Prosense P Series User manual

PRS‐UM

‐P‐EN‐Rev.0

PR

O

I

1‐08.2018

O

SE

N

nstal

l

Yukar

ı

Tel:(

9

N

SE P

l

atio

n

Prosense

ı

Mah.Har

m

9

0)216306

ww

w

Seri

e

n

and

Teknoloji

S

m

ansok.N

o

7788Faks

w

.prosense

.

e

s Ga

User

S

an.Ltd.Şt

i

o

:42Kartal

:(90)2164

7

.

com.tr

s Det

Man

u

i

.

İstanbul

7

38129

ecto

r

u

al

1

r

2

PRS‐UM‐P‐EN‐Rev.01‐08.2018

WARNING!

This manual must be carefully read by all persons who have or will have the

responsibility for installing, using or servicing this product.

Like any equipment, this product will perform as designed only if installed,

used and serviced in accordance with the manufacturer’s instructions.

Otherwise, it could fail to perform as designed and persons who rely on this

product for their safety could suffer severe personal injury or death.

The warranties made by Prosense with respect to this product are voided if the

product is not installed, used and serviced in accordance with the instructions

in this user guide. Please protect yourself and other by following them.

ImportantRemark

Thedetectorhasbeenfactory‐testedbeforedelivery,thecommissioning

afterinstallationmustincludethezero‐andspan‐adjustment.The

commissioninghastobeterminatedbyafunctiontestofthecompletegas

detectionsystem.

3

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Contents

ForYourSafety...........................................................................................................................................4

StrictlyfollowtheInstructionsforUse...............................................................................................4

Maintenance......................................................................................................................................4

Useinareassubjecttoexplosionhazards.........................................................................................4

Liabilityforproperfunctionordamage.............................................................................................4

IntendedUse......................................................................................................................................4

Introduction................................................................................................................................................6

Detectorbody.............................................................................................................................................7

SensorHead:..............................................................................................................................................7

Installation:.................................................................................................................................................8

Mountingthedetector:..............................................................................................................................9

Electricalconnections...............................................................................................................................10

Cabling......................................................................................................................................................11

Detectorgrounding..................................................................................................................................12

Defaultconfiguration...............................................................................................................................13

DetectorConfiguration.............................................................................................................................14

4‐20mAoutput:.......................................................................................................................................14

DetectorRS485serialcommunication:....................................................................................................14

DetectorRelaymodule:............................................................................................................................16

SystemStatus...........................................................................................................................................18

Firsttimeswitchon(Commissioning)..................................................................................................18

Calibration................................................................................................................................................19

Maintenance............................................................................................................................................20

Proactivemaintenance:........................................................................................................................20

OperationalLife:...................................................................................................................................20

Servicing...............................................................................................................................................21

Sensorreplacement:............................................................................................................................21

Sinterreplacement:..............................................................................................................................21

Sensorheadreplacement:...................................................................................................................21

Generalspecification................................................................................................................................22

Warrantystatement.................................................................................................................................23

4

PRS‐UM‐P‐EN‐Rev.01‐08.2018

For Your Safety

EnsurethatthisOperatingManualisreadandunderstoodBEFOREinstalling/operating/

maintainingtheequipment.PayparticularattentiontoWarningsandCautions.Alldocument

Warningsarelistedhereandrepeatedwhereappropriateatthestartoftherelevant

chapter(s)ofthisOperatingManual.Cautionsappearinthesections/sub‐sectionsofthe

documentwheretheyapply.

Strictly follow the Instructions for Use

Anyuseofthedetectorsrequiresfullunderstandingandstrictobservationofthese

instructions.Thedetectorisonlytobeusedforpurposesspecifiedhere.

Maintenance

ItisrecommendedtoobtainaservicecontractProsensetocarryoutallrepairs.Only

authenticProsensesparepartsshouldbeusedformaintenance.Pleasecheck“Maintenance”

sectionformoredetails.

Use in areas subject to explosion hazards

Equipmentorcomponentswhichareusedinpotentiallyexplosiveatmospheresandhave

beentestedandapprovedaccordingtointernationalorEuropeanregulationsmaybeused

onlyundertheconditionsspecifiedhere.Modificationsofcomponentsortheuseoffaultyor

incompletepartsarenotpermitted.Incaseofrepairsofequipmentorcomponents,the

nationalregulationsmustbeobserved.

Liability for proper function or damage

Theliabilityfortheproperfunctionofthedetectorisirrevocablytransferredtotheowneror

operatortotheextentthatthedetectorisservicedorrepairedbypersonnelnotemployedor

authorizedbyProsenseorifthesensingheadisusedinamannernotconformingtoits

intendeduse.Prosensecannotbeheldresponsiblefordamagecausedbynon‐compliance

withtherecommendationsgivenabove.Thewarrantyandliabilityprovisionsofthetermsof

saleanddeliveryofProsensearelikewisenotmodifiedbytherecommendationsgivenabove.

Intended Use

ThePseriesdetectorsareintendedtobeusedforstationary,continuousmonitoringfor

combustiblegas/airorvapour/airmixturesbelowtheLowerExplosionLimit(LEL)resp.below

10%oftheLELunderatmosphericconditions.Thedetectorsaremarkedbythedevice

categoriesII2G.Thuscanbeoperatedinhazardousareaswithpotentiallyexplosive

atmospheresofzones1and2.Thetypeofprotectionforgasexplosionprotectionaccording

todevicecategory2(zones1or2)isflameproofenclosureandincreasedsafety,"d".The

enclosureprotectionisIP65.

AccordingtotheATEXDirective2014/34/EUthedetectorisanassemblyconsistingofthree

components(SensorHead,enclosureandcablegland),whereallthesethreecomponentsare

typeapprovedaccordingtoATEXDirective2014/34/EUandmarkedbythedevicecategoryII

2G.Thusthisdetectorissuitabletobeoperatedinhazardousareaswithpotentiallyexplosive

5

PRS‐UM‐P‐EN‐Rev.01‐08.2018

atmospheresofzone1andzone2.ThePseriesdetectorscomprisesagassensortypeEx‐

proof(protectiontypeflameproofenclosuredtype).Itmustnotbeoperatedatambient

temperatureslowerthan–20(°C).Themaximumambienttemperatureis50(°C)for

temperatureclassT6.

Nottobeusedinoxygenenrichedatmospheres

InconjunctionwiththecentralcontrollersProsensedetectorswithpreadjusted

alarmthresholdsaudibleandvisiblealarmdevicesorautomaticcountermeasures

canbeactivatedbeforethedetectedgasesorvapourscanformdangerous

flammableortoxicmixtureswithair.

