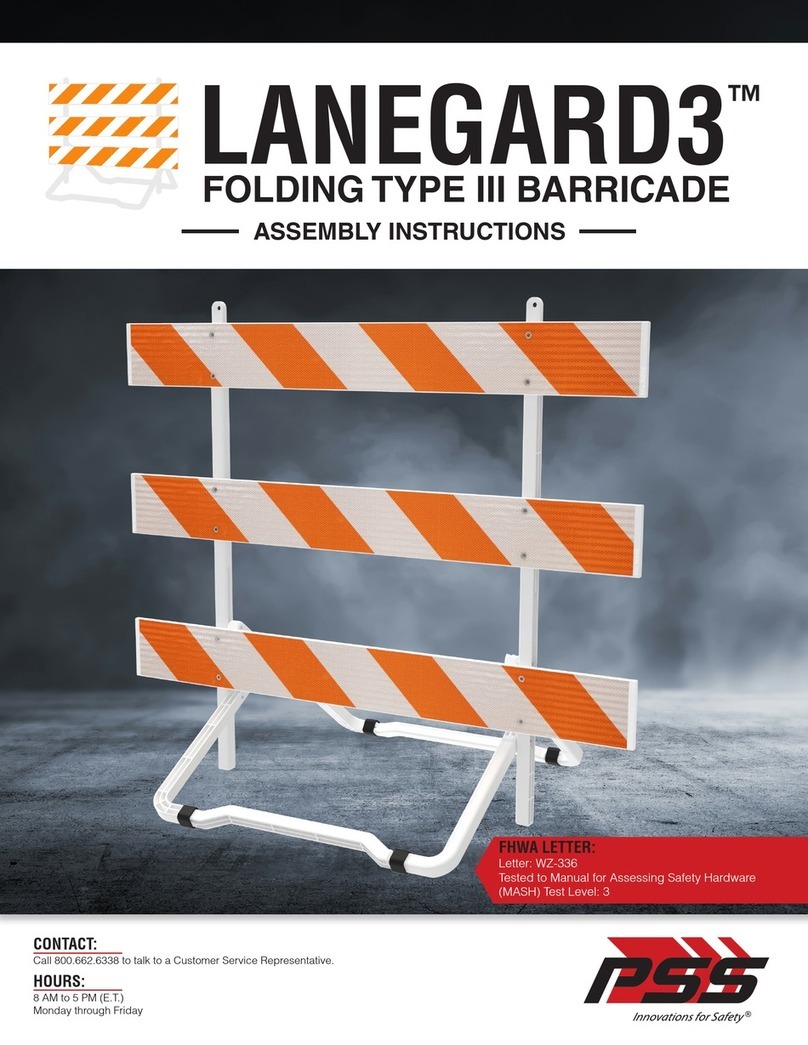

PSS FRISTGARD FOLDABLE CONE Guide

CONTACT:

Call 800.662.6338 to speak with a Customer Service Representative.

HOURS:

