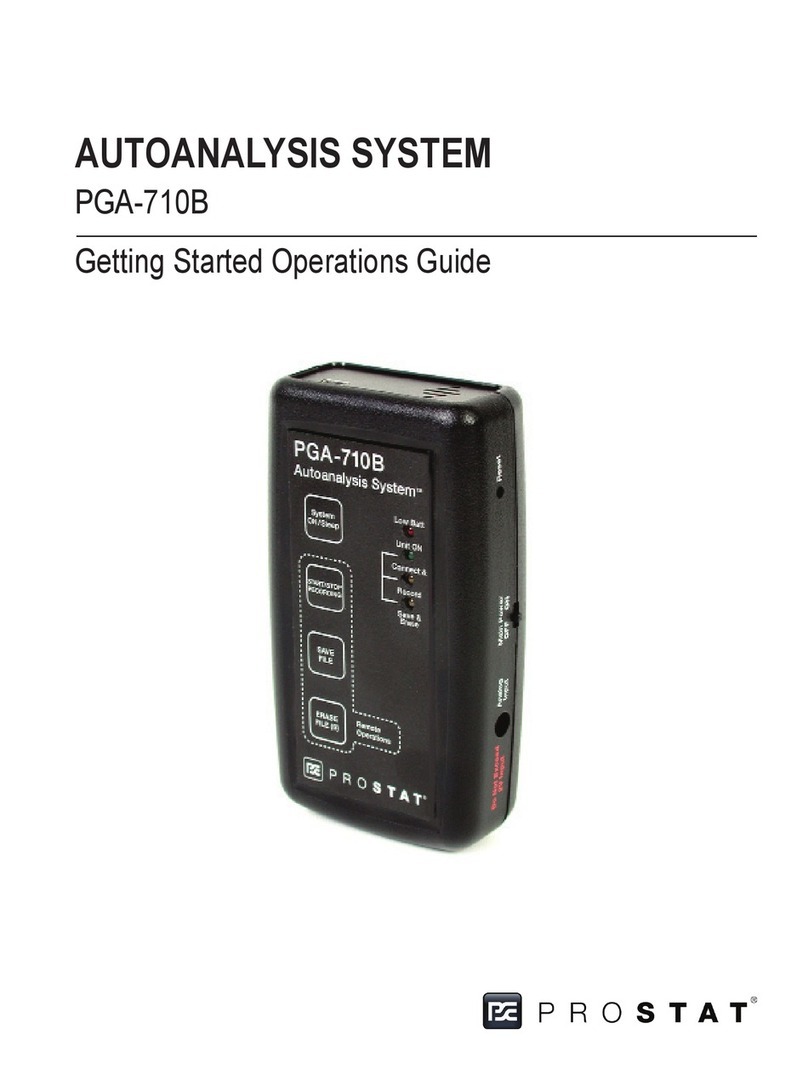

Prostat PGA-710B User manual

User Manual

PGA-710B

AUTOANALYSIS SYSTEM

PROSTAT® PGA710B AUTOANALYSIS SYSTEM

Secon Topic Page

I. ESD Control Elements 4

II. PGA-710B Autoanalysis Set Content 4

III. Cauons & Warnings 6

IV. Instrument Setup & Computer Connecon 6

V. Controls 9

VI. Preparaon for Recording Operaons 11

VII. Generang Printed Charts & Reports 23

VIII. Basics of Voltage Decay Analysis 27

IX. Recording Test Data Without Computer Connecon (Remote Tesng) 30

X. Exporng & Imporng Data to and from Excel®Spreadsheets 32

XI. Modifying XML Config File Defaults 34

XII. Warranty Informaon 38

General Specificaons 39

Applicaon Soware System Requirements 40

Table of Contents

Copyright © 2012 by Prostat® Corporaon. All rights reserved. Printed in the United States of America. No part of this

manual may be used or reproduced in any manner whatsoever without wrien permission. For informaon contact