Pleasebealertedinfollowingspecialconditionsmayhaveimpactonmeasuringfunctiondue

tothenatureofmeasuringmethod:

1.Veryhighgasconcentrations

InfraredandPellistorsensorsusedtodetectflammableandtoxicgases.Themeasuring

methodbasedonheatproducedbyreactiononthecatalyticoxidationofaflammablegas

whenpellistorsensorused.Incaseofhighgasconcentrationsthereisnotenoughoxygenin

thesensortoperformoxidationprocesscorrectly.Hencethemeasuringsignaldecreasesat

highgasconcentrationsandevencanleadtomeasuringsignalwithinthemeasuringrange

again.Aconnectedcontrollermustbeoperatedwithalarmdevices,outputs,andalarm

thresholdsoperatingaslatchedifthemeasuringrangeisexceeded.Inthiscasedonotreset

latchingalarmswithouthavingensuredasafeconditionbymeansofanindependentgas

concentrationsmeasurement.

2.Minimumoxygenconcentration

Themeasuringprincipleofheatofreactionneedsaminimumoxygenconcentrationof12%

byvol.,otherwisethemeasuringvalueswillbetoolowbecauseofoxygendeficiency.

3.Long‐termgassingwithmethaneatverylowtemperatures

IftheProsensePseriesflammablegasdetectorsareoperatedapplyingwithmethaneatvery

lowtemperatures,themeasuringsignalatlongtermexpositionmaydecreaseafteralarm

activationandmayleadtomisinterpretation.

Ifagasalarmoccurs,necessaryactionsneedtobetakenimmediately.Thedecreaseofthe

measuringsignalshouldnotmeanthatthegasconcentrationhasbeendecreased.We

recommendtokeepalarmsontheassociatedcontrollersandnottoresetthesealarms

withoutperformingmeasurementwithanindependentgazdetectorstomakesure

conditionsaresafe.

6

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Introduction

TheProsensecomprisesagasdetectorbodyandachoiceofsensorsheadsfordetecting

flammablegas,toxicgasandoxygen.TheconstructionofProsenseallowsittobeusedin

hazardousarealocations;itmayalsobeusedinotherareasnotclassifiedashazardous.

Prosensedetectorscanbeconfiguredwithawiderangeofdifferentsensorsmaybeusedto

detectabroaderrangeoftargetgases.Thedetectorcanbeconfiguredwithoptionalrelay

boardfeaturesthreeprogrammablerelaysforcontrollingexternalequipmente.g.alarms,

sirens,valvesorswitches.Thedetectorprovidesanindustrystandard3‐wire,4‐20mAsource

orsinkoutputforconnectiontoadedicatedgasdetectioncontrolsystemorPLC.

