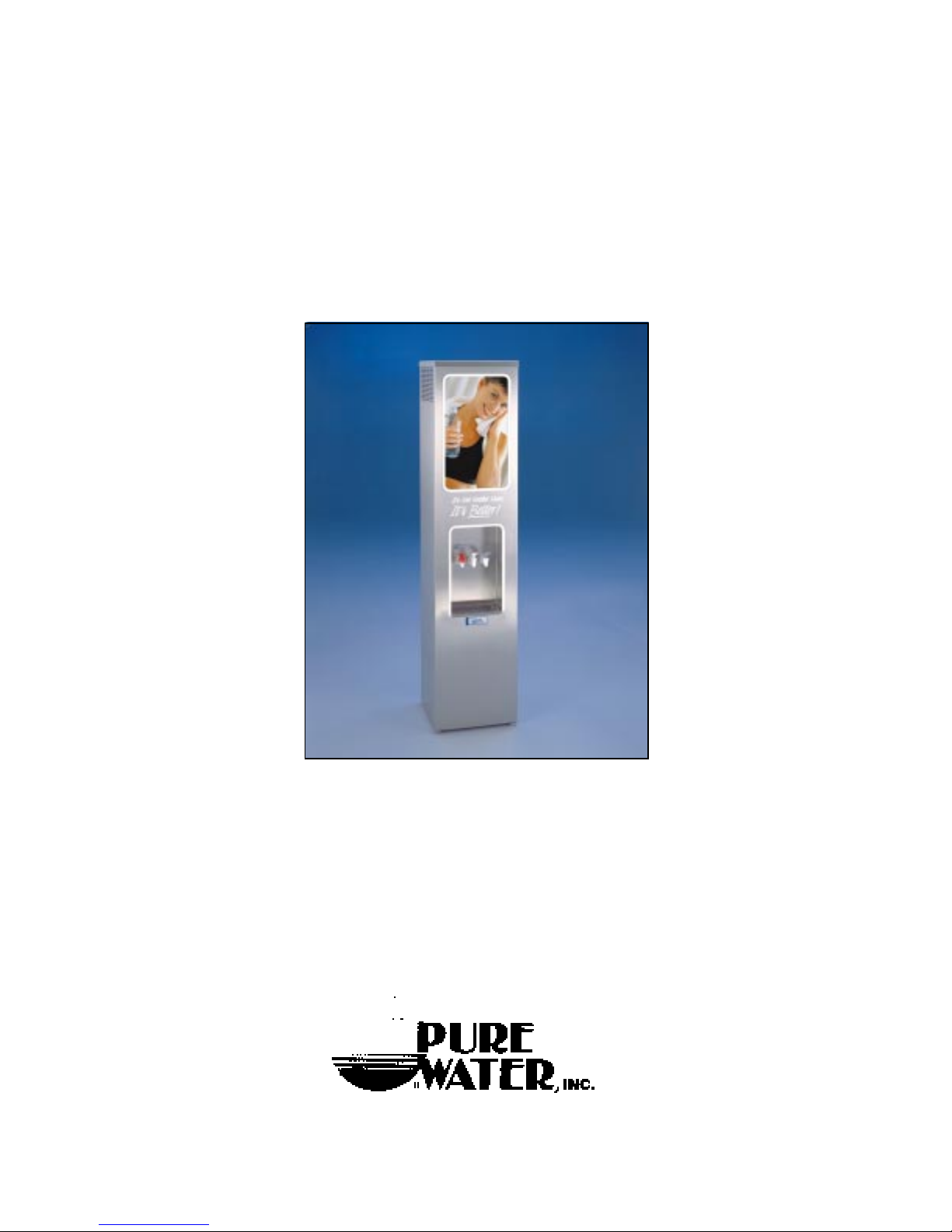

Fountain Classic Owner’s Manual Page 7

12. Post FilterPost Filter

Post FilterPost Filter

Post Filter—The carbon filter enhances the flavor of the distilled water

before it enters the storage tank.

13. Distilled Water Storage TankDistilled Water Storage Tank

Distilled Water Storage TankDistilled Water Storage Tank

Distilled Water Storage Tank—This tank holds distilled water for use

through any of the water spigots. This tank contains floats that turn the

distiller off when full, and turns the distiller back on when the tank is 1/3

empty.