8 AM to 5 PM (E.T.)

Monday through Friday

HINGE AND BAND REPLACEMENT INSTRUCTIONS

TM

2FirstGard Hinge and Band Replacement Instructions

BOARDWALK ASSEMBLY INSTRUCTIONS

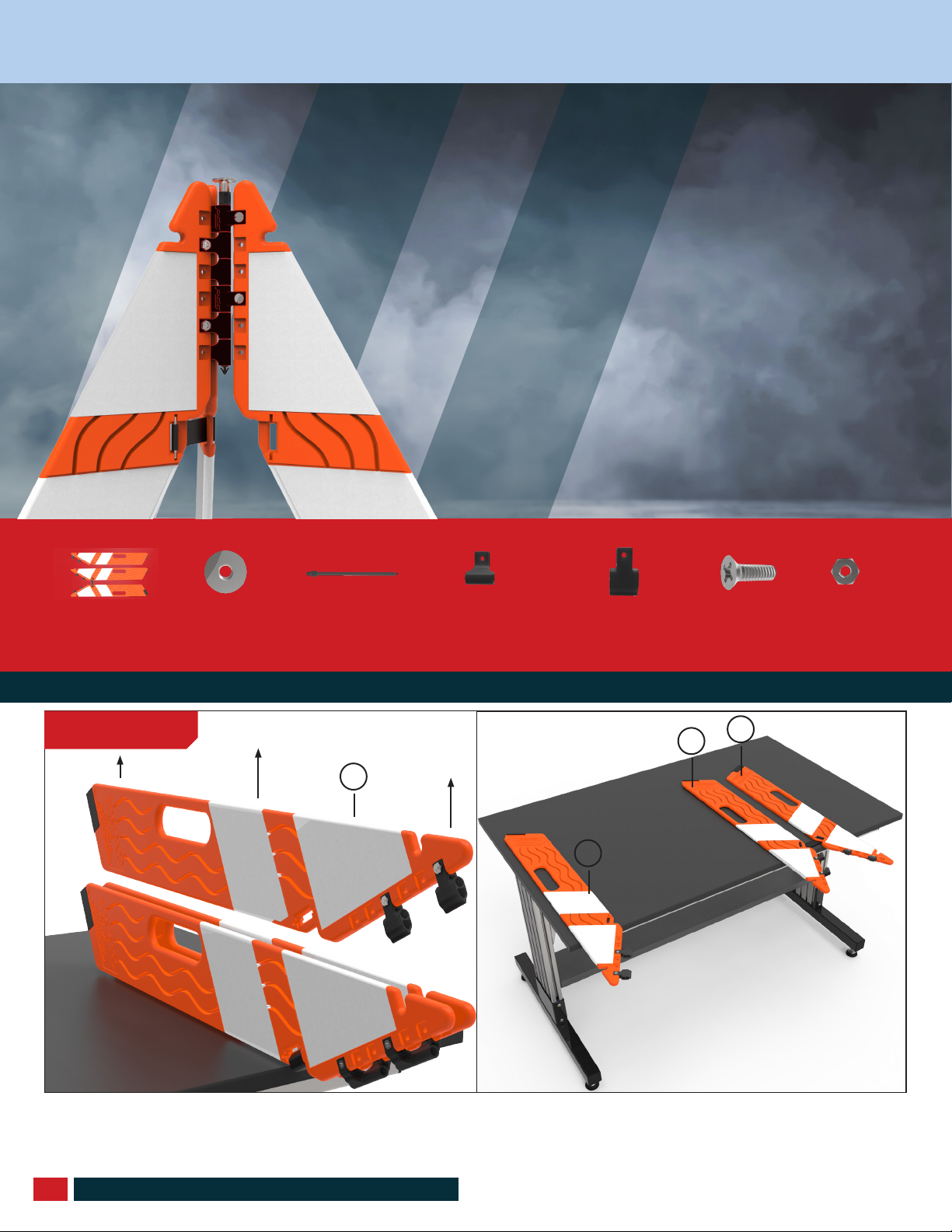

FIRSTGARD™REPAIR KIT COMPONENTS

TABLE OF CONTENTS

PAGE

03

PAGE

11

PAGE

07

PAGE

05

NYLON PIN

REMOVAL

BAND

REPLACEMENT

HINGE COMPONENT

REPLACEMENT

NYLON PIN

REPLACEMENT

1.2.3.

1.Band - Quantity 1

2. Hinge Component (Center) - Quantity 2

3.Hinge Component (Offset) - Quantity 4

4. Nylon Pin - Quantity 1

5. Weld Nut - Quantity 1

6. 10-24 Nylon Lock Nut - Quantity 6

7.Roll Pin - Quantity 2

8. 10-24 x 5/8” Screw - Quantity 6

5.6.7.8.

4.

