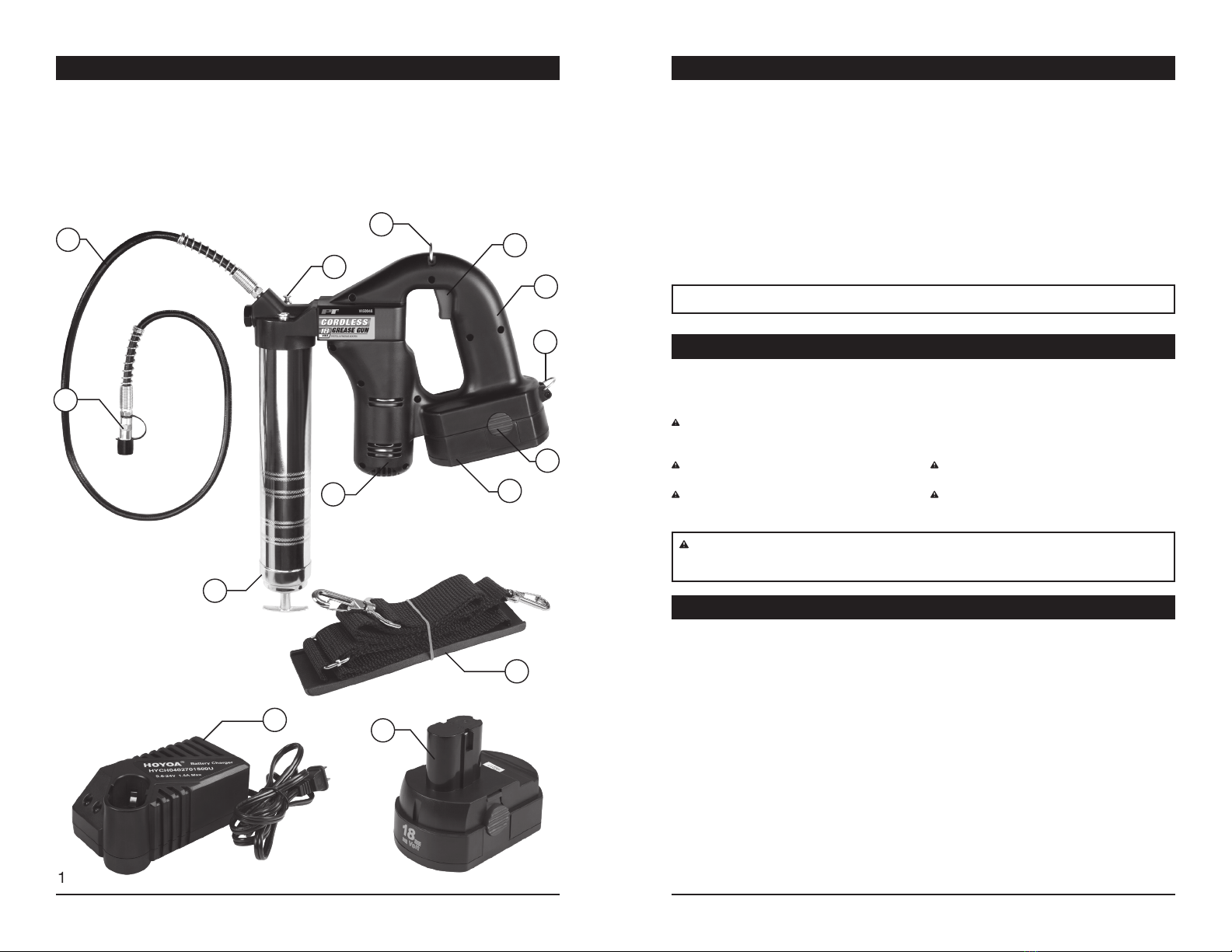

3 4

IMPORTANT SAFETY INFORMATION

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep Control the

tool, personal movement and the work environment to avoid personal injury or damage to the

tool. Stay alert, watch what you are doing and use your common sense.

• Keep articles of clothing, jewelry, hair, etc., away from moving parts to avoid entanglement.

• Do not operate any machine / tool when tired or under the influence of drugs, alcohol or

medications.

• Do not overreach when operating a tool. Proper footing and balance enables better control of

a tool in unexpected situations.

• Use clamps or other practical ways to support or secure the work piece to a stable platform.

Holding the work piece by hand or against your body is not stable and may lead to loss of

control and injury.

WARNING! The grease gun can develop high pressure, up to 8,000 PSI. Use safety glasses

and gloves for protection during operation. Keep hands clear of the exposed rubber portions of

the hose. Replace hose if there is any sign of damage or excess ware.

WARNING! Extreme pressure may cause the nozzle extension or flex hose to burst. Use only

approved hoses and follow whip instructions and warnings

• Always wear fuel and oil-resistant gloves when working with fluids.

• Do not store the tool under extreme conditions.

• Do not adapt the tool for any other purpose than what it was originally intended for.