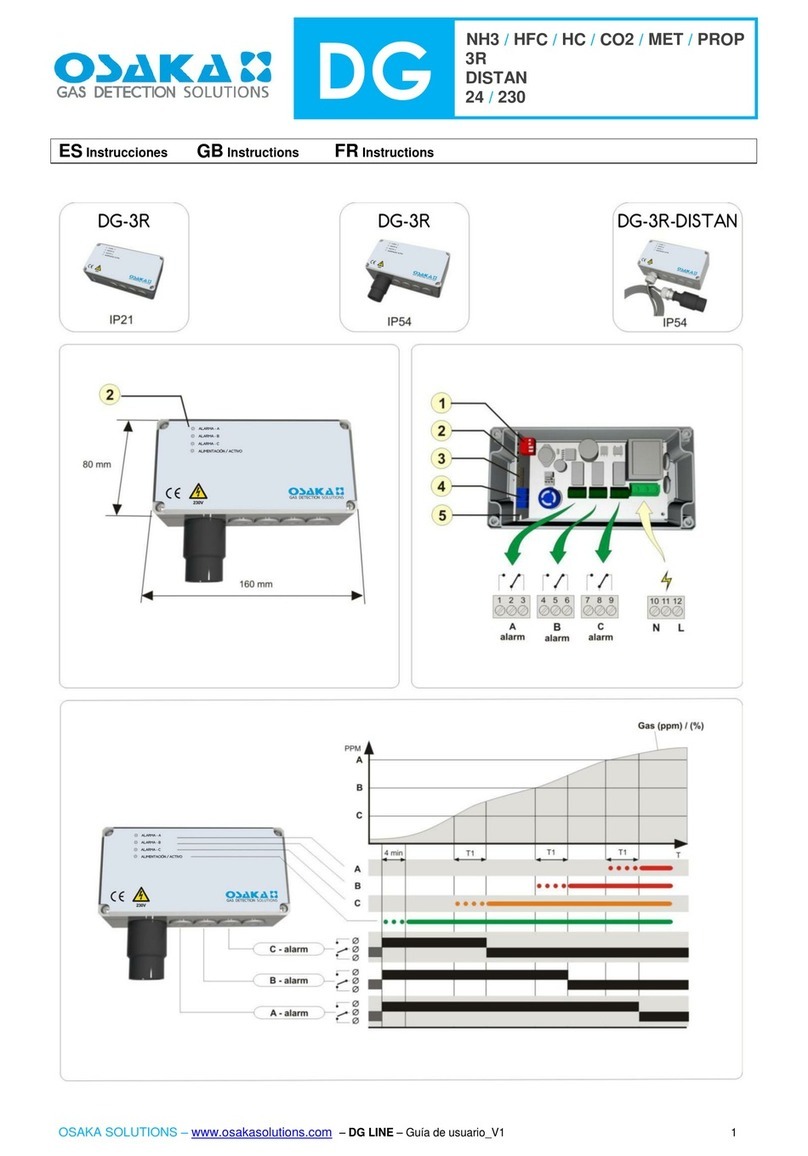

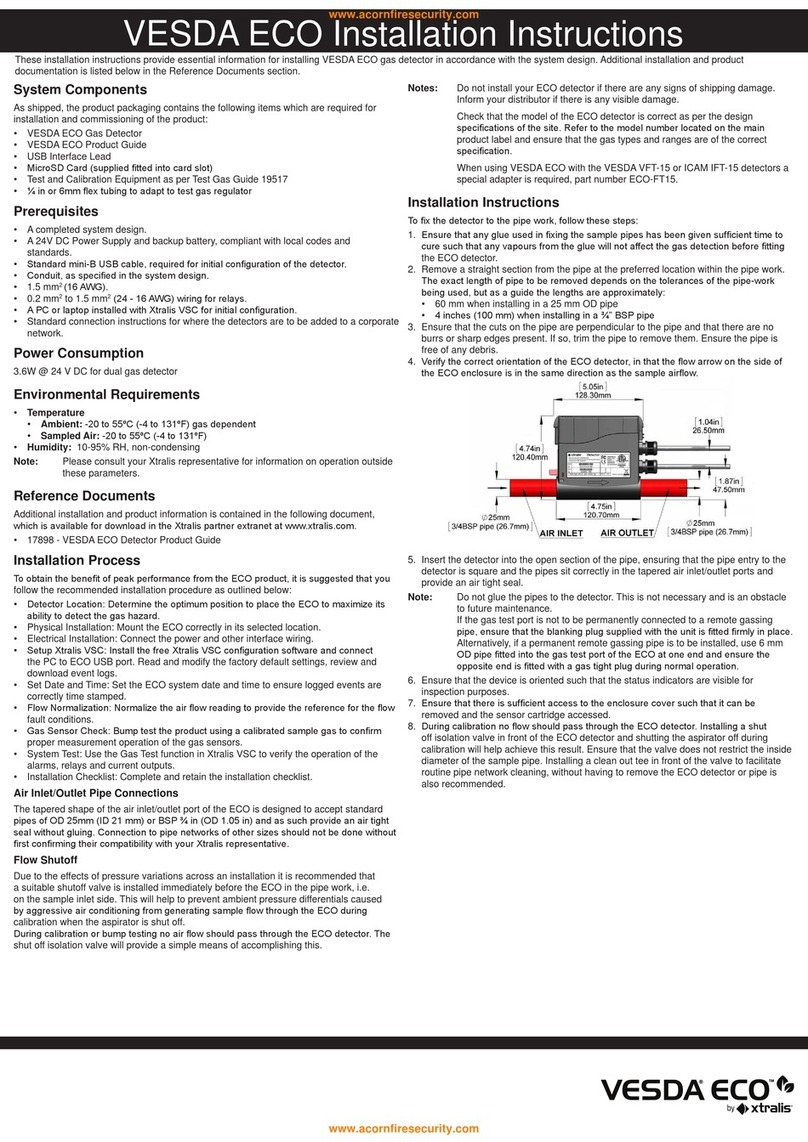

Prosensedetectorscomprisesofthemainpartsasshownbelow:

Diagram1:Explodedview

Cover

Body

Mountingplate

Lockinggrubscrew

Fieldcableentriesx2

Sensorheadsocket

Sensorheadbody

Sensorholder

Sinter

Sensorheadcab

Sinternut

Lockinggrubscrew

7

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Detector body

Thedetectorenclosurehasthreethreadedentries.Thetwocableentrieseithersideofthe

upperpartofthetransmitterhousingareforconnectingthepowersource,signaloutput

andrelaycontactstoassociatedsignallingequipment.Thebottomentryallowsdirect

connectionofthesensorsocket.Thereisamountingplateincorporatedintothetransmitter

housingallowingforvariousmountingconfigurationoptions.

Diagram2:DetectorbodyandSensorHeadcomponents

1:Sensorheadbody

2:Sensorholder

3:Sensorheadcap

4:Sinternut

5:Sinter

6:Junctionbox–Detectorbody

7:Wallmountingadapter

8:Junctionboxcover

Sensor Head:

TheProsensesensorheaddesignedtodedectflammable,toxicgaeseandoxygen.Theymay

includeNDIRinfrared,pellistororelektrocjemicalsensorsdependingofthetargetgasand

range.

8

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Installation:

Gasdetectorsshouldbemountedwhereapotentialhazardofgasismostlikelytobe

present.Thefollowingpointsshouldbenotedwhenlocatinggassensors.

Whenlocatingdetectorsconsiderthepossibledamagecausedbynaturaleventse.g.

rainorflooding.

Considereaseofaccesstothegasdetectorforfunctionaltestingandservicing.

Considerhowescapinggasmaybehaveduetonaturalorforcedaircurrents.

Note:Theplacementofgasdetectorsshouldbedeterminedfollowingtheadviceofexperts

havingspecialistknowledgeofgasdispersion,expertshavingknowledgeoftheprocessplant

systemandequipmentinvolved,safetyandengineeringpersonnel.Theagreementreached

onthelocationofdetectorsshouldberecorded.

Eachgashasdifferentnaturedependingontheirdensity.Thedensityofwhichislowerthan

air,suchashydrogen,methaneorammoniathesensorheadmustbelocatedabovea

possibleleakoratthehighestpointsatwhichmajorconcentrationsofgasmaybefound.

Thegasesandvapourswithadensitygreaterthanair,thesensorheadmustbeinstalled

beneathapossibleleakoratthelowestpointsatwhichsuchgasesandvapoursmaybe

present.

Prosensemayprovidecableglandtogetherwithdetectorinregardstocustomerrequests.

ThecableglandprovidedbyProsensehasATEXcertificationandprovidesatleastIP65level

protection.Thecableglandsareonlysuitableforfixedinstallations.Cablesshallbe

effectivelyclampedtopreventpullingortwisting.Toprovidenecessaryprotectioncable

glendcouplingshouldbefixedwith20Nmtorquewhenusedwiththreesealings;18Nm

whenusedwithtwosealings;16Nmwhenusedwithonesealing.Itisthefinal

assamblers/usersresponsibilitytoensurethethreadedjointbetweencableglandandthe

enclosuremeetalltherequirementsoftheapplicablestandartsfortheassembly.Cable

glandsealingsaresuitableforthecirculartypecables.Ifothershapedcableswillbeusedthe

sealingsshouldbereplacedwithsuitableones.ThecableglandsprovidedbyProsenseare

suitabletousetemperaturerangeinwhichdetectorworks.

Prosensemayprovideplugsandadaptorstogetherwithdetectorinregardstocustomer

requests.TheplugsandadaptorsprovidedbyProsensehaveATEXcertificationandprovides

atleastIP65levelprotection.Thesepartsshouldbemountedtodetectorbodyinsuchaway

thataccidentalrotationorlooseningwillbeprevented.Itisthefinalassamblers/users

responsibilitytoensurethethreadedjointbetweenfittingandtheenclosuremeetallthe

requirementsoftheapplicablestandartsfortheassembly.Foradaptorsandplugswith

nominalsizeofthreadequalorlowerthan25mmaliminiumalloyshallnotbeused.Only

oneadaptorspermittedforeachcableentry;plugsshallnotbeusedwithadaptors.The

plugsandadaptorsprovidedbyProsensearesuitabletousetemperaturerangeinwhich

detectorworks.