3FirstGard Hinge and Band Replacement Instructions

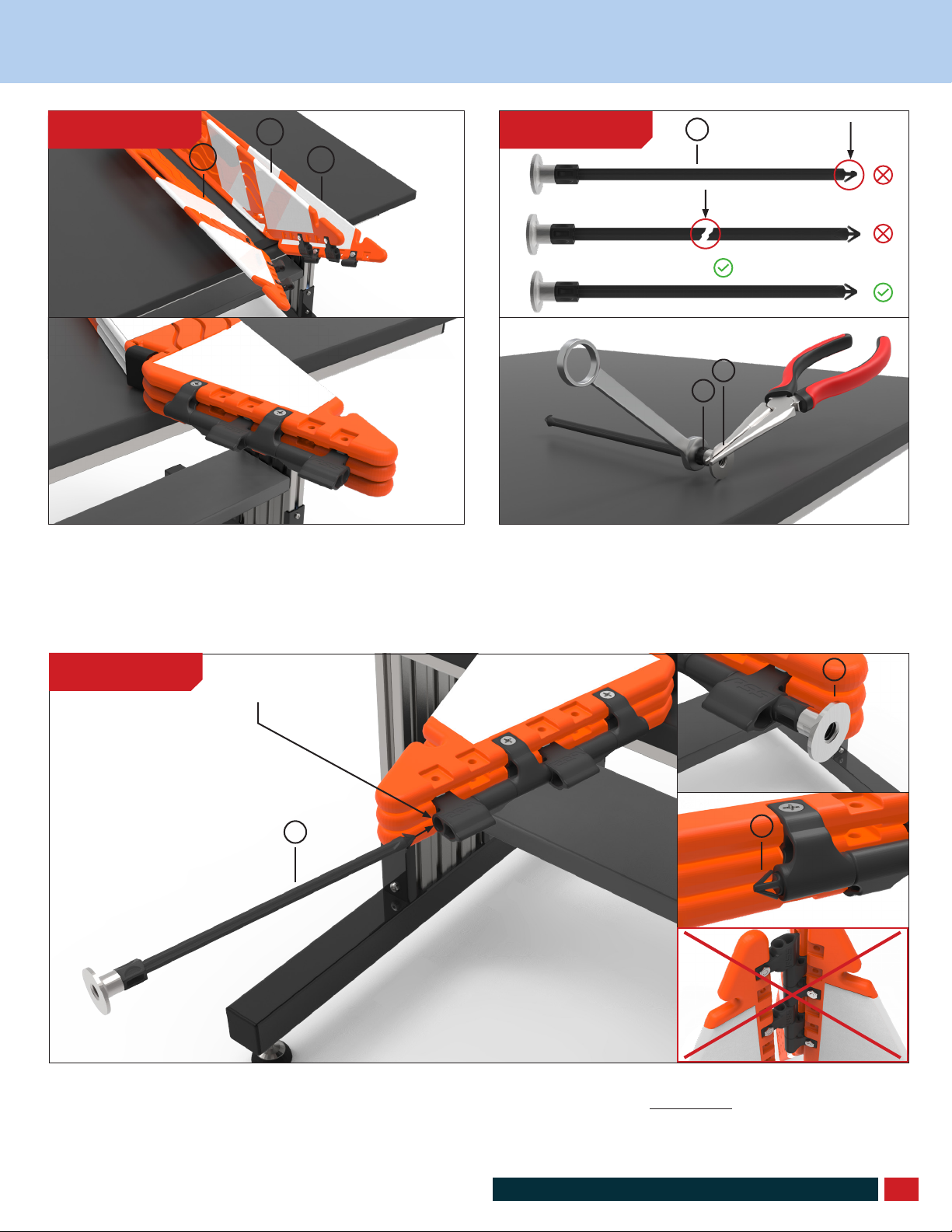

Place FirstGard (A) on table folded

STEP 1

REMOVAL

NYLON PIN

A.

PARTS NEEDED FOR NYLON PIN REMOVAL

TOOLS REQUIRED - NEEDLE-NOSE PLIERS

Part A.

FirstGard

Quantity - 1

Part B.

Weld Nut

Quantity - 1

Part C.

