handwheel

Control Proportional

Actuator Case Material Aluminum Alloy, Powder coated

Motor Protection 230°F/110°C Thermal F* Class

*Totally Enclosed Non-Ventilated Motors

Ambient Temperature

Operating Range

-22°F to +125°F

-30°C to +52°C

FM_P28 24 PN4-DC Ver E 080223

Product Specications

• These actuators are designed to be used between a horizontal and upright

position. Do NOT mount the assembly with the actuator top below a horizontal

position.

• When installing conduit, use proper techniques for entry into the actuator. Use

drip loops to prevent conduit condensate from entering the actuator.

• Mechanical travel stops are factory calibrated for 90 degree operation. These

stops are NOT designed to adjust mechanical rotation by more than +/- 3

degrees, they are for positioning the handwheel only.

• Both NPT conduit ports MUST use proper equipment to protect the NEMA 4X

integrity of the housing.

• The internal heater is to be used in ALL applications.

• Do NOT install the actuator outdoors or in humid environments unless it is

powered up and the heater is functioning.

• Use proper wire size to prevent actuator failure (see chart on page 4 for proper

wire sizing).

• All terminals accept 12-16AWG solid/stranded wire.

Identifying Torque Switch Units:

• -TS in Product Name on label.

• Units with Torque Switches have

additional switches mounted on

the motor plate (see photo).

Page 3 of 17 P2/3 12 24 VDC Proportional Series

ISO

Imperial

FM_P28 24 PN4-DC Ver E 080223

Shipping and Handling

1. This actuator is shipped in the FULLY CW position (2 color position indicator

shows “CLOSE” and the Reference Dimple aligns with “0”). (The “1” mark is the

FULLY CCW position).

2. NOTE, THIS ACTUATOR MUST HAVE WATER TIGHT EMT FITTINGS, WITH

CONDUIT DRAINAGE INSTALLED AND POWER SUPPLIED TO UNIT TO

KEEP THE HEATER WARM AT THE TIME OF INSTALLATION.

3. Storage: This unit should NOT be stored outside unless it is powered up

and has proper conduit terminations. When NOT powered up, it should be

stored in a clean, dry environment at all times.

4. This actuator has been factory calibrated to operate between 0 degrees and

90 degrees. Most quarter-turn products will not require recalibration of

these settings. If any travel adjustment is necessary, please refer to pages 6-8

for instructions.

Product Mounting and Setup

1. Fully CLOSE the valve or damper to which the actuator is to be mounted.

• Keep in mind this actuator rotates CW (as viewed from above the unit) when driving CLOSED.

2. Assemble necessary linkage components and attach the actuator to the driven device.

3. Tighten mounting bolts, making sure actuator is centered on the device drive shaft.

4. Utilize the handwheel to check for unobstructed manual operation from fully CCW to fully CW positions BEFORE

applying power to the unit.

5. Make the electrical connections per wiring diagram on page 4.

• Connect POWER to terminals marked 1 and 2 on the switch card.

• Actuator accepts any one of 4-20mA, 1-5vdc or 2-10vdc signal.

• Connect CONTROL wires on the control card (DMC 400) to terminals marked J2T4 and J2T5. The positive wire

MUST connect to terminal marked J2T5 or the controller will not function.

• The drain wire on the signal cables must be grounded at ONE END ONLY! (Preferably at the supply end).

6. Do NOT apply power at this time.

Installation Notes

12VDC for P2

or P3 only

Torque Switches (if equipped)

For units equipped with torque switches:

Torque switches provide mechanical

overload protection for both the actuated

device and the geartrain.

These are factory set and are not

adjustable without proper equipment.

Torque switches are set to limit actuator

torque to approximately 105% of the

actuator rated output.

The wiring diagram above shows the

internal wiring connections between

the control board, the torque switches

and the motor. The upper torque switch

controls loading in the CW direction,

while the lower switch controls loading in

the CCW direction.

Wire sizing data is provided in the table to

assist in the selection of the proper wire size for

ProMation actuators using various wire sizes

over distance.

Please make sure to reference the correct

voltage and do not exceed the indicated length

of the wire run for each model.

WARNING! Do NOT adjust the

torque switch cam settings.

This will VOID the warranty.

Optional torque switch wiring (-TS) is interposed

between motor end of travel wiring and controler

Page 4 of 17 P2/3 12V 24DC Proportional Series

MAX distance between Actuator and Supply (feet)

Actuator P2 P3

Voltage 24VAC/VDC 24VAC/VDC

4.5A 5.0A

16 58 52

14 93 84

12 143 128

10 242 218

8362 326

Wire

Gage

Amps

Wire Sizing Chart

FM_P28 24 PN4-DC Ver E 080223

Wiring Diagram

Proportional Control

The Default Settings of the controller are as follows:

• Input Signal: 4-20mA (may be changed)

• Output Signal: 4-20mA (cannot be changed)

• Signal Response: Direct Acting (open = CCW)

• Loss of Command: Fail in Position

Input Signal Options:

• 4-20mA (default)

• 1-5vdc, 0-5vdc, 0-10vdc (Wire as shown on page 4, J2,

terminal 6 and select Command Type from Calibration Menu.

J2 Connector

J1 Connector

Calibration Menu

J3 Connector

for Optional

Feedback

or Modbus

Control

Options

For MODBUS

control paramters,

see

[ProMation Modbus

prmtrs 800-192B.

pdf]

MODE

Button

Select ▼

Button

Select ▲

Button

Fuse

Calibration LED Indicators

Fault Detection:

• Fault Indicator will flash and motor outputs are

turnedountilallfaultsarecorrected.

• All Faults show on the same LED

• See Fault Table for priority listing of faults

Controller Notes:

• Limit (Cam) Switches (SW1 and SW2) can cause

a Motor Stall Fault if set too close to the 0° (CW)

or 90° (CCW) positions.

