SPECIFICATIONS

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Don not expose to rain. Keep work area well lighted. Do not use electrically powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let them handle machines, tools, extension cords, or air hoses.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit rust. Always lock up tools and keep out of reach of children.

5.

Use the right tool for the job. Do not attempt to force a small tool or attachment to do the work of a larger industrial tool. There are certain applications for which this tool

was

designed. It will do the job better and more safely at the rate for which it was intended. Do not modify this tool and do not use this tool for a purpose for which it

was

not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

7. Use eye protection. Always wear ANSI approved impact safety goggles when working, when performing maintenance, and when replacing the hose.

8. Do not over reach. Keep proper footing and balance at all times. Do not reach over or across running machines or air hoses.

9. Maintain tools with care. Keep tools clean for better and sager performance. Follow instructions for lubricating and changing accessories. Special tool cords and air

hoses

periodically and, if damaged, have them repaired by an authorized technician. The handles must be kept clean, dry and free from oil and grease at all times.

10. Disconnect air supply. Disconnect air hose when not in use.

11. Stay alert. Watch what you are doing. Use common sense. Do not operate any tool when you are tired.

12. Check for damaged parts. Before using any tool, any part that appears damaged should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts or mounting fixtures; and any other condition that may affect proper operation.

Any

part that is damaged should be properly repaired or replaced by a qualified technician.

13. Guard against electric shock. Prevent body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerator enclosures.

14. Replacement parts and accessories. When servicing, use only identical replacement parts. Use of any other parts will void the warranty. Only use accessories intend-

ed

for use with this tool Approved accessories are available from Performance Tool.

15. Do not operate tool under the influence of alcohol or drugs. Read warning labels if taking prescription medicine to determine if your judgement or reflexes are impaired

while taking drugs. If there is any doubt. Do not operate the hose reel.

16. Maintenance. For your safety, maintenance should be performed regularly by a qualified technician.

17. Compressed air only. Never use combustible gases as a power source.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be

under stood by the operator that common sense and caution are factors which can not be built into this product, but must be supplied by the operator.

WARNING: The brass components of this product contain lead, a chemical known to the State of California to cause birth defects (or other reproductive harm). (California

Health & Safety code 25249.5. et seq.)

When unpacking, check to make sure the parts listed on page 4 are included.

If any parts are missing or broken, please contact Performance Tool.