Nylon Pin

Quantity - 1

FIRSTGARD™NYLON PIN REMOVAL

FirstGard Hinge and Band Replacement Instructions 4

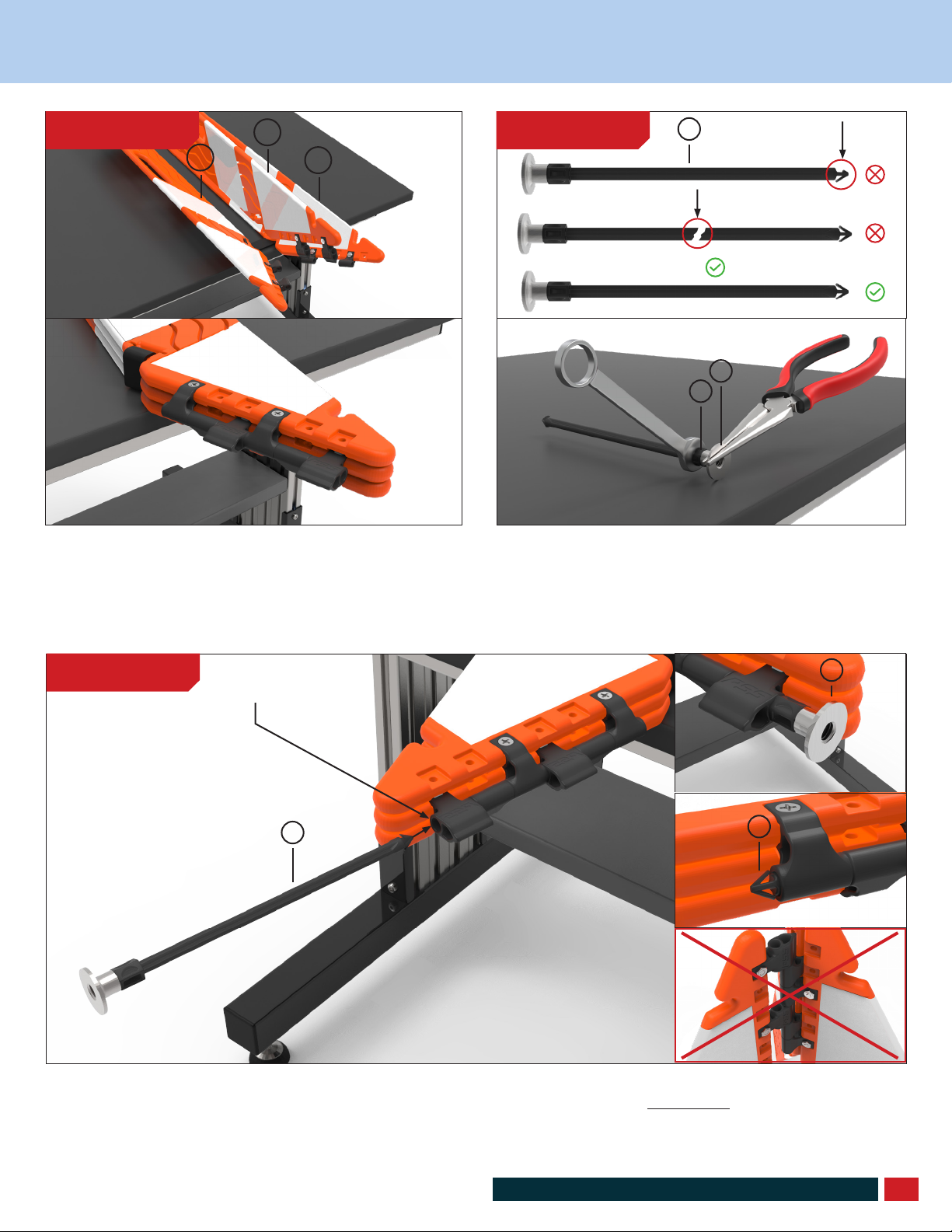

Using needle-nose pliers, squeeze the barbs on the nylon pin (C).

Use the weld nut (B) on the top of the nylon pin (C) to pull the pin out. If the pin is in one piece and the barbs can still function, the nylon

pin is still usable.

STEP 2

STEP 3

B.

C.

C.

C.

FIRSTGARD™NYLON PIN REMOVALFIRSTGARD™NYLON PIN REMOVAL

5FirstGard Hinge and Band Replacement Instructions

With the nylon pin (C) out, finger-tighten the weld nut (B) on top of

the nylon pin — flange side up.

Grip the flange of the weld nut (B) with pliers and using a 7/16”

wrench on the nylon pin (C), tighten an additional ¼ turn past fin-

ger-tight.

STEP 1 STEP 2

PIN REPLACEMENT

FIRSTGARD™PIN REPLACEMENT

PARTS NEEDED FOR FIRSTGARD HINGE REPLACEMENT

TOOLS REQUIRED - 7/16” WRENCH, PLIERS

Part A.

FirstGard Cone Panels

Quantity - 1

Part B.

Weld Nut

Quantity - 1

Part C.

Nylon Pin

Quantity - 1

C. B.

C. B.

FirstGard Hinge and Band Replacement Instructions 6

Align the round barrel holes on the hinge components.

Insert the nylon pin (C) into the barrel of the hinge. The weld nut (B) should be on the top of the cone and the barbs of the nylon pin should

point towards the bottom. Note: Be sure the nylon pin is going through the hinge component’s round barrel rather than the open hinge

cavities.

STEP 3

STEP 4

FIRSTGARD™PIN REPLACEMENT

C. C.

B.