This proportional control card has been calibrated and tested at the factory to operate

between 0 degrees and 90 degrees operating range. Controller position settings control the

actuator, adjustment of cam settings may aff ect controller operation, resulting in a fault.

Proportional Control

Fault LED Indicators

J7 Connector

The AC Controller Shown.

Calibration sequence is the

same for both AC and DC

Diagram of Controller

Page 5 of 17 P2/3 12 24 VDC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

Loosen Mechanical Stops

1. BEFORE power is applied, use a 17mm wrench and a 5mm hex key to

loosen the LEFT and RIGHT SIDE mechanical stops.

2. Turn the stop screws 5-6 turns CCW to allow electrical cam stop adjustment

to keep the internal stops from running into the mechanical stop screws.

3. Leave the stop screws out until controller calibration is complete.

Understanding Cam Operation

4. The lowest cam, Cam 1 controls SW1, a CW limit switch secondary to the

controller board. It will interrupt power to the board and motor if it changes

state and shows as a fault on the controller board.

5. The second cam, Cam 2 controls SW2, a CCW limit switch secondary

to the controller board. It will interrupt power to the board and motor if it

changes state and shows as a fault on the controller board.

6. The third cam, Cam 3 controls SW3, a CW (CLOSED) auxilary switch

connected to the optional outputs 7-9 of the 430-10100 Switch Card.

7. The uppermost cam, Cam 4 controls SW4, a CCW (OPEN) auxilary switch

connected to the optional outputs 10-12 of the 430-10100 Switch Card.

CW Mechanical Stop

CLOSE, 0°, 4mA, Red Cams

Mechanical Stop

Adjustment Positions

This actuator has been factory calibrated to operate between 0 degrees and 90 degrees. Proportional

Controllerpositioningchangesdierentfrom0and90degreeswilllikelyinvolvealsochangingcam

settings. If cam adjustments cause the controller board to show faults, you will need to reposition

the cam further outside your range of travel. Back out the mechanical stops before making any cam

setting change so the gear train does not strike a mechanical travel stop.

Serious Damage to the actuator will result if the motor is allowed to drive the gear train into

the mechanical stop!! Be sure the mechanical stops are out before making adjustments.

Cam 2

Cam 4

Cam 1

Cam 3

The mechanical stop screws limit handwheel operation ONLY and are NOT to be used as an electrical travel limiting device.

0

SW4 Aux Switch

SW2 CW Limit Switch

CCW Mechanical Stop

Controller CW

End of Travel

Controller CCW End of Travel

SW3 Aux Switch

SW1 CW Limit Switch

CW Mechanical Stop

10

20

30

40

45

50

60

70

80

90

Practical Cam Considerations

8. SW1 and SW2 can be used as electrical limit switches. For

proper function their cams must be set outside (or beyond) the

CLOSE and OPEN positions of the proportional controller.

9. SW1 and SW2 do not impact initial controller calibration unless

their cams are set within controller travel limits.

10. After changing any cam settings, test the actuator limits for

proper functionality.

CCW Mechanical Stop

OPEN, 90°, 20mA, Green Cams

Setting Limit Switches and Auxiliary Switches (Cams)

Page 6 of 17 P2/3 12V 24DC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

Cam 1

Adjust Cam 3 (SW3 -- CW auxiliary switch)

1. The THIRD cam is Cam 3, the CW auxiliary switch (SW3) cam. When the

actuator is in its CW position set this cam. Use a 2.5mm hex key to free up the

cam set screw. Once it is free, rotate the hex key to the RIGHT 10-15 degrees

to reset the switch roller arm. Then snug the set screw up against the camshaft

(CW) until slight pressure is felt. Then SLOWLY rotate the hex key and cam to

the LEFT until you hear the “click” on the third switch. Continue to rotate the

cam between 3 and 5 degrees to the LEFT to make sure the auxiliary cam

switch changes state before the actuator reaches its end of travel electrically.

Tighten the cam set screw.

Adjust Cam 4 (SW4 -- CCW auxiliary switch)

1. The FOURTH cam is Cam 4, the CCW auxiliary switch (SW4) cam. When the

actuator is in its CCW position set this cam. Use a 2.5mm hex key to free up

the cam set screw. Once it is free, rotate the hex key to the LEFT 10-15 degrees

to reset the switch roller arm. Then snug the set screw up against the camshaft

(CW) until slight pressure is felt. Then SLOWLY rotate the hex key to the RIGHT

until you hear the “click” on the fourth switch. Continue to rotate the cam between

3 and 5 degrees to the RIGHT to make sure the auxiliary cam switch changes

state before the actuator reaches its end of travel electrically. Tighten the cam set

screw.

Cam 3

Cam 4

COM

NO

NC

CLOSED

LIMIT

SWITCH

LESS

CLOSED

FURTHER

CLOSED

COM

NO

NC

OPEN

LIMIT

SWITCH

LESS

OPEN

FURTHER

OPEN

COM

NO

NC

CW LIMIT SWITCH

LESS

CW

FURTHER

CW

COM

NO

NC

CCW LIMIT SWITCH

LESS

CCW

FURTHER

CCW

COM

NO

NC

CLOSED

LIMIT

SWITCH

LESS

CLOSED

FURTHER

CLOSED

COM

NO

NC

OPEN

LIMIT

SWITCH

LESS

OPEN

FURTHER

OPEN

COM

NO

NC

CW LIMIT SWITCH

LESS

CW

FURTHER

CW

COM

NO

NC

CCW LIMIT SWITCH

LESS

CCW

FURTHER

CCW

Adjust Cam 1 (SW1 -- CW limit switch)

1. The lowest cam is Cam 1, the CW limit switch (SW1) cam. Once the actuator is

at its required CW position turn POWER OFF. Use the handwheel to drive more

CW by 1-2°. Use a 2.5mm hex key to free up the cam set screw. Once it is free,

rotate the hex key to the RIGHT 10-15 degrees to reset the switch roller arm.