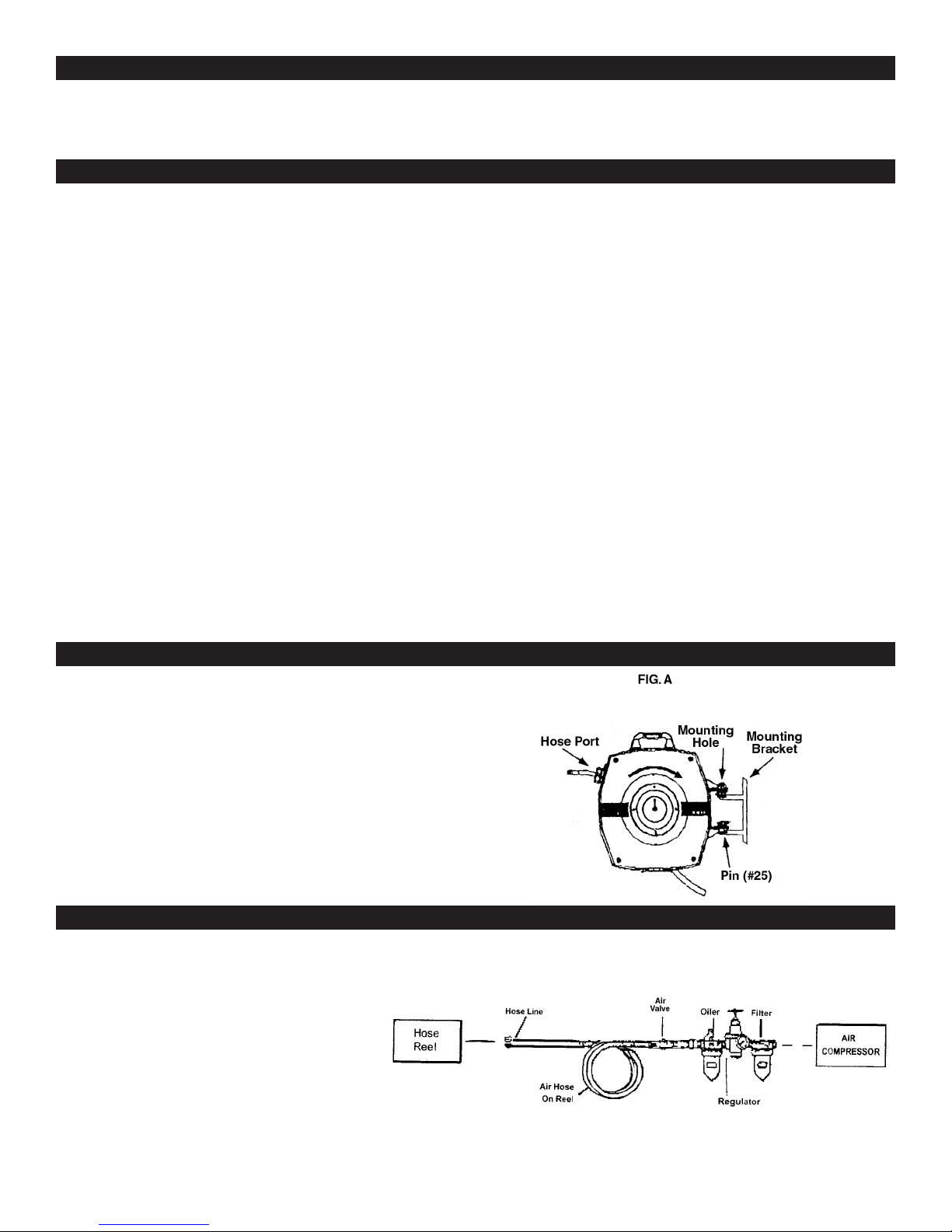

1. Before attaching the Mounting Bracket (#11), make

sure the mounting surface is capable of supporting the

weight of the hose reel and hose, and can withstand

the stress of pulling and retracting the hose.

2. Secure the Mounting Bracket (#11) to the mounting

surface with four lag bolts (Not included). Make sure the

mounting surface is solid. If going through sheet rock,

it must have studs for the bolts to penetrate.

3. Mount the Hose Reel so that the Hose port is facing

up as shown in Figure 1.

4. Guide the Pins (#25) into the holes on the Mounting

Bracket (#11) until they snap into place. To remove the

Hose Reel, gently lift up on the Hose Reel to separate

it from the Mounting Bracket (#11) and pull it away from

the bracket.

1. You will need to prepare an air connector (not included)

to connect to the air inlet on the Supply Hose (#22) of

the Hose Reel. First, Wrap the air connector (not included)

with pipe thread seal tape before connecting to a

3/8 in. I.D. Air Source Hose (not included). Connect the

Air Source Hose to the Hose Reel.

2. Follow the same instructions for preparing the end of the

tool hose (#19)

Note: If you are not using an automatic oiler system,

before operation, add a few drops of Pnuematic Tool Oil

to the airline connection. Add a few drops more after each

WARNING: When using tools basic safety precautions should always be followed to reduce the risk of personal injury and damage to equipment.