9

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Mounting the detector:

Thedetectorshouldbemountedverticallyasthesensorheadpointingdownwards.Detector

hastobemountedsuchthatthesensor'sgasentrancearea.

Theinstalllocation

shouldbeisolatedfromvibration,directsunlightandhavetemperaturestability

avoidedexternalinfluencessuchassplashingwater,oil,corrosiveaerosols

shouldhaveatleast30cmfreespacebeneaththesensorheadtoprovide

accessibilityforcalibrationwork.

shouldbeinairflowbetweenpossibleleakorcollectionpointandpossiblesourceof

ignition.

Prosensedonotrecommendtoinstalldetectorsto:

directlyaboveacookingunit,

directlyaboveasinkunit,

closetoanextractorunit,

outdoorwithoutprotectionagainsttherain,

inplaceswheretemperatureisoutsidetheadmissibleoperatingrange,

incorrosiveenvironments,

insideairvents.

inenvironmentswheresiliconcanbefound.

TheProsensedetectorhasanindependentmountingplateconsistingoftwomountingholes

andtwoholestoattachtodetectorbody.Themountingplatecanbeadjustableontwo

diagonalwayontodetectorbody.Thedetectormaybefixeddirectlytoasurfacemounting.

Followbelowstepstomountthedetector:

1‐ Decidewhichdiagonalwaytouseandadjustmountingplateondetectorbodyif

necessary.

2‐ Checkandmakesuremountingplateiscompletelyfixedtodetectorbody

3‐ Mountthedetectortothesurfaceviausingtwooutermountingholesonmounting

plate.

Diagram3:Detectormountingplate

Wallmountingholes

Detectorbodymountingholes

10

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Themountingplateinstalledinbelowpositionatfactory:

Diagram4:Defaultinstallatonofmountingplate

Electrical connections

Caution:Allelectricalconnectionsshouldbemadeinaccordancewithanyrelevantlocalor

nationallegislation,standardsorcodesofpractice.

Prosensedetectorscanoperatebetween12‐24VDC.Theconnectionsocketlocatedon

mainboardasgivenindiagram8anddetailsgiveninbelowtable2:

Output Usage

V+ Powerinput(+)12VDC–24VDC

V‐ Powerinput(‐)12VDC–24VDC

S CurrentOutputSignal(4mA–20mA)

Tablo1:Detectoroutputportsandtheirusage

Thedetectordesignedtogive4‐20mAcurrentoutputsignal.Itisalsopossibletoget

voltageoutputviausinganadditionalresistor.Belowtable3givesrecommendedresistor

specificationstogetcorrectvoltageoutputfromdetectordependingofthepowersource

level:

DetectorPowerVDC Resistor Signallevel(4mA–20mA)

12VDC–24VDC 250Ω,tolerance%1 1VDC–5VDC

12VDC–24VDC 500Ω,tolerance%1 2VDC–10VDC

Table2:Detectorpowerandtheoutputresistor

Pleaseconsiderthecablelenghtwhenperforminginstallationinthefield.TheProsense

detectorrequiresapowersupplybetween12VDCand24VDC.Makesurethataminimum12

VDCsupplyavailableatthedetectorentranceandconsiderthevoltagedropduetocable

resistanceincaseoflongdistanceapplications.Themaximumloopresistanceinthefield

cableiscalculatedasfollows:

Rloop=(Vcontroller–Vdetectormin)/Idetector

11

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Example;

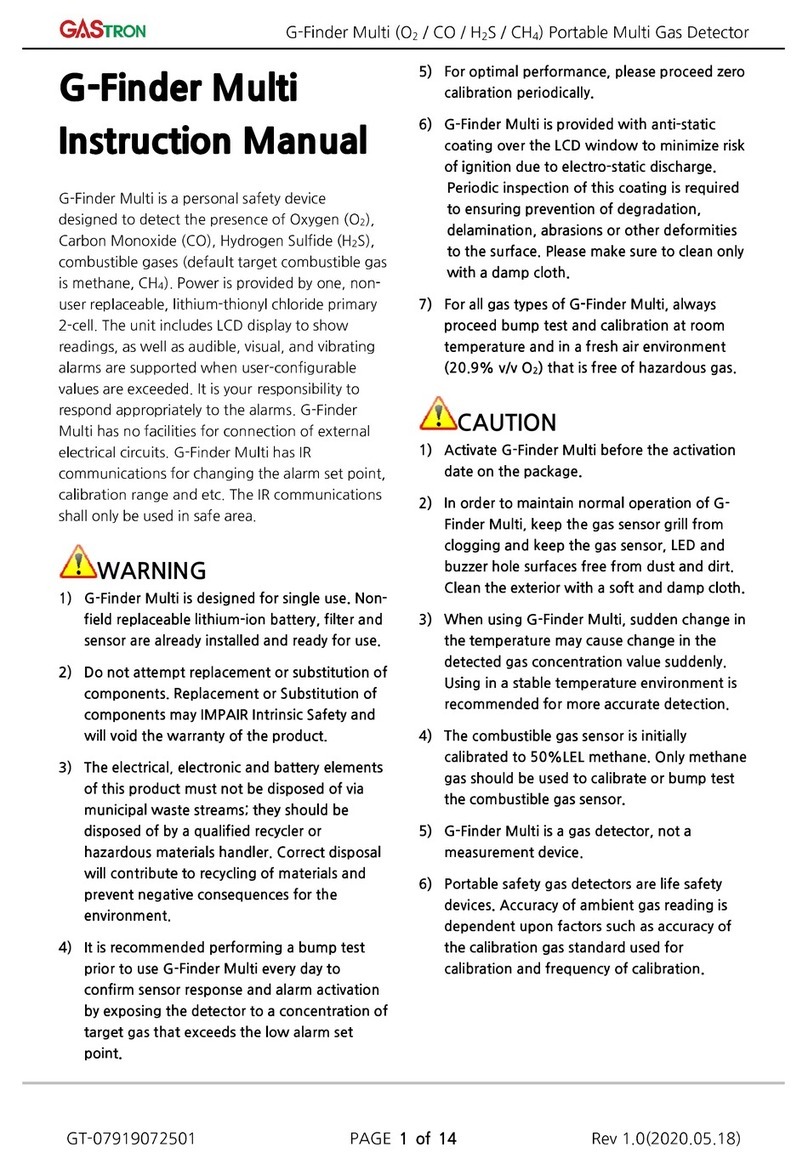

Diagram5:Fieldcabling

Thecontrollerorpowersupplyissupplyinganominal24VDC(Vcontroller),thedetector

minimumallowablevoltageis12VDC(Vdetectormin),thereforethemaximumallowable

voltagedropbetweenthecontrolleranddetectoris12VDC;thismeansavoltagedropof6V

ineachcore(V+coreandV‐core).Minimumpowerconsumptionofthedetectorwithout

anyoptionalmoduleis1W.Thecurrentrequiredtodrivethedetectorattheminimum

voltageis

(I=P/V) 1.0/12=85mA(Idetector).