Prostat Corporaon, 1072 Tower Lane, Bensenville, IL 60106 USA

Prostat is the registered trademark of Prostat® Corporaon

4Rev. E / October 4, 2018

PGA-710B Autoanalysis System

Product Overview

The PROSTAT® PGA-710B Autoanalyzer is an electrostac data analysis periph-

eral device for use with PROSTAT’s PFK-100 Instrument Set, which incorporates a

PFM-711A Electrostac Field Meter, CPM-720 Charge Plate Monitor and PCS-

730 Charging Source. Using the Autoanalysis System Applicaons Soware, the

PGA-710B will record, plot over me and automacally analyze body voltage

generaon, electrostac decay, voltage retenon and other electrostac events.

Its disncve Voltage Generaon analysis feature is designed to document and

calculate projected levels of typical Human Body and other voltages generated

in the manufacturing process.

It will also document and assess electrostac decay funcons, variaons in volt-

age retenon, and ambient temperature and relave humidity during each test.

Once tests and analysis are completed, this unique system will construct and

generate detailed wrien test reports.

I. ESD Control Elements

Examples of ESD Control products that can be evaluated using the PGA-710B Graphic Autoanalyzer in-

clude, but are not limited to:

Ionizaon Device and System Offset Voltage & Decay Performance

Footwear and Flooring combinaons

Worksurface Voltage Suppression

Rolling Carts

Record process equipment field voltages

Chairs (Sing and Standing Funcons)

Packaging Materials & Systems

Producon Aids & Materials

Other tests & evaluaon

II. PGA-710B Autoanalysis Set Contents

The Autoanalysis System consists of the following components:

A. PGA-710B Autoanalyzer

The Autoanalyzer is an electronic data logging device incorporang analog signal to digital conver-

sion, compung, memory, and temperature and relave humidity sensing capabilies. The Auto-

analyzer receives input from a measurement instrument, such as a Prostat PFM-711A Field Meter.

Its output is typically via USB to a computer using Windows XP or later operang system. The unit

is powered by a rechargeable lithium-ion baery.

NOTE

Do not connect a device having an input voltage greater than ±2.0 volts to the Autoana-

lyzer. Voltages over ±2.0 V may damage the device and will void the warranty. For further

informaon regarding instrument connecons contact Prostat customer service.

5

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

B. PGA-710B Autoanalysis System Applicaon Soware Flash Drive

The Autoanalysis System Applicaons Flash Drive includes the necessary programs to communi-

cate with, and operate the Autoanalyzer, install analycal programs, drivers and addional Mi-

crososoware. Before opening or loading soware, please be sure to review the Autoanalysis

System Soware license agreement.

C. Documentaon

Documentaon includes this Operang Manual, a Quick Start Guide, a Product Key Number for

access to the Applicaon Soware, a Tesng Guide for Flooring and Ionizers, and a Help file link in

the Applicaon Soware.

D. Connecons & Accessories

The following cables and accessories are provided:

1. USB cable for connecon of the PGA-710B Autoanalyzer to a computer USB port. Computer is

not provided. (Part Number: PGA-710USB)

2. Shielded analog cable connects the analog output of a Prostat PFM-711A Field Meter (field

meter not provided) and the signal input of the PGA-710B Autoanalyzer (Part Number: PGA-

710AnaCab).

3. The shielded voltage measurement cable with ground is used for body voltage, body reten-

on and other measurement. Connect the green shield lead to ground to reduce the effects of

ambient electrical noise. (Part Number: PGA-710ChgGen lead)

4. Input Shorng Shunt used to “zero” the PGA-710B Autoanalyzer during normal operaons.

(Part Number: PGA-710CC)

5. Body voltage Hand Wand and Cable accessories. (Part Number: PFA-861-H)

6. Baery Charger (Part Number: PGA-710 Charger)

E. Shielded Measurement Cable

The shielded measurement cable is intented for use with the Prostat CPM-720 charge plate moni-

tor for measuring body voltage generaon, charge retenon, remote equipment and other elec-

trostac voltage sources. The signal conductor insulaon is Red and the shield insulaon is Green.

