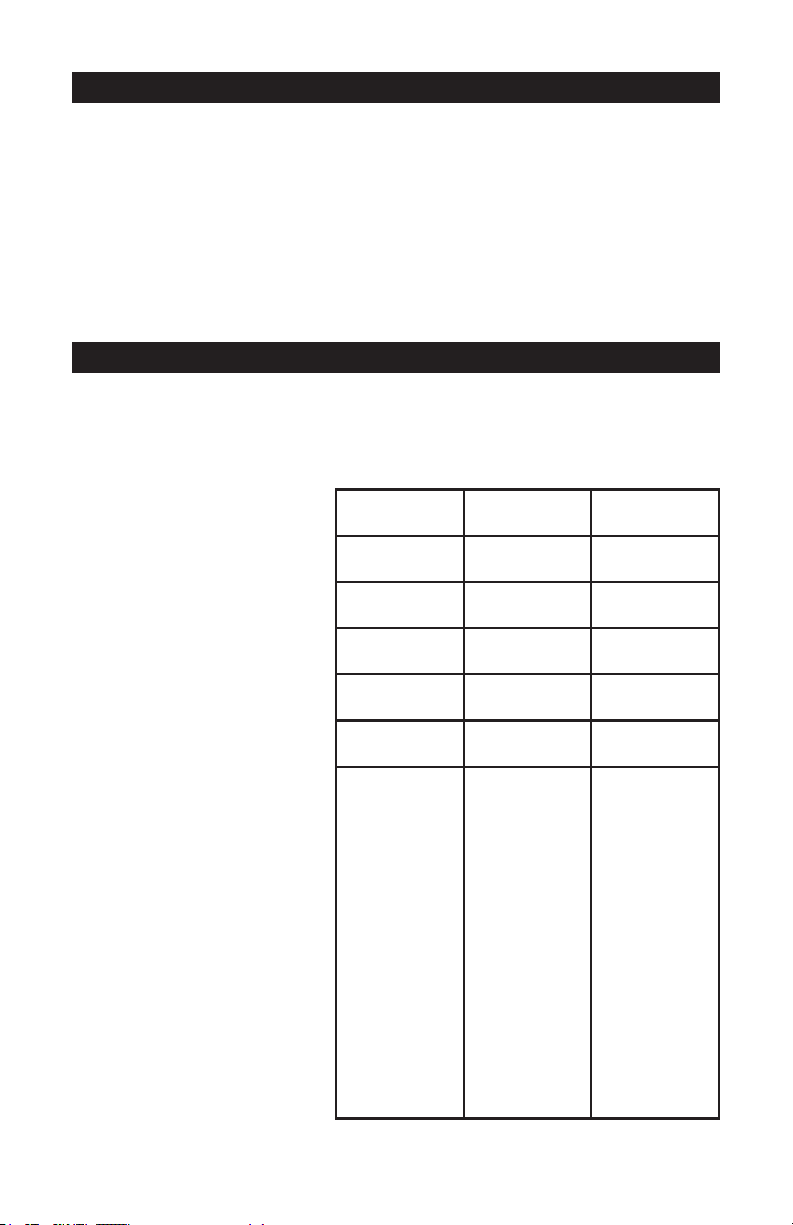

UNPACKING AND INSPECTION

After opening the carton, unpack your new product and related parts and accessories. Please

inspect it carefully for any damage that may have occurred during transit. Please check it against

the photograph on carton. If any parts are missing, please call customer service at 1-800-426-1262

between 6 a.m. and 5 p.m. Pacific time.

WARNING: DO NOT operate this product if damaged during shipment, handling or misuse.

Do not operate the product until the parts have been replaced or the fault rectified. Failure to do

so may result in serious personal injury or property damage. All damaged parts must be repaired

or replaced as needed prior to operating this product. Check to see that all nuts, bolts and fittings

are secure before putting this product into service.

If you have any questions, or require assistance with damaged or missing parts, please contact

our customer service department at 1-800-426-1262. Please have the serial number, model

number, and date of purchase available for reference when calling.

1. Study, understand and follow all instructions

before operating this device.