Maximumpowerconsumptionofthedetectorwhenoptionalrelaymodulesinstalledandall

relaysareactiveis2.5W.Thecurrentrequiredtodrivethedetectorattheminimumvoltage

(I=P/V) 2.5/12=210mA(Idetector).

So,themaximumfieldcableloopresistance(Rloop)=12/0.21=56Ohms,or28Ohmsper

core,(allowingforcomponentvariations,losses,etc.).

Thefollowingtablesshowthemaximumcabledistancesbetweenthecontrollerand

transmitterassumingavoltagedropof6Vineachcoreandfordifferentcableparameters.

Thetablesareexamplesonlyandactualcableparametersandsourcepowersupplyvoltage

fortheapplicationshouldbeusedtocalculatethemaximumcabledistanceallowedatthe

installationsite.Typicalcabledatafordetectorwithrelaymodule:

Cablesize Cabletype Cableresistance MaximumCablelength(L)

(crosssectionalarea) nearestequivalent Ω/km Meters

0.5mm2 20AWG 36.8Ω/km ~500

1.0mm2 17AWG 19.5Ω/km ~800

1.5mm2 16AWG 12.7Ω/km ~1200

2.0mm2 14AWG 10.1Ω/km ~1500

2.5mm2 13AWG 8.0Ω/km ~1800

Table3:Typicalcabledetailsandmaximumdistanceforcabling

Cabling

Theuseofindustrialgrade,suitablyshieldedfieldcableisrecommended.Thebestpractices

shownthat,screened3cores(plusscreen90%coverage),suitablymechanicallyprotected

coppercablewithasuitableexplosion‐proofgland,or¾”NPTsteelconduit,dependingon

thedistancebetweensignalreceivedorcontrolpanelanddetector0.5to2.5mm2(20to13

AWG)conductorscangivebetterresults.Ensurethecableglandisinstalledcorrectlyand

fullytightened.

12

PRS‐UM‐P‐EN‐Rev.01‐08.2018

CableandEarth/Groundregimes

EffectiveEarth/GroundbondingisimportanttoensuregoodEMCandRFIimmunity.The

followingdiagramsshowexamplesofhowtoearth/groundbondthecableatenclosures.

Thesameprinciplesapplytoconduitinstallations.Thesebondingtechniquesprovidegood

RFI/EMCperformance.Earth/groundloopsmustbeavoidedtopreventtheriskoffalse

signalvariation.TheEarthScreenofthefieldcableshouldbe“tiedtoEarth”orconnectedto

Groundatonepointonly.ItiscommonpractisetoadoptaSTAREARTHconnectionregime

whereallinstrumentationScreensareconnectedatonecommonpoint.TheScreenatthe

otherendofthecableshouldbe“parked”orterminatedintoablankterminal.

Diagram6:Grounding

Detector grounding

EachdetectorhasgroundingscrewwhichutilizesgroundingfordetectormainPCBto

detectorbody.Thescrewshouldbelocatedcorrectyandfixedforalltimes.Incaseofany

maintenanceactivitythisscrewshouldbecheckedandfixedtomakesureforproper

grounding.ItisrecommendedtoutilizeaNo14AWGcopper,(StrandedorSolid),wire.The

followingdiagramsshowwheretoinstallthewireintothegroundscrewoftheenclosure.To

connectgroundingwire,loosenthescrewsufficiently;wrapthewirearoundthescrewina

“U”shape;raisetheclampandplacethewirebetweentheclampandgroundbase;lower

theclampandtightenthescrew.

Diagram7:Detectorgroundingscrew

13

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Default configuration

Prosensedetectorspreconfiguredtoprovidesignalfromanalogoutputdependingonthe

detectorandgastype:

Function Value/Setting Meaning

Signaloutput

2.0mA Fault

2.0mA Warmup

3.0mA Calibration

4.0mAto20.0mA Normalgasmeasurement

22.0mA Maximumoverrange

AlarmRelay1*

Valueisgasdependant Loweralarmlevel

De‐energized Energizesonalarm

ContactNormallyOpen(NO) Closesonalarm

AlarmRelay2*

Valueisgasdependant Higheralarmlevel

De‐energized Energizesonalarm

ContactNormallyOpen(NO) Closesonalarm

FaultRelay*

2.0mA DetectorFault

Energized De‐Energizesonalarm

ContactNormallyOpen(NO) Closesonalarm

(*)Relaysareonlyavailablewithoptionalrelaymodule

Table4:Detectordefaultconfigurationdetails

DetectorMainboardandconnectiondetailsgivenindiagram8:

Diagram8:Detectormainboardandconnections

S

V‐

V+

B

A

SensorConnections

Relaymodule

connections

Address

switches

14

PRS‐UM‐P‐EN‐Rev.01‐08.2018

DetectorhasintegratedRS485Serialcommunicationdevices.Hencebothdigitalandanalog

outputsareavailableonboard.Portdefinitionsaregivenintable6:

Port Usage

V+ Powerinput(+)12VDC–24VDC

V‐ Powerinput(‐)12VDC–24VDC

S CurrentOutputSignal(4mA–20mA)

A RS485SerialcommunicationoutputportA

B RS485SerialcommunicationoutputportB

Table5:Detectoroutputportsandtheirusage

Detector Configuration

TheProsensededecorhasthreedifferenttypesofconnectiondependingoninstalled

boards:

1.Single4‐20mAoutput(defaultoption)

2.RS485Modbusserialcommunicationoutput

3.3‐Relayoutputs

4-20 mA output:

Thedefaultconfigurationprovidessingle4‐20mAsignaloutput.Prosensedetectorscanbe

connectedtocontrolpanelsonthemarkethaving4‐20mAinputsignal.Signalwiringfrom

detectorandthecontrolpanelshouldbecarriedoutbyshieldedcables.Wirescrosssection

dependsonthedistancebetweenthecontrolpanelandthedetector.Thedetailsgivenin

powercablingarevalidaswellforsignaloutput.Werecommendtousevaluesgivenintable

4(seepage13)ascablingbestpractices.