Round barrel

Hinge Cavities

7FirstGard Hinge and Band Replacement Instructions

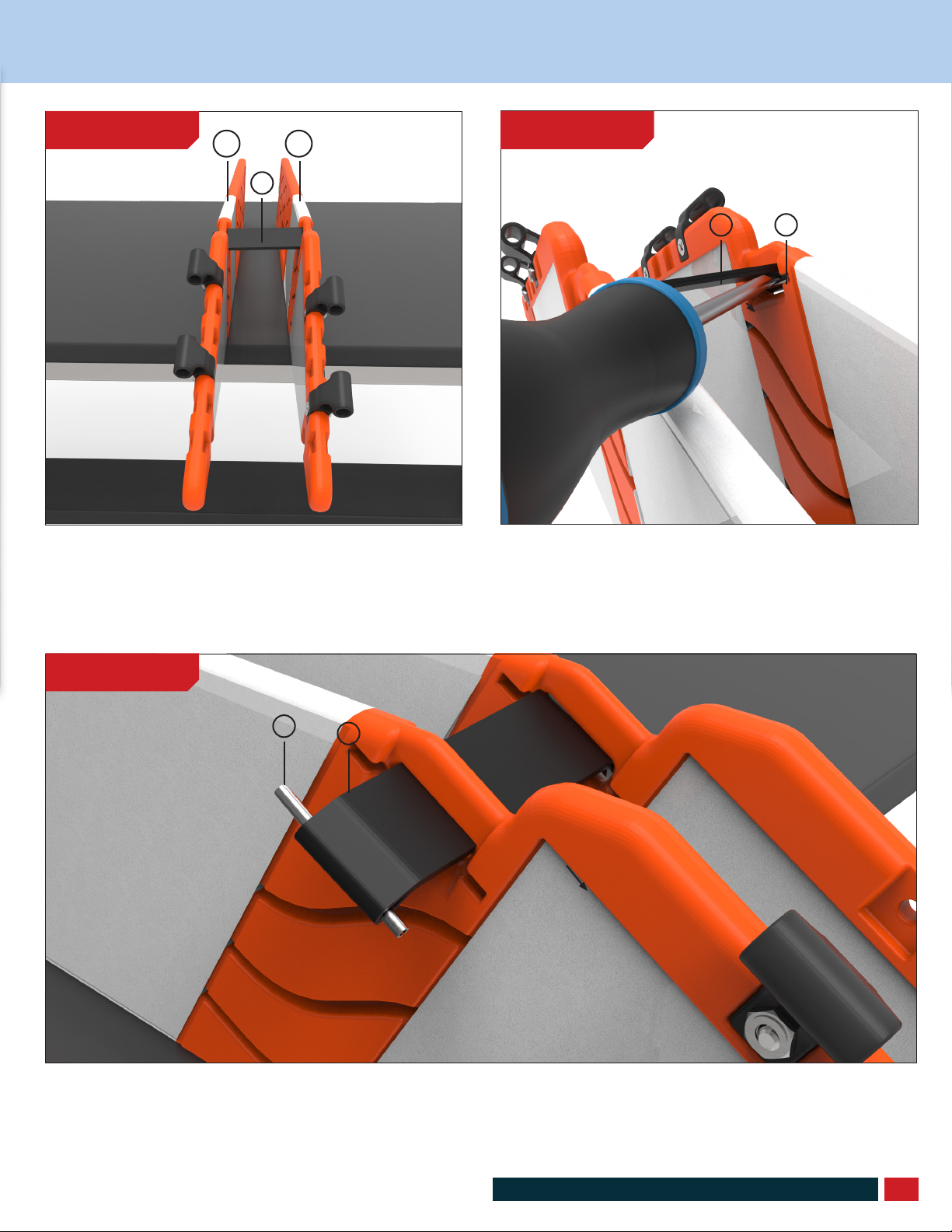

With the nylon pin removed, take out the center panel (A2) and set aside. Allow the two baned panels to lie flat on the table.

STEP 1

REPLACEMENT

HINGE COMPONENT

FIRSTGARD™HINGE REPLACEMENT

PARTS NEEDED FOR FIRSTGARD HINGE REPLACEMENT

TOOLS REQUIRED - PHILIPS-HEAD SCREWRIVER, 7/16” WRENCH, PLIERS

Part A.

FirstGard Cone Panels

Quantity - 1

Part B.

Weld Nut

Quantity - 1

Part C.

Nylon Pin

Quantity - 1

Part E.

Hinge Components

Panels A2

Quantity - As Needed

Part D.

Hinge Components

Panels A1 & A3

Quantity - As Needed

Part F.