OPERATION

UNPACKING & INSTALLATION

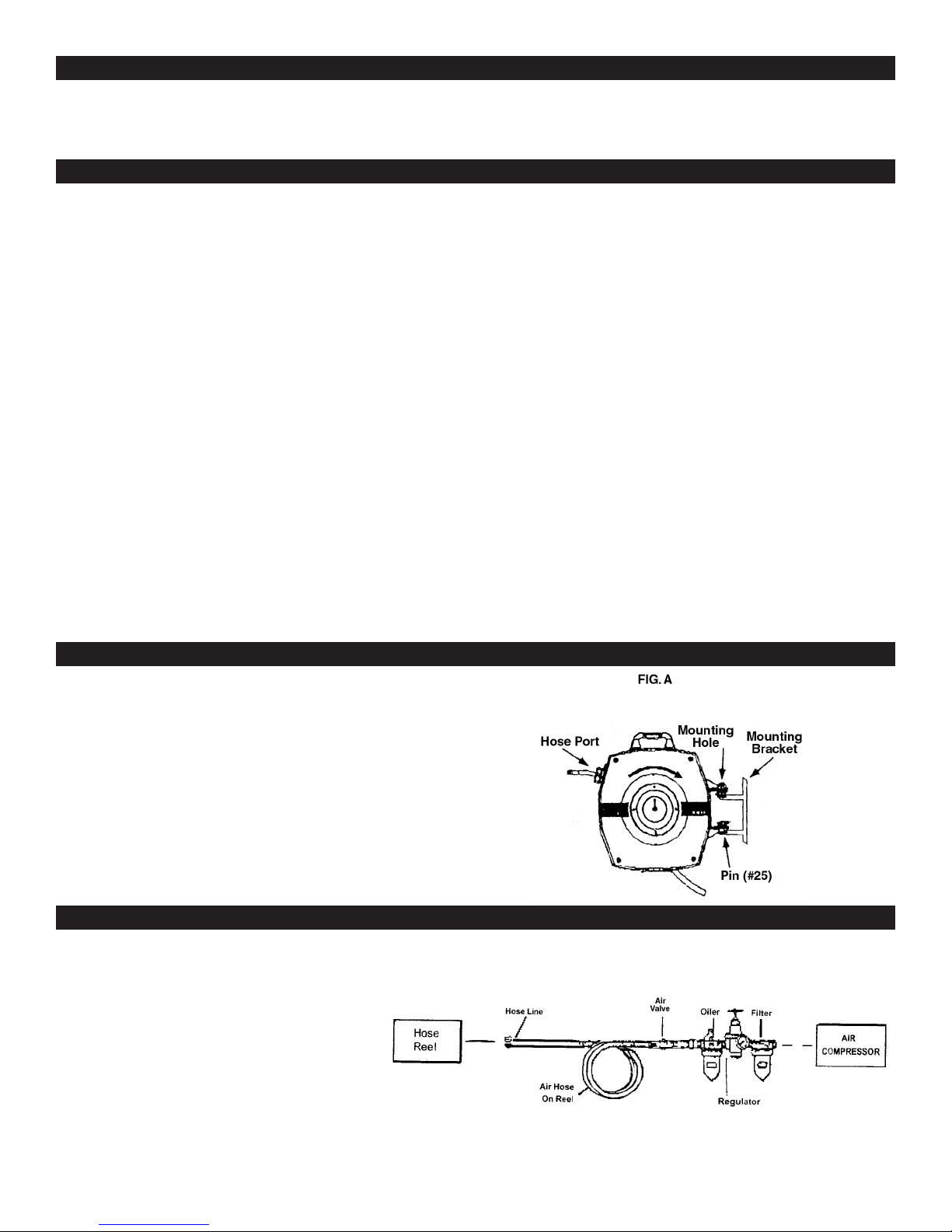

For best service you should incorporate an oiler, regulator,

and inline filter as shown in the diagram below.

SAFETY, WARNINGS & PERCAUTIONS

Maximum Working Pressure ....................................................300 PSI

Burst Pressure..........................................................................900 PSI

Air Outlet ............................................................3/8 in. - 18 Male NPT

Air Inlet ...............................................................3/8 in. - 18 Male NPT

Hose Dimensions ........................................................... 50 ft. x 3/8 in.

Inlet Hose ........................................................................ 36 in. Length