Pleaseavoidanyinterruptionincaseanyjunctionsonwires.Theshieldistobegrounded

fromthecontrolpanelsideonlyandneverconnecttheshieldtothedetector.Pleasemake

sureclutchingorcrimpingaparatsarenotloosenoroxidized.

Iftheanalogoutputshortcutduetoanerrortheoutputwillbedroppedto2mAasdetector

hasaselfdefendingmechanismimplemented.Analogoutputwillbeautomatically

deactivatedifanalogoutputwouldnotbeusedasportleftemptyornoconnection(or

incorrectconnection)madetoit.

Detector RS485 serial communication:

DetectorhasintegratedRS485Serialcommunicationdevices.TheRS485communicationAB

portsarelocatedinanothersocket.IfonlyRS485serialcommunicationwillbeused

connectiontodetectorshouldmadeby4wirethat2forpower(V+,V‐)and2forRS485

(A,B).IfbothRS485Serialcommunicationandanalogoutputwillbeusedthen,5wireshould

beused(V+,V‐,S,A,B).Thetotallenghtoftheconnectionlineshouldnotexceed1000

15

PRS‐UM‐P‐EN‐Rev.01‐08.2018

meters.ThewiringfordetectorsutilizedwithRS485boardshouldbedonebyusing

connectioncableEIARS4852corewireswithsection0.22/0.35mm2andshielded.

Nominalcapacitybetweenthewires<50pF/mandnominalimpedance120Ohms.

Detectorswillbewiredindaisychain(bus)mode.Werecommendnottousestarmode

connectionduetonegativeimpactofinterference.Eachdetectorshouldhaveunique

addressnumberinthechain.Thedetectorswouldnotberecognisedbycontrolpanelif

sameaddressgiventothem.Detectorscanhaveaddressesbetween1to63.Addresszero(0)

isreserved.TheaddressofdetectorcanbeadjustedviausingDIP‐Switchsetontheboard:

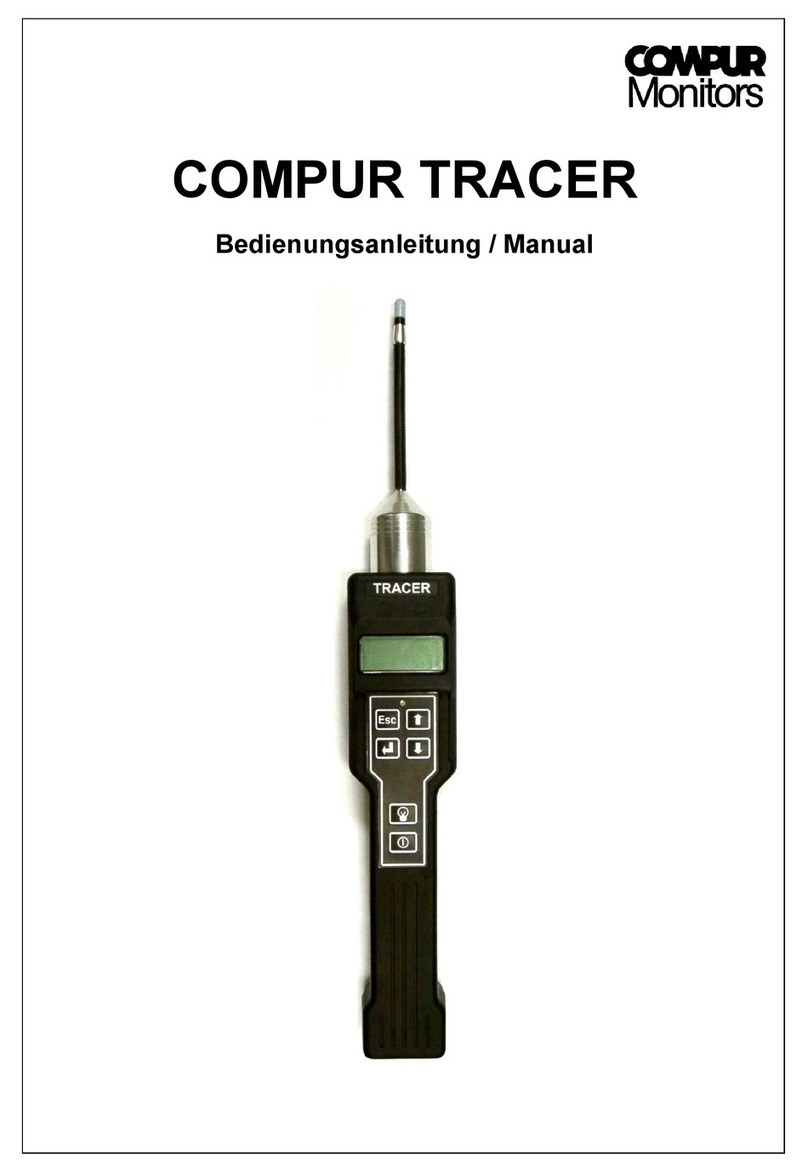

Diagram9:RS485Modbusserialcommunicationaddressandswitchposition

Thelastdetectorinthechainshouldhave120OhmsRS485terminationresistor.Theresistor

isalreadyimplementedontheboardbydefaultbutnotactivated.Usershouldactivatethe

terminationresistorviausingtheterminationpinoncetheinstallationcompleted:

Diagram10:RS485Modbusserialcommunicationmoduleendoflinejumper

12345

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

29

25

26

27

30

28

RS485termination

p

ins

16

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Thepowerconnectionwerecommendtouseseperate2wirecablewithspecificationgiven

earlierinthisdocument(seeElectricalConnectionssectionatpage11).Oncethecablingis

completedpleasecheckeachdetectorhasatleast12VDCpower.