Connect the Red lead to the CPM and the object being measured. Connect the Green shield to

ground to reduce the effects of ambient electrical noise and transmied energy. Do not connect

the shield to the ground plate of the CPM.

6Rev. E / October 4, 2018

PGA-710B Autoanalysis System

Figure 1: Schemac of Test Setup

III. Cauons & Warnings

A. There are no user serviceable parts in the unit. Do not open the PGA-710B Autoanalyzer, or dam-

age the warranty seal. Only authorized Prostat technicians can provide repair and mechanical

updates. Opening the unit or damaging the seal will void the warranty.

B. To prevent low voltage shock or damage to the unit or operator, do not operate the device when

wet, or in a wet environment.

C. Do not exceed ± 2.0 volt signal input to the Autoanalyzer. Higher voltages may damage the unit

and will void the warranty.

NOTE: Contact Prostat Customer Service for informaon regarding feasibility of connecng other

than Prostat instruments and devices to the Autoanalyzer.

D. The Autoanalyzer is a precision instrument. Consider it as fragile. It can be damaged by abuse. As

with other fine instruments do not drop or cause mechanical shock.

E. The Autoanalyzer’s analycal program funcon is based on operator input and the data supplied.

Thus, the representave accuracy and value of system calculaons are based on operator input

and acons. Prostat is not responsible for data analysis results or the decisions made based on

PGA-710B Autoanalysis System data analysis.

IV. Instrument Setup & Computer Connecon

The PGA-710B Autoanalyzer connects to a Prostat PFM-711A Electrostac Field Meter via its analog out-

put lead and to a computer using USB cable. The PGA-710B and accompanying soware converts the field

meter and computer into a digital chart recording system with automac analysis and reporng features.

The USB connecon provides opmal data transfer between the PGA-710B and the computer.

A. System Compability

The PGA-710B is intended for use ONLY with computers using current versions of Windows XP,

Vista 32-bit/64-bit, Win7 32-bit/64-bit and Win8 operang systems. Note that systems other than

Windows 2003 may be required to download a Microsoupgrade (.NET plaorm) for proper

7

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

operaon. The Autoanalysis System Applicaons disk includes the Microso.NET Framework 4.0

plaorm, which will be installed with operator approval. Periodically check for .NET soware up-

dates at the Microsoweb site.

Systems using Windows XP should be:

• Updated with current service pack 3 crical updates

• Download current .NET Framework 4.0 version

• Then check for, and download current updates to the .NET Framework before loading the

Autoanalysis soware.

B. Prior to Use

Charge the PGA-710B’s baery for 8-14 hours using the supplied AC/DC converter. Esmated

operang baery life is approximately 8–10 hours of operaon without connecon to USB port or

supplied baery charger. The unit charges when connected to the computer via USB.

Soware Installaon

Autoanalysis soware requires .NET Framework 4.0 installed on your computer. It can be installed either

thru Windows Update or from the installaon Flash Drive.

For your convenience, .NET Framework 4.0 will install automacally from the Flash Drive if it’s not already

installed.

Figure 2: .NET Framework 4 installaon

C. Device Drivers

This version of soware is delivered with device drivers for Windows 7 through Win10. The drivers

will install automacally from the Flash Drive once you iniate the main installaon. In the event

it didn’t install properly, you can be found them on the Flash Drive in folder Drivers. Install the file

named VCP_V1.3.1_Setup or VCP_V1.3.1_Setup_x64 located in the Drivers folder. Once complet-

ed, you can connect the device to your computer. Windows will complete the installaon of the

drivers.

8Rev. E / October 4, 2018

PGA-710B Autoanalysis System

D. Quick Start: Soware Installaon & Instrument Connecons

To load the Autoanalysis Applicaon soware:

1. Insert the Flash Drive into the computer’s USB Port

2. Select Open folder from the dialog box and double-click filename “Install.cmd”.

3. Follow the on-screen instrucons.

4. If prompted to install the .NET Frame-

work 4.0 Package, click Yes

5. Connect PGA-710B to computer via USB

cable. Refer to Figures 1 – 7.