Screw

Quantity -

As Needed

Part G.

Nut

Quantity -

As Needed

A2.

A2.

A1. A3.

FirstGard Hinge and Band Replacement Instructions 8

Assess which panel has a broken hinge component (D & E) Note:

It is crucial that the orientation and slot location of the component

matches the orientation and slot in the panel back into the same

position as this will affect the alignment of the panels.

Slide the broken hinge component (D) off.

Using a philips-head screwdriver, remove the metal screw and

nut (F and G) from the broken hinge component (D).

STEP 2

STEP 4

STEP 3

FIRSTGARD™HINGE REPLACEMENT

D. D.E.

A.

F.

G.

D.

D.

A2 A1 A3

9FirstGard Hinge and Band Replacement Instructions

FIRSTGARD™HINGE REPLACEMENT

Repeat steps 3-7 for all broken hinge pieces.

STEP 7

Slide the new hinge component (D) onto the FirstGard panel (A1

or A3) in the same location and orientation it was removed.

Place a nut (G) into the recess in the hinge component (D).

Place a screw (F) into the opposite side of the hole of the

hinge component. Using a wrench and screw driver, tighten the

hardware. Note: Be sure to not overtighten hardware as it may

damage the panel and/or the hinge component.

Fold the two banded panels (A1 and A3) together leaving enough

room for the third panel (A2) between. The hinge components

should be facing inward.

STEP 5 STEP 6

STEP 8

F.

D.

G.

D.

A1. /

A3.

A3.

A1.

FirstGard Hinge and Band Replacement Instructions 10

FIRSTGARD™HINGE REPLACEMENT

Lower the disconnected panel (A2) between the two banded

panels (A1 and A3) and close all of the panels together. Align the

round barrel on the hinge components.

Assess if the current nylon pin (C) is intact. If the barbs or pin are

not as shown, using a 7/16” wrench, finger-tighten weld nut (B) on

top of the nylon pin—flange side up. Grip the flange with pliers and

tighten it an additional ¼ turn past finger-tight.

Insert the nylon pin (C) into the barrel of the hinge. The weld nut (B) should be on the top of the cone and the barbs of the nylon pin should

point towards the bottom. Note: Be sure the nylon pin is going through the hinge component’s round barrel rather than the open hinge

cavities.

STEP 9 STEP 10

STEP 11

C. C.

B.

C.

B.

A1.

A2.

A3.

Round barrel

C. Replace due to

missing barb

Replace due to

broken pin

Usable

11 FirstGard Hinge and Band Replacement Instructions

REPLACEMENT

BAND

FIRSTGARD™BAND REPLACEMENT

PARTS NEEDED FOR FIRSTGARD HINGE REPLACEMENT

TOOLS REQUIRED - FLAT BLADE SCREWRIVER, 7/16” WRENCH, PLIERS

Part A.

FirstGard Cone Panels

Quantity - 1

Part B.

Weld Nut

Quantity - 1

Part C.

Nylon Pin

Quantity - 1

Part H.

Band

Quantity - 1

Part I.

