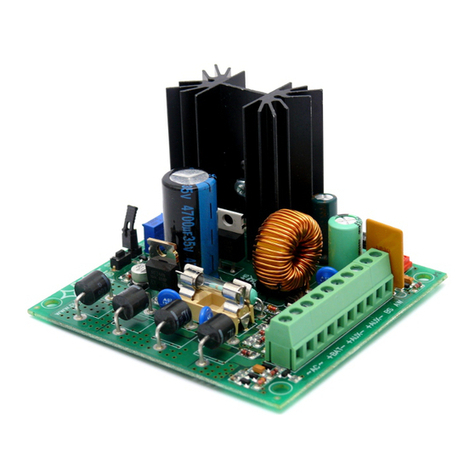

Module MPSB48 (technical outputs)

2-nd enviromental class, temperature: -10 oC÷40 oC

relative humidity 20%...90%, without condensation

Protection class EN 60950-1:2007

I (first) - requires a protective conductor (PE)

power-supply: Φ0,63÷2,5 I/O PCB: Φ0,41÷1,63

battery output BAT: 6,3F-2,5/40cm,

output of optical signalization: plug 3-pin 5 mm

Electrical strength of insulation:

- between input (network) circuit and output circuits

of power-supply (I/P-O/P)

- between input circuit and PE protection circuit (I/P-

FG)

- between output circuit and PE protection circuit

(O/P-FG)

3000 V/AC min.

1500 V/AC min.

500 V/AC min.

Insulation resistance:

- between input circuit and output or protection

circuit

Vibrations and impulse waves during transport

according to PN-83/T-42106

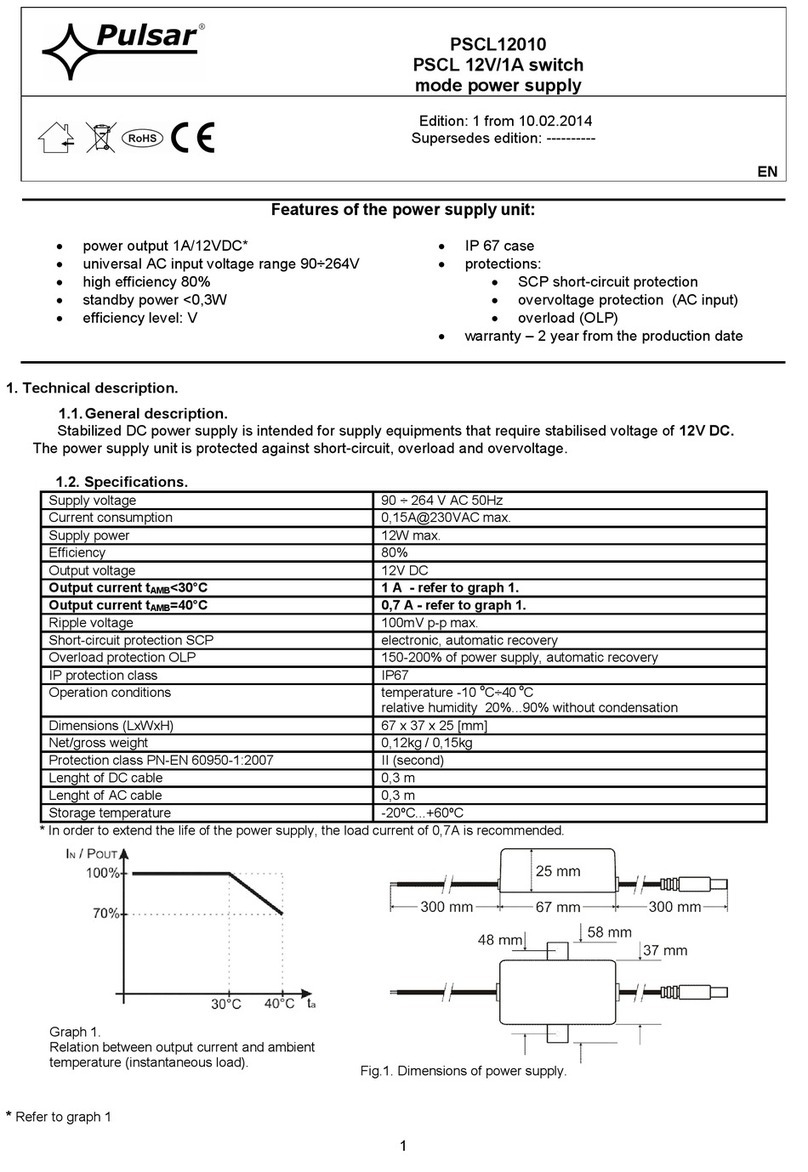

1.3. Output current vs temperature.

Chart 1.

Allowable output current from the power

supply depending on ambient temperature.

2. Installation.

2.1. Requirements.

The buffer power supply shall be mounted by the qualified installer having appropriate (required and necessary

for a given country) permissions and qualifications for connecting (operating) 230V/AC installations and low voltage

installations. The device shall be mounted in closed rooms, according to the environment class II, of the normal air

humidity (RH=90% max. without condensation) and the temperature within the range from -10°C to +40°C.

The power supply shall be mounted in a close casing (a cubicle, a terminal device) and in order to fulfill LVD and

EMC requirements the rules for power-supply, encasing and shielding shall be observed according to application.

Due to the power supply design, the PE wire has to be connected to the corresponding connector of the

supply unit.

Prepare the power supply loading balance before installation. Under normal operation, the total current

drawn by the device may not exceed I=1A. Maximum battery charging current 0,3A. Total device current + battery

1,3Amax.

2.2. Installation procedure.

1. Before beginning installation, ensure that the power in the 230V AC power supply circuit is disconnected.

2. Install the unit in the previously selected place.

3. Connect the 230VAC power leads. Connect the PE cable (yellow-green) to an appropriate terminal on the

power supply unit (marked with ).

See chart 1