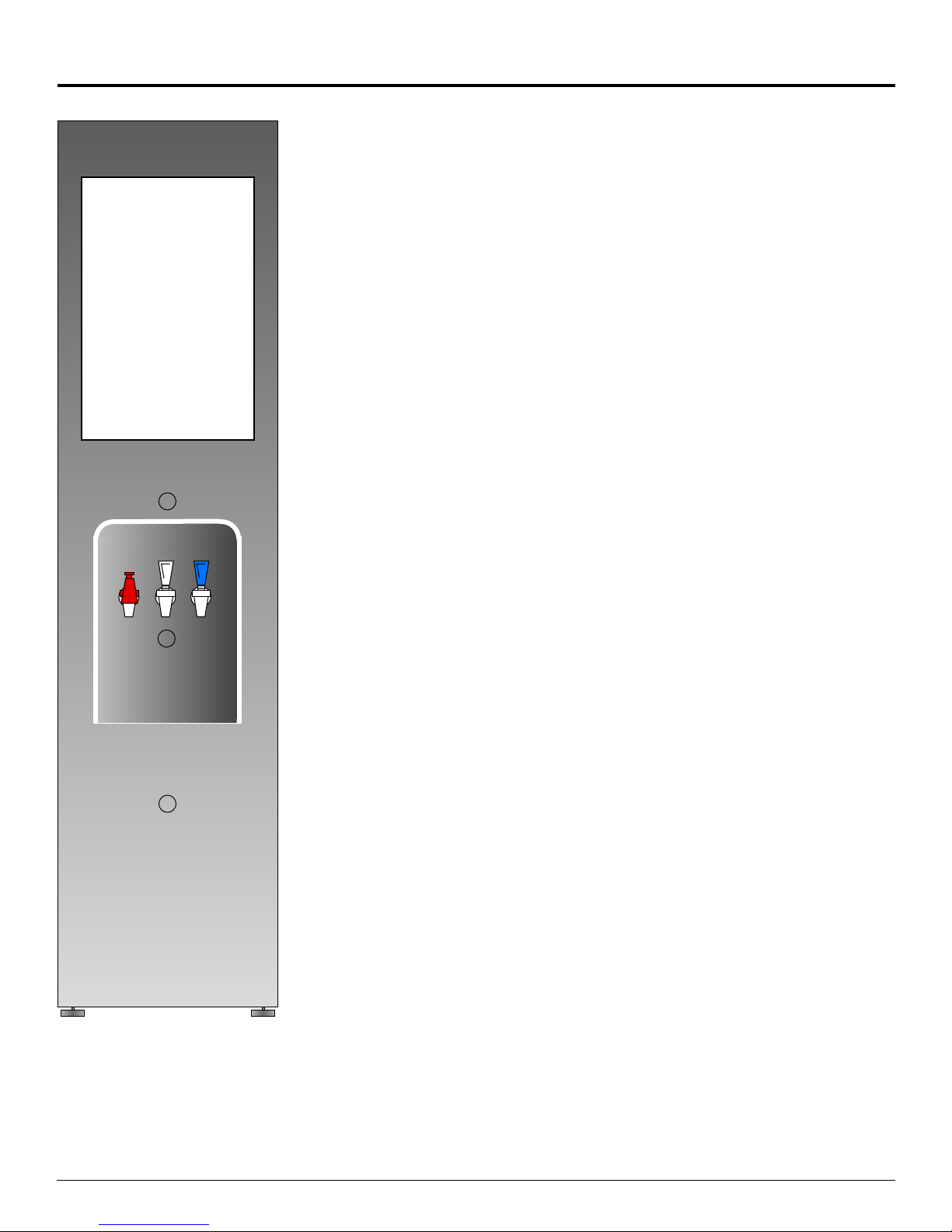

14. Water Dispenser SectionWater Dispenser Section

Water Dispenser SectionWater Dispenser Section

Water Dispenser Section—This section is composed of either two or three

main sections, depending on your unit:

a. The hot water tank holds up to 3/8 gallon, and quickly heats the water

for use at the hot water spigot. The hot water temperature is adjust-

able from 140˚F to 190˚F. (Three temperature unit only)

b. The cold water tank holds up to 3/4 gallon, and chills the water for use

at the cold water spigot. The cold temperature is adjustable from 40˚F

to 50˚F.

c. The reservoir holds up to 9.25 gallons for use at the room temperature

water spigot. The water is at room temperature.

15. Dispenser Hot Water Switch*Dispenser Hot Water Switch*

Dispenser Hot Water Switch*Dispenser Hot Water Switch*

Dispenser Hot Water Switch*—This switch allows the dispenser to heat the

water for the hot water spigot.

Important:Important:

Important:Important:

Important: This switch must be in the OFF position until the storage tank

is filled the first time.