2. DO NOT exceed rated capacity. Overloading

can cause damage to or failure of this product.

3. Use only on hard, level surface capable of

sustaining the load. Use of jack on other than

hard level surfaces can result in jack instability

and possible loss of load.

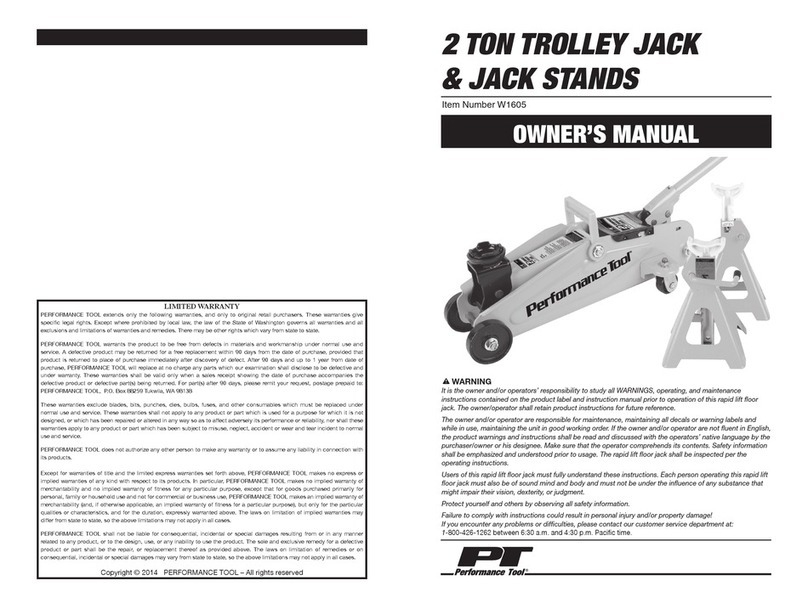

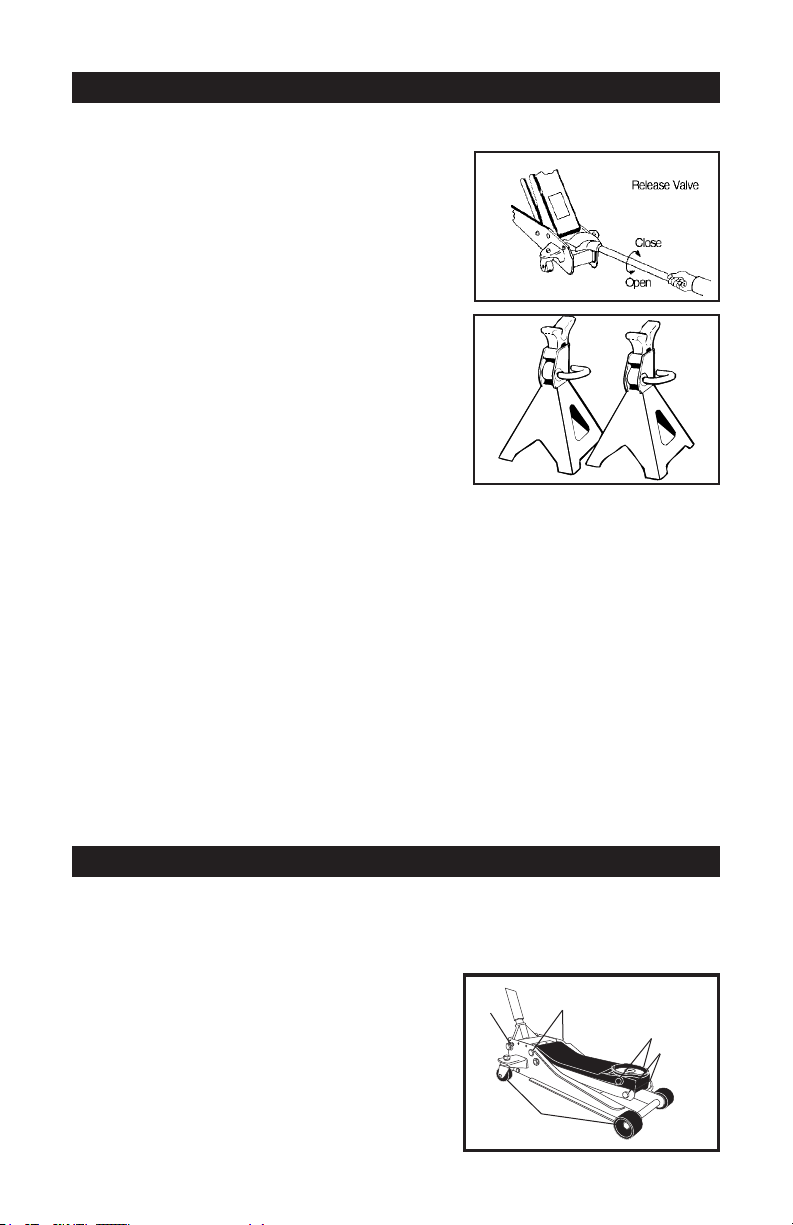

4. Lifting device only. Immediately after lifting,

support the vehicle with appropriate means.

Ensure that no personnel pass underneath

load until load is securely supported by jack

stands.

5. DO NOT adjust safety valve.

6. Wear ANSI approved safety goggles and

heavy duty work gloves during use.

7. Keep clear of load while lifting and lowering.

8. Lower load slowly.

9. DO NOT use for aircraft purposes.

10. Apply parking brake and chock tires before

lifting vehicle.

11. Lift vehicle only at vehicle manufacturer

recommended lift locations.

12. Inspect before every use; do not use if parts

are loose or damaged.

13. Do not alter this product in any way.

14. Keep your work area clean and well lit.

Cluttered work areas invite accidents.

15. Keep bystanders, children, and visitors away

while operating this product. Distractions can

cause you to lose control.

16. Stay alert. Watch what you are doing, and use

common sense when operating this product.

Do not use this product while tired or under

theinuenceofdrugs,alcoholormedication.

17. Store idle jacks out of reach of children and

other untrained persons. Jacks are dangerous

in the hands of untrained users.

18. Tool/equipment service must be performed

onlybyqualiedrepairpersonnel.Serviceor

maintenanceperformedbyunqualied

personnel could result in a risk of injury.

19. When servicing this product, use only

identical replacement parts - refer to attached,

product-specicpartslistanddiagram.Follow

instructions in the Care & Maintenance