6. Connect the PGA-710B to your PFM-

711A Field meter via analog signal cable

7. Slide PGA-710B’s baery cut offswitch

to the ON posion.

8. Press the System ON/Sleep panel

membrane pad and release when LED’s

energize.

9. Your computer should recognize NEW HARDWARE.

10. Aer installaon Prostat “Autoanalysis System” shortcut will be installed on the desk top.

NOTE: The first me the PGA-710B soware is opened, the operator has an opportunity to select

desired language and temperature display in either Celsius or Fahrenheit.

Both language and preferred temperature display can be changed at any me using the tool bar

View >Language and View >Temperature Scale

Figure 3: USB Connecon

Figure 4: Front Panel Figure 5: Analog Input & Reset

9

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

V. Controls

A. Operator controls include:

1. Main Power Baery Bus Isolaon Slide Switch

(Figure 7): Isolates baery from unit electron-

ics during storage and between operang

sessions.

a. In OFF posion Baery Charging (LED 4)

remains OFF when unit charges using AC/

DC converter.

b. Note that small green LED next to Charger

Connecon will energize during charging.

See circle in Figure 7.

c. In ON posion, unit is energized in “sleep”

mode but is not operaonal unl System ON/Sleep (Pad 1) buon is pressed.

2. PAD 1 System ON/Sleep: Places unit in Normal Operaon or Sleep modes.

Figure 6: Front Panel

Pad 4: Erase

[In Remote Ops]

Pad 3: Save

[In Remote Ops]

Pad 2: Start/Stop

[In Remote Ops]

Pad 1: On/Sleep

LED 1: Low Ba.

LED 2: Unit ON

[Start/Stop]

LED 3: Computer

Connected [Save]

LED 4: Baery

Charging [Erase]

Figure 7: Main Power Baery Bus Slide

Switch Isolates Baery during Storage

10 Rev. E / October 4, 2018

PGA-710B Autoanalysis System

a. Press ON: LED’s #2 - #4 flash, then GREEN LED #2 blinks slowly to indicate unit is ON and

operang. (Figure 8)

b. Press Sleep: Press and hold pad unl LED’s #2 - #4 energize temporarily, then release pad to

place unit in standby or “sleep” mode. LED’s are OFF.

3. PAD 2 Start/Stop Recording Records data when in Remote Mode, i.e., when not connected to a

computer. Remote operaons allow recording and storage of individual test files for computer

download at a later me.

4. PAD 3 Save File when in Remote Mode. Once a remote test cycle is completed, i.e., PAD 2 is

pressed to stop recording, pressing PAD 3 saves the test data as an individual file in the unit’s

memory.

5. PAD 4 Erase File(s) when in Remote Mode.

a. Press Once erases current test before it is saved in unit memory

b. Press and Hold unl LED’s 2–4 flash rapidly in sequence Erases ALL FILES in memory

6. Reset Re-boots PGA-710B in the case of latch up. See Figure 5.

B. LED Indicators

LED indicators provide informaon in computer connect and remote operaonal modes.

1. LED 1 RED: Low Baery level. Charge baery via USB connecon to computer or using AC/DC

converter. (See Baery Consumpon in Techni-

cal Specificaons on page 39)

a. Unit operates normally during either

charging mode. During operaon more

current is used than provided by USB con-

necon. Periodically recharge baery with

the AC/DC charger.

b. Note that LED 1 does not operate, i.e.,

indicate low baery or energize, when Bat-

tery Bus Isolaon Switch is OFF.

2. LED 2 GREEN: Electronics energized and oper-

ang.

a. ON when PGA-710B is energized, i.e.,

Baery Bus Isolaon Switch is ON and System ON/Sleep pad is pressed. It blinks slowly to

indicate unit is energized and operang.

b. When in remote operaons

1) Energized when unit turned ON, blinks to indicate unit energized and operang

2) Energized when PAD 2 Start/Stop Recording is pressed

Figure 8: ON/OFF: Power up or place PGA-

710B into “sleep mode”.