Then snug the set screw up against the camshaft (CW) until slight pressure is

felt. Then SLOWLY rotate the hex key pushing the cam to the LEFT until you

hear the “click” on the bottom switch indicating that correct adjustment has been

achieved. Tighten the set screw.

2. Use the handwheel to

check to be sure this is the correct CW position you require

(refer to Page 6). Repeat step 1 if further adjustment is needed.

Adjust Cam 2 (SW2 -- CCW limit switch)

1. The second cam is Cam 2, the CCW limit switch (SW2) cam. Once the actuator

is at its required CCW position turn POWER OFF. Use the handwheel to drive

more CCW by 1-2°. Use a 2.5mm hex key to free up the cam set screw. Once

it is free, rotate the hex key to the LEFT 10-15 degrees to reset the switch roller

arm. Then snug the set screw up against the camshaft (CW) until slight pressure

is felt. Then SLOWLY rotate the hex key pushing the cam to the RIGHT until you

hear the “click” on the second switch indicating that correct adjustment has been

achieved. Tighten the set screw.

2. Use the handwheel to

check to be sure this is the correct CCW position you

require (refer to Page 6). Repeat step 1 if further adjustment is needed.

Listed here for reference. Mechanical stops must be out before

changing cam settings. Proceed ONLY if adjustments are required.

Cam 2

Cam Adjustments

Page 7 of 17 P2/3 12 24 VDC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

This procedure will assume that the actuator is installed correctly both mechanically and electrically with correct

POWER and SIGNAL, the cams are factory set 1-2° beyond 0° and 90°, and the mechanical stop screws are out.

This proportional control card has been

calibrated and tested at the factory to operate

between 0 degrees and 90 degrees operating

range.

END OF TRAVEL

• Test the travel of the actuator with the handwheel

by rotating from 0° to 90° and listen/feel for the

change of state of the limit switches. If Cams 1

and 2 are outside the desired range of travel,

skip step 2.

• Set cams per the Setting Limit Switches and

Auxiliary Switches (Cams) section:

• Cam 1 for approximately -1°.

• Cam 3 for approximately 3°.

• Cam 2 for approximately 91°.

• Cam 4 cam for approximately 87°.

The open and close end of travel cams (Cam

1 and Cam 2) must be set outside the desired

range of travel of the proportional card. If they

trip, the proportional card stops the motor and

reports a stall condition.

Connect Signal, Feedback and Power per wiring

diagram:

• Signal - (Optional) 4-20mA in uses Terminal 5

(+) and 4 (-) and 0-10V in uses Terminals 7

(+) and 5(-) on J2

• Feedback - The HR feedback option for 24AC,

120AC and 230AC is self powered. 4-20mA

out uses Terminal 6 (+) and 5 (-). 0-10V out

uses Terminals 7 (+0 and 5(-). Use a known

accurate meter to calibrate.

• Feedback - The HR-ISO option and feedback

for all 12 and 24VDC controllers utilizes loop

(external) power. THe power can come from

the board via terminal 8 or from an external

power source.

• Apply line power.

• The AUTO green LED will light.

• The Red AUX POSITION OUT LED will blink

if there is no control signal.

0

SW4 Aux Switch

SW2 CW Limit Switch

CCW Mechanical Stop

Controller CW

End of Travel

Controller CCW End of Travel

SW3 Aux Switch

SW1 CW Limit Switch

CW Mechanical Stop

10

20

30

40

45

50

60

70

80

90

NOT OPEN*

OPEN COM*

OPEN*

NOT CLOSED*

CLOSED COM*

CLOSED*

12

11

10

9

8

7

M

SW3

SW4

THERMAL

SWITCH

AC DRIVE

MOTOR

AUXILIARY

SWITCH

(STANDARD)

AUXILIARY

SWITCH

(STANDARD)

* CONNECTIONS

OPTIONAL

GND Screw

P(2-13) 120PN4(7)-HR

Actuator ships in fully closed position!

Items within dotted line indicates internal components

6

5

4

3

2

1

J1

HEATER

SW1

SW2

J2

E1

E2

J3

1

12 43

430-10100 Switch Card

BLK

RED

WHT

BLK

WHT

Capacitor

ProMation

F

NONE

Use For:

WD-850-P4222 F

5

4

3

2

1

ANALOG

ALL SWITCHES

SHOWN WITH

ACTUATOR IN

FULL OPEN

POSITION

Close POSITION

FEEDBACK

1K ohm

J4

FACTORY

CONNECTOR

430-10102 Controller

GRY

ORG

BLU

J2

GND

L1 Hot

L2 Neutral

DHC-100

OTX-100

1

2

3

4

5

J1

6

4 3 12

SIGNAL IN

FEEDBACK OUT

(-)

+4-20mA

GND(-)

Amperage Out +4-20mA

WHT

BLK

BLU

RED

8 (+15v OUT)

7

6

GRN

WHT18

(+) 1-5, 0-5, 0-10vdc

ALTERNATE SIGNAL IN

5

7

6

Voltage Out

NOT OPEN*

OPEN COM*

OPEN*

NOT CLOSED*

CLOSED COM*

CLOSED*

12

11

10

9

8

7

M

SW3

SW4

THERMAL

SWITCH

AC DRIVE

MOTOR

AUXILIARY

SWITCH

(STANDARD)

AUXILIARY

SWITCH

(STANDARD)

* CONNECTIONS

OPTIONAL

GND Screw

P(2-8)-120PN4(7)-HR-ISO

Actuator ships in fully closed position!