*Three temperature unit only

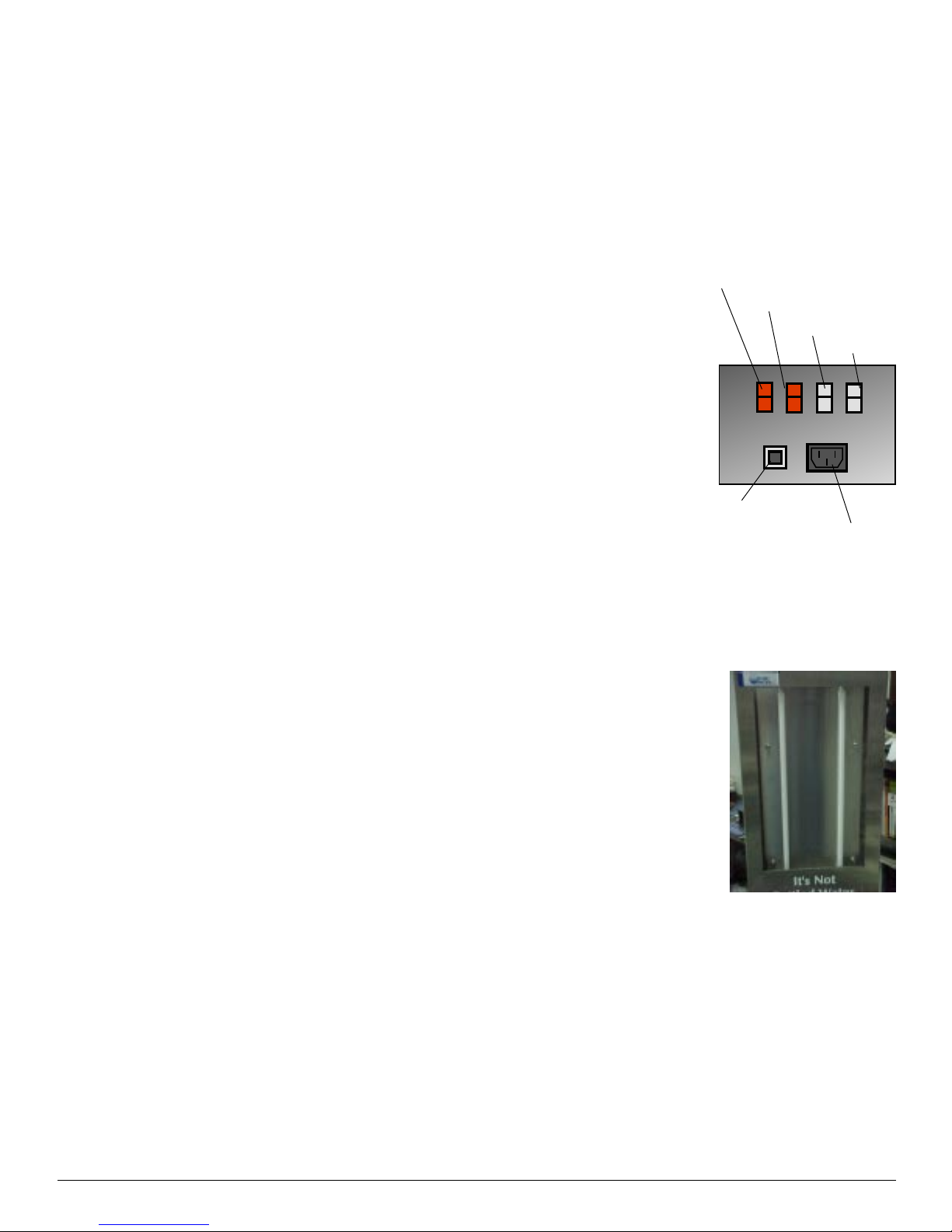

16. Main Electrical Control BoxMain Electrical Control Box

Main Electrical Control BoxMain Electrical Control Box

Main Electrical Control Box—This electrical

box has all of the controls for the unit.

Distiller Power SwitchDistiller Power Switch

Distiller Power SwitchDistiller Power Switch

Distiller Power Switch—Controls the power for

the distillation unit.

Cooler Power SwitchCooler Power Switch

Cooler Power SwitchCooler Power Switch

Cooler Power Switch—Controls the power to

the cooler and hot tank.

Light Power SwitchLight Power Switch

Light Power SwitchLight Power Switch

Light Power Switch—Turns the lighted display

panel on the front of the unit on.

Fan Power SwitchFan Power Switch

Fan Power SwitchFan Power Switch

Fan Power Switch—This switch is used to either

Steam Sterilize (when the switch is off), or distill (when the switch is on).

Steam Sterilizing instructions are found on page 10.

Circuit BreakerCircuit Breaker

Circuit BreakerCircuit Breaker

Circuit Breaker—This breaker provides electrical circuit protection for the

unit.

Plug AdapterPlug Adapter

Plug AdapterPlug Adapter

Plug Adapter—This plug provides power for the entire unit through the

power cord.

17. Emergency Overflow FloatEmergency Overflow Float

Emergency Overflow FloatEmergency Overflow Float

Emergency Overflow Float—Turns the unit off automatically if water fills the bottom pan.

7

9

8

6

16

5

4

15

14

13

10

12

11

17

Circuit Breaker

Distiller

Power

Cooler

Power Light Fan

Plug Adapter