11

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

c. During file management in remote operaons:

1) Blinks slowly in tandem with LED’s #3 during file recording

2) Blinks fast with LED’s #3 to indicate file needs to be SAVED or ERASED

3) Blinks fast, alternately with LED’s #3 & #4 during erase of ALL FILES in memory

3. LED 3 ORANGE/YELLOW:

a. ON and Blinking when PGA-710B is connected & communicang with computer

b. When in remote operaons, energized when PAD 2 Start/Stop is pressed

c. During file management in remote operaons:

1) Blinks slowly in tandem with LED’s #2 during file recording

2) Blinks fast with LED’s #2 to indicate file needs to be SAVED or ERASED

3) Blinks fast, alternately with LED’s #2 & #4 during erase of ALL FILES in memory

4. LED 4 YELLOW:

a. ON when PGA-710B is connected to computer, energized steady ON to indicate the baery

is charging

b. LED 4 is ON when unit is ON and connected to the AC/DC charger

c. During file management in remote operaons:

1) Blinks once when file is saved

2) Blinks fast, alternately with LED’s #2 & #4 during erase of ALL FILES in memory

VI. Preparaon for Recording Operaons

A. Follow these inial steps to explore the

PGA-710B’s operaonal capabilies.

1. Connect the PGA-710B to the com-

puter via the USB cable

2. Connect the PGA-710B to the PFM-

711A Field Meter analog output

3. Energize computer and instruments

4. On computer, click “Autoanalysis

System” shortcut to start soware

5. The Session Wizard automacally opens the Start Screen. Choose from:

a. Start a New Session

b. Load Saved Session file

c. Import from Device

d. Start a New Session Wizard, or

e. Close the Start Screen

Figure 9: Autoanalysis Soware Start Screen

12 Rev. E / October 4, 2018

PGA-710B Autoanalysis System

6. Select “Start a New Session Wizard” and Click OK as in Figure 9, will open Session Wizard Test

Type screen (Figure 10). Select Test Type and provide the requested informaon to be included

in test reports. See The Session Wizard secon below for further details.

7. To open a fresh chart, simply select “Start a New Session”.

8. Press New Document symbol on the tool bar to open addional new files

B. The Session Wizard

The Session Wizard is used to enter test infor-

maon, material idenficaon, locaon and

notes. All informaon entered in the Wizard will

be included in the generated charts and test re-

ports. Informaon is entered in any of the basic

test scenarios: General Test, Voltage Genera-

on Test, and Decay Test. The Wizard consists

of an Opening Screen, Two General Informaon

Screens and Test Specialty screens for Voltage

Generaon and Decay Tests.

C. Opening Screen

The Opening Screen (Figure 10) is used to des-

ignate the type of test to be conducted. In the

illustraon at right, decay tesng is the intent of

the test.

D. General Informaon Screens

Two screens provide fields for a variety of descripve and locaon informaon that is included on

all charts and in detailed reports. The following two screens are included in all test type formats.

E. Specialty Screens: Decay Tests

Decay measurements are used primarily for ionizaon tesng. Decay tests have a beginning volt-

age where ming begins or is “Reset”, and an ending voltage where ming stops, or is “Cutoff”.

The following screens and windows are used to enter Reset and Cutofftest voltages.

1. Designate the voltages used to Start and Stop the decay me period.

Figure 10: Use the first Session Wizard Window to Des-

ignate the Type Test

Figure 11: Technician, Material and General Informaon Screens

13

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

a. The Reset Voltage starts the ming calculaon period.

b. CutoffVoltage ends the ming calculaon period.

2. The Decay Window offers two means to designate Reset and CutoffVoltages.

a. Standard Reset and CutoffVoltages are (See Figure 12):

1,000 Volts – 100 Volts

1,000 Volts – 50 Volts

1,000 Volts – 10 Volts

b. Check the Custom Box to enter any two voltages for evaluaon. Figure 12.