Items within dotted line indicates internal components

6

5

4

3

2

1

J1

HEATER

SW1

SW2

J2

E1

E2

J3

1

1 2 43

430-10100 Switch Card

BLK

RED

WHT

BLK

WHT

Capacitor

ProMation

F

NONE

Use For:

WD-850-P4221 G

5

4

3

2

1

ANALOG

ALL SWITCHES

SHOWN WITH

ACTUATOR IN

FULL OPEN

POSITION

Close POSITION

FEEDBACK

1K ohm

J4

FACTORY

CONNECTOR

430-10102 Controller

GRY

ORG

BLU

J2

GND

L1 Hot

L2 Neutral

DHC-100

+

-

ANALOG

OTX-101

1

2

3

4

5

J1

6

4 3 12

SIGNAL IN

Internal Power

FEEDBACK

(-)

+4-20mA

-

4-20mA

WHT

BLK

BLU

RED

8 (+15v OUT)

7

6

GRN

WHT18

WHT18

(+) 1-5, 0-5, 0-10vdc

ALTERNATE

SIGNAL IN

+

-

ANALOG

8

4-20mA

MONITOR

DC

Power

Supply

+

-

+

-

Isolated Power

FEEDBACK

4-20mA

+

HR AC- Self Powered

-ISO AC and DC - Loop Powered

Pre Calibration Preparation

Calibration - End of Travel, Feedback

Page 8 of 17 P2/3 12V 24DC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

Calibration Interface Notes

TheAUTO LED is lit during normal operation. Pressing MODE

will enter the calibration sequence to change operational

parameters. The MODE sequence goes in one direction.

Each time MODE is pressed the current parameter is saved

and the next one is presented. One can cycle through the

operational parameters without changing them by pressing

MODE repeatedly.

Begin Calibration

1. Apply Line Power - The AUTO green LED will light

2. Press MODE until MANUAL/FB POT CAL LED is

lit.

• You may calibrate this as often as needed but it

mayaecttheCWandCCWendpositionsifit

changes.

3. Use▲and▼orhandwheeltopositiontheactuator

to the mid position (i.e. 50% open or 12 mA).

• Blinking amber MANUAL/FB POT CAL light

means you need to adjust the potentiometer

position.

4. Feedback Potentiometer Calibration (FB POT CAL

LED is blinking).

4.A Check Potentiometer Gear Engagement as

shown.

4.B Loosen the potentiometer shaft hex screw. Use

a screwdriver to adjust the potentiometer shaft

until the amber LED is steady.

NOTE: The amber LED blinks more rapidly as you approach

the proper mid position. The farther from that position, the

slower the blinkrate.

5. Set Closed (CW) Position (CLOSE LED is lit)

5.A The motor will drive to approximately the 25%

position.

5.B Use the handwheel or the ▲ and ▼ to position

the actuator in the desired CLOSE position (i.e.

4mA).(Youmusttoucheither▲or▼beforethe

handwheel responds).

5.C Press MODE to conrm setting. This will also

move you to the next user input setting.

5.D This CLOSE position is now set.

5.E If the AUX CLOSE OUTPUT LED is lit, ignore it

5.F OPEN LED is lit.

Potentiometer Gear Engagement

When the actuator is at CW position, the potentiometer

pinion gear and the camshaft sector gear should

not be past the point of engagement. If the sector

gear should have at least 2 full teeth contacting

the potentiometer pinion gear. If not, contact your

distributor for mechanical recalibration instructions.

Hex Screw

Potentiometer

Shaft

2

4

Calibrating the proportional control board

Page 9 of 17 P2/3 12 24 VDC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

6. Set Open (CCW) Position (OPEN LED is lit)

6.A The motor will drive to approximately the 75% position.

6.B Use the handwheel or the ▲ and ▼ to position the

actuator in the desired OPEN position (i.e. 20 mA).

(Youmusttoucheither▲or▼beforethehandwheel

responds).

6.C Press MODE to conrm setting. This will also move

you to the next user input setting.

6.D This OPEN position is now set.

6.E If the AUX OPEN OUTPUT LED is lit, ignore it.

6.F AUX CLOSE OUTPUT is lit.

The motor may drive an arbitrary position.

7. Aux Close Output Settings (AUX CLOSE OUTPUT is lit)

7.A This feature requires an additional optional board.

7.B Press MODE to skip.

7.C AUX OPEN OUTPUT is lit.

The motor may drive an arbitrary position.

8. Aux Open Output Settings (AUX OPEN OUTPUT is lit)

8.A This feature requires an additional optional board.

8.B Press MODE to skip

8.C COMMAND TYPE LED is lit.

9. Set Input Signal (COMMAND TYPE LED is lit)

9.A Use▲and▼toselectthecommandsignaltypegoing

into the DHC-100 board from the column left of the

LEDs.

• 4-20mA (factory setting)

• 1-5VDC

• 0-5VDC

• 0-10VDC

9.B Press MODE to set Input Signal

Calibrating the proportional control board (continued)

Page 10 of 17 P2/3 12V 24DC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

10. Set Loss of Signal (LOSS OF COMMAND LED is lit)

10.A Use▲and▼ to select the fail position on loss of

signal. Select from the column right of the LEDs.

• CLOSE - fails close (4mA)

• OPEN - fails open (20mA)

• (BothO)-failsinplace(default)

10.B Press MODE to set

10.C AUX POSITION OUT CAL LED is lit.

The motor may drive an arbitrary position.

11. Trim the accuracy of the feedback (AUX

POSITION OUT CAL LED is lit)

11.A The position of the actuator is

unimportant for this step.

11.B CLOSELEDshouldbeflashing

11.C Use▲and▼toadjustthemAfeedback

for the CLOSE position (i.e. 4.00mA).