Detector Relay module:

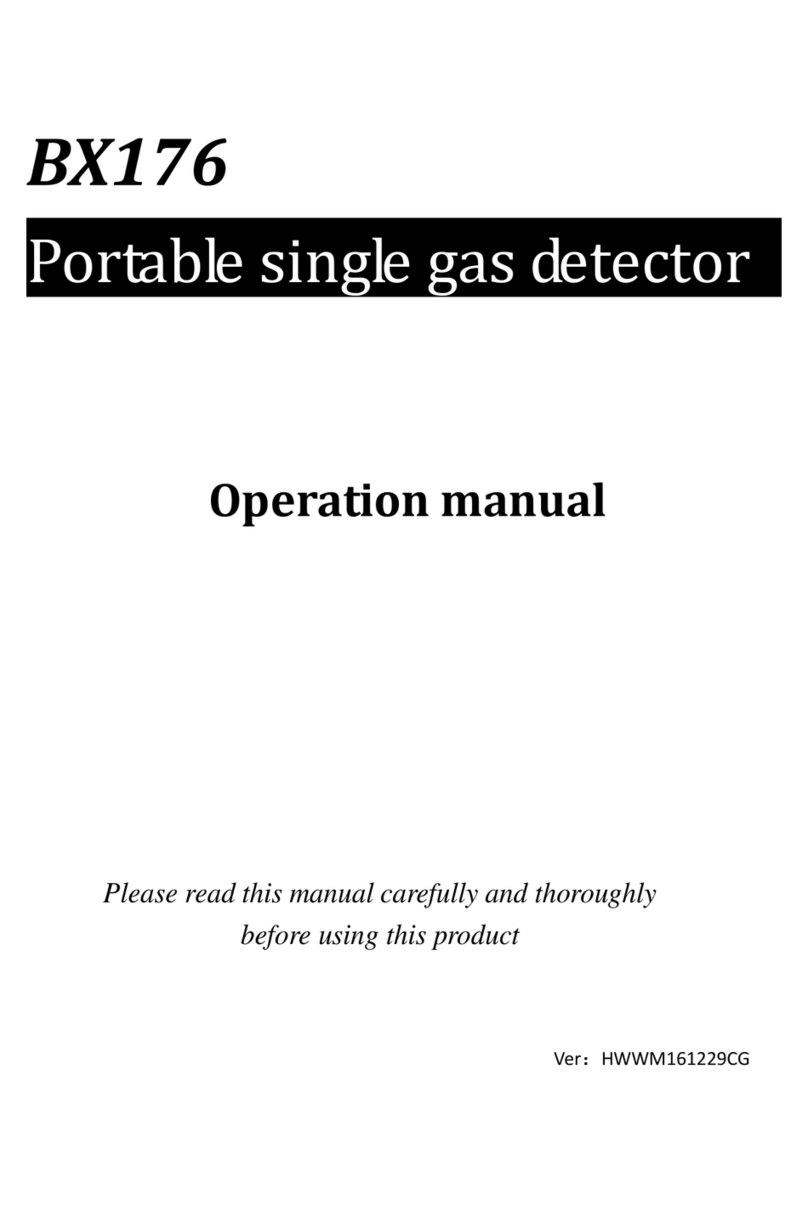

ProsenseprovidesoptionalrelaymodulesforProsensedetectors.Therelaymoduledetails

aregivenbelow:

Diagram11:Relaymodule

Therelayboardhas3relayoutputs:

Port Usage

Fault FaultRelayoutput

Al1 Alarm1Relayoutput

Al2 Alarm2Relayoutput

Table6:Relaymoduleoutputportsandtheirusage

FaultRelayoutputpins

Alarm1,Alarm2andFaultLEDs PowerLED

Alarm1Relayoutputpins

Alarm2Relayoutputpins

Mainboardconnection

RelayoutadjutmentpinsNO/NC

SW1andSW2

Alarmleveladjustmentpins

17

PRS‐UM‐P‐EN‐Rev.01‐08.2018

AlloutputpinslocatedonProsenseIRdetectorcanbeusedsimultanously.Thatmeansuser

canuseallrelayoutputs,analog(4‐20mA)outputandRS485digitaloutputatsametimeif

implementationequipmentallowstheirusage.

Eachrelayhas3pinstoadjusthowtobehaveincaseofalarmwhichare

NO:NormallyOpen

NC:NormallyClose

Therelayoutputpinpositionsshownbelow:

NormallyOpen(NO)

NormallyClose(NC)

Table7:Relayoutputpinpositions

TheFaultrelayissettoNO(NormallyOpen–Energised)andenergised.Hencefaultrelay

LEDisalwaysactive.Itdoesnotmeanthatthereisafaultondetector.IfthepowerLEDis

activeandfaultLEDisoffitmeansthatthereisafaultconditiononthedetector.Thefault

relaywillbede‐energizedincaseofpowerfailure.

ThealarmrelayssettoNO(NormallyOpen–De‐Energised)positionatfactory.

ThealarmlevelsarealsoadjustableviausingSW1andSW2alarmlevelpins.Alarmlevelsare

definedaspercentageinLELforflammablegases.Thealarmlevelscanbeadjustedusing

jumperstoswitchSW1andSW2.Possibleoptionsaregivenintable9:

SW1 SW2 Al1Level Al2Level

Open Open 10LEL 15LEL

Open Closed 10LEL 20LEL

Closed Closed 20LEL 25LEL

Closed Open 20LEL 40LEL

Table8:Alarmlevelpinpositions

Oxygendetectors:

Foroxygendetectorstheoutputvaluesandmeaningsaredifferentasoxygenisnaturally

availableinatmosphere:

Port Usage

Fault FaultRelayoutput

AL1 Alarm1Relayoutput‐LowerlevelforOxygen

AL2 Alarm2Relayoutput‐HigherlevelforOxygen

Table10:RealymoduleoutputmeaningsforOxygendetectors

18

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Alarmlevelsarealsodifferentasgiveninbelowtable:

SW1 SW2 Al1Level Al2Level

Open Open 19%vol 23%vol

Open Closed 19%vol 22%vol

Closed Closed 18%vol 22%vol

Closed Open 18%vol 23%vol

Table11:Alarmlevel(%Vol)pinpositionsforOxygendetectors

System Status

TheProsenseIRdetectorshasoneLEDonmainboardtoshowactualstatusofthedetector.

InnormalconditionswhieldetectorworksproperlytheLEDblinkswith1secondperiod(one

blinkinasecond).IfdetecorisinfaultconditionLEDilluminateswith250msperiod(four

blinksinasecond)andthedetectoranalogoutputgives2mAonSport.Ifdetectorcouldnot

getenoughpower(lowerthan12VDC)itwillalsoraisefaultstatus.

First time switch on (Commissioning)

WARNING

ThefollowingprocedurerequiresthedetectorCovertoberemovedwhilecarryingout

supplyvoltagechecks.Thereforetheappropriatepermitstoworkshouldbesoughtin

preparation.

PriortocarryingoutanyHOTWORKensurelocalandsiteproceduresarefollowed.

Ensurethattheassociatedcontrolpaneloutputactuationisinhibitedsoastopreventfalse

alarms.