Roll Pin

Quantity - 2

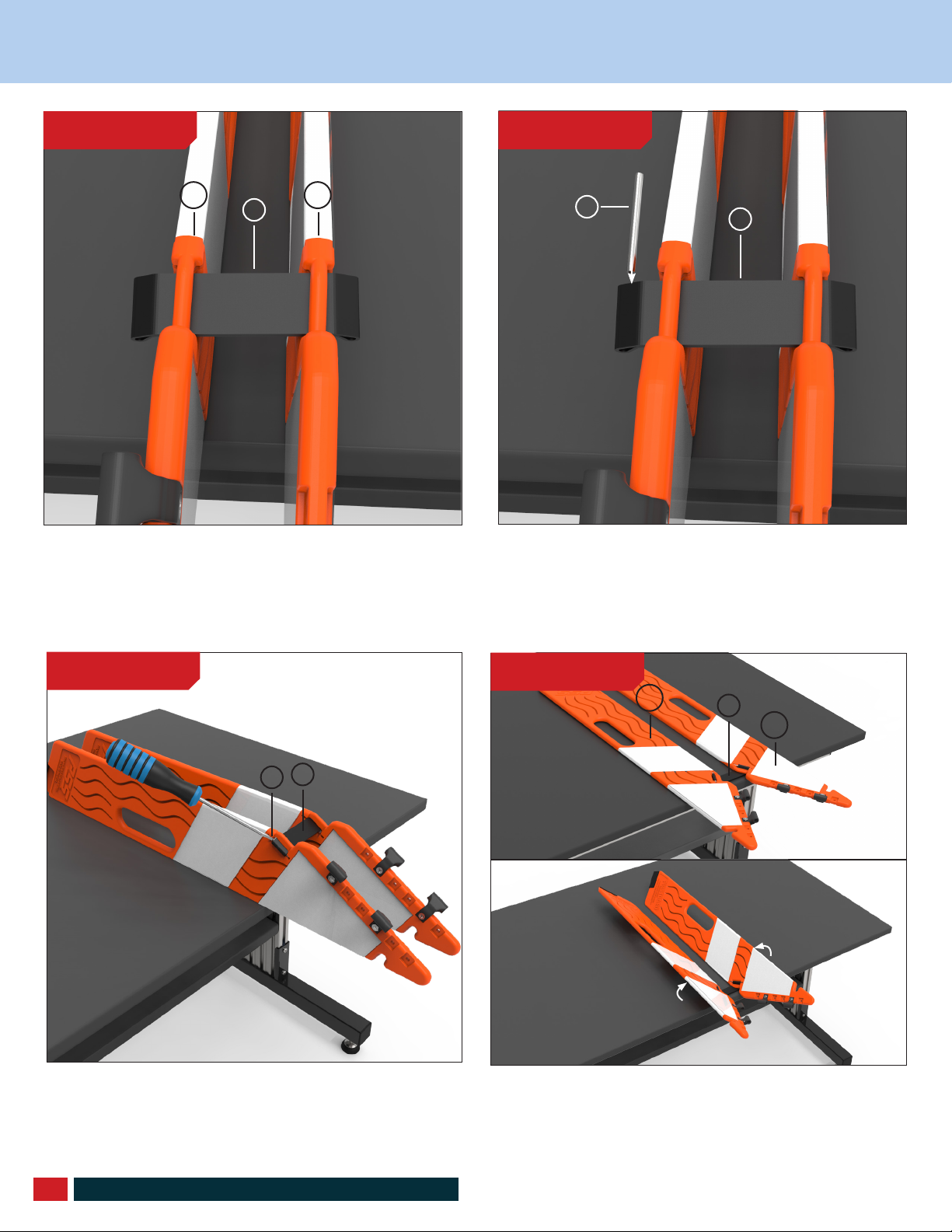

With the nylon pin removed, take out the center panel (A2) and set aside. Allow the two baned panels to lie flat on the table. Note: If your

band is missing, please skip to step 4.

STEP 1

A2.

A2.

A1. A3.

FirstGard Hinge and Band Replacement Instructions 12

Position the two banded FirstGard panels (A1 and A3) so that the

band (H) is facing upward and the hinge components are facing

away from each other.

Slide the roll pin (I) out from the loop of the band (H). Repeat step for for the other panel.

Using a small flat blade screwdriver, push the roll pin (I) through

the back of the panel. Be sure to not press on the band (H) as it

could damage the band.

STEP 2

STEP 4

STEP 3

FIRSTGARD™BAND REPLACEMENT

H.

H. I.

H.

I.

A1. A3.

13 FirstGard Hinge and Band Replacement Instructions

FIRSTGARD™BAND REPLACEMENT

Insert the roll pin (I) into the other side of the band (H). Press the

roll pin into its pocket until it clicks into place. You may need to

press the roll pin with a flat blade screwdriver to fully click it into

place. Be sure to press on the pin itself as pressing on the pin

through the band may damage the band.

STEP 7

Be sure that both roll pins are removed before this step. Hold the

FirstGard panels (A1 and A3) together with the barrels of the hing-

es pointed outward. Thread the band (H) through both slots.

Insert a roll pin (I) into one side of the band (H). Press the roll pin

into its pocket.

STEP 5 STEP 6

H.

H.

H.

I.

I. H.

Fold the two banded panels (A1 and A3) away from each other so

that they lay flat on your work serface and the band is flat. Begin

folding the two banded panels together leaving enough room

for the third panel between. The hinge components and roll pins

should be facing inward.

STEP 8

A1.

A1.

A3.

A3.

FirstGard Hinge and Band Replacement Instructions 14

FIRSTGARD™BAND REPLACEMENT

Lower the disconnected panel (A2) between the two banded

panels (A1 and A3) and close all of the panels together. Align the

round barrel on the hinge components.