Read using a known accurate multimeter.

11.D PressMODEtoconrmsetting.

11.E OPENLEDshouldbeflashing

11.F Use▲and▼toadjustthemAfeedback

for the OPEN position (i.e. 20.000mA).

This isread on a known accurate

multimeter.

11.G PressMODEtoconrmsetting,

Calibrating the proportional control board (continued)

Page 11 of 17 P2/3 12 24 VDC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

AUTO LED is lit. The actuator is now responding to the

4-20mA signal.

Calibration is complete.

Reinstall mechanical stop screws.

• CCW Stop - drive to the OPEN position and power

down actuator.

• With handwheel, drive more open until you hear the

SW2 switch make.

• Drive the handwheel 1/2 turn more OPEN.

• Use wrench and hex key to install the CCW Stop

screw on the stop boss.

• With the handwheel, insure the end stop is

approximately 1/2 handwheel turn after the SW2

switch makes.

• CW Stop - drive to the CLOSE position and power

down actuator.

• With handwheel, drive more close until you hear the

SW1 switch make.

• Drive the handwheel 1/2 turn more CLOSE.

• Use wrench and hex key to install the CW Stop

screw on the stop boss.With the handwheel, insure

the end stop is approximately 1/2 handwheel turn

after the SW1 switch makes.

Complete Calibration

Page 12 of 17 P2/3 12V 24DC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

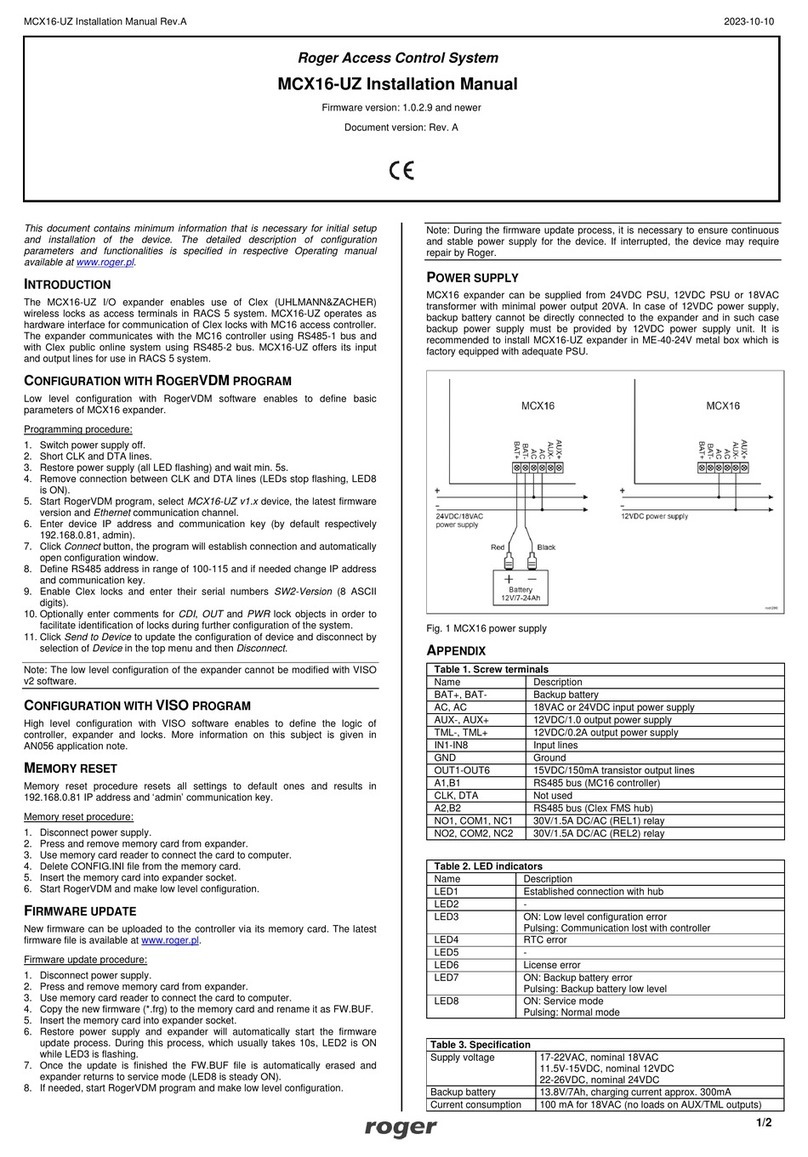

RED YEL GRN FAULT 12, 24

VDC

24,120,

230 VAC

flash OFF OFF Low Voltage X Supply voltage is less than 10VDC

flash flash OFF Motor 1 Stall X X No motor movement in direction 1 upon

command with motor amperage load

flash OFF flash Motor 2 Stall X X No motor movement in direction 2 upon

command with motor amperage load

flash flash flash Double Stall X No motor in either direction movement upon

command

flash ON OFF Motor 1 Current Trip X Current on motor line 1 is higher than current

trip setting

flash OFF ON Motor 2 Current Trip X Current on motor line 2 is higher than current

trip setting

flash ON ON Double Current Trip XCurrent too high in both motor directions

ON OFF OFF Over Voltage X Supply voltage is higher than 30VDC

ON flash OFF Motor 1 No Motion X No motor movement in direction 1 upon

command with no motor amperage load

ON OFF flash Motor 2 No Motion X No motor movement in direction 2 upon

command with low motor amperage load

ON flash flash Double No Motion X No motor movement in either direction upon

command with low motor amperage load

OFF OFF flash Feedback Alarm X X Feedback signal from potentiometer out of

range or not present

OFF flash OFF Loss of Command X X Command signal is disconnected

OFF ON OFF Command Out of Range X X Command singal is out of range

OFF flash flash Feedback Alarm and Loss

of Command X X Both potentiometer and command signals are

lost

OFF ON flash Feedback Alarm and

Command Out of Range X X Potentiometric signal is lost, command signal is

out of range

FAULT INDICATORS

Motor Amperage Limiter

0A

3A

6A

9A

12A

The DC controllers are equipped with adjustable amperage limiting that

is set by the rotational potentiometer adjacent to the J7 connector. The

amperage draw on the motor is limited by the aperage setting as shown

in the inset. TThe setting should be adjusted to a reasonalb elevel above

the running current expected for the actuator and its load. When the motor

currentexceedsthetripsetting,themotoristurnedoandaCurrentTrip

fault condition is indicated.