F. Specialty Screens: Voltage Generaon Tests

Voltage generaon measurements may

take several forms. In many tests, the

movement is repeous, much like a walk-

ing measurement. The Wizard screen at

the right (Figure 13) allows the operator to

esmate the number of cycles before the

measurements begin. The number can be

changed later as necessary.

However, it is the number of operator en-

tered cycles that drive the soware’s inial

algorithm analysis. Thus, it is important to

be able to define the number of walking

steps or test cycles so that automac analy-

sis proceeds effecvely.

G. Customize Charts & Create Templates

Figure 12: Standard Reset and CutoffVoltages (le), or check the Custom Box (right) and Manually Enter

Figure 13: Enter the Number of esmated Voltage Gen-

eraon Test Cycles

14 Rev. E / October 4, 2018

PGA-710B Autoanalysis System

A new file can be configured with various indicators, voltage lines, alignment arrows, etc. One

could construct a “template” using various desirable features for future use. When a New file is

opened, record & control funcons are acvated. Use the following to add custom labels and refer-

ence lines.

1. Select Document on the menu bar and a drop down menu appears

2. Highlight Voltage Custom Labels and Click. See

Figure 14.

3. The Voltage Label Properes window opens.

See Figure 15, below.

4. Click on “Add”; 0.00 appears in the “Label Val

ues” and the “Label Properes” windows.

5. In the “Behavior” secon True indicates the

zero Label (0.00) and Line will appear in

the chart.

6. In “Colors” both Label and Line colors are

individually selected using the drop down ar

row. In Figure 15, the zero Label and Line will

be Red. To change colors press the down

arrow(s) to open the color selecon drop

down menu(s). Choose from several colors

(Figure 16) for customizing lines and labels.

7. “Value” allows different lines to be inserted in

a chart at various voltage levels. For example, we

might add colored lines at +100 and -100 volts to easily see any voltage generated peak that

“exceeds ±100 volts”.

8. Click the “Add” buon and 0.00 appears in Label Value. To create a disncve Label and Line

at +100 volts enter “100” in the Data “Value” secon. Open the Color Drop down menu for

“LabelColor” and “LineColor” and select Blue. 100 will appear in the “Label Values” window.

9. Repeat for “-100”, i.e., enter “-100” in the Data “Value” secon. Open the Color Drop down

Figure 14: Customize Chart Using Voltage Labels and

Lines

Figure 15: One can create various Chart Voltage Lines &

Labels in several colors

15

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

menu and select Blue. -100 will appear

in the “Label Values” window. See Figure

17. Click OK and your plong chart re-

sembles Figure 18, on the next page.

Use the various scale adjustment arrows

to center the 0.00 Line, adjust the chart

voltage and me sweep ranges to meet

ancipated test needs. Once prepared

to your liking, and before recording data,

save the chart as a template to reduce

future setup me. For example, save the

file as “ChgGen Template1.tst”. When-

ever the file is recalled the chart sengs

are as you lethem and the file is ready

to record data and be saved with a new

name.

NOTE

Creang Test Templates are convenient and save a great deal of me. However,

once data is recorded and saved in a file it cannot be reused as a template.

Figure 16: Color Drop down Menu Used to Change Label

& Line Colors

Figure 17: In the Data secon enter Voltage Value

where a Chart Line is desired

16 Rev. E / October 4, 2018

PGA-710B Autoanalysis System

H. Set

PGA-

710B Time & Date

In preparaon to record and analyze data, confirm PGA-

710B system date and me are correct.

1. Press Edit on the menu bar to open the drop down

menu.

2. Select Device Control and a Device Control window

(Figure 19) appears on the screen.

3. With the PGA-710B energized and connected to the

computer via USB cable, Click the “Device Time” Read

buon. The Read window will display the computer’s

current date and me sengs.

4. Press the Set Device Time buon to set the PGA-

710B’s me clock to the computer.