Assess if the current nylon pin (C) is intact. If the barbs or pin are

not as shown, using a 7/16” wrench, finger-tighten weld nut (B) on

top of the nylon pin—flange side up. Grip the flange with pliers and

tighten it an additional ¼ turn past finger-tight.

Insert the nylon pin (C) into the barrel of the hinge. The weld nut (B) should be on the top of the cone and the barbs of the nylon pin should

point towards the bottom. Note: Be sure the nylon pin is going through the hinge component’s round barrel rather than the open hinge

cavities.

STEP 9 STEP 10

STEP 11

C. C.

B.

C.

B.

A1.

A2.

A3.

Round barrel

C. Replace due to

missing barb

Replace due to

broken pin

Usable

We are a proud member of:

PSS |2444 Baldwin Road, Cleveland, OH 44104 |800.662.6338 |PSS-Innovations.com |Copyright © 2022 |11/22

Follow us on:

CONTACT:

Call 800.662.6338 to speak with a Customer Service Representative.

HOURS:

8 AM to 5 PM (E.T.)

Monday through Friday

Other PSS Safety Equipment manuals

Popular Safety Equipment manuals by other brands

babcockdavis

babcockdavis BCGVS-EW-P Installation, operation & maintenance manual

OEZ

OEZ CS-BD-A011 Instructions for use

ABS Safety

ABS Safety UniGlide PRO manual

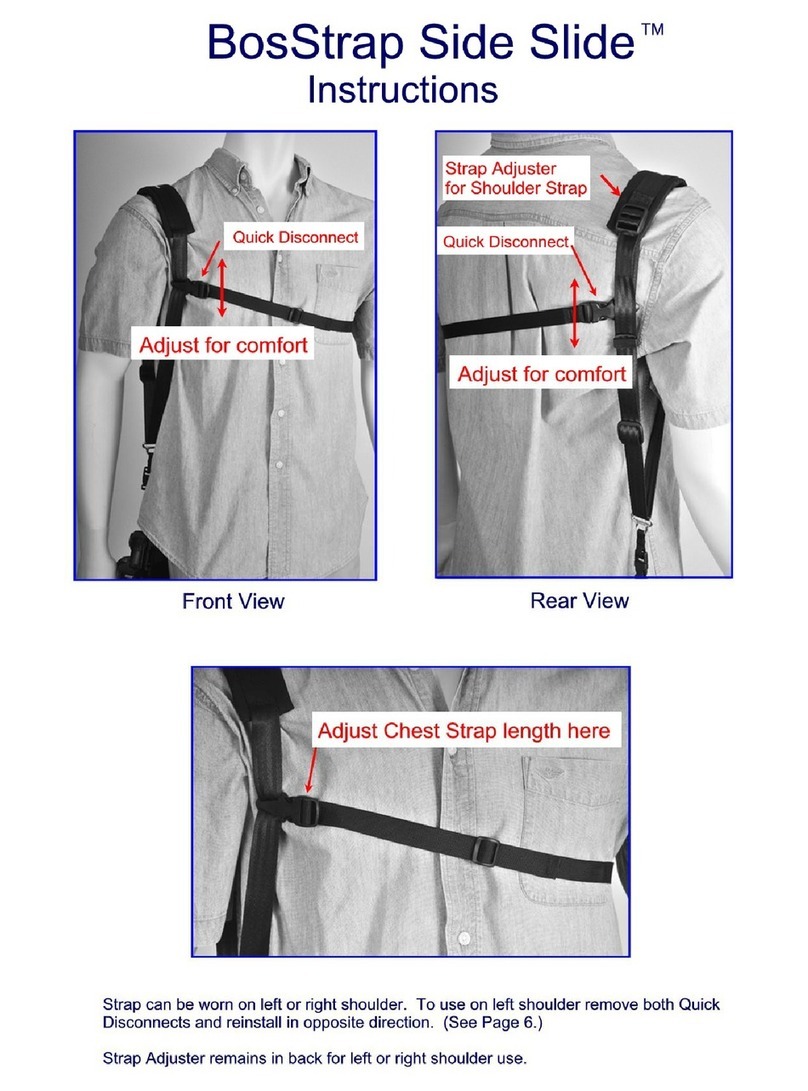

BosStrap

BosStrap Side Slide instructions

Federal Signal Corporation

Federal Signal Corporation QuadraFlare DOT Installation and service instructions

STRUMIN

STRUMIN LiteMESH Technical documentation