section of this manual. Use of unauthorized

parts or failure to follow maintenance

instructions may create a risk of injury and

may void any applicable warranty.

20. Maintain labels and nameplates on this

product. These carry important information. If

unreadable or missing, contact Performance

Tool for a replacement.

21.Beforeuse,readmanufacturer’sinstruction

manual for the vehicle (or object) you will lift.

22. When lifting only one wheel, support the load

immediately with one jack stand (not included)

placed under the side of the vehicle being

lifted. Align the saddle of the jack stand

directlyunderthevehicle’sframeor

recommended lifting point.

23. When lifting the entire front end or rear end

of a vehicle, support the load immediately

with two jack stands. Align the saddles of the

jackstandsdirectlyunderthevehicle’sframe

or recommended lifting points. Also, adjust the

jack stands to the same height.

24. Do not work under the vehicle without properly

supporting the vehicle with jack stands.

25.Avoiddangerousoncomingtrafc.Usethe

Jack as far away from the roadside as possible.

26. Industrial applications must follow OSHA

requirements.

27. Do not allow anyone inside the vehicle while

using the Jack. Keep all bystanders a safe

distance away from the vehicle.

28. Do not support both ends of the vehicle at the

same time.

29. Before lowering the jack, remove all tools and

equipment from under the vehicle.

30. The warnings, precautions, and instructions

discussed in this manual cannot cover all

possible conditions and situations that

may occur. The operator must understand that

common sense and caution are factors, which

cannot be built into this product, but must be

supplied by the operator.

WARNING: This is a lifting device only. Load must be supported immediately by jack stands.

IMPORTANT SAFETY INFORMATION

3