Caution:Thefollowingprocedureshouldbefollowedcarefullyandonlyperformedby

suitablytrainedpersonnel

1. Removethedetectorcover

2. Configurethedetector'sanalogueoutputsignalandpowerinputconnectionsdone

correctly

3. Checkthatallelectricalconnectionsareterminatedcorrectly

4. SwitchOntheexternalpowersupplytofeedthedetector

5. UsingaDigitalMultiMeter(DMM),checktheSupplyVoltageattheterminalsV+(24V)

andV‐(0V),thisshouldbeaminimumsupplyvoltageof12VDC(Maximumsupply

voltageis24VDC)

6. CheckLEDstatusondetectormainboard.LEDwillbeluminatedrightafterappying

power.

7. WaittwominutesandconfirmthatLEDblinkingwithonesecondperiod.

8. SwitchOfftheexternalpowertothedetector.

9. Fitthecoverandmakesurenonofthecablescauseanobstructionwhilefittingcover

10. Switchonexternalpowertothedetector.

19

PRS‐UM‐P‐EN‐Rev.01‐08.2018

Calibration

Itisrecommendedtoperiodicallycarryoutcalibrationtoensurecorrectoperation.

Calibrationshouldbedonebyapersonwhotrainedandcertifiedbylocalorinternational

authorities.

Prosensedetectorcalibrationincludestwostepswhicharezeroandspancalibration.During

thecalibrationbothstepshavetobecompleted.Otherwisethecalibrationwouldnotbe

savedandvaluesinvalidatedbydetectorinternalcontrolmechanism.Detectorshouldbe

poweredandstabilizedforatleast30minutesbeforecalibration.Zerocalibrationshouldbe

donebycleanairorN2gasdependingofthedetectorandsensortype.Spancalibration

shouldbedonebyspecificgascombinationsandlevelsdependingofthedetectorand

sensortype.PleasecontactProsensetogetzeroandspancalibrationgasdetails.

Tocalibratethedetector,useanappropriatespangascylinder,constantflowregulatorand

ProsenseGasCap.Theflowratesusedforcalibrationgasareasfollows:

Gas Flowrate(L/Min)

CleanairorN2forzeroing 0.5to1.0

Falmmable(Catalytic) 0.5to1.0

O2 0.5to1.0

H2S 0.5to1.0

CO 0.5to1.0

H2 0.5to1.0

Flammable(IR) 0.4to0.6

CO2IR 0.4to0.6

Table9:Gasflowratesforcalibration

CalibrationproceduremayvarydependingontheProsensedetectormodel.IfProsenseGas

Monitorsoftwareavailableforcalibration,firstenablecommunicationbetweendetectorand

computerviasettingthefirstaddressswitchtoONposition.Thengivecleanair(N2forIR

sensors)gastosensorheadtoperformzero.ItwouldbebettertofollowtheADCvaluein

graphtoseeandmakesuresensorhasbeenstabilized.Thenpress“SetZero”buttontostart

zeroing.Detectorwillautomaticallysetthezerolevel.Followingzeroingapplythespangas

immediatelly.Gasconcentrationmayvarydependingofthegasandsensortype.For

flammablegaseswithPellistorandCatalyticsensörs30LELmethanestabilizedwithcleanair

(O2andN2);forflammablegaseswithIRsensors50LELmethanegasstabilizedwithN2should

beused.Applythegastothesensorandwaitatleast2minutes.AlsomonitorADCvalueon

graphtomakesuresensorreadinghasbeenstabilized.Thenpress“SetSpan”buttontostart

spancalibration.Itisnecessarytocontinueapplyinggaswhiledetectorautomaticallysetsthe

spanlevel.Itmaytakeanothertwominutestocomplete.Formoreinformationpleaseseethe

ProsenseGasMonitorsoftwareuserguide.

20

PRS‐UM‐P‐EN‐Rev.01‐08.2018

IfProsenseGasmonitorsoftwareisnotavailablefollowbelowprocedurestepbystep.

Otherwisethecalibrationwouldnotbecompletedandnonofthevaluesrecorded.

1‐ Putdetectorincalibrationmode.Toenablecalibrationmodethelastswitchon

addressswitchboardshouldsettoON.IfitwasOFFitshouldneedtosettoON.Ifit

wasalreadyONitshouldneedtosetfirstOFF,then10secondslatersettoON.

2‐ Applyzerogas(cleanairorN2dependingofthedetectorandsensortype)tothe

sensorforzeroing.TheLEDonmainboardwillsolidfor75secondsandthanitwill

returntonormalspeed(1secondperiod).OnceLEDreturnedtonormalflashingspeed

zeroingiscompleted.

3‐ Applyspangasandwait75seconds.

4‐ SetlastswitchtoOFFpositiontostartspancalibration.

5‐ Detectorwillsetspanlevelautomatically.TheLEDonmainboardwillsolidfor75

secondsandthanitwillreturntonormalspeed(1secondperiod).OnceLEDreturned

tonormalflashingspeedspancalibrationiscompleted.

Itisnotpossibletoperformonlyzerooronlyspancalibration.Itshouldbedoneingiven

order.Analogoutputwillsetto3mAlevelduringcalibrationstepsperformed,alarmsandfault

statusorrelayswillbedeactivated.Ifyouwantomonitoranalogoutputviausinga

multimeteryoumustusearesistorwhileseriallyconnectingthemultimeter.Otherwise

detectorwillthinksomeonehasdidshortcircuitonanalogoutputhenceitwillenablesaving

modeandsetoutputlevelto2mA.

Maintenance

Proactive maintenance:

Allgasdetectorsincludingbothforflammableandtoxicgasesshouldhavetopassa

functionaltestandcalibrationeverythreetosixmonthsaccordingtoEN60079‐17industiral

standarts.Thetestresultsandcalibrationreportsshouldberecordedinmaintenancebooks.

Operational Life:

Flammablegassensormadebyusingthepellistorsthatsufferfromalossofsensitivitywhen

inthepresenceofpoisonsorinhibitors,e.g.silicones,sulphides,chlorine,leador

halogenatedhydrocarbons.Thepellistorsarepoisonresistanttomaximizethe

operationallifeoftheCatalyticflammablesensor.Atypicaloperatinglife,subjecttothe

presenceofpoisons/inhibitorsis36months.

TheNDIR(infrared)flammablegassensorisnotaffectedbythementionedpoisonshence

hasalongerlifespan.

Table of contents

Other Prosense Gas Detector manuals

Popular Gas Detector manuals by other brands

Riken Keiki

Riken Keiki SD-1DEC operating manual

RKI Instruments

RKI Instruments 35-3001A-05 Series Operator's manual

Dräger

Dräger X-am 3500 Instructions for use

Riken Keiki

Riken Keiki 04 Series Operation manual

Xtrails

Xtrails VESDA ECO installation instructions

International Gas Detectors

International Gas Detectors POR-MULT user manual