2.0 General Overview

The PushCorp, Inc. SWS100 Series Servo Weld Shaver provides a fast and effective

means to accurately remove excess material from a surface. The Weld Shaver is

designed to remove random, inconsistent surface features such as seam welds, parting

lines, and flashing, leaving behind a known, consistent, smooth surface. The SWS100 is

ideal for use in applications where force-based, abrasive-only operations fail. Using the

SWS100 can produce significant cost savings since one set of inserts can often out last

hundreds of abrasive disks. A large selection of replaceable Carbide cutting inserts are

used to literally peel metal away. The Weld Shaver/AFD combination forms a unique

system where force control and positioning are used to perform accurate machining

operations with a robot.

The SWS100 enables accurate surface machining by utilizing Tracking Wheels to follow

over the part surface profile. An appropriate Adjustable Force Device is used to hold the

Tracking Wheels firmly against the part surface. This arrangement allows the Weld

Shaver to maintain contact with complex surfaces while compensating for any robot/part

misalignment.

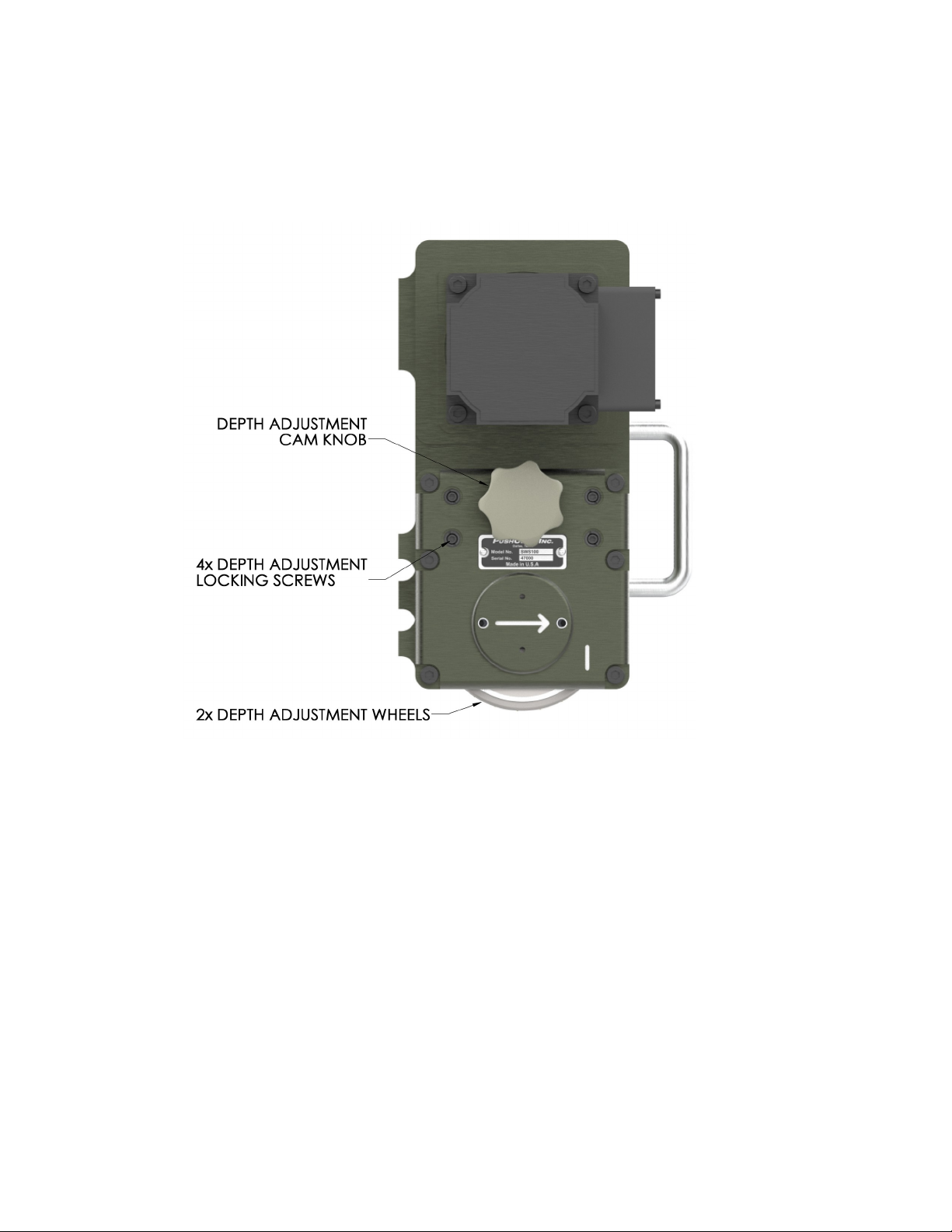

The SWS100 is comprised of two primary components: a Slot Cutter assembly, and a

high torque Servo Motor. PushCorp offers two variations of weld shavers differentiated

by their horsepower: 3.7HP and 7. HP; the overall structure of the two variations are

similar and only differ in height and torque. For each variation of shaver, PushCorp offers

a manually and remote method of adjusting the cutter height relative to the parent

material.

The machining operation is performed by a 5 inch (1 5mm) diameter Sandvik Coromill®

331 Slot Cutter with replaceable Cutter Inserts. Each Slot Cutter is capable of machining

a 0mm wide path. The SWS100 Series Weld Shavers may be configured with one, two,

or three Slot Cutters allowing a width of cut ranging from 0mm to 59mm. The cutting

depth of the Slot Cutter can be adjusted to any position from 0.1 inch ( .5mm) above the

surrounding part surface to 0.1 inch ( .5mm) below.

A Servo Motor provides the power to turn the Slot Cutter, and allows precision adjustable

speed control through a 0-10VDC analog interface. The SWS100-3.7 Series uses a 3.7

Horsepower motor with a speed range of 0 to 4 00 RPM; the SWS100-7. Series uses a

7. Horsepower motor with a speed range of 0 to 500 RPM. The belt and pulley drive

provides a 1.5:1 reduction ratio for the SWS3.7, and a 1.3:1 reduction ratio for the

SWS7. ; this reduction reduces the speed and increases the output torque at the Slot

Cutter. The Servo Motor allows the Weld Shaver to control Slot Cutter speed within 5%.

The projected life of this high quality Servo Motor is over 30,000 hours.

Simple reliable construction combined with high torque, precision speed controlled servo

technology make the PushCorp SWS100 Servo Weld Shaver a rugged, state-of-the-art

technology capable of providing flexible, cost-effective weld machining operations.

January, 0 3