3Copyright © Puretec Pty Ltd 2021 SOL-E3 Commercial Series User Guide

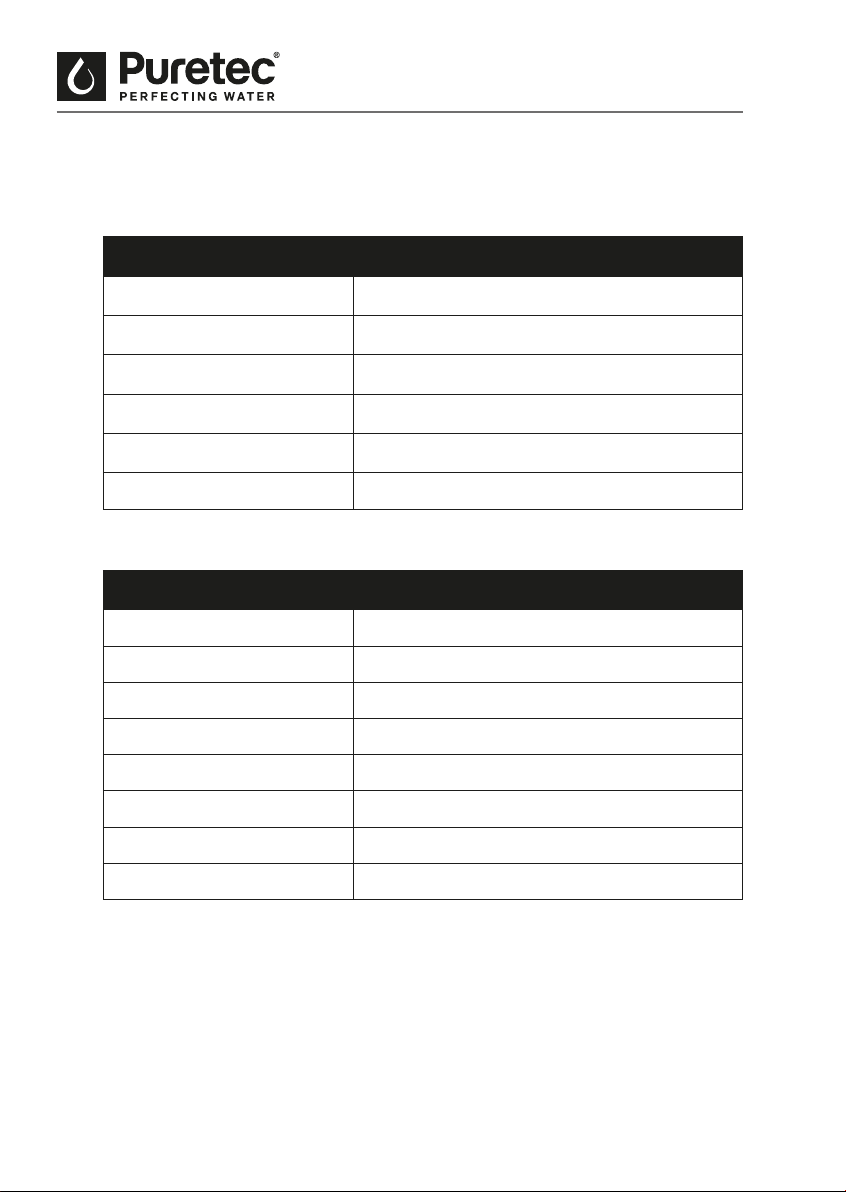

Puretec Customer Service

Puretec Customer Service

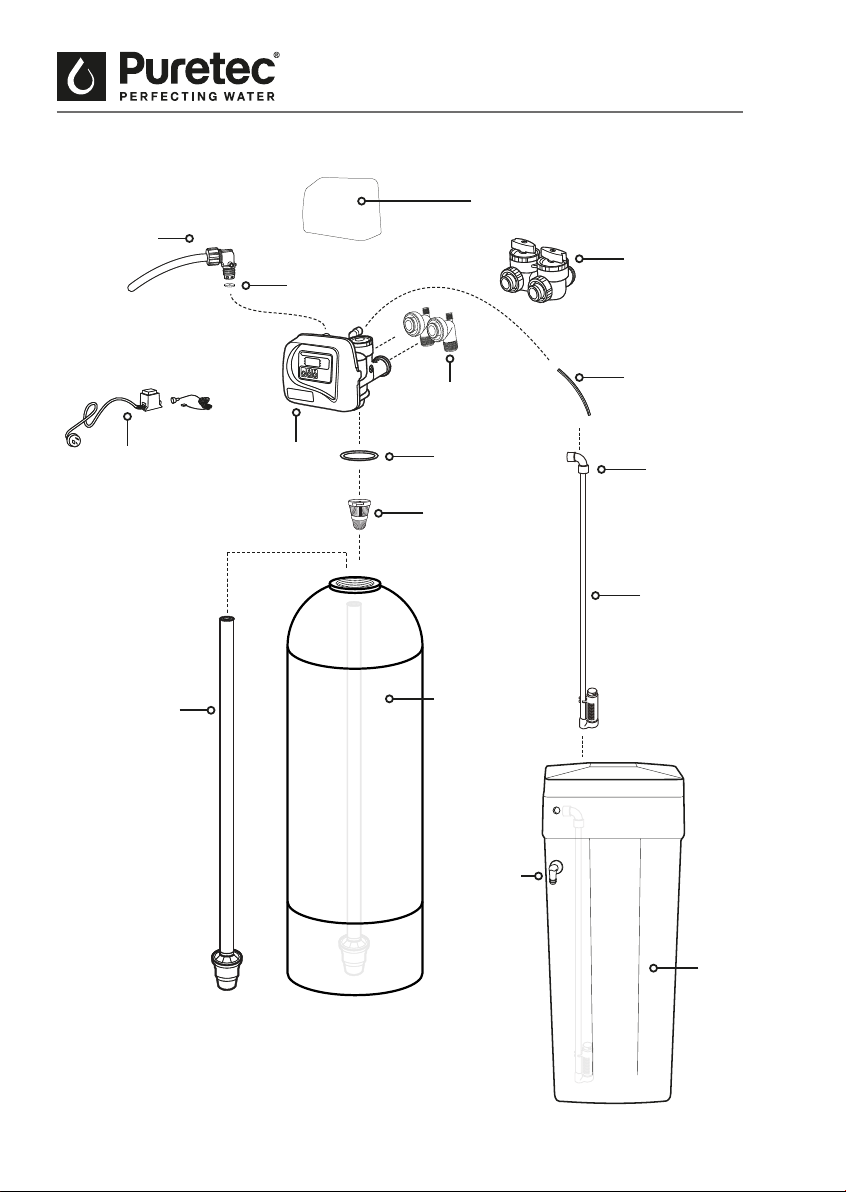

Thank you for purchasing a Puretec Sorol Volumetric Water Soening System. Your

system is a proven performer manufactured from only quality materials and components.

It will give years of reliability and trouble free operation if maintained properly.

This user guide is designed for Puretec SOL-E3 Water Treatment Systems. Be careful to

ensure the information and illustration is applicable to your particular unit.

Caution: Do not use with water that is microbiologically unsafe or without

adequate disinfection before or aer the system.

The systems are designed for metropolitan supply water but can be used in other

situations. For other types of water supply, please contact your local Puretec dealer.

Puretec Water Soeners are designed to run economically for many years, dependent on

the initial installation and periodic maintenance.

Flush system for 5 minutes or more, aer any period of non-use, more than 2 weeks.

Note: For point of entry installations an approved dual check backow prevention device

must be installed.

When line pressure exceeds 500 kPa, a pressure limiting valve must be installed.

Note: Water soener salt not supplied.

Installation Note: A water lter system/tap, like any product, has a limited life and may

eventually fail. Also sometimes failure happens early due to unforeseen circumstances.

To avoid possible property damage, this product should be regularly examined for

leakage and/or deterioration and replaced when necessary. A drain pan, plumbed to an

appropriate drain or outtted with a leak detector, should be used in those applications

where any leakage could cause property damage, and/or the water supply should be

turned o if no one is home/present.

INSTALLATION SHOULD BE COMPLETED BY QUALIFIED TRADESPEOPLE. FAULTY

OPERATION DUE TO UNQUALIFIED PERSONS WILL RESULT IN VOIDED WARRANTY

COVERAGE.

Warning: Chlorine (free chlorine) tolerance is 1ppm - high chlorine levels permanently

damage the soening resin & is not covered under warranty. If chlorine exceeds this

limit, we recommend a carbon pre-lter such as the WH2 or CFS Series. Please refer to

Puretec for a specic recommendation. In any case, a carbon pre-lter is recommended

to protect against chlorine spikes & prolong the resin life.