5. Press Done to close the window.

I. Sampling Rate

The PGA-710B’s default Sampling Rate is 50 samples/second, which is suitable for most auding

and analysis applicaons. To confirm or modify the rate proceed as follows:

1. Open the Edit drop down menu.

2. Select Device Control and a Device Control window (Figure 20) appears on the screen.

3. With the PGA-710B energized and connected to the computer via its USB cable, Click the

Figure 18: New Chart with Red Zero Line and Blue Labels and lines at ±100

Figure 19: Use Edit drop down Menu to Access

Device Control Window for seng Set PGA-710B

Date & Time

17

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

“Sampling Rate” Read buon. The Read window

will display the computer’s current sampling

rate.

4. To change the sampling rate, click the drop

down menu arrow as seen in Figure 21:

a. Highlight the desired rate, i.e., 50, 100 or

200 samples per second

b. Press Set

c. Press Done in the Device Control window to

complete the sampling rate change.

J. Temperature & Relave Humidity Sensor Factory Calibraon &

Adjustments

To ensure the sensor is operang based on factory design and ini-

al calibraon, all adjustments or bias must be “cleared” from the

sensor. To “clear” the soware sengs:

1. From the Edit drop down menu, select Device Control (See

Figure 22)

2. Confirm the Humidity (Rh%) Value window is set at

0.0, and click Clear

3. Confirm the Temperature (F) Value window is set at

0.0, and click Clear

4. Click Done to close the window.

Once sensors are reset, use a calibrated temperature and

humidity instrument as a reference to set the appropri-

ate bias for the most accurate temperature and humidity

mesasurements. Follow the instrucons below for srng

temperature and humidity bias.

K. Creang a Temperature or Relave Humidity Bias

If an acceptable temperature and humidity instru-

ment is available, the PGA-710B’s sensor can be

operaonally adjusted to approximate the reference

as follows (See Figure 23):

1. From the Edit drop down menu, select Device

Control

2. Enter the reference humidity in the Value win-

dow and click the Set buon

3. Enter the reference temperature in the Value

Figure 20: Use Edit Menu to Access Device Con-

trol Window to Set Sampling Rate per Second

Figure 21: Select Sampling Rate

Figure 22: Clearing Humidity and Temperature

Bias adjustments

Figure 23: Adjusng Temperature and Humidity

Bias

18 Rev. E / October 4, 2018

PGA-710B Autoanalysis System

window and click the Set buon

4. Click Done to reset the sensor and close the window

Once a new seng is entered into the soware, temperature and humidity indicaons will be based on

the exisng sensor performance plus the influence of the new net seng bias. For example, if the exisng

indicaon is 70°F and the seng input is 65°F, a -5° bias will be added to the sensor’s measurement, and it

will subsequently indicate 65°F. A similar adjustment can be made for relave humidity.

L. Open Current (Real Time) Measurement Digital Display

A lepanel area includes real me measurements of volatge,

temperature and relave humidity. To display an addional

real me measurement window showing the values of volt-

age, temperature and relave humidity during the recording

process:

1. Press Edit on the menu bar and select Current Measures.

See Figure 24 and 25.

2. Place the Current Measures window in a convenient loca-

on.

Data Recording Controls

The data recording Controls are located at the upper lecorner of

the screen. See Figures 25 and 26, below. The symbols are similar to the controls of a tradional tape

recorder (for those who may remember tape recorders). From leto

right, the controls are:

1. Preview: Green Triangle starts chart plot and indicates

magnitude of data. Data is not recorded, it allows adjust-

ments before recording.

2. Record: Pressing the Red Circle begins data entry to file.

When recording, the circle becomes Red and the plot

trace changes color.

3. Pause: The vercal Parallel Bars allow stop and start of

data entry during Playback and

when recording in General Mea-

surement and Decay test modes.

Pause does not funcon when

recording Voltage Generaon.

4. Stop: The Black Square stops either Preview or Recording funcons.

If used to Stop the Preview funcon, when Preview is pressed again

it resets the recording point to start ongoing Preview or Recording.