The amperage limiter setting essentially performs the same function as

torque switches. The limiter is for the actuator motor, so other components

in the system (gears, couplings, packing, seats, etc.) also place a load on

themotor.Theeectofthesecomponentswillvarywithtemperatureand

age. Therefore the amperage draw on the motor may vary accordingly.

The J7 Connector is used in conjuction with local control stations (LCS) or

motor control stations (MCC) for local control of the actuator. Both AC and

DC controllers contain the J7 connector

J7

Connector

Page 13 of 17 P2/3 12 24 VDC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

Commissioning

WARNING! Do NOT

adjust the torque

switch cam settings.

This will VOID the

warranty.

After completing all mounting and wiring procedures and main power is available, it is now possible to commission

the actuator.

1. Utilize the handwheel to rotate the actuator and damper, valve or other connected device through its full travel from

full CW to full CCW and back again to check for any possible interference. Do NOT utilize any mechanical advantage

devices to rotate the handwheel (pipes, wrenches, extension bars, etc.).

2. Manually position the actuator to its mid-stroke position.

3. Make certain the 3 wire orange plug is fully seated on the 3-pin receptacle on the switch board.

4. Apply correct power to the unit.

5. Measure correct power on terminals 1 and 2 on the switch board.

6. Measure correct power on the two heater terminals on the switch board.

7. CommandtheelddevicetogenerateaCCWsignal.TheactuatorrotatesinaCCWdirection(asviewedfromabove).

8. Actuator will stop when it reaches it’s full CCW position.

9. CommandtheelddevicetogenerateaCWsignal.TheactuatorrotatesinaCWdirection(asviewedfromabove).

10. Actuator will stop when it reaches it’s full CW position.

11. Generateamid-positionsignalattheelddevicetomovetheactuatoroitsfullCWtripposition.

12. Actuators with no -TS options are now commissioned and operational. See below for additional -TS steps.

Test Torque Switch functions

1. Generate a 4mA or 20mA control signal and let the actuator

drive towards that CW or CCW position.

2. As the motor is running, simulate a torque switch event: Depress

the top or bottom torque switch and hold it (one will immediately

stop the motor).

3. Release the torque switch.

4. Test recovery from the torque switch event.

• Move the handwheel 2° in either direction

• Signal the motor to drive.

5. Repeat steps 1 through 4 in the opposite direction (20mA or

4mA) to test the opposing direction torque switch functionality.

Testing Torque Switch Electrical Operation

TS units incorporate a torque overload protection system. In NORMAL operating

mode, the torque switch drive cam is in this position:

High Torque Cam

(bottom) for CCW

Output Drive Rotation

High Torque Cam

(top) for CW Output

Drive Rotation

High Torque Switch

(top) for CW Output

Drive Rotation

High Torque Switch

(bottom) for CCW

Output Drive Rotation

Commissioning for TS units

Page 14 of 17 P2/3 12V 24DC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

Torque Switch cams shown with the lower

cam in a TRIPPED position (high torque in the

CCW Output Drive Direction)

High Torque Cam

(bottom) for CCW

Output Drive Rotation

High Torque Cam

(top) for CW Output

Drive Rotation

High Torque Switch

(bottom) for CCW

Output Drive Rotation

High Torque Switch

(top) for CW Output

Drive Rotation

WARNING! Do NOT

adjust the torque

switch cam settings.

This will VOID the

warranty.

Test Torque Switch CCW Mechanical Operation

1. Rotate the manual override handwheel in a CCW direction to continue to drive the output drive in a CCW direction until

the drive system reaches the end of its MECHANICAL travel either by coming into contact with the mechanical stop

screw OR it reaches the end of the valve (or damper) travel. This is indicative of an increasing force required to rotate

the handwheel.

2. At this point the torque switch cam shaft starts to rotate in a CW direction. (There is no need to continue to rotate the

handwheel further in the CCW direction, the torque switch cam shaft would continue to rotate in the CW direction until

the LOWER cam trips the LOWER high torque switch).

3. At this point, stop rotating the handwheel as you’ve simulated reaching the electrical drive limit of the actuator under

excessively high torque situations in the CCW output drive direction.

Torque Switch cams shown with the upper

cam in a TRIPPED position (high torque in

the CW Output Drive Direction)

High Torque Cam

(bottom) for CCW

Output Drive Rotation

High Torque Cam

(top) for CW Output

Drive Rotation

High Torque Switch

(bottom) for CCW

Output Drive Rotation

High Torque Switch

(top) for CW Output

Drive Rotation

WARNING! Do NOT

adjust the torque

switch cam settings.

This will VOID the

warranty.

Test Torque Switch CW Mechanical Operation

1. Rotate the manual override handwheel in a CW direction to continue to drive the output drive in a CW direction until

the drive system reaches the end of its MECHANICAL travel either by coming into contact with the mechanical stop

screw OR it reaches the end of the valve (or damper) travel. This is indicative of an increasing force required to rotate

the handwheel.

2. At this point the torque switch cam shaft starts to rotate in a CCW direction. (There is no need to continue to rotate the

handwheel further in the CW direction, the torque switch cam shaft would continue to rotate in the CCW direction until

the UPPER cam trips the UPPER high torque switch).