• When operating the tool, use proper eye and hearing protection as well as protective gloves.

• To maintain complete control, firmly hold your tool with both hands.

• Never point the tool towards yourself.

• Never force the tool. Excessive pressure could bend or break the tool or accessory, resulting

in damage to the tool, your work piece or serious personal injury.

•

Do not use the battery charger in damp or wet locations. Do not use the grease gun or charger

if it has been dropped, damaged, left outdoors, or immersed in liquid. To avoid electrical shock,

do not handle the charger, its power cord plug or the grease gun with wet hands.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is left

attached may result in personal injury.

• Disconnect the power source supply or battery block before changing accessories or before

storing the tool. These preventive safety measures reduce the risk of accidental starting of

the tool.

• Protect yourself against electric shocks when working on electrical equipment. Avoid body

contact with grounded surfaces such as pipes, radiators, cooking stoves and refrigerators.

There is an increased chance of electrical shock if your body is grounded.

BATTERY CHARGER SAFETY INFORMATION

1. A battery operated tool with internal batteries or a separate battery pack must only be

powered by the included battery. Do not, for instance, mix different brands of tools and

batteries or use adapters to allow you to use a battery pack with a different voltage. Using

another battery pack could cause a fire.

2. Batteries must only be recharged with the included charger. A charger that may be suitable

for one type of battery could cause a fire when used with another battery.

3.Setthetool’striggerswitchtotheOFFpositionbeforeinstallingorremovingthebatterypack.

This will prevent injury due to accidental starts.

4. Do not use the battery charger in damp or wet locations.

5. Do not store battery packs in containers / spaces with loose metal objects. Battery pack

terminals could be short circuited if they come into contact with metal objects. In addition to

damaging the battery pack, you increase the risk of a fire.

NOTICE: Before using your tool for the first time, discharge the battery and then charge the

battery pack completely.

WARNING! Never burn batteries, as they can explode in a fire. Do not charge leaking batteries.

Only a qualified service technician should perform maintenance on the battery pack. Contact local

solid waste authorities for instructions on correct disposal or recycling of the battery pack.

WARNING: Do not use the tool if the trigger does not function properly. Any tool that cannot

be controlled with the ON / OFF switch is dangerous and must be repaired.

1. Use the correct tool for the job. Maximize tool performance and safety by using the tool for its

intended task.

2. Do not modify this tool or use for a purpose for which it was not designed.

3. This tool was designed for a specific function.

DO NOT:

a. Modify or alter the tool; all parts and accessories are designed with built-it safety features that

may be compromised if altered.

b. Use the tool in a way for which it was not designed.

UNPACKING

1. Carefully remove the tool from the package.

2. Retain packing material until you have carefully inspected and satisfactorily installed or

operated the tool.

3. Inspect the parts carefully to make sure the tool was not damaged while shipping.

CHARGER OPERATION

1. Insert the battery pack into the charging socket of the charger. Then, plug the charger into the

nearest grounded, electrical outlet. The battery is charging when the green light is illuminated

and the red light goes out.

NOTICE:

Make sure the power circuit voltage is the same as that shown on the charger

specifications plate.

2. Before using the grease gun for the first time, be sure to discharge the new battery before

charging. All new rechargeable batteries come with 80% charge from the factory. If the

battery pack is installed in the gun, remove it by depressing the two battery release buttons

(one button on each side of the battery pack) and pull the battery pack out of the gun.

3. As a battery pack approaches the discharged state, you will notice a sharp drop in tool

performance. When the tool is unable to perform the task at hand, it is time to recharge the

battery pack. Recharging the battery pack before this condition is reached will reduce the

total work life of the pack. Discharging the pack beyond this point can damage the pack.

4. Start the charging process by plugging in the battery charger to the power source and

inserting the battery into the battery charger slot. After the charging process is complete

(approximately 1 hour), the green light will go out and the red light will illuminate. Remove the

charger from the wall outlet and disconnect the battery pack.

NOTICE:

Battery temperatures will increase during and shortly after use. Batteries may not

accept a full charge if they are charged immediately after use. Allow the battery pack to cool to

room temperature before charging for the best results.

INSTALLING GREASE CARTRIDGE

1. Depress the follower key and pull back on the follower handle. Until the follower rod is fully

extended (approximately 8 in. or 20 cm).

NOTICE: It may be necessary to loosen the grease tube assembly in order to break the vacuum seal.

2. Identify the style grease cartridge you have, paper or plastic. One end will have a replaceable

cap that exposes the grease. The other end will have a pull tab or foil seal

3. Remove the replaceable cap from the end of the grease cartridge. Insert that end into the

grease gun barrel. It should rest on the rubber plunger at the bottom of the barrel.

4. Remove the pull tab or foil from the exposed end of the cartridge.

5. Depress the follower key and push the follower rod forward into the grease tube assembly.

Purge the air from the head.

CARE AND MAINTENANCE