5. Short Cut Keys (Figure 27): Several funcon keys are assigned to

assist in chart control:

Figure 24: Access Current Measures

through the Edit Menu

Figure 25: Current Measures window

displays Voltage, Temperature and

Humidity

Figure 26: Chart Controls

are similar to those of a

tape recorder

19

Rev. E / October 4, 2018

PGA-710B Autoanalysis System

a. F5 Preview: Starts chart display of voltage and measurement

levels. NOTE: Data is not entered into the file during Preview

b. F6 Record: Begins data capture of all measurement levels

c. F7 Pause: Stops and Starts Chart recording and playback

d. F8 Stop: Ends Preview, Recording or Playback.

e. F11 Auto Balance: Will align Preview or Recorded data to center

of chart. Can also be used to automacally align Voltage, Tem-

perature or Humidity.

f. F12 Auto Min Max: Will automacally align display data to ver-

cally ulize the enre chart view using the maximum and minimum data values.

N. Auxiliary Chart Control Window

When the LePanel Control is closed to maximize the chart display the Auxiliary Chart Control

window may be opened and posioned anywhere for operaonal convenience.

1. Open this window by selecng Chart Control on the Edit drop down

menu.

2. Use the mouse to drag and posion the window in a convenient loca-

on.

Display Temperature & Humidity Data

Temperature and Relave humidity are sensed and measured by the PGA-710B. The sensor is mounted

in the boom shell opening of the case for exposure to ambient condions. It measures temperature and

humidity external to the PGA-710B. Assuming the PGA-710B is stored

in the area overnight, it requires only a few minutes for the system to

reach opmum performance.

To display temperature and, or humidity, check the Show Temperature

and Show Humidity boxes listed under Charts in the lepanel (Figure

28). The default temperature display is Celsius (°C). To display Fahren-

heit (°F) or both °C and °F:

1. Open Document drop down menu and select Appearance Opons.

The “Chart Properes” window is opened (Figure 29).

2. In the Appearance secon click TempaxesVisibility drop down menu

arrow. Select desired temperature scale(s).

The Appearance Opons, Chart Properes window (Figure 29) estab-

lishes what is to be displayed, i.e., Celsius (°C), Fahrenheit (°F) or both.

Checking, or un-checking the “Show” boxes (Figure 28, above) deter-

mines whether or not the selected items are displayed in the chart.

See Temperature & Relave Humidity Sensor Factory Calibraon & Adjustments for specificaons and set-

ng Rh or temperature bias.

Figure 27: Short Cut Key

Controls

Figure 28: Check Show Tempera-

ture and Humidity Boxes to display

related

20 Rev. E / October 4, 2018

PGA-710B Autoanalysis System

Basics of Analyzing Body Voltage Generaon

For detailed measurement suggesons, see “How to Measure” manual. Once a recorded data file is estab-

lished, use the following guidelines for analysis:

1. Trim unwanted data from beginning or ending traces by using the Edit menu and click on Trim-

ming…. A floang Edit window will open (Figure 30, below).

2. Press Trim Letab and place the cursor on the plot trace at the selected point. Repeat with

Trim Right.

3. Take care in selecng trim points to clearly define data to be evaluated by the soware.

OPERATIONAL HINT

The System’s algorithm looks for paerns in Minimum and Maximum peak

values. One needs to define the beginning and end of a set of Minimum and

Maximum peaks. Every Minimum Peak must have a Maximum Peak.

a. Posion the Letrim point to define a starng point

for the analysis. It should represent an inial

Minimum or Maximum value. Referring to Figure 30,

the Letrim cursor is placed before a Minimum peak

as shown by the circle.

b. Posion the Right trim point to define the ending

point of the analysis. It should represent a final Mini

mum or Maximum value. Referring to Figure 30, the

Right trim cursor is placed just aer a Maximum peak

as shown by the circle at the right of the figure.

IMPORTANT NOTE: Maximum Peaks are posioned ver-

cally “Highest” on the chart, while Minimum Peaks are

posioned “Lowest” on the chart.

Figure 29: Chart Properes Window

Figure 30: Trim Data Trace to Idenfy Range

of Minimum & Maximum Peaks to be used for

Analysis and reporng.

Other manuals for PGA-710B

2

Table of contents

Other Prostat Analytical Instrument manuals