3. At this point, stop rotating the handwheel as you’ve simulated reaching the electrical drive limit of the actuator under

excessively high torque situations in the CW output drive direction.

4. Generateamid-positionsignalattheelddevicetomovetheactuatoroitsfullCWtripposition.

Commissioning for TS units (continued)

5. Actuator is now commissioned and operational.

Page 15 of 17 P2/3 12 24 VDC Proportional Series

FM_P28 24 PN4-DC Ver E 080223

Page 16 of 17 P2/3 12V 24DC Proportional Series

1

1

2

2

A A

B B

Drawn By

Finish

Promation Engineering Inc.

16138 Flight Path Drive

Brooksville, Fl 34604

Phone: 352-544-8436

Fax: 352-544-8439

This Document is the property of ProMation Engineering,

Inc. Distribution of this document without the written

consent of the owner is Strictly forbidden.

Failure to comply will incur a liability for Damages.

Checked By

4/8/2015

P2~P3 F07 F10 Dim Data

Rev.

H

NO SCALE Sheet Number: 1

Material

ProMation Engineering, Inc.

DJG

KHL

9/16/2020

P2_3 F07 F10 8P22 DimData.idw

Created:

Last Checked:

Part No.

Dwg. Name

Dimensional Data for P2~P3 Actuators

Engineering Change Notice

Change Date Description Name

04.25.13 Document transferred to Inventor format KHL

11.12.13 Added rounded edges on Drive Coupling Data KHL

04.15.2014 Added tolerance on drive coupling data KHL

10.07.2014 Pushed square dimension to three decimal places KHL

REV

A

B

C

D

E

F

Dimensional Tolerances (Unless Otherwise Noted):

X ±2.5mm [X.X ±.1]

X.X ±.3mm [X.XX ±.01"]

X.XX ±.13mm [X.XXX ±.005"]

ALL TOLERANCE FEATURES IN mm

G04.08.2015 Added Isometric view of Drive Coupling and "Depth" tag for clarity KHL

H09.16.20 Added F10 mount DJG

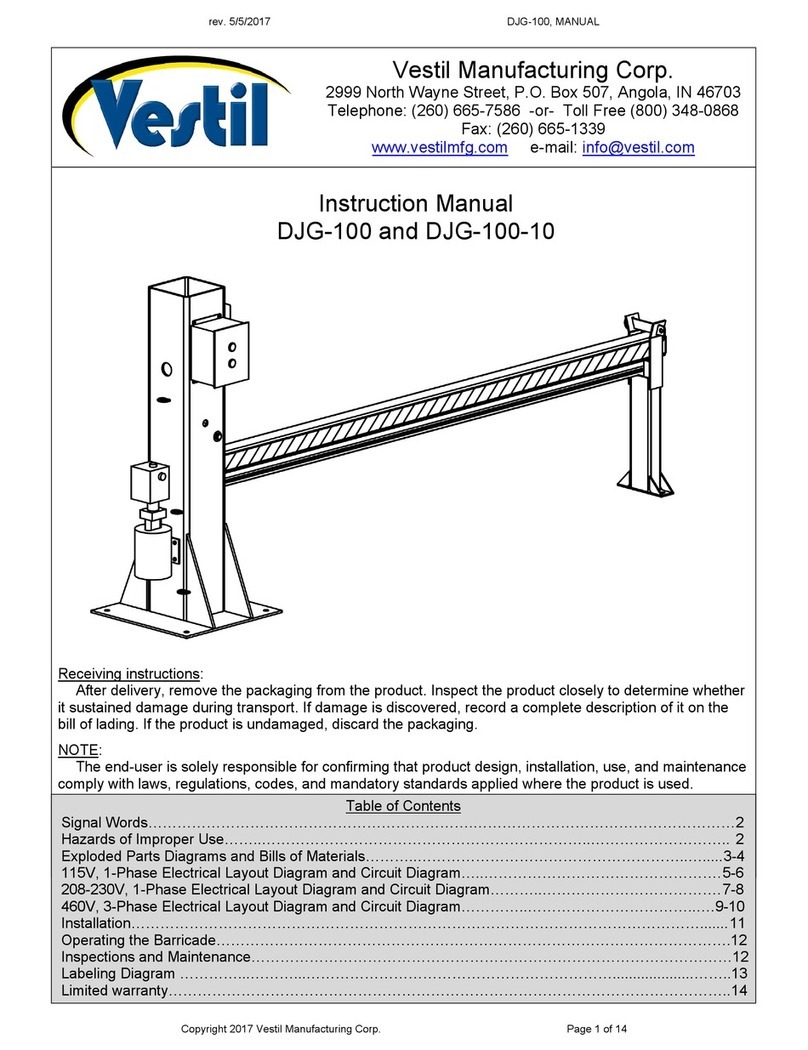

Drive Coupling Fabrication Data

22.00 -.13

.00

+mm

0.866 -0.005

0.000

+in

22.00 -.13

.00

+mm

0.866 -0.005

0.000

+in

30.00 mm

1.181 in

Depth

30.00 mm

1.181 in

324 mm

12.8 in

210 mm

8.3 in

229 mm

9.0 in

189 mm

7.5 in

123 mm

4.8 in

300 mm

11.8 in

Add 257mm

[10.1"] to allow

for cover

removal

96 mm

3.8 in

102.0 mm

4.02 in

ISO 5211 F10

(4) M10x1.25

24mm 1"

22.0 mm

0.866 in

Square

(2) 3/4" NPT

EMT Entry

88 mm

3.4 in

124 mm

4.9 in

166 mm

6.5 in

100 mm

3.9 in

8 mm

0.3 in

132 mm

5.2 in

70.0 mm

2.76 in

ISO 5211 F07

(4) M8x1.25

20mm 0.8"

P2/3 Series Dimensional Data

ISO 5211 Mount

|-----------Add 33 mm (1.30 in) for -TS-----------|

FM_P28 24 PN4-DC Ver E 080223

Page 17 of 17 P2/3 12 24 VDC Proportional Series

Drawn By

Finish

Promation Engineering Inc.

16138 Flight Path Drive

Brooksville, Fl 34604

Phone: 352-544-8436

Fax: 352-544-8439

This Document is the property of ProMation Engineering,

Inc. Distribution of this document without the written

consent of the owner is Strictly forbidden.

Failure to comply will incur a liability for Damages.

Checked By

2/9/2021

P2-3 S and L Imperial Dimensional Data

Rev.

A

NO SCALE Sheet Number: 1

Material

ProMation Engineering, Inc.

DJG

PMR

2/9/2021

P2_3 S and L DimData.idw

Created:

Last Checked:

Part No.

Dwg. Name

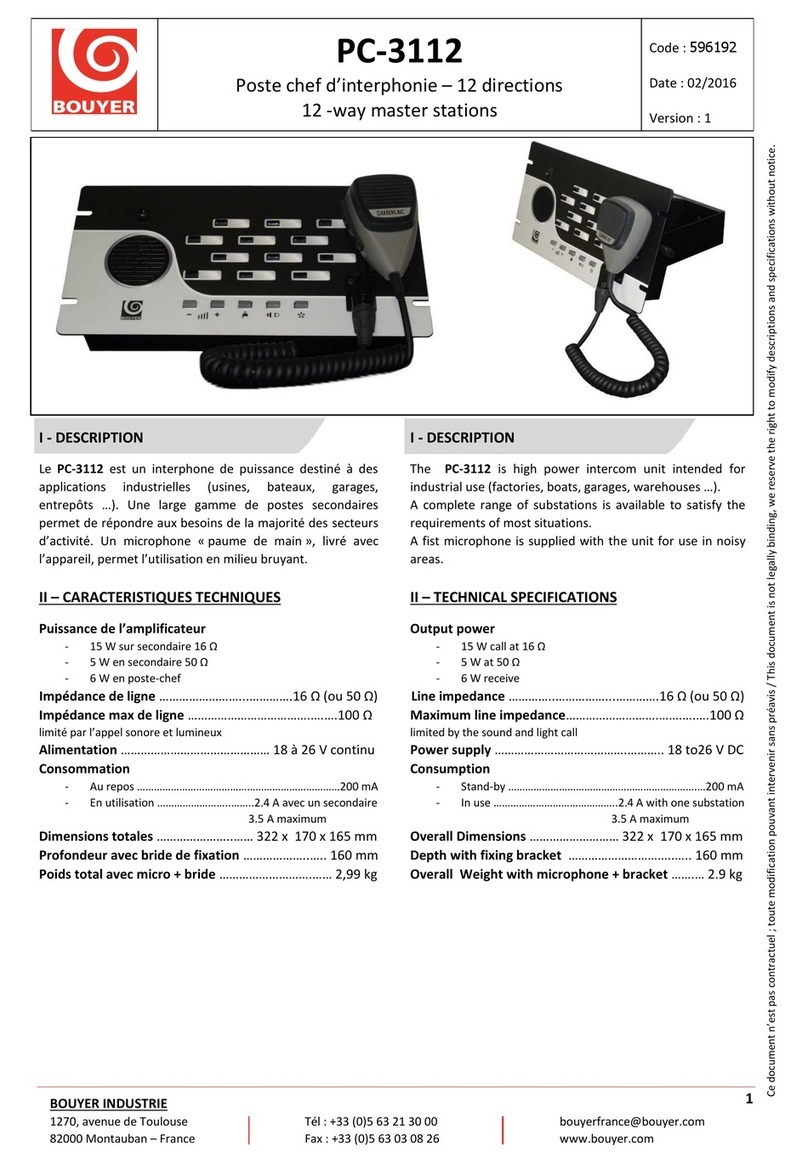

Dimensional Data for P2-3 S and L Imperial Mount Actuators

Engineering Change Notice

Change Date Description Name

02.09.2121 New using P2-3 S .... DimData.idw as model layout DJG

REV

A

B

C

D

E

F

Dimensional Tolerances (Unless Otherwise Noted):

X ±2.5mm [X.X ±.1]

X.X ±.3mm [X.XX ±.01"]

X.XX ±.13mm [X.XXX ±.005"]

ALL TOLERANCE FEATURES IN mm

1

1

2

2

A A

B B

FD

d

93 mm

3.7 in

318 mm

12.5 in

Add 257mm

[10.1"] to allow

for cover

removal

208 mm

8.2 in

123 mm

4.8 in

85 mm

3.3 in

B

1

D

F

(2) 1/2" NPT

EMT Entry

231 mm

9.1 in

55 mm

2.2 in B

2

P2-3 L

P2-3 S

L

Dimensions

Model Unit D F d L BHC1 B1 B1

Depth BHC2 B2 B2

Depth

P2-3 S in 0.75 0.5 1.26 4.1 3.25 ⅜-16 UNC 0.56

mm 19.05 12.7 32 105 82.6 14.2

P2-3 L in 0.875 0.625 26.1 3.25 ⅜-16 UNC 0.56 5 ½-13 UNC 0.63

mm 22.23 15.88 50.8 154 82.6 14.2 127 16

BHC

1

BHC

2

Single

Mount

Only

P2/3 Series Dimensional Data

Imperial Mount

Mechanical Data

|---Add33mm(1.30in)for-TS---|

FM_P28 24 PN4-DC Ver E 080223

This manual suits for next models

7

Table of contents

Other Promation Engineering Control System manuals